Introduction

Understanding the various parts of a power pole is crucial for ensuring the safe and reliable transmission of electricity. From insulators to grounding equipment, each component plays a vital role in maintaining the integrity of power lines. However, there are common misconceptions about power pole parts that need to be addressed. In this article, we will provide an overview of Spark Fittings, a leading manufacturer of equipment for power pole components.

Importance of understanding power pole components

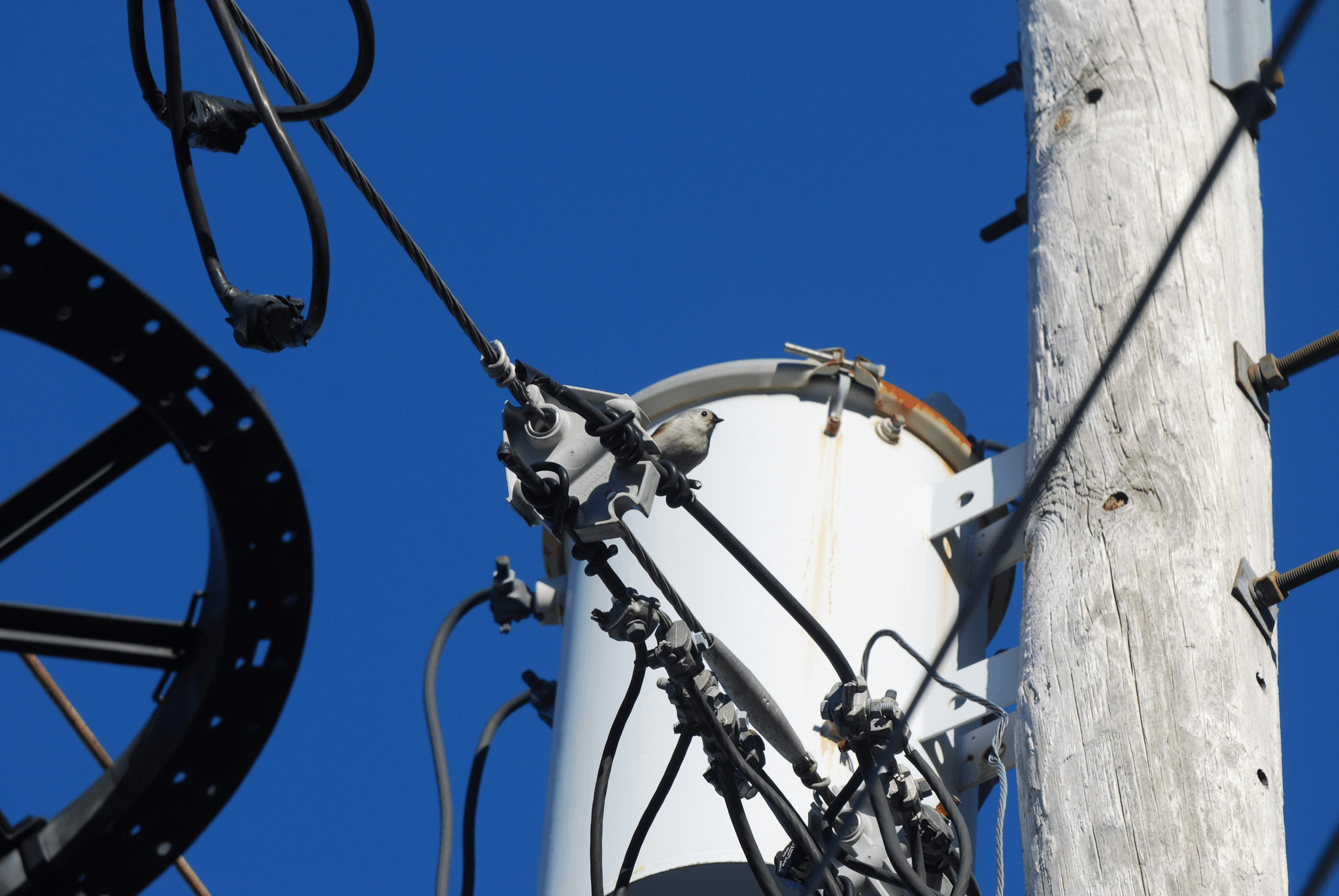

Knowing what the components of a power pole are and how they function is essential for anyone working in the electrical industry or living near power lines. The electrical box on the pole, commonly known as a transformer, is just one of many crucial elements that make up a power pole. Understanding the purpose and function of each part can help prevent accidents and ensure efficient energy distribution.

Common misconceptions about power pole parts

Many people may not realize that the four wires on a power pole serve different purposes - two are for delivering electricity, while the other two are used for communication and control signals. Additionally, there's often confusion about what all the objects on an electric power pole are called and what role they play in supporting electrical infrastructure.

Overview of Spark Fittings

Spark Fittings is a leading company specializing in manufacturing equipment for preformed armor rods, tension clamps, and cable accessories for ADSS and OPGW. Our machines help customers produce high-quality preformed products for the transmission and distribution of electricity, as well as electrified railways.

Understanding the Power Pole Structure

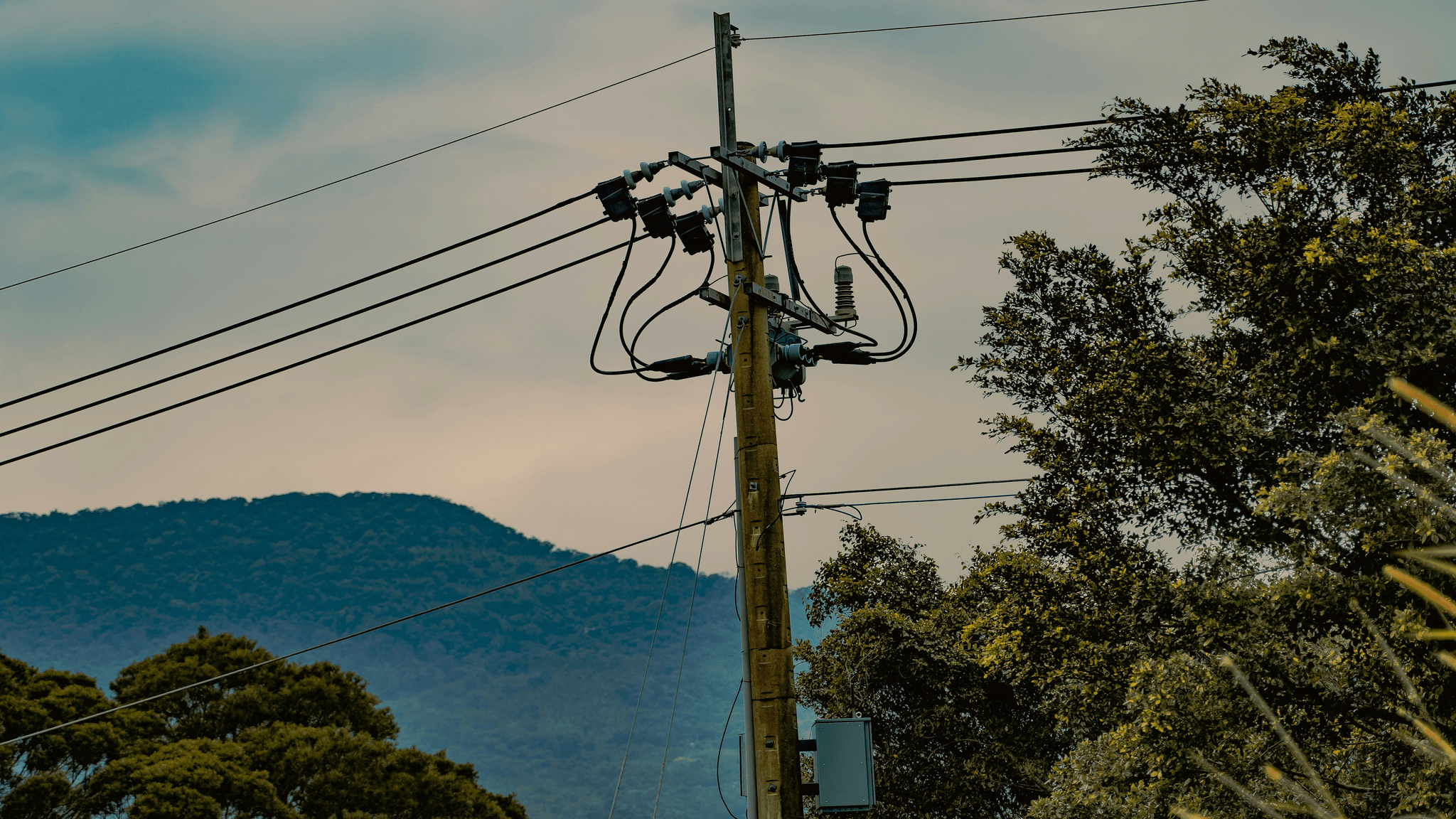

When it comes to understanding the power pole structure, it's important to know the main components of a power pole. These include the pole itself, cross arms, insulators, transformers, and various hardware and fittings. Each component plays a crucial role in supporting power lines and ensuring reliable electrical transmission.

Main components of a power pole

The main components of a power pole are the pole itself, which is typically made of wood, steel, or concrete, and provides vertical support for the power lines. Cross arms are horizontal structures attached to the pole that hold the insulators and provide support for the electrical conductors. Insulators are essential for preventing electrical current from flowing down the pole and ensuring safe transmission.

Materials used in power pole construction

Power poles are constructed using a variety of materials depending on their intended use and location. Wood is commonly used for distribution poles due to its availability and cost-effectiveness. Steel poles are often used for transmission lines as they offer greater strength and durability. Concrete poles are also utilized in areas prone to harsh weather conditions or environmental factors that may affect wooden or steel poles.

Role of each part in supporting power lines

Each part of the power pole structure plays a vital role in supporting power lines. The pole itself provides vertical support, while cross arms hold insulators and provide horizontal support for electrical conductors. Insulators prevent electrical current from flowing down the pole and ensure safe transmission by keeping conductors at a distance from grounded parts of the structure.

Remember that Spark Fittings offers high-quality equipment for preformed armor rods, tension clamps, and cable accessories for ADSS and OPGW to help ensure reliable electrical transmission.

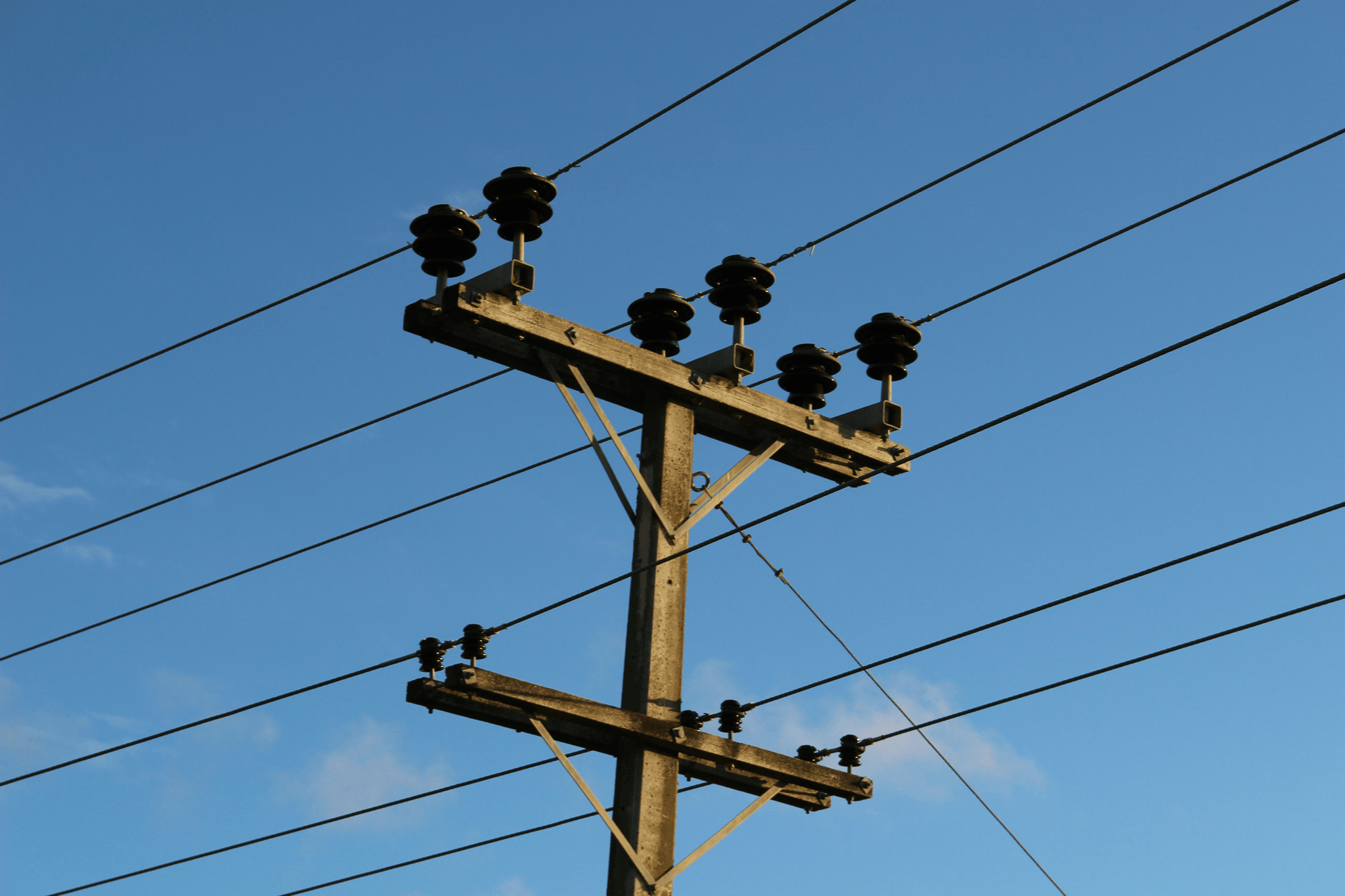

Types of Insulators

When it comes to power pole components, insulators play a crucial role in preventing electrical current from flowing down the pole. Porcelain insulators are traditional and widely used, known for their durability and ability to withstand high temperatures. On the other hand, polymer insulators are lightweight and resistant to corrosion, making them ideal for harsh environmental conditions.

Porcelain insulators

Porcelain insulators, also known as ceramic insulators, are made from clay, quartz, and feldspar. These materials are fired at high temperatures to create a strong and non-conductive surface that can withstand extreme weather conditions. The main advantage of porcelain insulators is their ability to provide long-term insulation for power lines without degrading over time.

Polymer insulators

Polymer insulators are constructed using high-grade silicone rubber or ethylene propylene diene monomer (EPDM) materials. These modern insulators offer excellent resistance to UV radiation and chemical exposure, making them suitable for coastal or industrial areas where pollution levels are high. Additionally, polymer insulators are lightweight and easy to handle during installation.

Benefits and drawbacks of each type

Porcelain insulators have a long track record of reliability and durability but can be heavier and more prone to damage during handling or transportation. On the other hand, polymer insulators offer lightweight design and excellent resistance to environmental factors but may have a shorter lifespan compared to porcelain counterparts.

Hardware and Fittings

When it comes to power pole hardware and fittings, it's essential to have reliable equipment for various components. Spark Fittings offers top-notch equipment for preformed armor rods, which are crucial for maintaining the integrity of power lines. These rods provide protection against damage from environmental factors and ensure the longevity of power pole installations.

Spark Fittings' equipment for preformed armor rods

Spark Fittings provides a range of machinery designed specifically for the production of preformed armor rods. These high-quality tools enable efficient manufacturing processes, resulting in durable and reliable products that enhance the performance of power pole installations. With Spark Fittings' equipment, customers can rest assured that their power lines are well-protected.

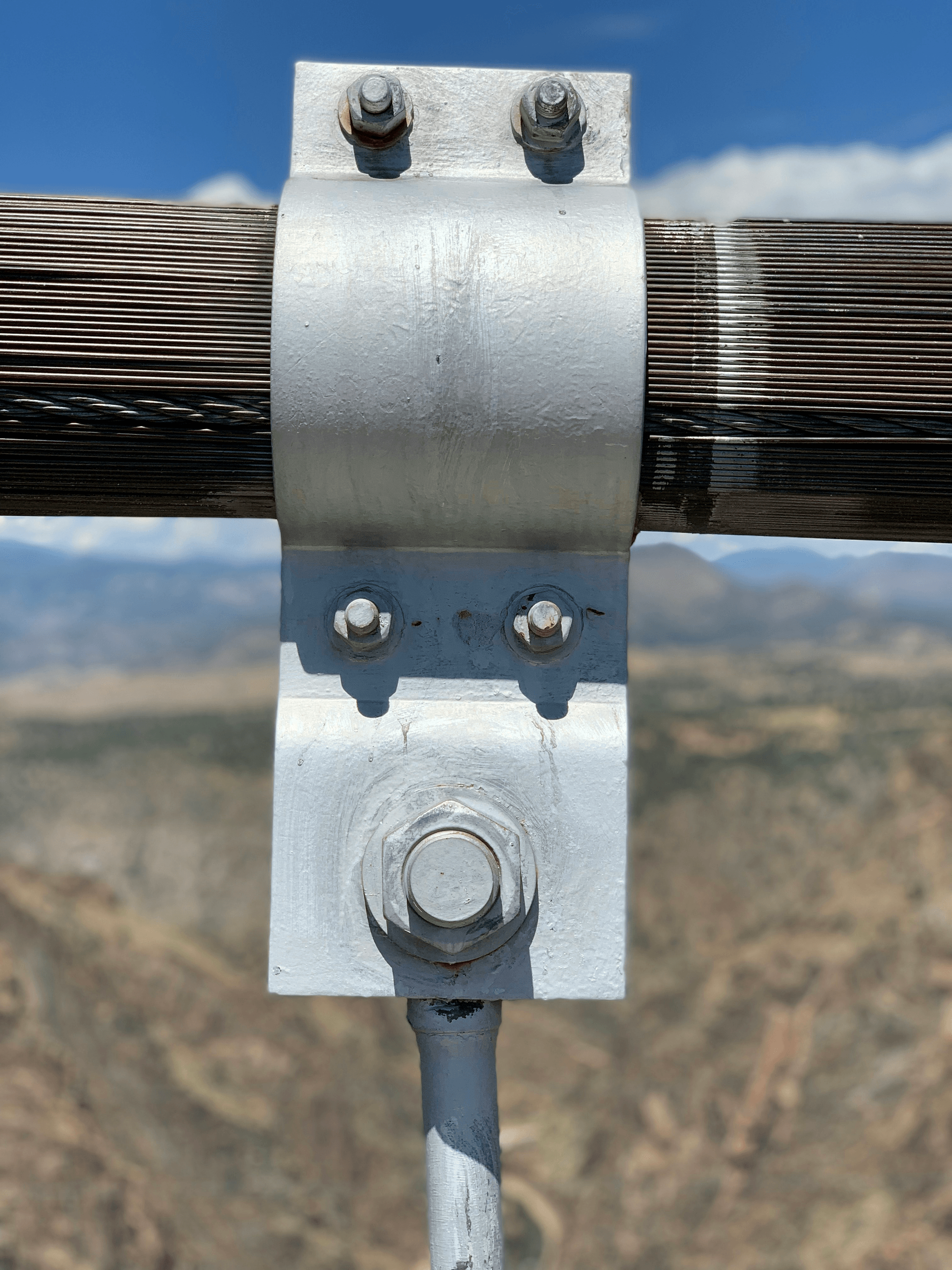

When it comes to installing power poles, tension clamps play a vital role in ensuring secure and stable placements. These clamps are designed to withstand the forces exerted on power lines and provide essential support for the poles. Choosing high-quality tension clamps is crucial for the safety and reliability of electrical transmission systems.

Tension clamps for power pole installation

Spark Fittings offers a range of tension clamps that are engineered to meet industry standards and deliver exceptional performance. With their durable construction and precise design, these clamps provide the necessary strength and stability required for secure power pole installations. By using Spark Fittings' tension clamps, customers can be confident in the long-term integrity of their electrical infrastructure.

In addition to providing equipment for preformed armor rods and tension clamps, Spark Fittings also offers a selection of cable accessories specifically designed for ADSS (All-Dielectric Self-Supporting) and OPGW (Optical Ground Wire) applications. These accessories play a crucial role in supporting and protecting fiber optic cables used in modern communication networks.

Cable accessories for ADSS and OPGW

Spark Fittings' cable accessories are engineered to meet the unique requirements of ADSS and OPGW installations, ensuring optimal performance and longevity. By incorporating these high-quality accessories into their projects, customers can enhance the reliability and efficiency of their communication networks while maintaining seamless integration with existing power pole infrastructure.

Grounding and Bonding

Proper grounding is crucial for the safety and reliability of electrical transmission. The components of a power pole, such as insulators and hardware, rely on effective grounding to ensure the flow of electricity without interference or danger to personnel. Without proper grounding, power poles are susceptible to damage from lightning strikes and other electrical surges.

Importance of proper grounding

The electrical box on the power pole, also known as the service point, is where the power lines connect to the customer's service entrance conductors. It is essential that this connection point is properly grounded to prevent electrical hazards and ensure a safe flow of electricity to homes and businesses. Additionally, grounding protects against voltage surges caused by lightning strikes or other external factors.

Types of grounding equipment

Grounding equipment includes ground rods, which are driven into the earth near a power pole to provide a low-resistance path for electrical currents. Additionally, ground clamps are used to secure the grounding conductor to the ground rod and other metallic objects in the vicinity of the power pole. These components work together to create a reliable grounding system that protects against electrical hazards.

Ensuring safety and reliable electrical transmission

Proper bonding between metal components on a power pole ensures that they are at the same electrical potential, preventing dangerous differences in voltage that can lead to electric shock or equipment damage. By using high-quality bonding connectors and conductors, Spark Fittings' customers can ensure that their power poles are effectively grounded and bonded for safe and reliable electrical transmission.

Maintenance and Inspection

Regular inspections of power pole components are crucial for ensuring the safety and reliability of electrical transmission. The components of a power pole include the pole itself, cross arms, insulators, transformers, and the electrical box, also known as a service point. These inspections involve checking for signs of wear and tear, corrosion, or damage caused by environmental factors or wildlife.

Procedures for repair and replacement are necessary when any part of a power pole is found to be damaged or compromised. This may involve replacing insulators, repairing or reinforcing the cross arms, or replacing the electrical box if it shows signs of deterioration. Spark Fittings provides equipment for preformed armor rods that are essential for reinforcing and repairing power pole components to ensure their longevity.

Extending the lifespan of power pole parts can be achieved through regular maintenance and proper care. This includes applying protective coatings to prevent corrosion, trimming vegetation around poles to prevent damage from falling branches, and ensuring that hardware such as tension clamps are securely fastened. By taking these measures, power pole components can remain in optimal condition for longer periods.

Spark Fittings is committed to providing high-quality equipment that contributes to the safety and longevity of power pole components. By offering reliable machinery for preformed armor rods, tension clamps, and cable accessories for ADSS and OPGW, we support our customers in maintaining their infrastructure at the highest standards possible. Regular maintenance using our products ensures that power poles continue to serve their purpose effectively.

Remember that regular inspections, proper repair procedures when needed, and proactive maintenance measures all contribute to extending the lifespan of power pole parts while also ensuring safe and reliable electrical transmission. By understanding the importance of each component on a power pole and taking appropriate action when necessary, you can help maintain a robust electrical infrastructure for years to come.

Conclusion

Regular power pole maintenance is crucial to ensure the safety and reliability of electrical transmission. Understanding the key considerations for power pole safety, such as proper grounding and high-quality equipment, is essential for preventing accidents and outages. Spark Fittings is dedicated to providing top-notch power pole equipment to support efficient electricity distribution.

Importance of regular power pole maintenance

Regular inspection and maintenance of the various components of a power pole, including insulators, hardware, and fittings, are essential for identifying potential issues before they escalate into safety hazards or service disruptions. By staying proactive with upkeep, utility companies can minimize risks and maximize the lifespan of their infrastructure.

Key considerations for power pole safety

Understanding the parts of a power pole and their roles in supporting electrical lines is crucial for ensuring overall safety. From the insulators that prevent current leakage to the tension clamps that secure conductors in place, each component plays a vital role in maintaining a secure electrical grid. Proper grounding also mitigates the risk of electrical faults and ensures reliable transmission.

In addition to understanding the individual components of a power pole, it is important to regularly inspect and maintain these structures to ensure their continued safety and reliability. Regular inspections can identify any signs of wear, damage, or deterioration that could compromise the integrity of the power pole. By addressing these issues promptly, utility companies can prevent potential hazards and maintain a robust electrical grid for the community.

Spark Fittings' commitment to high-quality power pole equipment

Spark Fittings provides top-of-the-line equipment for preformed armor rods, tension clamps, and cable accessories used in electricity transmission systems. With our high-quality products, utility companies can trust that their power poles are equipped with reliable components that meet industry standards for safety and performance.

Furthermore, Spark Fittings is dedicated to staying ahead of industry trends and innovations, ensuring that our products are always at the forefront of technology. We continuously invest in research and development to create cutting-edge solutions that improve the efficiency and reliability of power pole equipment. By choosing Spark Fittings, utility companies can be confident that they are investing in state-of-the-art components that will enhance the performance of their electricity transmission systems.