Introduction

In the world of utility infrastructure, pole guy wire plays a pivotal role in ensuring stability and safety. These wires are essential for supporting utility poles, allowing them to withstand various environmental stresses while maintaining their vertical integrity. Understanding the intricacies of pole guy wire, including the different types and applications, is crucial for anyone involved in construction or maintenance of electrical systems.

Understanding Pole Guy Wire Basics

Pole guy wire is a tensioned wire used to support and stabilize utility poles, providing necessary resistance against lateral forces such as wind or ice accumulation. Typically made from high-strength materials like steel or aluminum, these wires ensure that utility poles remain upright and functional over time. Familiarity with terms like Big Grip Dead Ends and Guy Wire Dead End Grips will enhance your understanding of how these components work together to secure the structure.

Importance of Guy Wire in Infrastructure

The importance of guy wire in infrastructure cannot be overstated; it is fundamental for maintaining the structural integrity of power lines and telecommunications systems. By effectively distributing loads and minimizing swaying, guy wires prevent potential failures that could lead to service outages or hazardous situations. Without proper installation and maintenance of these cables, communities could face significant disruptions in essential services.

Spark Fittings and Their Role

Spark Fittings is a leading company specializing in manufacturing equipment for preformed armor rods, tension clamps, and cable accessories crucial for ADSS (All-Dielectric Self-Supporting) and OPGW (Optical Ground Wire). Their products enhance the reliability of pole guy wire systems by ensuring secure connections between components like Big Grip Dead Ends and other fittings used during installation. With a focus on quality production methods, Spark Fittings supports effective transmission and distribution of electricity across various infrastructures.

What is Pole Guy Wire?

Pole guy wire is an essential component in the construction and stability of utility poles. It serves a critical role by providing additional support, ensuring that poles remain upright against various environmental factors such as wind and ice. Understanding its purpose is crucial for anyone involved in infrastructure development or maintenance.

Definition and Purpose

Pole guy wire is a tensioned cable that anchors utility poles, helping to stabilize them in place. Its primary purpose is to resist lateral forces that could topple the pole, making it vital for maintaining the integrity of electrical transmission lines. Without proper installation of pole guy wire, utility poles would be at risk of leaning or falling over, which could lead to power outages or even accidents.

Common Materials Used

Typically, pole guy wires are made from high-strength materials like steel or aluminum due to their durability and ability to withstand heavy loads. Steel wires are often galvanized for corrosion resistance, making them suitable for outdoor applications where exposure to elements is unavoidable. Aluminum options are lighter but still provide adequate strength, catering to specific installation needs while ensuring ease of handling.

Applications in Utility Poles

In utility applications, pole guy wires are commonly used with Big Grip Dead Ends and other types of Guy Wire Dead End Grips to secure the cables effectively. They play a pivotal role in telecommunications as well as electrical distribution systems by stabilizing poles that carry overhead lines. Additionally, they can be found in various terrains—urban settings with dense infrastructure or rural areas where environmental challenges may arise—demonstrating their versatility across different applications.

The Functionality of Guy Wire Dead End Grips

Guy wire dead end grips play a crucial role in securing pole guy wires, ensuring stability and safety in various applications. These grips are specifically designed to handle the tension exerted on guy wires, which support utility poles and other structures. Understanding their functionality is essential for anyone involved in infrastructure development or maintenance.

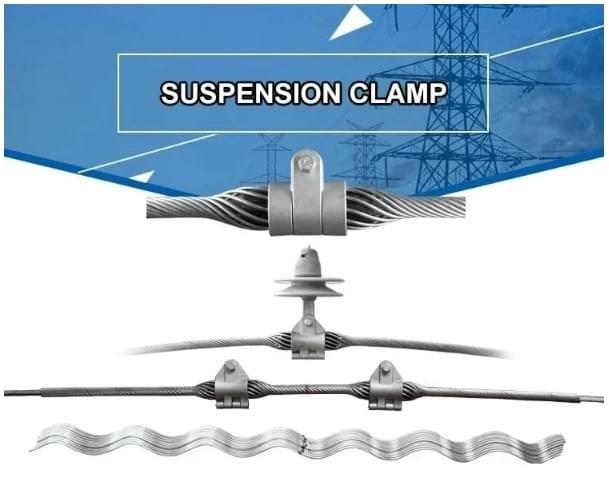

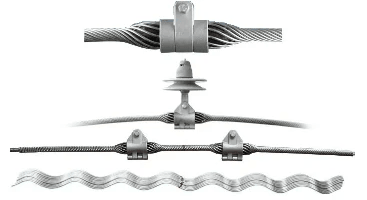

Introduction to Big Grip Dead Ends

Big Grip Dead Ends are a type of Guy Wire Dead End Grips that provide exceptional holding strength for pole guy wires. They are engineered to accommodate the unique demands of electrical installations, particularly where high tension is involved. This innovative design allows for effective anchoring of guy wires, making them indispensable in maintaining the integrity of utility poles.

How Dead Ends Secure the Wire

Dead ends secure the wire by effectively clamping it at critical points along its length, preventing slippage and ensuring that the wire remains taut under varying loads. The preformed nature of Big Grip Dead Ends allows them to distribute stress evenly across the wire, reducing wear and tear over time. This method not only enhances performance but also extends the lifespan of both the pole guy wire and its associated fittings.

Benefits of Using Guy Wire Dead End Grips

Using Guy Wire Dead End Grips offers numerous advantages, including improved safety and reliability for infrastructure projects. They simplify installation processes by providing a straightforward method to secure pole guy wires without complicated rigging techniques. Additionally, these grips reduce maintenance needs over time due to their robust design, allowing for more efficient use of resources in electrical installations.

Key Differences in Types of Wires

Understanding the differences between various types of wires is crucial for anyone involved in utility infrastructure. Among these, pole guy wire, stay wire, and wire rope serve distinct purposes and are designed for specific applications. This section will clarify these differences to help you make informed decisions when selecting the right materials.

What is the difference between guy wire and stay wire?

Guy wire and stay wire may seem similar at first glance, but they have different functions in supporting structures. Pole guy wire is primarily used to stabilize vertical structures like utility poles by providing lateral support, while stay wire serves a similar purpose but is typically used with structures that need to be anchored at an angle, such as masts or towers. The tension in guy wires helps resist lateral forces, while stay wires are often fixed at multiple points along their length for added stability.

What is the difference between wire rope and guy wire?

Wire rope and guy wire differ mainly in their construction and intended use. Wire rope consists of several strands of metal wires twisted together, giving it flexibility and strength suitable for lifting or pulling heavy loads; it's commonly found in cranes or elevators. In contrast, pole guy wire is usually made from single-strand steel or other materials designed specifically for tensioning applications—its primary role is to provide structural support rather than lift loads.

Understanding the Strength and Usage

When discussing strength and usage among these types of wires, it’s essential to consider factors such as tensile strength, material composition, and application context. Pole guy wires are engineered to withstand significant tension without deformation; they are often paired with Big Grip Dead Ends or Guy Wire Dead End Grips for secure anchoring points that enhance stability further. Choosing the right type involves understanding your project's specific needs—whether you're looking at pull strength with Pulling Grips for Wire or ensuring proper alignment with appropriate Guy Wire Grip Sizes.

Selecting the Right Guy Wire Grip Sizes

Choosing the right guy wire grip sizes is crucial for ensuring the stability and safety of pole guy wire installations. The correct grip size guarantees that the tension is evenly distributed, reducing wear and tear on both the wire and fittings. Additionally, selecting the appropriate size can help prevent accidents and failures in utility infrastructure.

Overview of Guy Wire Grip Sizes

Guy wire grip sizes vary based on several factors, including wire diameter and application requirements. Typically, these grips are categorized into small, medium, and large sizes to accommodate different types of pole guy wires. Understanding these categories helps in selecting Big Grip Dead Ends that perfectly match your specific needs.

The sizing of Guy Wire Dead End Grips is critical for ensuring a secure connection between the wire and anchor points. Incorrect sizing can lead to slippage or excessive strain on both the grip and the pole guy wire itself. Therefore, familiarity with various grip sizes will enhance your installation practices significantly.

Factors Influencing Your Choice

Several factors influence your choice of guy wire grip sizes, including environmental conditions, load requirements, and installation methods. For instance, if you’re working in an area prone to high winds or heavy snowfall, you may need a larger grip to handle increased tension on the pole guy wire effectively. Similarly, understanding what is the difference between guy wire and stay wire can also guide your selection process.

Material quality plays a significant role as well; choosing grips made from durable materials ensures longevity under various stress conditions. Additionally, considering whether you need Pulling Grips for Wire during installation can also inform your choice regarding grip size—larger grips may be necessary for easier handling during setup or maintenance tasks.

Recommendations for Different Applications

When it comes to recommendations for different applications involving guy wires, it's essential to match your grip size with specific use cases effectively. For standard utility poles subjected to minimal stressors, medium-sized Guy Wire Dead End Grips typically suffice; however, heavier applications such as telecommunications towers may require larger grips designed for high-stress environments.

If you're unsure about which size to choose or want more tailored solutions based on unique project requirements—consulting a Preformed Guy Grip Dead End Manufacturer could provide valuable insights into optimal selections tailored specifically for your needs. Always remember that proper sizing not only enhances performance but also extends the lifespan of both poles and wires involved in electrical distribution systems.

Practical Uses of Pulling Grips for Wire

Pulling grips for wire play a crucial role in the installation and maintenance of pole guy wire systems. These grips help streamline the process of pulling wires through conduits or across spans, ensuring that installations are efficient and secure. By utilizing pulling grips effectively, utility companies can enhance the reliability of their electrical systems while minimizing potential hazards.

Importance in Electrical Installations

In electrical installations, the importance of using pulling grips cannot be overstated. They provide a secure connection to pole guy wire and facilitate the smooth transition of wires through tight spaces or over long distances. This is particularly vital when dealing with high-tension applications where improper handling could lead to equipment damage or safety issues.

Moreover, pulling grips ensure that wires maintain their integrity during installation, which is essential for long-term performance. The use of Big Grip Dead Ends and Guy Wire Dead End Grips further enhances this reliability by securing the wire at critical points along its path. When you consider what is the difference between guy wire and stay wire, it becomes clear that proper installation techniques using these tools are fundamental to maintaining structural stability.

How to Use Pulling Grips Effectively

To use pulling grips effectively, it's essential first to choose the appropriate size based on your specific application needs; understanding guy wire grip sizes is key here. Once you've selected the right grip, attach it securely to your pole guy wire before beginning any pulling operation. Make sure that all connections are tight and free from any debris that could compromise performance.

It's also advisable to work in teams when using these grips; one person can manage the pulling while another monitors tension levels on the line. This collaborative approach not only enhances safety but also ensures a smoother installation process overall. Additionally, familiarize yourself with different types of grips available in the market—such as those from Spark Fittings—to find high-quality options tailored for your projects.

Case Studies of Successful Installations

Numerous case studies illustrate how effective pulling grips have transformed electrical installations involving pole guy wire systems. For example, a recent project involved installing new transmission lines across rugged terrain where traditional methods would have been cumbersome and time-consuming. By utilizing preformed Guy Wire Dead End Grips along with specialized pulling grips, crews significantly reduced installation time while ensuring robust support for high-voltage lines.

Another noteworthy case involved a municipal utility upgrading its infrastructure after severe storm damage caused widespread outages. The team employed Big Grip Dead Ends and various sizes of guy wire grip sizes to expedite repairs without compromising safety or quality standards. These real-world applications highlight not only how essential these tools are but also how they can lead to innovative solutions in challenging environments.

Conclusion

In the world of infrastructure, the importance of pole guy wire cannot be overstated. These essential components provide stability and support to utility poles, ensuring they stand tall against environmental challenges. As we've explored, understanding the various elements associated with guy wire—from Big Grip Dead Ends to Guy Wire Dead End Grips—enhances our appreciation for their role in maintaining safe and reliable utilities.

The Essential Role of Pole Guy Wire

Pole guy wire serves as a lifeline for utility structures, anchoring them securely in place while allowing them to withstand wind forces and other stresses. Without this critical component, utility poles would be vulnerable to tipping over or collapsing under pressure. The use of high-quality materials and innovative designs like Big Grip Dead Ends ensures that these wires perform effectively over time.

Best Practices for Installation and Maintenance

To maximize the efficiency of pole guy wire installations, it's vital to adhere to best practices during both installation and ongoing maintenance. Proper tensioning is crucial; too loose can lead to sagging while too tight can cause damage to poles or wires themselves. Regular inspections should also be conducted to check for wear and tear on Guy Wire Dead End Grips, ensuring they remain functional throughout their lifespan.

Future Innovations in Guy Wire Technology

The future looks bright for innovations in guy wire technology, with advancements paving the way for even more robust solutions. Companies like Spark Fittings are at the forefront of this evolution, creating high-quality preformed products that enhance performance across various applications. As we continue to explore what is the difference between guy wire and stay wire or delve into what is the difference between wire rope and guy wire?, it becomes clear that ongoing research will lead us toward even more effective designs tailored for modern infrastructure needs.