Introduction

Armoured cable, also known as armored cable, is a type of electrical wiring that is protected by a layer of metal armor. This armor provides extra protection against physical damage and moisture, making it ideal for use in harsh environments. There are various types of armoured cable available, each designed for specific applications and requirements. Choosing armoured cable offers peace of mind and ensures the safety and reliability of your electrical systems.

Understanding Armoured Cable

Armoured cable consists of a conductive core surrounded by insulation, with a metal armor layer protecting the entire assembly. The armor is typically made from steel or aluminum, providing robust protection against external elements. This type of cable is commonly used in outdoor and underground installations where additional durability is required.

Types of Armoured Cable

There are different types of armoured cables available, including steel wire armoured (SWA) cable, steel tape armoured (STA) cable, and more. Each type has unique features and benefits that make it suitable for specific applications. Understanding the differences between these types can help you choose the right one for your project.

Why Choose Armoured Cable

When it comes to electrical installations in challenging environments, armoured cable is the go-to choice for many professionals. Its robust construction provides protection against mechanical damage, rodent attacks, and moisture ingress, ensuring long-term reliability and safety. The added peace of mind that comes with using armoured cable makes it a preferred option for critical installations.

What is an Armoured Cable?

An armoured cable is a type of power cable that has an additional layer of protection in the form of cable armour. This armour provides extra protection from physical damage, moisture, and other environmental factors, making it suitable for use in harsh conditions such as underground or outdoor installations. Armoured cables are commonly used in industrial, commercial, and residential settings for their durability and safety features.

Construction of Armoured Cable

The construction of armoured cable typically consists of several layers, including the conductor, insulation, bedding, armouring, and sheathing. The conductor is the core component that carries the electrical current, while the insulation provides electrical insulation and protection. The armouring layer is made up of materials such as steel wire or aluminum tape wound around the cable to provide mechanical protection. Finally, the outer sheath protects the cable from external elements.

Core components of Armoured Cable

The core components of armoured cable include the conductor, which can be made of copper or aluminum depending on the application requirements. The insulation material is crucial for preventing electrical leakage and ensuring safety. The armouring material can be steel wire or aluminum tape, providing strength and durability to withstand external forces. These core components work together to create a robust and reliable power cable suitable for various applications.

Benefits of using Armoured Cable

The benefits of using armoured cable are numerous, including enhanced mechanical protection against physical damage and impact resistance. The additional layer of armouring also provides protection against moisture ingress and chemical exposure, making it ideal for outdoor or underground installations. Furthermore, armoured cables offer improved safety features due to their robust construction, reducing the risk of electrical hazards.

Cable Armour vs. Shielding

Key differences between Cable Armour and Shielding

When comparing cable armour and shielding, it's important to note that cable armour provides mechanical protection, while shielding offers protection against electromagnetic interference. Cable armour consists of metal layers, such as steel or aluminum, that protect the cable from physical damage, making it suitable for harsh environments. On the other hand, shielding is typically made of conductive materials like copper or aluminum foil, providing a barrier against external electrical noise.

Which one is better for your needs?

The choice between cable armour and shielding depends on the specific requirements of your application. If your priority is to safeguard the cable from physical damage in rugged conditions, then cable armour would be the better option. However, if your concern is minimizing electromagnetic interference in sensitive electronic equipment or communication systems, then shielding would be more suitable.

Impact on cable performance and safety

The use of cable armour enhances the durability and lifespan of the cable by protecting it from moisture, abrasion, and other environmental hazards. On the other hand, shielding ensures signal integrity by reducing electromagnetic interference and improving overall performance. Both options contribute to safety by preventing potential damage to the cables and maintaining reliable operation in different settings.

Can Armoured Cable be Used as Earth?

When it comes to electrical installations, armoured cables are often used as a means of providing mechanical protection. However, they can also serve as an effective earth connection in certain scenarios. By utilizing the cable armour as earth, it can provide additional safety and protection against electrical faults. This method is commonly used in industrial settings and outdoor installations where the risk of damage or interference is higher.

Exploring the use of Cable Armour as Earth

Using cable armour as earth involves connecting the metallic armouring of the cable to an earth electrode, effectively creating a path for fault currents to safely dissipate into the ground. This method is often preferred in areas where traditional earthing methods may not be practical or effective. It is important to ensure that proper bonding and grounding techniques are followed to maintain electrical safety and compliance with regulations.

Safety considerations and regulations

When considering using cable armour as earth, it is crucial to adhere to safety regulations and guidelines set forth by relevant authorities. Proper insulation resistance tests should be conducted to ensure that the armouring provides a reliable path for fault current without posing any risks of electric shock or fire hazards. Additionally, regular maintenance and inspections are necessary to ensure the integrity of the armoured cable's earth connection.

Best practices for using Cable Armour as Earth

To effectively use cable armour as earth, it is essential to employ best practices such as ensuring proper termination of the armouring at both ends of the cable, using suitable clamps and connectors designed for this purpose, and verifying that the resistance between the armouring and earth electrode meets specified standards. Implementing these best practices can help maximize safety and reliability when utilizing armoured cable for earthing purposes.

In addition to proper termination and suitable clamps, it is also important to regularly inspect the armoured cable to ensure that it remains in good condition and free from any damage that could compromise its effectiveness as an earth. Regular maintenance and inspection can help identify any potential issues early on and prevent safety hazards or unreliable earthing. Furthermore, it is crucial to follow manufacturer guidelines for installation and usage of armoured cable as earth, as deviating from these recommendations could lead to ineffective earthing and increased risk of electrical accidents.

Armoured Cable in Use

Armoured cable is widely used in various applications due to its durability and protection capabilities. It is commonly used in residential, commercial, and industrial settings for power distribution, underground wiring, and outdoor installations. The robust construction of armoured cable makes it suitable for harsh environments, such as construction sites, oil refineries, and manufacturing facilities.

Common applications of Armoured Cable

In residential settings, armoured cable is often used for outdoor lighting, underground wiring for pools or spas, and powering sheds or outbuildings. In commercial buildings, it is commonly employed for electrical distribution systems and wiring that requires extra protection from physical damage. Industrial applications include power transmission in hazardous locations where the cable needs to withstand exposure to moisture, chemicals, or extreme temperatures.

In addition to residential, commercial, and industrial applications, armoured cable is also commonly used in agricultural settings. Farmers often use armoured cable to power barns, stables, and other agricultural buildings where the electrical wiring needs to be protected from the elements and potential damage. The rugged construction of armoured cable makes it an ideal choice for outdoor use on farms where exposure to moisture, chemicals, and physical wear and tear is common.

Industry-specific uses

The versatility of armoured cable allows it to be utilized across various industries such as mining, petrochemicals, telecommunications, and transportation. In mining operations, armoured cable is essential for powering heavy equipment and machinery in rugged environments. In the telecommunications industry, it is employed for underground cabling to ensure reliable communication networks.

Advantages and limitations of using Armoured Cable

The primary advantage of using armoured cable is its ability to provide mechanical protection against impact and abrasion while also offering resistance to moisture and chemicals. However, the rigidity of the armour can make installation more challenging compared to non-armoured cables. Additionally, the cost of armoured cable may be higher than other types of wiring due to its enhanced durability and protective features.

Furthermore, the use of armoured cable is often necessary in environments where the risk of physical damage to the wiring is high, such as in industrial settings or outdoor installations. The added protection provided by the armour can help prevent costly downtime and repairs due to damaged cables. Despite the challenges of installation, the peace of mind that comes with knowing your wiring is well-protected can outweigh the initial difficulties.

By understanding the common applications and industry-specific uses of armoured cable along with its advantages and limitations you can make an informed decision when choosing the right type of wiring for your specific needs.

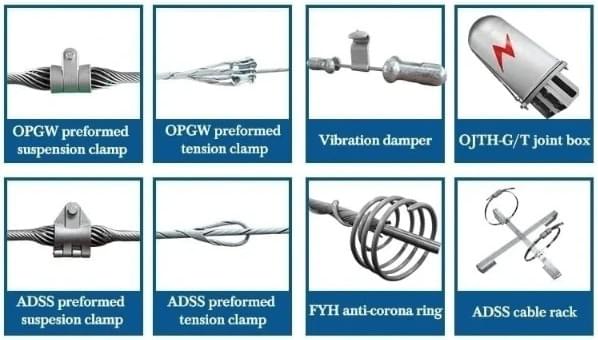

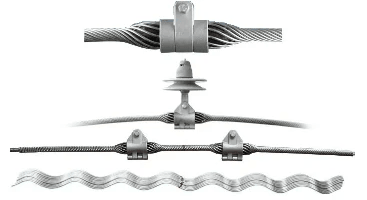

Unraveling Armor Rod

When it comes to armor rods, the raw materials play a crucial role in determining their effectiveness. Aluminum wire, galvanized steel wire, and aluminum clad steel wire are commonly used in manufacturing armor rods. It's essential to choose the right material that matches the conductor’s raw material to prevent corrosion. Additionally, color coding is a key feature of armor rods, aiding in easy identification of conductor size during installation. Spark Fittings also offers customized armor rod options to meet specific requirements.

Raw materials of Armor Rod

The raw materials used in manufacturing armor rods include aluminum wire, galvanized steel wire, and aluminum clad steel wire. These materials are chosen based on their compatibility with the conductor’s raw material to prevent corrosion and ensure durability.

Choosing the right material for your needs

Selecting the appropriate armor rod material is crucial for ensuring optimal performance and longevity. Matching the armor rod material with the conductor surface material is essential to prevent corrosion and maintain the integrity of the cable system.

The importance of color code and customized options

Color coding is a valuable feature of armor rods as it allows for easy identification of conductor size during installation. Additionally, Spark Fittings offers customized armor rod options to meet specific requirements, ensuring versatility and tailored solutions for various applications.

Conclusion

When it comes to choosing the right armoured cable for your needs, it's important to consider the construction, core components, and benefits of using cable armour. Whether you're looking for durability, protection, or safety, armoured cable is a reliable choice for various applications.

Choosing the Right Armoured Cable

With different types of armoured cable available in the market, it's essential to understand the specific requirements of your project. Consider factors such as environmental conditions, voltage levels, and installation methods to select the most suitable armoured cable for your application. Additionally, think about the potential for future expansion or upgrades in your system, as choosing a cable with extra capacity can save you time and money down the line. It's also important to consider the level of protection needed for your cable - for instance, if it will be exposed to mechanical damage or corrosive substances, a more heavy-duty armoured cable may be necessary.

Armoured Cable for Your Safety

The use of armoured cable provides an added layer of safety and protection in electrical installations. The robust construction and shielding properties of cable armour help prevent damage from external elements and reduce the risk of electrical faults or hazards.

Armoured cable technology is constantly evolving to meet the changing needs of electrical installations. Manufacturers are developing new materials and designs to enhance the durability and performance of armoured cables. These advancements ensure that users can rely on the safety and protection provided by armoured cables, even in the most challenging environments. As a result, the future of armoured cable technology looks promising, with continued improvements in quality and reliability.

The Future of Armoured Cable Technology

As technology continues to advance, so does the innovation in armoured cable technology. With ongoing developments in materials and manufacturing processes, the future holds promising improvements in the performance and efficiency of armoured cables.

Remember that when considering options like Spark Fittings' armor rods made from aluminum wire or galvanized steel wire, customization options are available to meet specific project requirements. As industry standards evolve, staying informed about new advancements in armoured cable technology can help you make informed decisions for your projects.