Introduction

When it comes to the reliable transmission of electricity, understanding pole line hardware essentials is crucial. From anchoring solutions to insulators and conductor accessories, every component plays a vital role in ensuring the safety and efficiency of power line poles. Whether it's for electrical distribution or aerial hardware, having a solid grasp of the basics of power line poles is essential for anyone working in the industry.

Understanding Pole Line Hardware Essentials

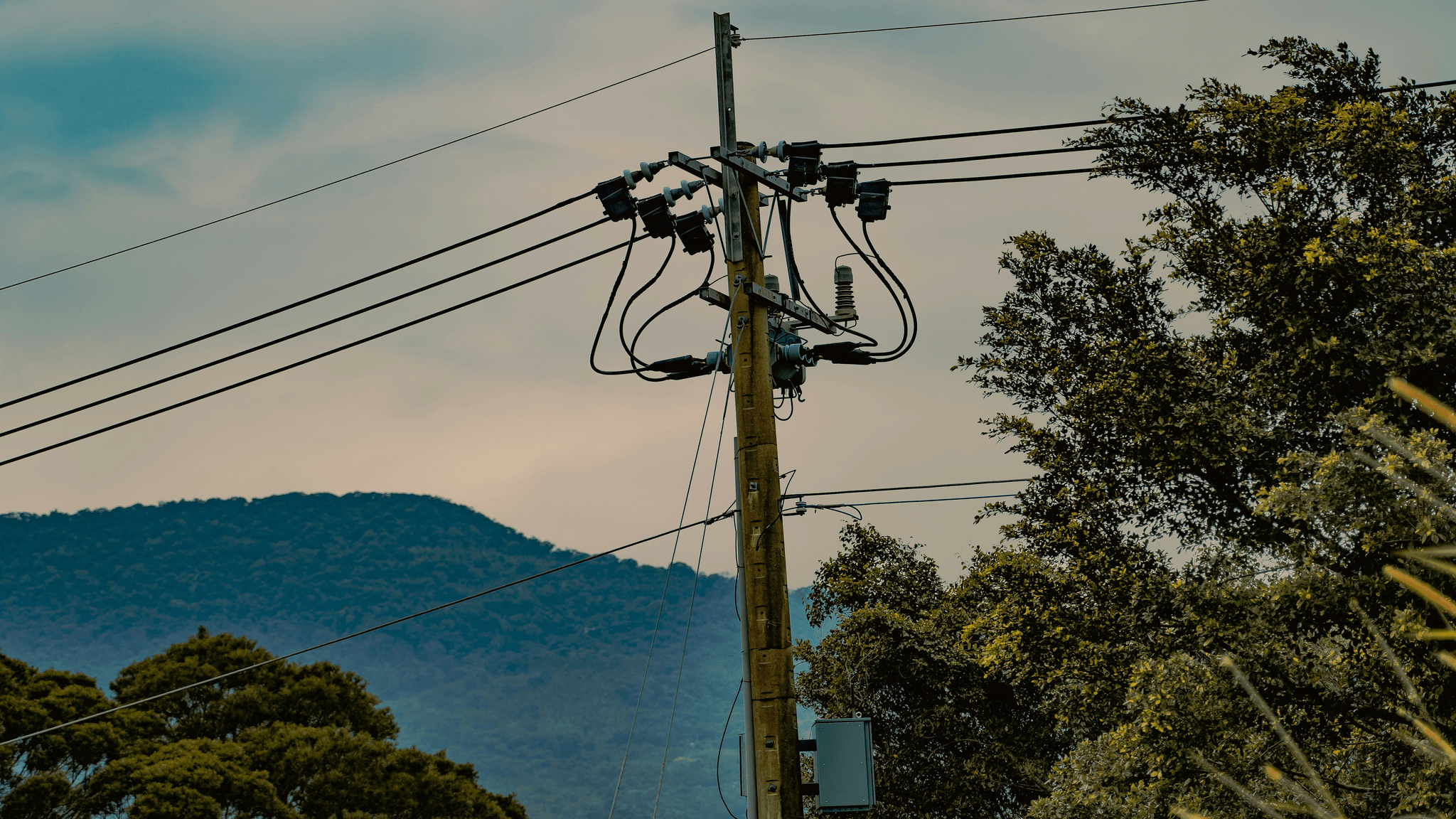

Pole line hardware encompasses a wide range of equipment and accessories used in the construction and maintenance of power line poles. This includes everything from anchors and insulators to fittings and braces, all designed to support and secure electrical distribution systems.

Importance of Pole Line & Aerial Hardware

The significance of pole line and aerial hardware cannot be overstated when it comes to maintaining a reliable electrical grid. These components are essential for supporting power lines, ensuring their stability, and protecting them from environmental factors such as wind, ice, and lightning.

Basics of Power Line Poles

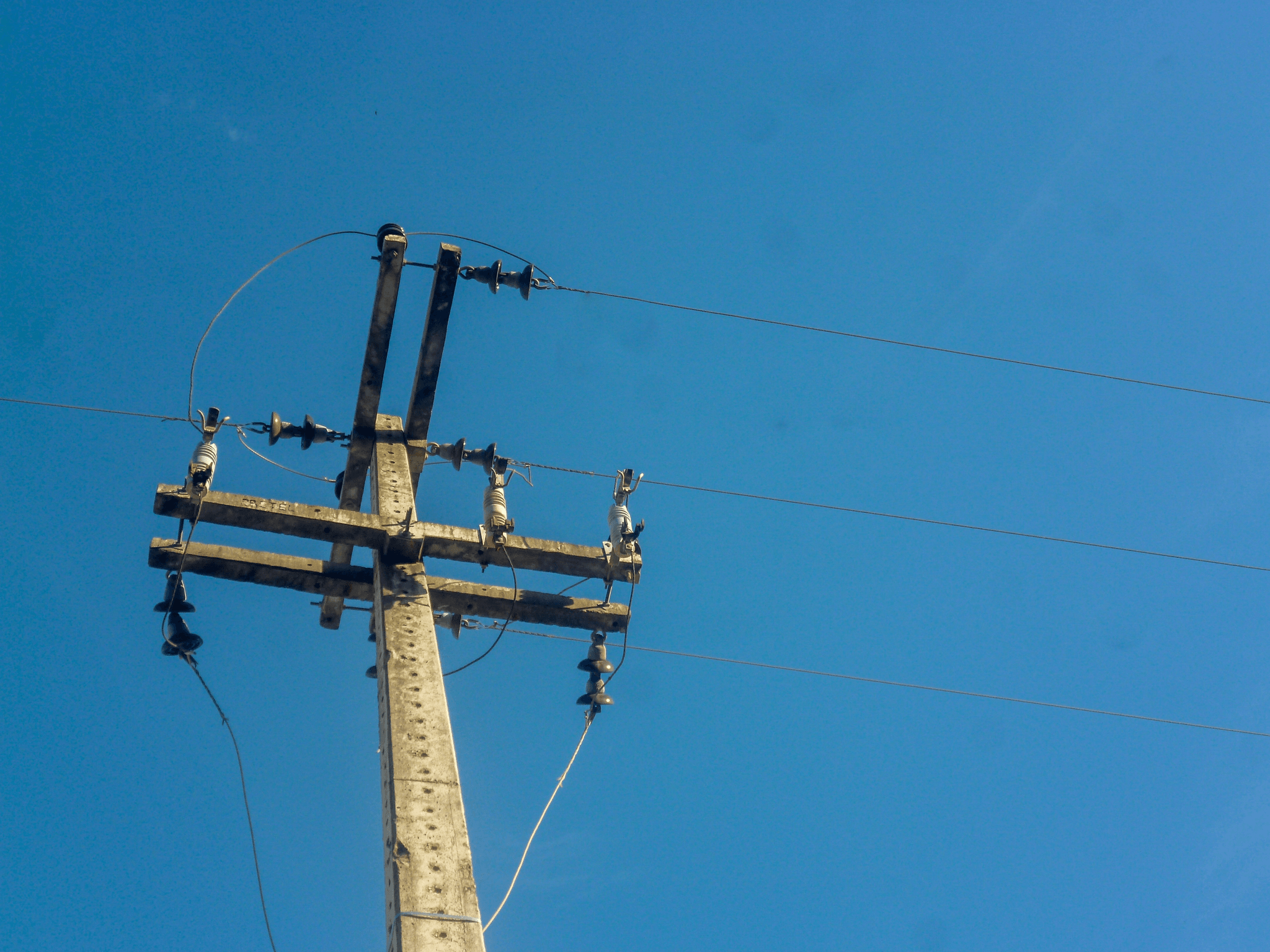

Power line poles are the backbone of electricity distribution networks, providing support for overhead power lines that carry electricity from generating stations to consumers. Understanding the different parts of a power pole and their functions is crucial for ensuring the safe and efficient transmission of electricity.

Exploring Different Types of Pole Line Hardware

When it comes to anchoring solutions for power line poles, there are various options available to ensure stability and reliability. From guy wire anchors to helical anchors, choosing the right solution depends on factors such as soil conditions, pole height, and environmental considerations. These anchoring solutions play a crucial role in supporting the weight and tension of power line poles, ultimately contributing to the safety and longevity of the entire infrastructure.

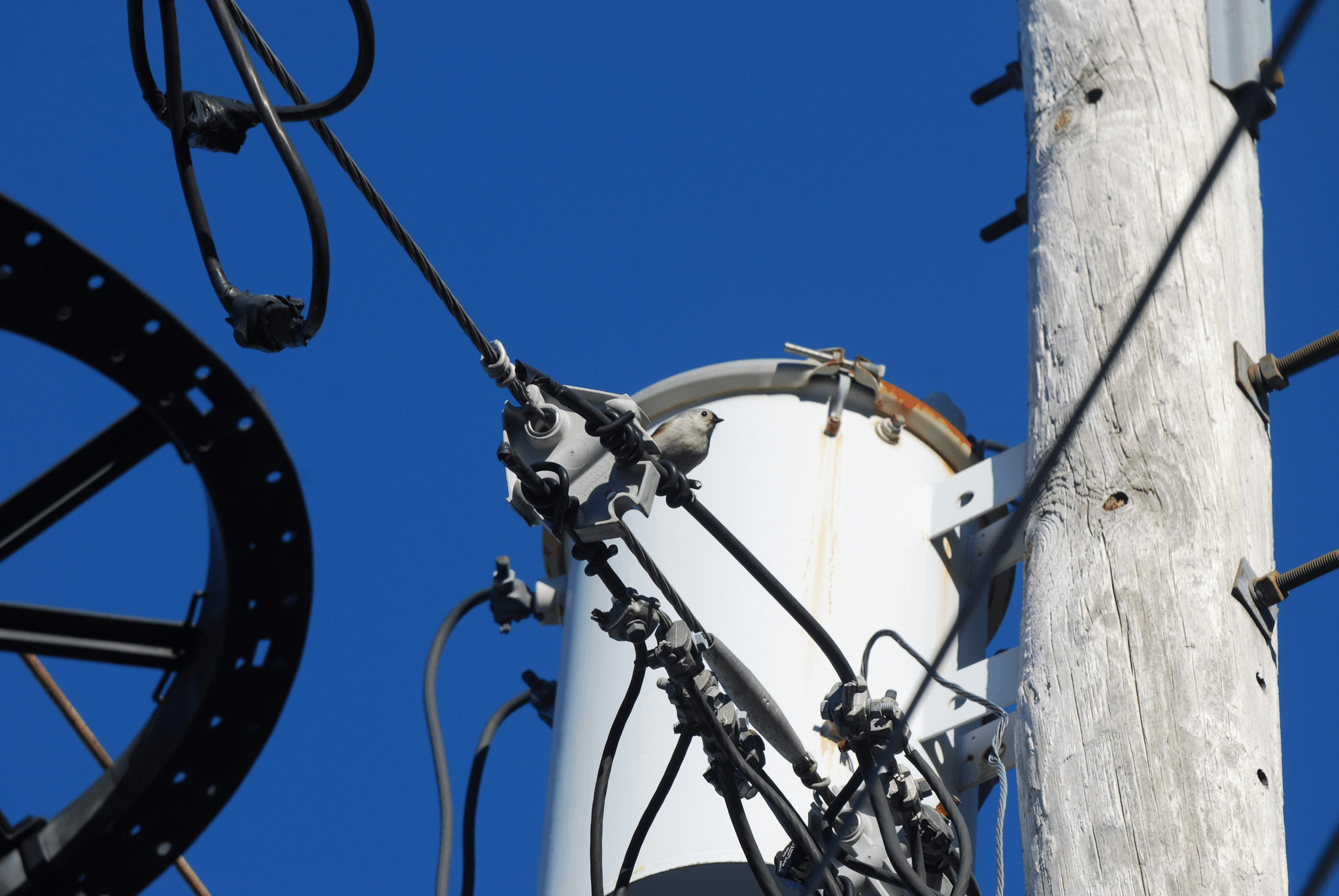

Insulators and conductor accessories are essential components of power line poles, serving to insulate and protect the conductors from the pole structure. Insulators prevent electrical current from flowing through the pole itself, while conductor accessories such as clamps and connectors ensure secure attachment and proper electrical conductivity. The right combination of insulators and conductor accessories is vital for maintaining efficient power transmission while minimizing risks of electrical faults or failures.

Spark Fittings Products offer a comprehensive range of equipment designed for preformed armor rods, tension clamps, and cable accessories for ADSS and OPGW systems. Their high-quality products are crucial for ensuring reliable performance in overhead transmission lines by providing support, protection, and connectivity for critical components. With Spark Fittings' expertise in manufacturing specialized hardware, customers can trust in the durability and effectiveness of their pole line equipment.

Components of a Power Pole

When it comes to the parts of a power pole, crossarms and braces play a crucial role in supporting the conductors and insulators. These components are typically made of wood, steel, or fiberglass, and are designed to withstand the weight and tension of power lines. Proper installation and maintenance of crossarms and braces are essential for the overall stability and safety of power line poles.

Crossarms and Braces

Crossarms are horizontal structures attached to the power pole, providing support for the conductors that transmit electricity. They come in various lengths and configurations, depending on the specific requirements of the power line. Braces, on the other hand, are diagonal supports that help reinforce the crossarms, ensuring they can withstand heavy loads and adverse weather conditions. Together, these components form a sturdy framework for reliable power transmission.

In addition to providing support for conductors, crossarms also serve as a platform for insulators, which help to prevent the flow of electricity into the pole. This is crucial for maintaining the integrity of the power line and ensuring safety for both workers and the public. By securely holding the insulators in place, crossarms play a key role in preventing electrical accidents and minimizing power outages due to equipment failure.

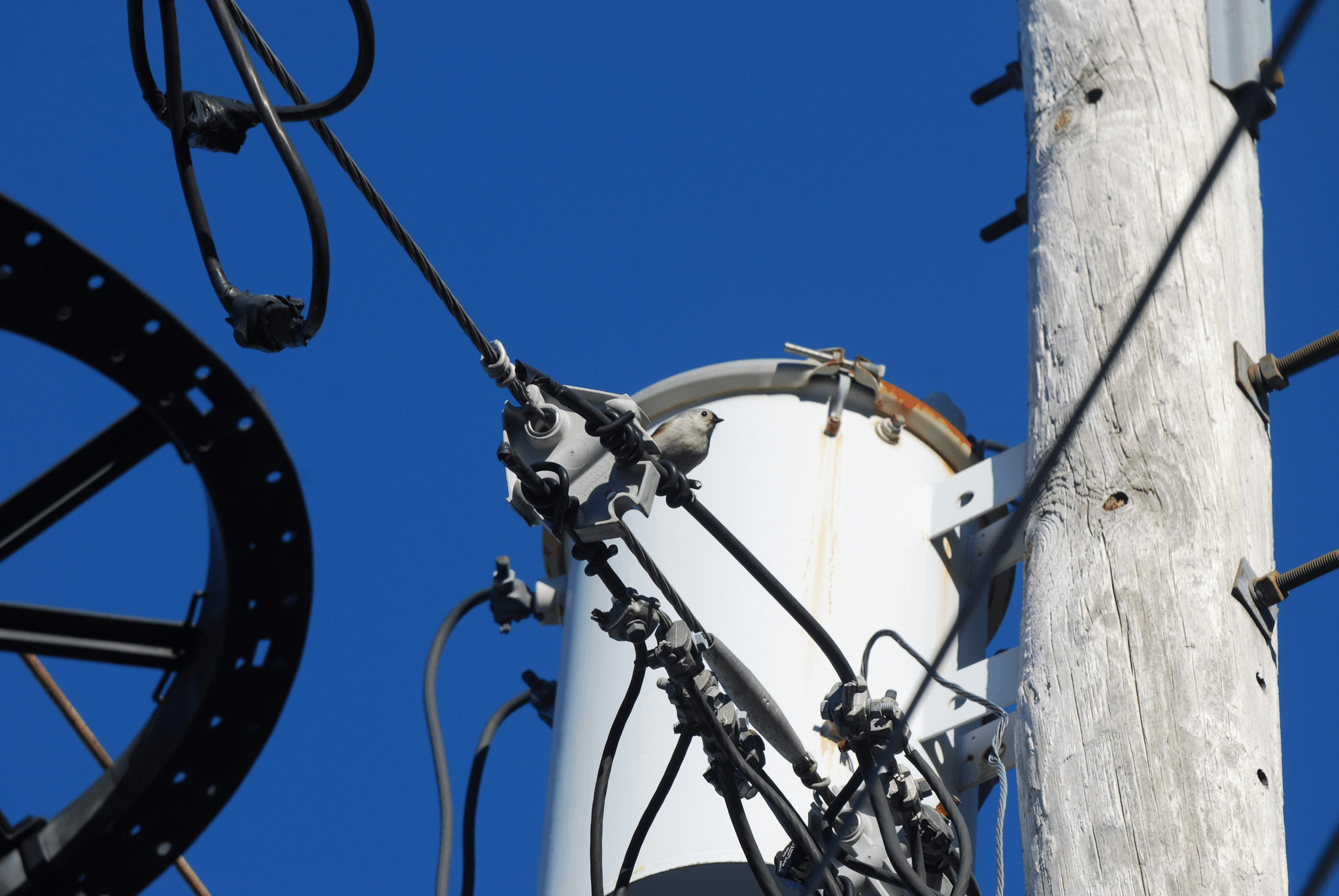

Pole Line Hardware for Overhead Ground Wires

Overhead ground wires serve as an additional safety measure by providing a path for lightning strikes to reach the ground without damaging the power line equipment or causing outages. The hardware used to support these wires includes clamps, brackets, and fittings specifically designed to secure them to power poles with maximum strength and durability.

In addition to providing a path for lightning strikes, overhead ground wires also help to mitigate the risk of power line equipment damage and outages caused by other environmental factors such as high winds and heavy snow. This additional layer of protection ensures that the electrical distribution system remains reliable and resilient in the face of adverse weather conditions. By using high-quality clamps, brackets, and fittings designed for maximum strength and durability, utility companies can effectively safeguard their infrastructure against potential damage.

Utility Pole Hardware for Electrical Distribution

Utility pole hardware encompasses a wide range of components essential for electrical distribution systems. This includes everything from pole top pins and crossarm pins to guy hooks and anchor rods. Each piece of hardware plays a critical role in maintaining the integrity of power line poles while ensuring efficient distribution of electricity to homes, businesses, and other facilities.

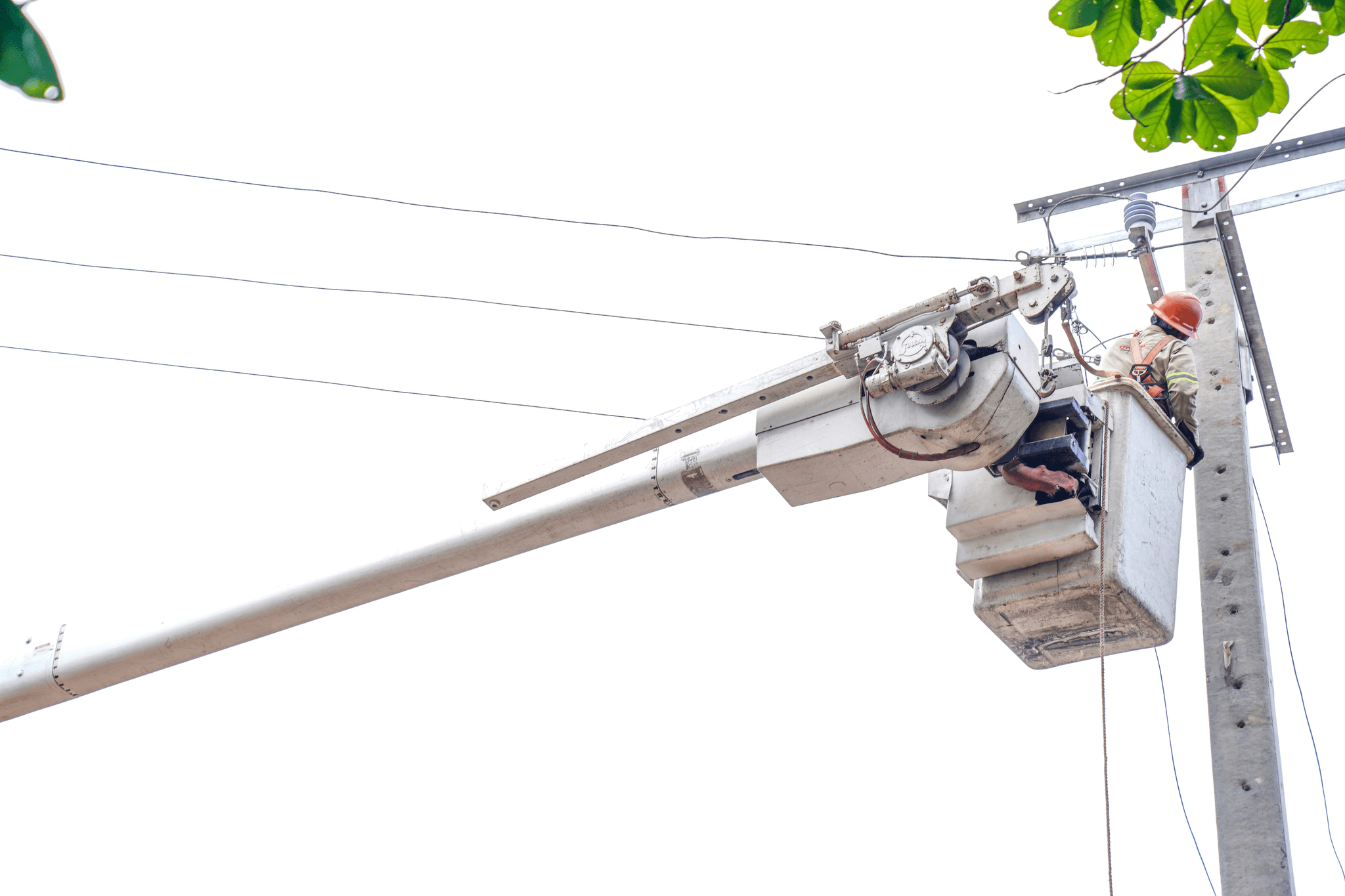

Utility pole hardware is subject to wear and tear over time, especially in areas prone to extreme weather conditions. Therefore, it's crucial to conduct regular inspections and maintenance to ensure the safety and reliability of the electrical distribution system. By proactively addressing any signs of corrosion, damage, or weakness in the hardware, utility companies can prevent potential outages and hazards, ultimately saving time and resources.

Installation and Maintenance of Pole Line Hardware

Tips for Properly Installing Tension Clamps

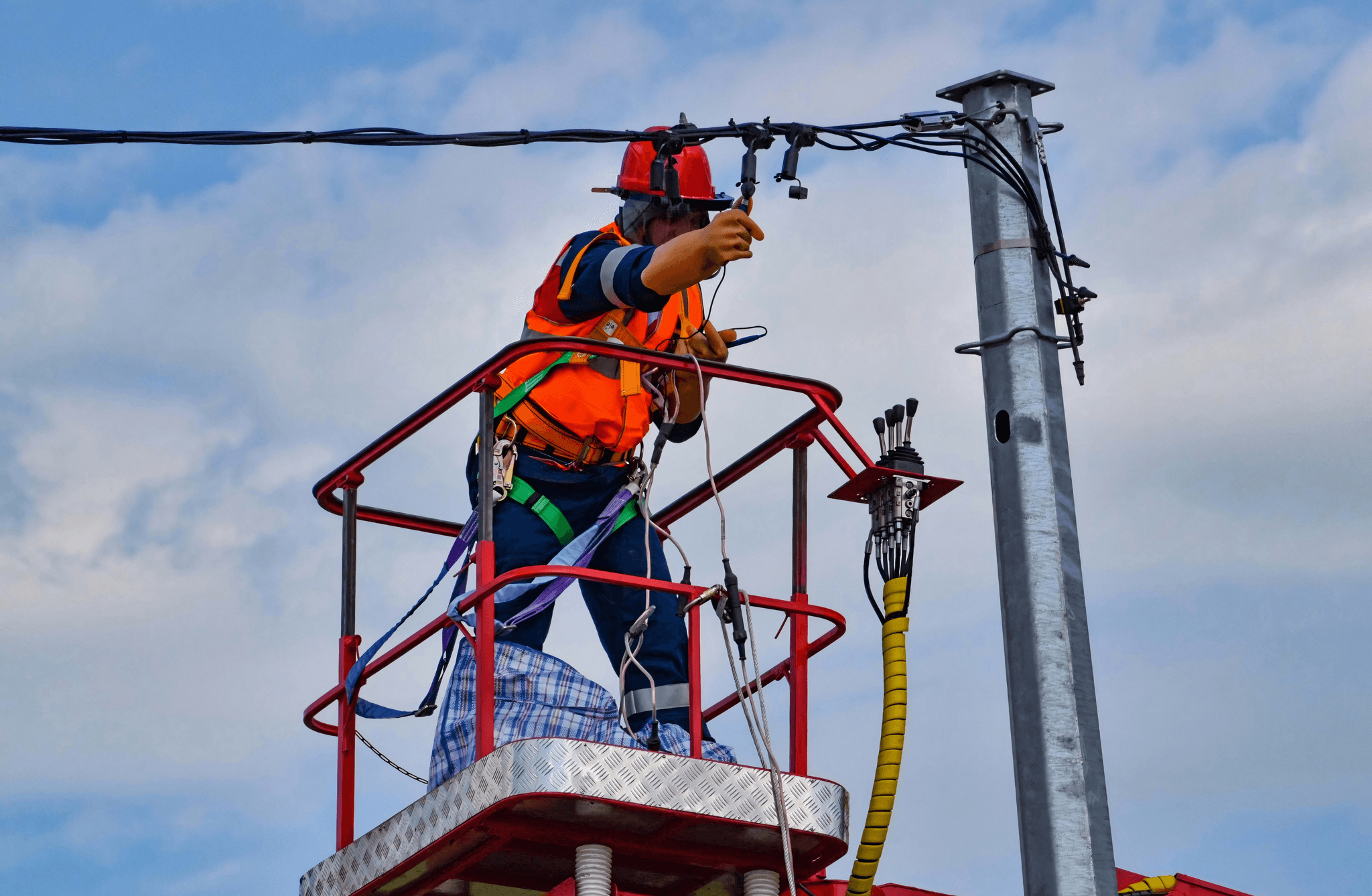

When installing tension clamps on power line poles, it's crucial to ensure that the clamps are positioned correctly to provide adequate support for the conductors. Proper alignment and tightening of the clamps are essential to prevent any sagging or damage to the power lines. Regular inspections should also be conducted to check for any signs of wear or corrosion on the tension clamps.

To ensure the proper installation of tension clamps, it is important to use the correct tools and equipment. This includes using torque wrenches to tighten the clamps to the manufacturer's specifications. Additionally, ensuring that the conductors are properly aligned within the clamps is essential for maintaining the integrity of the power lines. By using proper tools and following manufacturer guidelines, you can prevent any potential issues with tension clamp installation.

Best Practices for Preformed Armor Rods

Preformed armor rods play a critical role in protecting power line conductors from abrasion and damage caused by environmental factors. It's important to follow manufacturer guidelines for installing these rods, ensuring they are evenly spaced and securely fastened to the conductor. Regular maintenance checks should be carried out to replace any worn or damaged armor rods, maintaining the integrity of the power lines.

It is also essential to consider the type of environment in which the power lines are located when selecting preformed armor rods. Different environmental conditions, such as coastal areas or industrial zones, may require specific types of armor rods to provide optimal protection for the conductors. By choosing the right armor rods for the specific environmental factors, you can ensure the longevity and effectiveness of the power line protection system.

Cable Accessories for ADSS and OPGW Systems

For ADSS (All-Dielectric Self-Supporting) and OPGW (Optical Ground Wire) systems, selecting the right cable accessories is essential for reliable transmission of electricity and data signals. Proper installation of cable accessories such as suspension clamps, dead-end grips, and vibration dampers is crucial to ensure the longevity and performance of these systems. Regular inspections should be conducted to identify any potential issues with these accessories.

In addition to the installation of cable accessories, it is important to consider the environmental factors that may impact the performance of ADSS and OPGW systems. Weather conditions such as high winds, ice, and lightning can put stress on the cables and accessories, potentially leading to damage or failure. Therefore, selecting durable and weather-resistant materials for cable accessories is crucial in ensuring the reliability of these systems in all types of conditions.

Safety Measures for Working with Power Line Poles

Understanding the Risks of Electricity Power Lines

Working with electricity power lines poses significant risks to workers and the public. Accidental contact with live wires can result in severe injury or even death. It is crucial for all personnel to be aware of the dangers associated with power lines and to follow strict safety protocols when working near them.

It is also essential for workers to use quality pole line hardware when working with electricity power lines. High-quality hardware can help ensure the stability and reliability of the power lines, reducing the risk of accidents or malfunctions. By using durable and well-made hardware, workers can contribute to a safer working environment and minimize the potential for unexpected incidents.

Importance of Using Quality Pole Line Hardware

Using high-quality pole line hardware is also crucial for minimizing maintenance costs and extending the lifespan of power line poles. When inferior hardware is used, it can lead to premature wear and tear, requiring frequent replacements and repairs. By investing in top-notch hardware, utility companies can save money in the long run by reducing the need for constant maintenance and replacements.

Common Hazards Associated with Power Pole Parts

Power pole parts, such as insulators, conductor accessories, and tension clamps, are susceptible to wear and tear over time. Common hazards include corrosion, mechanical damage, and degradation due to environmental factors. Regular inspections and maintenance are necessary to identify potential issues and prevent equipment failure.

Remember that safety should always be a top priority when working with power line poles. Understanding the risks associated with electricity power lines is crucial for preventing accidents. Using quality pole line hardware is key to maintaining a reliable electrical distribution system. Be mindful of common hazards associated with power pole parts and prioritize regular maintenance to ensure safe operations.

Conclusion

Ensuring Reliable Transmission with Quality Pole Line Hardware

When it comes to maintaining a reliable power distribution system, the quality of pole line hardware cannot be overstated. By using high-quality materials and components, such as those offered by Spark Fittings, you can ensure the efficient and safe transmission of electricity.

Importance of Regular Maintenance for Power Line Poles

Regular maintenance of power line poles is essential for ensuring their longevity and functionality. By inspecting and replacing worn or damaged parts, such as insulators, conductor accessories, and anchoring solutions, you can prevent costly outages and ensure the safety of the electrical distribution system. In addition to regular inspections, it's important to invest in high-quality equipment for electrical distribution. Choosing the right materials and tools can make a significant difference in the performance and durability of power line poles. Whether it's selecting durable insulators or corrosion-resistant conductor accessories, investing in top-notch equipment will ultimately save time and money in the long run.

Choosing the Right Equipment for Electrical Distribution

Selecting the right equipment for electrical distribution is crucial for ensuring the efficiency and safety of power line poles. From choosing the appropriate tension clamps to selecting cable accessories for ADSS and OPGW systems, every component plays a vital role in maintaining a reliable power transmission network.

By prioritizing the use of high-quality pole line hardware and implementing regular maintenance practices, you can ensure that your power line poles remain in optimal condition for years to come. Additionally, by choosing the right equipment for electrical distribution, you can mitigate potential risks and maximize the efficiency of your power transmission network.