Introduction

Armored cable, also known as armoured cable, is a versatile and durable wiring solution used in various electrical applications. It provides an extra layer of protection for electrical conductors, making it suitable for use in high-risk environments and outdoor installations. Understanding the benefits and limitations of armored cable is essential for making informed decisions about its usage.

Understanding armored cable

Armored cable consists of a metal sheath that encases the electrical conductors, providing protection against physical damage, moisture, and other environmental hazards. This added layer of defense makes it ideal for use in harsh conditions where standard wiring may be vulnerable to damage.

Benefits of using armored cable

The primary benefit of using armored cable is its ability to withstand external stressors and provide long-term durability. It offers enhanced safety and protection for electrical wiring, reducing the risk of damage or failure in challenging environments.

Common misconceptions about armored cable

One common misconception about armored cable is that it is only suitable for outdoor use. However, armored cable can also be used indoors in high-risk environments where additional protection is required. Understanding when to use armored cable and its specific applications can help dispel these misconceptions.

What is armored cable?

Armored cable, also known as armoured cable, is a type of electrical wiring that is protected by a flexible metal sheath. This sheath is typically made of steel or aluminum, providing a layer of protection against physical damage and environmental hazards. The components of armored cable include conductors for carrying electrical current, insulation to prevent leakage, and the outer armor for added protection.

Structure and components of armored cable

The structure of armored cable consists of conductors that carry the electrical current, surrounded by insulation to prevent electrical leakage. This core is then encased in a flexible metal armor that provides protection against physical damage and environmental hazards. The armor may be made of steel or aluminum, depending on the specific requirements of the installation.

Types of armored cable

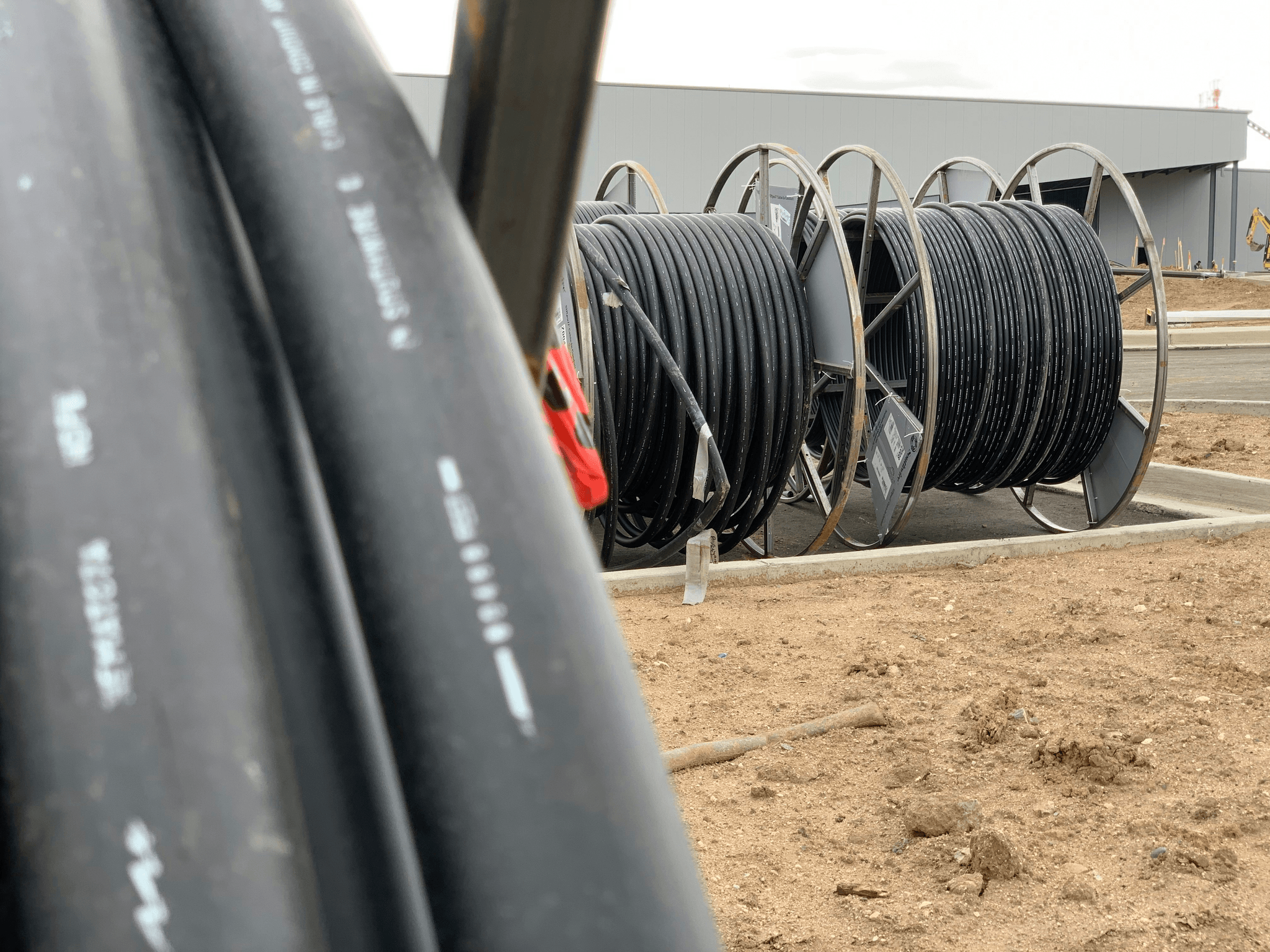

There are several types of armored cables available, including steel wire armored (SWA) cable and aluminum wire armored (AWA) cable. SWA cables are commonly used in outdoor applications and industrial environments due to their robust construction. AWA cables are lightweight and more flexible, making them suitable for indoor installations where flexibility is required.

In addition to SWA and AWA cables, there are also non-metallic armored cables available for specific applications. These cables are constructed with a layer of interlocking aluminum or steel armor, providing protection against mechanical damage and rodent attacks. The non-metallic armor also offers resistance to corrosion and moisture, making them suitable for use in harsh environments such as underground installations or areas with high humidity.

Advantages of using armored cable

Armored cables offer several advantages over traditional wiring methods. They provide enhanced protection against mechanical damage, moisture, and corrosive elements, making them ideal for outdoor and high-risk environments. Additionally, they offer improved resistance to fire hazards and electromagnetic interference, ensuring reliable performance in critical applications.

Do you know when to use armored cable?

Armored cables are commonly used in outdoor applications where protection from physical damage and environmental hazards is essential. They are also preferred in high-risk environments such as industrial facilities where reliability and durability are crucial factors in ensuring electrical safety.

Can I use armored cable instead of conduit?

While both serve as protective enclosures for electrical wiring, conduit offers more flexibility in terms of routing wires through complex spaces while armored cables provide better overall protection against physical damage and environmental hazards.

What is armored wire used for?

Armored wire is primarily used for electrical wiring installations that require additional protection against mechanical damage, moisture, corrosion, fire hazards, and electromagnetic interference.

When would you use armoured cable?

Armoured cables are recommended for long-term durability considerations in critical applications such as industrial facilities or outdoor installations where exposure to harsh conditions poses a risk to traditional wiring methods.

Where can armored cable not be used?

It's important to consider the limitations and restrictions of using armored cables in certain scenarios such as tight spaces or areas with excessive movement where flexibility may be required beyond what an armoured cable can provide.

When to use armored cable

When considering when to use armored cable, it is important to assess the specific application and environment. For outdoor applications, such as in landscaping or outdoor lighting, armored cable provides protection against moisture, corrosion, and physical damage. In indoor settings where wiring may be exposed to potential hazards or rough handling, armored cable offers an extra layer of safety and durability.

Outdoor vs. indoor applications

In outdoor applications, where exposure to harsh weather conditions and potential damage from landscaping activities is a concern, armored cable is the ideal choice for ensuring long-term reliability and safety. The durable construction of armored cable protects against moisture intrusion and physical impact, making it suitable for use in outdoor lighting systems, irrigation systems, and other landscaping projects.

High-risk environments

High-risk environments such as industrial facilities or construction sites often require wiring solutions that can withstand extreme conditions and potential hazards. Armored cable is designed to provide protection against mechanical damage, chemical exposure, and other risks commonly found in these environments. Its robust construction makes it a reliable choice for powering heavy machinery or equipment in industrial settings.

Long-term durability and safety considerations

When long-term durability and safety are top priorities in electrical installations, armored cable is the preferred option. Its protective armor provides resistance against rodent damage, abrasion, and other common causes of wire failure over time. By choosing armored cable for these applications, you can ensure reliable performance and reduced maintenance needs over the lifespan of the electrical system.

Where armored cable should not be used

Armored cable is not suitable for use in areas with high levels of moisture or humidity, as it may lead to corrosion and compromise the integrity of the cable over time. Additionally, it should not be used in situations where extreme flexibility is required, as the rigid structure of armored cable may limit movement and cause strain on the wiring system.

Limitations and restrictions of armored cable

One limitation of armored cable is its inability to bend sharply, making it unsuitable for applications that require tight turns or intricate routing. Furthermore, due to its construction, armored cable may not be the best choice for installations that involve frequent repositioning or adjustments, as this can lead to damage and potential safety hazards.

Additionally, armored cable may not be the best choice for outdoor installations in harsh environments where it may be exposed to extreme temperatures, moisture, or corrosive materials. In these scenarios, alternative cable options such as underground feeder (UF) cable or liquid-tight flexible metal conduit (LFMC) may be more suitable due to their ability to withstand environmental challenges and provide long-term reliability. These alternatives offer greater flexibility and durability, making them a better choice for outdoor applications that require rugged and weather-resistant cabling solutions.

Alternatives to armored cable in specific scenarios

In scenarios where flexibility and maneuverability are crucial, flexible metal conduit or liquid-tight flexible metal conduit can serve as viable alternatives to armored cable. These options provide the necessary protection for wiring while allowing for greater movement and adaptability in challenging environments.

In addition to providing flexibility and maneuverability, flexible metal conduit and liquid-tight flexible metal conduit also offer resistance to moisture and corrosion, making them ideal for use in outdoor or damp environments. This added protection ensures the longevity and reliability of the wiring, further enhancing the suitability of these alternatives in specific scenarios where armored cable may not be practical.

Regulatory compliance and safety standards

It's important to adhere to industry regulations and safety standards when determining whether armored cable is appropriate for a specific application. Consulting with experts who are well-versed in these standards can help ensure that your wiring solution meets all necessary requirements for safety and performance.

Do you know when to use armored cable? When considering your wiring needs, it's essential to weigh the benefits against the limitations of using armored cable. By understanding where it should not be used and exploring alternative solutions when necessary, you can make informed decisions that prioritize safety and efficiency in your electrical installations.

Choosing the right armored cable for your project

Factors to consider when selecting armored cable

When considering the use of armored cable, it's important to assess the environmental conditions of the installation site. Factors such as exposure to moisture, extreme temperatures, or physical damage should be taken into account. Additionally, the electrical load and potential hazards in the area should influence your choice of armored cable. Consulting with industry experts like Spark Fittings can provide valuable insight into these considerations.

In addition to environmental conditions and potential hazards, it's important to consider the customization options and specifications of armored cable. Different installation sites may require specific types of armored cable, such as those with enhanced fire resistance or increased flexibility. Understanding the unique needs of your project and the available customization options can help ensure that you select the most suitable armored cable for your application. Spark Fittings can assist in navigating these options and finding the best fit for your project.

Customization options and specifications

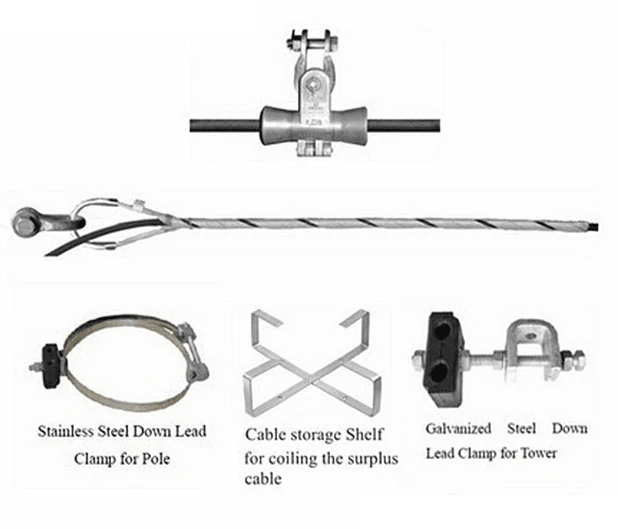

Armored cables come in various types and sizes to accommodate different applications. Customization options allow for tailored solutions based on specific project requirements. Spark Fittings offers customization services for armor rods, ensuring that they match the conductor's raw material and surface material to prevent corrosion between different elements. The color coding provided by Spark Fittings also facilitates easy identification of conductor sizes during installation.

In addition to customization options for armor rods, Spark Fittings also provides tailored solutions for cable jacketing. This allows for the selection of specific materials and thickness to ensure optimal protection against environmental factors such as moisture, UV exposure, and abrasion. By consulting with industry experts at Spark Fittings, project managers can receive guidance on the most suitable jacketing materials based on the application and operating conditions. This ensures that armored cables are not only customized for conductor compatibility but also for overall durability and longevity.

Consultation with industry experts for guidance

When in doubt about which type of armored cable is best suited for your project, seeking guidance from industry experts can be invaluable. Spark Fittings, as a professional manufacturer of preformed armor rods and cable accessories, has extensive experience in providing solutions for various applications. Their expertise can help you make informed decisions regarding the selection and customization of armored cable based on your specific needs.

In addition to helping you select the right armored cable for your project, industry experts can also provide valuable insights into the installation and maintenance of these cables. Spark Fittings can offer guidance on best practices for installing armored cables to ensure optimal performance and longevity. Their expertise can help you avoid common pitfalls and ensure that your installation is done correctly the first time, saving you time and money in the long run.

Armored cable installation and maintenance

When it comes to the installation of armored cable, it's crucial to follow best practices to ensure safety and efficiency. Proper handling and securing of the cable during installation is essential, as well as using appropriate tools for cutting and stripping the armor. It's also important to adhere to manufacturer guidelines for bending radius and support spacing to prevent damage to the cable.

Best practices for installation

Regular inspections and maintenance procedures are key to ensuring the long-term reliability of armored cable. Inspections should include checking for any signs of wear or damage, as well as verifying proper grounding and bonding. In addition, regular testing of the cable's insulation resistance can help identify potential issues before they escalate.

Regular inspections and maintenance procedures

In the event that issues arise with armored cable, troubleshooting common problems is essential for maintaining a safe electrical system. Common issues such as abrasions, kinks, or cuts in the armor should be addressed promptly to prevent exposure of the conductors. Additionally, addressing any issues with grounding or bonding can help mitigate potential safety hazards.

Troubleshooting common issues with armored cable

Conclusion

When to use armored cable is a crucial consideration for any wiring project. Whether it's for outdoor or high-risk environments, armored cable offers long-term durability and safety. Spark Fittings provides customized armor rods made from aluminum wire, galvanized steel wire, or aluminum clad steel wire to ensure corrosion resistance and easy installation.

Ensuring electrical safety with armored cable

Using armored cable in high-risk environments and outdoor applications ensures electrical safety and protection against physical damage. The durable construction of armored cable provides an extra layer of security for the wiring, reducing the risk of electrical hazards and potential accidents. Additionally, armored cable is resistant to corrosion and moisture, making it ideal for use in areas where exposure to the elements is a concern. This added resilience ensures that the electrical system remains reliable and safe even in challenging conditions.

Making informed decisions for your wiring needs

Understanding when to use armored cable is essential for making informed decisions about your wiring needs. It's important to consider factors such as environmental conditions, potential risks, and long-term durability when choosing the right type of armored cable for your project.

When considering environmental conditions, it's important to think about factors such as moisture, temperature, and exposure to corrosive materials. Armored cable is a great choice for areas with high moisture levels or where the cable may be exposed to potential damage from external elements. By choosing the right type of armored cable, you can ensure that your wiring will withstand the challenges posed by different environmental conditions.

The versatility and reliability of armored cable from Spark Fittings

Spark Fittings offers a wide range of customized armor rods with color-coded identification for easy installation and maintenance. Their expertise in manufacturing preformed armor rods ensures versatility, reliability, and compliance with safety standards for various wiring applications.

Additionally, Spark Fittings' armored cable is designed to withstand harsh environmental conditions, making it suitable for both indoor and outdoor use. The high-quality materials used in the manufacturing process ensure durability and longevity, reducing the need for frequent replacements and maintenance. This reliability translates to cost savings for customers in the long run, making Spark Fittings' armored cable a practical choice for various wiring projects.