Introduction

Armor rods are an essential component in the installation of transmission lines, providing support and protection to the conductor. They are used to prevent damage from vibration and wind, ultimately increasing the lifespan of the conductor. When it comes to armor rod installation, knowing how to wrap and twist them properly is crucial for a successful installation process.

What is an armor rod used for?

Armor rods are used to protect conductors from damage caused by vibration and wind. They provide support and enhance the lifespan of the conductor, making them a critical component in transmission line installations.

How do you wrap armor rods?

Wrapping armor rods involves carefully securing them around the conductor using a specific technique. Proper wrapping ensures that they provide optimal support and protection to the conductor.

How do you twist armor rods?

Twisting armor rods is a key step in their installation process, ensuring that they are securely fastened around the conductor. The correct twisting technique is essential for maintaining proper tension and torque, which are crucial for preventing damage to the conductor.

Understanding Armor Rods

Armor rods are essential components in the installation of transmission lines, providing support and protection to the conductors. They are used to prevent damage from vibration and wind, ultimately increasing the lifespan of the conductor. Proper armor rod installation is crucial for maintaining the integrity of the transmission line and ensuring its long-term functionality.

Importance of armor rod installation

The installation of armor rods is vital for maintaining the structural integrity of transmission lines. When properly installed, armor rods provide crucial support to conductors, preventing damage from external factors such as wind and vibration. Additionally, they help to extend the lifespan of the transmission line by reducing wear and tear on the conductors.

Types of armor rod materials

There are various types of materials used in the manufacturing of armor rods, including aluminum wire, galvanized steel wire, and aluminum clad steel wire. Each material offers unique benefits and is chosen based on specific requirements such as conductor surface material and environmental conditions.

Choosing the right armor rod material for your conductor

Selecting the appropriate armor rod material is essential for ensuring compatibility with the conductor's raw material. It is important to avoid corrosion between different elements by choosing an armor rod material that is similar to the conductor surface material. The color code provided with each type of armor rod also aids in identifying conductor size during installation.

Installation Instructions for Armor Rods

When it comes to armor rod installation, it's crucial to follow a step by step guide for flawless execution. Start by wrapping the armor rod tightly around the conductor, ensuring that it is evenly distributed along the length. Next, twist the armor rod in a clockwise direction to achieve the desired tension and torque. This will provide the necessary support and protection for the conductor.

Step by step guide to flawless armor rod installation

To begin, make sure that the conductor is clean and free from any debris or contaminants. Then, carefully wrap the armor rod around the conductor in a helical pattern, ensuring that there is no overlap or gaps between turns. After wrapping, use a twisting tool to apply tension and torque to the armor rod, securing it in place and providing optimal support for the conductor.

Importance of proper tension and torque

Proper tension and torque are essential during armor rod installation as they ensure that the rod effectively supports and protects the conductor. Insufficient tension can lead to slippage or inadequate support, while excessive tension can cause damage to both the armor rod and conductor. It's crucial to achieve the right balance to maximize performance and longevity.

Common mistakes to avoid during installation

One common mistake during installation is applying uneven tension along the length of the armor rod, which can lead to imbalance and potential failure under stress. Another mistake is using incorrect tools or techniques for twisting, resulting in inadequate support for the conductor. It's important to be mindful of these potential pitfalls and ensure a thorough understanding of proper installation methods.

Benefits of Armor Rod Single Support

Armor rod single support offers numerous benefits for transmission line conductors, making it an essential component for the longevity and efficiency of the system. By providing additional support and protection, armor rods effectively increase the lifespan of conductors, reducing the need for frequent maintenance and replacements. This ultimately leads to cost savings and improved overall performance of the transmission line.

Increased conductor lifespan

The use of armor rod single support significantly extends the lifespan of conductors by minimizing wear and tear caused by environmental factors such as wind, vibration, and other external forces. This proactive approach to protecting the conductor ensures that it remains durable and reliable over an extended period, reducing downtime and maintenance costs for transmission line operators.

Furthermore, the use of armor rod single support also helps prevent damage from vibration and wind, which can cause the conductor to weaken and eventually fail. By providing an extra layer of protection, the armor rod single support reduces the risk of structural damage to the conductor, ensuring that it can withstand harsh environmental conditions without compromising its performance. This added resilience not only extends the lifespan of the conductor but also enhances the overall reliability of the transmission line, offering peace of mind to operators and consumers alike.

Prevention of damage from vibration and wind

Armor rod single support acts as a shield against potential damage from vibration and wind, which are common challenges faced by transmission lines. By providing a secure grip on the conductor, armor rods effectively dampen vibrations and reduce the impact of strong winds, preventing structural damage that could compromise the integrity of the entire system.

In addition to protecting against vibration and wind, armor rod single supports also help to maintain the proper spacing and tension of the conductor. This is crucial for ensuring the efficient transmission of electricity along the line. By preventing sagging or swaying of the conductor, armor rods contribute to the overall stability and reliability of the transmission system. This proactive approach to maintenance can help minimize downtime and costly repairs, ultimately saving time and resources for utility companies.

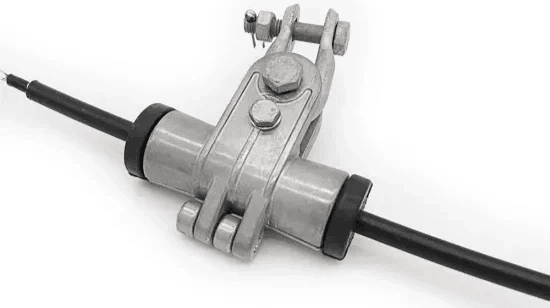

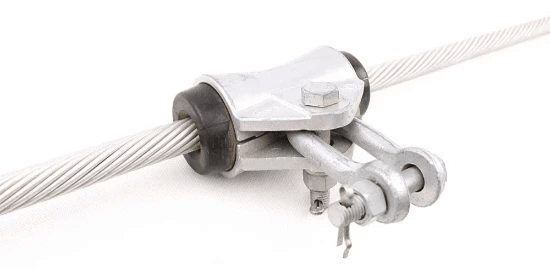

Preformed Armor Rod for Transmission Line

Preformed armor rods are a crucial component in ensuring the longevity and reliability of transmission lines. These preformed armor rods are designed to provide support and protection to the conductor, preventing damage from vibration and wind. They are made from high-quality materials such as aluminum wire, galvanized steel wire, and aluminum clad steel wire, ensuring durability and resilience in various environmental conditions.

Overview of preformed armor rod technology

Preformed armor rod technology involves the use of specially designed rods that are pre-shaped to fit around conductors without the need for twisting or wrapping. This innovative approach streamlines the installation process, saving time and effort while ensuring a secure fit around the conductor. The preformed design also allows for consistent tension and torque, minimizing the risk of over-tightening or under-tightening.

Advantages of preformed armor rods over traditional methods

Compared to traditional methods of wrapping or twisting armor rods around conductors, preformed armor rods offer several distinct advantages. They provide a more uniform distribution of pressure along the conductor surface, reducing the risk of damage due to uneven stress points. Additionally, their streamlined installation process ensures greater efficiency and accuracy in securing the conductor.

Furthermore, preformed armor rods are designed to withstand a wide range of environmental conditions, making them suitable for various transmission line configurations. This adaptability ensures that the conductor is adequately protected regardless of the terrain or climate in which it is installed. Additionally, the use of preformed armor rods can result in cost savings over time, as their durability and reliability reduce the need for frequent maintenance or replacement.

Customized armor rods for different transmission line configurations

One of the key benefits of preformed armor rods is their versatility in accommodating different transmission line configurations. Whether it's overhead lines, underground cables, or substation applications, customized preformed armor rods can be tailored to specific requirements. This flexibility allows for optimal support and protection tailored to each unique transmission line setup.

Furthermore, the ability to customize preformed armor rods for different transmission line configurations allows for more efficient and cost-effective solutions. By tailoring the armor rods to specific requirements, unnecessary material and labor costs can be minimized, resulting in a more streamlined and budget-friendly approach to transmission line support and protection. This level of customization also ensures that each transmission line setup receives the exact support it needs, without any excess or inadequate reinforcement.

The Role of Spark Fittings

When it comes to armor rod installation, using high-quality fittings is crucial for ensuring the longevity and effectiveness of the installation. Spark Fittings understands the importance of this, which is why they prioritize the use of top-notch materials and processes in their fittings.

Importance of using high-quality fittings during armor rod installation

High-quality fittings are essential for maintaining the integrity of armor rod installations. They ensure that the rods are securely fastened to the conductor, providing reliable support and protection against external factors such as wind and vibration. Spark Fittings recognizes this importance and is dedicated to producing fittings that meet the highest standards of quality and durability.

Furthermore, high-quality fittings also contribute to the longevity of armor rod installations. By using durable fittings, the risk of corrosion and wear and tear is minimized, ensuring that the rods remain in optimal condition for an extended period. This not only reduces the need for frequent maintenance but also enhances the overall performance of the conductor system, making it a cost-effective investment in the long run.

Spark Fittings' expertise in customized armor rod production

Spark Fittings excels in producing customized armor rods tailored to specific project requirements. Their expertise allows them to create rods that perfectly match conductor surface materials, preventing any potential corrosion issues. This level of customization ensures that each installation is optimized for performance and longevity.

In addition to their expertise in customized armor rod production, Spark Fittings also offers comprehensive installation support. Their team of experienced professionals can provide guidance and assistance throughout the entire installation process, ensuring that the customized armor rods are properly integrated and optimized for performance. This level of support sets Spark Fittings apart as a valuable partner in any project requiring customized armor rod solutions.

Spark Fittings' role in ensuring a flawless installation process

With their extensive knowledge and experience in armor rod production, Spark Fittings plays a crucial role in ensuring that every installation process is flawless. From selecting the right materials to providing expert guidance on proper installation techniques, they are committed to delivering exceptional support throughout the entire process.

Conclusion

To ensure a flawless armor rod installation, it is crucial to follow the step-by-step guide for wrapping and twisting the rods around the conductor. Choosing the right armor rod material is equally important, as it directly impacts the lifespan of the conductor. Spark Fittings plays a vital role in successful armor rod installation, offering customized solutions tailored to specific transmission line configurations.

How to ensure a flawless armor rod installation

Proper tension and torque during armor rod installation are essential for preventing damage from vibration and wind. Following a meticulous step-by-step guide for wrapping and twisting the rods around the conductor is key to achieving a flawless installation. Avoiding common mistakes during installation is also crucial for ensuring long-term effectiveness.

Choosing the right armor rod material is crucial for ensuring the effectiveness and longevity of the installation. Different materials offer varying levels of durability and resistance to environmental factors, so it's important to select a material that is best suited for the specific conditions of the installation site. Conducting thorough research and consulting with industry experts can help in making an informed decision when it comes to choosing the right armor rod material.

Importance of choosing the right armor rod material

The importance of selecting the correct armor rod material cannot be overstated, as it directly impacts the lifespan of the conductor. It is crucial to choose an armor rod material that matches the surface material of the conductor, thus avoiding corrosion between different elements. The color code on all types of armor rods also aids in identifying conductor size easily during installation.

In addition to selecting the right armor rod material, it is also important to consider the design and construction of the armor rods themselves. The shape, size, and configuration of the armor rods play a crucial role in maintaining the integrity and stability of the conductor. Choosing armor rods with a durable and robust design can help prevent damage to the conductor caused by external factors such as wind, ice, or wildlife interference. Furthermore, well-designed armor rods can provide additional support and protection to the conductor, ultimately extending its lifespan and reducing maintenance costs.

The role of Spark Fittings in successful armor rod installation

Spark Fittings specializes in customized armor rods and plays a pivotal role in ensuring successful installations. With expertise in manufacturing preformed armor rods and providing tailored solutions for various transmission line configurations, Spark Fittings offers unparalleled support for flawless armor rod installations.