Introduction

In the world of electrical engineering, understanding transmission and distribution cables is crucial for ensuring efficient power delivery. These cables serve as the backbone of our electrical systems, enabling the safe and reliable transport of electricity from generation points to end-users. With a variety of distribution wire types available, it’s essential to grasp their characteristics and applications to make informed decisions during installation.

Understanding Transmission and Distribution Cables

Transmission and distribution cables are designed to carry electrical energy over long distances while minimizing losses. Power distribution cables specifically cater to lower voltage levels, making them ideal for local distribution networks. When considering what are the three types of wires used in distribution, we typically refer to conductors that handle phase, neutral, and ground connections within a system.

Importance of Proper Installation Techniques

Proper installation techniques are paramount when working with distributor wire and cable systems. Incorrect installations can lead to inefficiencies or even hazardous situations that compromise safety and reliability. By adhering to best practices in installation, you ensure that your power distribution cables function optimally for years to come.

Overview of Main Distribution Wire Types

There are several main distribution wire types utilized in modern electrical systems, each serving distinct purposes based on their design and application needs. Understanding these types not only helps in selecting the right cable but also aids in comprehending how they fit into a 3-wire distribution system effectively. Familiarity with these wires can significantly enhance both installation quality and long-term performance.

Types of Transmission and Distribution Cables

Power Distribution Cables Explained

Power distribution cables are designed specifically for the safe and efficient transport of electricity from substations to homes or businesses. These cables come in various configurations and materials, enabling them to handle different voltage levels and environmental conditions. With proper installation techniques, these power distribution cables can significantly reduce energy losses while providing reliable service over long distances.

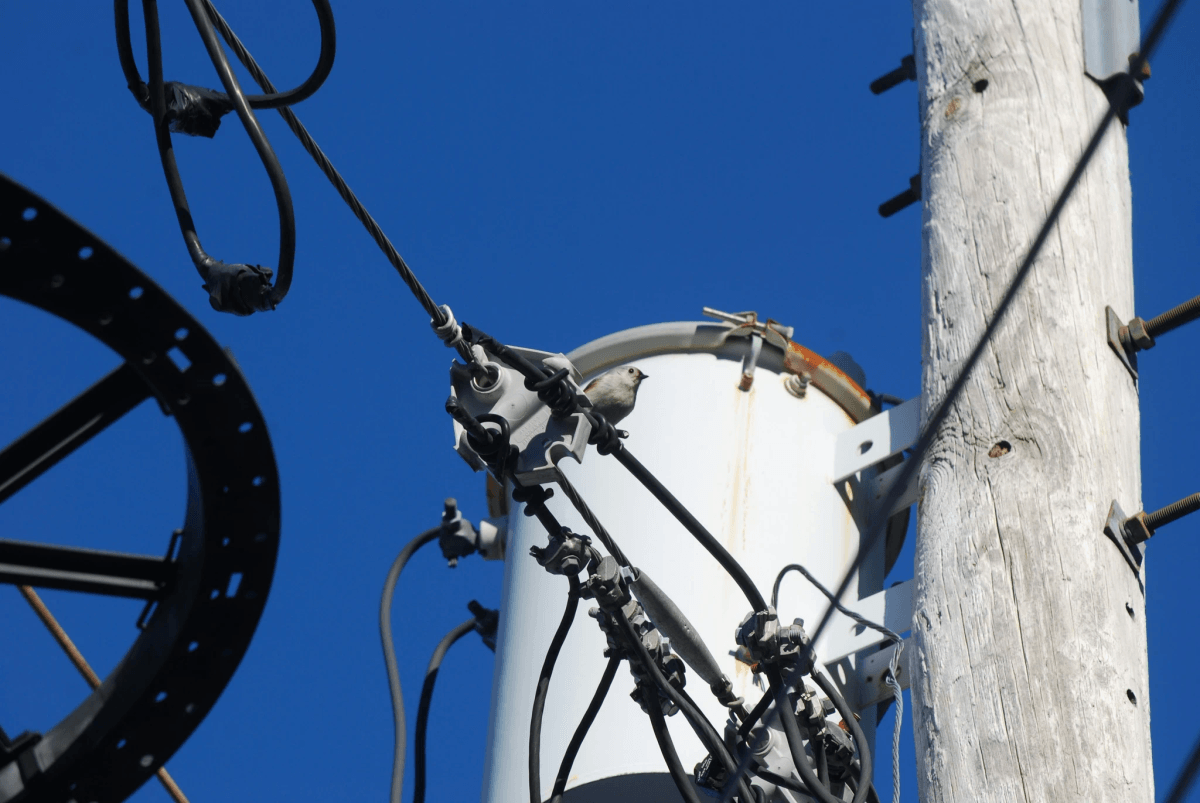

Generally speaking, power distribution cables can be categorized into two main types: overhead lines and underground cables. Overhead lines are typically used in rural areas where installation costs are lower due to less infrastructure interference. On the other hand, underground cables offer better protection against weather elements but require more complex installation processes.

As you consider your options for power distribution cables, it's essential to factor in not just performance but also safety standards that govern their use. After all, choosing the right type could mean the difference between a reliable electrical supply and potential hazards down the line.

Essential Distribution Wire Types

When discussing essential distribution wire types, it’s important to highlight that they serve as the backbone of any electrical system. Commonly used wires include copper conductors for their excellent conductivity properties and aluminum conductors for their lightweight characteristics—both offering unique advantages depending on specific project needs.

Moreover, insulated wires are often employed to ensure safety by preventing accidental contact with live components. The insulation material can vary based on factors like temperature rating or environmental exposure; therefore understanding these nuances is key when selecting your distributor wire and cable options.

In summary, knowing what are the three types of wires used in distribution systems—copper conductors, aluminum conductors, and insulated wires—will equip you with valuable insights for making informed choices about your electrical installations.

Overview of a 3-Wire Distribution System

What is a 3-wire distribution system? This configuration consists of three conductors: two hot wires carrying alternating current (AC) voltage and one neutral wire that serves as a return path for current flow. This setup allows for both single-phase and three-phase loads while providing flexibility in how electrical energy is distributed across circuits.

The beauty of using a 3-wire system lies not only in its efficiency but also its ability to balance loads effectively across phases—minimizing potential overloads on any single wire within your distributor wire and cable network. Additionally, this type of system allows users to tap into different voltage levels based on their specific requirements without needing multiple separate circuits.

In conclusion, understanding how a 3-wire distribution system works will empower you with knowledge about optimizing your electrical installations while ensuring compliance with industry standards—a win-win situation!

Key Installation Tools and Equipment

Must-Have Tools for Installation

First up on our must-have list are cable cutters and strippers; these are essential for preparing your distribution wires. A good pair of crimping tools is also crucial for securing connections between different distribution wire types, ensuring they withstand time and elements. Don’t forget about torque wrenches; they help you achieve the precise tension needed when connecting power distribution cables to avoid any loose ends that could lead to failures down the line.

Next, you’ll want to include a reliable multimeter in your toolkit. This handy device will allow you to measure voltage, current, and resistance—key factors in troubleshooting any issues with distributor wire and cable systems. Lastly, a sturdy ladder or lift can be invaluable when working at heights during installation; safety first!

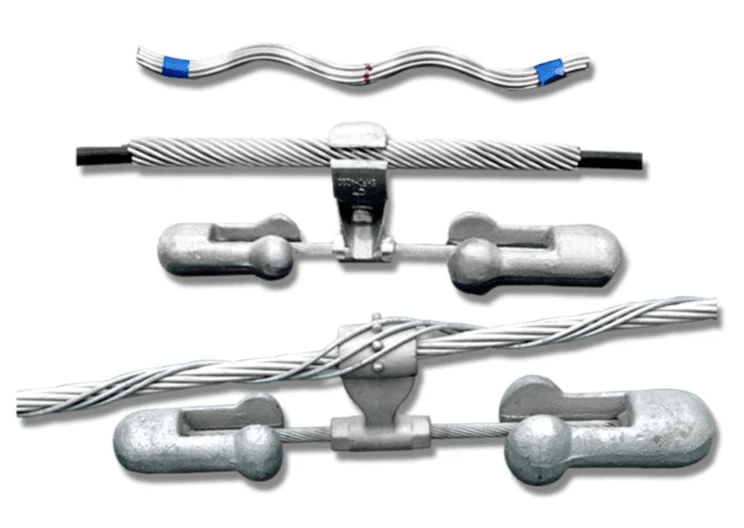

Role of Spark Fittings in Distribution Systems

Spark fittings play an integral role in maintaining safety within distribution systems by preventing electrical arcing during connections. These fittings ensure that when power flows through various distribution wire types, there’s minimal risk of sparks igniting surrounding materials or causing short circuits. Understanding how to properly install these components is vital for anyone working with power distribution cables.

In a 3-wire distribution system, spark fittings can be particularly important because they manage three distinct phases of electricity flow while minimizing interference between them. Utilizing high-quality spark fittings not only enhances safety but also contributes to the longevity of your distributor wire and cable setup by reducing wear over time due to electrical stress. Remember: even the best installation techniques won’t save you if you overlook this small yet mighty component!

Safety Equipment You Shouldn’t Ignore

Safety should always be at the forefront when dealing with electrical installations—after all, we're talking about power! Personal protective equipment (PPE) like insulated gloves and goggles should never be optional; they’re critical for protecting yourself from accidental shocks while handling different distribution wire types or connecting power distribution cables. A hard hat is also advisable if you're working in areas where overhead hazards might exist.

Additionally, using insulated mats can provide an extra layer of protection against electrical shock while working on live wires or near energized equipment in your 3-wire distribution system setup. Fire extinguishers rated for electrical fires should always be nearby as a precautionary measure—better safe than sorry! The right safety equipment not only protects you but ensures that your entire installation process runs smoothly without incident.

Step-by-Step Installation Process

When it comes to the installation of power distribution cables, a systematic approach is key. From preparing the site to connecting your distributor wire and cable, each step plays a crucial role in ensuring a successful installation. Let’s break down this process into manageable parts.

Preparing the Installation Site

Before diving into the installation of your power distribution cables, it's vital to prepare the site properly. Clear any debris, vegetation, or obstacles that might interfere with laying out your distribution wire effectively. Additionally, ensure that you have adequate space for maneuvering tools and equipment; this will make connecting your distributor wire and cable much easier later on.

Safety should always be a priority during preparation; check for any underground utilities that could pose hazards while digging or laying cables. Having a clean and organized workspace not only enhances safety but also improves efficiency as you install various distribution wire types. Remember, a well-prepared site can save time and prevent costly mistakes down the road.

Laying Out Power Distribution Cables

Once your site is prepped, it’s time to lay out those power distribution cables like an artist setting up their canvas! Start by following any specific guidelines related to depth and spacing for your chosen distribution wire types—this varies depending on local regulations and environmental factors. As you unroll the cables, ensure they are free from twists or kinks that could affect performance.

A 3-wire distribution system typically involves three conductors: one for live current, one for neutral, and one for ground—so keep these in mind as you arrange them accordingly. Proper layout not only ensures optimal functionality but also helps in future maintenance checks when inspecting connections between your distributor wire and cable. Always double-check measurements before securing anything in place!

Connecting Your Distributor Wire and Cable

Now comes the moment of truth: connecting your distributor wire and cable! It's essential to follow manufacturer instructions meticulously during this step since improper connections can lead to inefficiencies or even safety hazards down the line. Use appropriate connectors designed specifically for each type of distribution wire; this ensures compatibility and reliability.

When working with different distribution wire types within a 3-wire distribution system, pay close attention to color coding—typically black (live), white (neutral), and green or bare (ground). After making all necessary connections securely, it’s wise to perform an initial test before finalizing everything; this helps catch any issues early on while you're still in the troubleshooting phase!

Best Practices for Cable Maintenance

Maintaining your power distribution cables is crucial for ensuring their longevity and efficiency. Neglecting routine inspections and maintenance can lead to costly failures and unsafe conditions. By following best practices, you can keep your distribution wire in optimal condition and prevent potential issues.

Routine Inspection Techniques

Regular inspections of your distributor wire and cable are essential to catch any emerging problems early. Start by visually examining the insulation for signs of wear, cracking, or discoloration—these can indicate a need for immediate attention. Additionally, testing the connections at junction points will help ensure that all distribution wire types are functioning properly without any loose connections that could lead to power loss or safety hazards.

Another effective technique involves using thermal imaging cameras to detect hotspots in power distribution cables, which may suggest overloads or faulty components. Don't forget to document your findings during each inspection; this record will be invaluable for tracking changes over time. By implementing these routine inspection techniques, you not only enhance the reliability of your 3-wire distribution system but also extend the lifespan of all cable types involved.

Troubleshooting Common Issues

When it comes to troubleshooting common issues with distributor wire and cable, being proactive is key. One frequent problem is insulation damage caused by environmental factors or physical stress; if you notice any abrasions or tears in the insulation, it's time to take action before it leads to more severe issues like short circuits. Additionally, if you're experiencing inconsistent power supply from your distribution wire types, checking for loose connections should be one of your first steps.

Another issue that often arises is overheating due to excessive load on the power distribution cables; this can usually be resolved by redistributing loads more evenly across different circuits within your 3-wire distribution system. If you're still having trouble after addressing these common concerns, consulting with a professional can provide further insight into underlying problems that may not be immediately apparent. Remember, timely troubleshooting helps maintain not just performance but also safety standards in electrical installations.

Ensuring Long-Term Reliability of Distribution Cables

To ensure long-term reliability of your power distribution cables, consider implementing a comprehensive maintenance schedule tailored specifically for the unique demands of each installation site. This schedule should include regular inspections and prompt repairs as needed—after all, an ounce of prevention is worth a pound of cure when it comes to maintaining distributor wire and cable systems!

Furthermore, investing in high-quality materials suited for local environmental conditions can significantly enhance durability; choosing robust insulation materials will protect against moisture ingress or extreme temperatures affecting various distribution wire types over time. Lastly, educating staff about proper handling procedures during installation and maintenance will go a long way toward preventing damage before it even occurs.

Regulatory Compliance and Standards

In the world of power distribution cables, regulatory compliance and standards are not just bureaucratic jargon; they are essential components that ensure safety and efficiency in electrical installations. Understanding industry regulations helps professionals navigate the complex landscape of requirements that govern the use of distribution wire types. These regulations cover everything from installation techniques to maintenance protocols, ensuring that both the distributor wire and cable used meet stringent quality criteria.

Understanding Industry Regulations

Industry regulations for power distribution cables are set by various bodies to ensure that installations are safe and reliable. These regulations dictate how distribution wire must be manufactured, tested, and installed to minimize risks such as electrical faults or failures. Familiarizing oneself with these rules is crucial for anyone working with a 3-wire distribution system or any other configuration, as non-compliance can lead to severe consequences, including legal liabilities.

Importance of Adhering to Safety Standards

Safety standards not only protect workers during installation but also safeguard end-users from potential hazards associated with faulty wiring or improper connections. By following established guidelines for distributor wire and cable systems, professionals can significantly reduce the risk of accidents while ensuring long-term reliability.

Certifications for Cable Installation and Distribution

Certifications play a critical role in validating the expertise required for installing power distribution cables safely and effectively. Various organizations offer certifications that demonstrate a professional's competency in handling different types of distribution wire types according to industry standards. Achieving these certifications not only enhances credibility but also ensures adherence to best practices within the realm of electrical installations—something every installer should strive for in their career.

Conclusion

In wrapping up our exploration of transmission and distribution cables, it’s clear that understanding the nuances of installation techniques is crucial for optimal performance. Key installation techniques such as proper layout, secure connections, and routine maintenance ensure that power distribution cables function efficiently over time. Moreover, familiarity with various distribution wire types can significantly enhance the reliability of your electrical systems.

Final Thoughts on Distribution Cable Types

Understanding distribution wire types is fundamental for anyone involved in electrical installations or maintenance. Each type serves specific functions within a system; for example, what are the three types of wires used in distribution? They typically include phase wires, neutral wires, and ground wires—all integral to a 3-wire distribution system that enhances safety and efficiency. As technology advances, staying informed about new developments in power distribution cables will help you make better choices for your projects.

Importance of Professional Installation Services

While DIY enthusiasts may be tempted to tackle their own electrical projects using various distribution wire types, professional installation services offer unparalleled benefits. Experienced technicians not only possess the right tools but also understand complex regulations governing electrical work—ensuring compliance with safety standards every step of the way. Ultimately, investing in professional services guarantees long-term reliability for your distributor wire and cable systems while reducing risks associated with improper installations.