Introduction

In the world of manufacturing, understanding wire form machines is essential for optimizing production processes. These machines are pivotal in creating various wire forms that serve multiple industries, from automotive to aerospace. Selecting the right machine can significantly impact efficiency, cost-effectiveness, and product quality.

Understanding Wire Form Machines

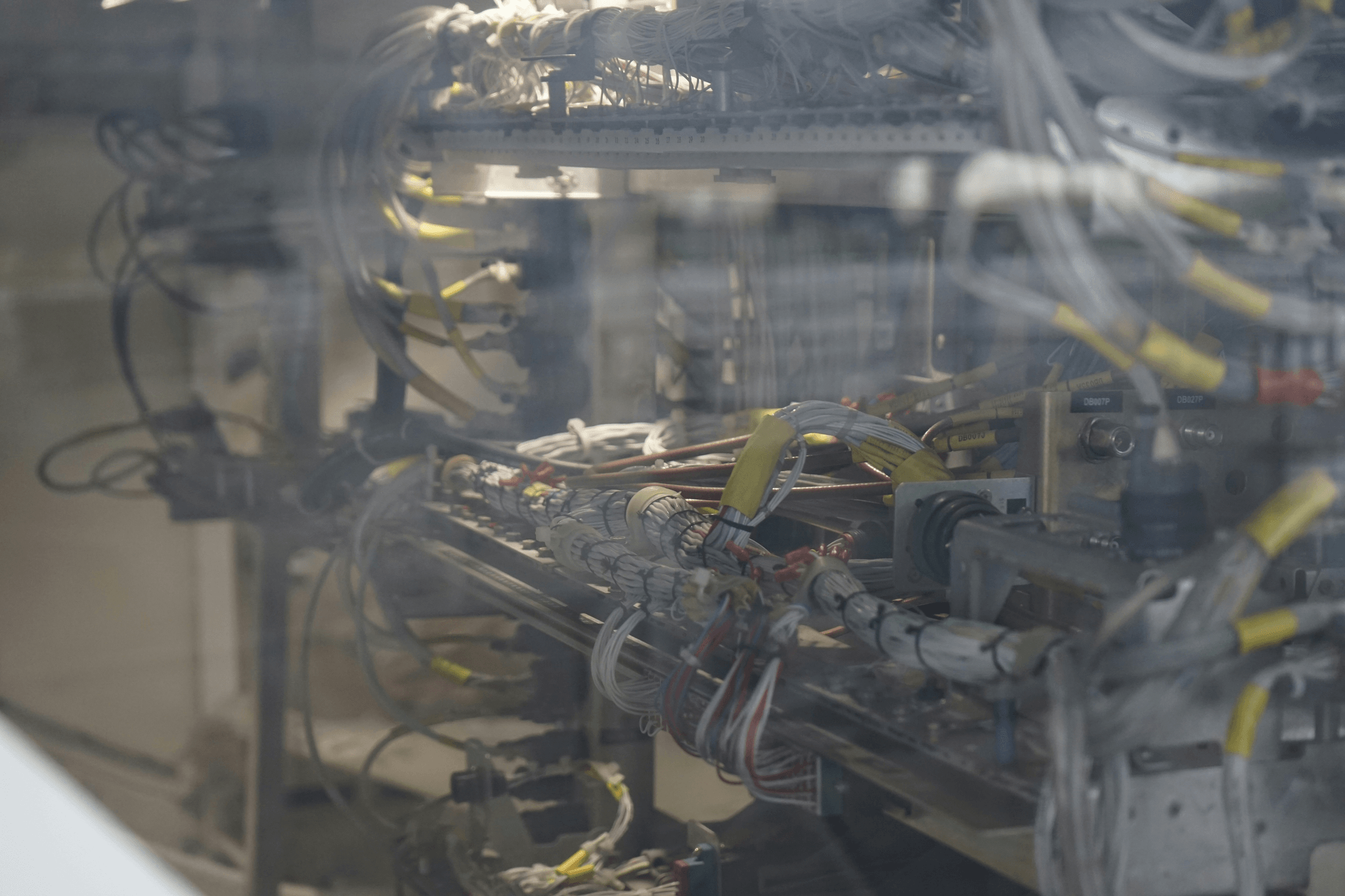

Wire form machines are specialized tools designed to shape and manipulate wire into specific forms for various applications. They come in different types, including traditional bending machines and advanced CNC coiling and bending machines. Each type has unique features that cater to different production needs, making it crucial to understand their functionalities.

Importance of Choosing the Right Machine

Choosing the right wire form machine can make or break your production line's success. The right machine not only enhances productivity but also ensures precision in creating complex shapes and designs needed in modern manufacturing. Moreover, investing in high-performance wire bending machines for steel bars can lead to improved durability and strength in final products.

Overview of Types and Features

There are several types of wire form machines available today, each equipped with features tailored to specific tasks. From manual options that require skilled operators to fully automated CNC wire cut machines that streamline production processes, understanding these variations is key. Knowing what a wire bending machine does and its capabilities will help you make informed decisions about which equipment best suits your business needs.

What Are Wire Forms?

Wire forms are versatile components crafted from various types of wire, designed to serve a multitude of purposes across different industries. They can be found in everything from automotive parts to household items, showcasing their adaptability and utility. Understanding what wire forms are is crucial for anyone looking to optimize their production processes with a wire form machine.

Definition of Wire Forms

Wire forms are essentially custom shapes made from metal wire, which can be bent, twisted, or coiled into specific configurations. These shapes can vary widely in size and complexity, depending on the application they are intended for. In essence, they represent the intersection of functionality and creativity in manufacturing, allowing designers to innovate while meeting practical needs.

Common Applications of Wire Forms

The applications of wire forms are as diverse as the industries that use them. Common uses include components in furniture design, brackets for industrial machinery, and even intricate designs in jewelry making. Given their versatility, high performance wire bending machines for steel bars often play a pivotal role in producing these essential components efficiently and accurately.

Benefits of Using Wire Forms

Utilizing wire forms comes with numerous advantages that make them an appealing choice for manufacturers. First off, they offer significant strength-to-weight ratios due to their material properties; this means you can achieve durability without adding unnecessary bulk. Moreover, employing a CNC wire cut machine enhances precision in production processes while reducing waste—leading to more cost-effective manufacturing overall.

What Is a Wire Bending Machine?

Wire bending machines are essential tools in the manufacturing process of wire forms, enabling the precise shaping of metal wires into various configurations. These machines can range from simple manual devices to advanced CNC coiling and bending machines, each designed to meet specific production needs. Understanding what a wire bending machine is and how it operates is crucial for anyone involved in the production of wire forms.

Explanation of Wire Bending Technology

Wire bending technology refers to the methods and processes used to manipulate metal wires into desired shapes and forms. This technology encompasses various techniques, including twisting, coiling, and bending, which can be performed manually or through automated systems. The evolution of wire bending has led to the development of high performance wire bending machines for steel bars that offer increased efficiency and precision in production.

Key Functions of Bending Machines

The primary function of a wire bending machine is to accurately bend wires into specified angles or shapes as required by different applications. These machines can produce intricate designs that are often impossible to achieve manually, significantly enhancing productivity in manufacturing settings. Additionally, modern wire form machines come equipped with features like programmable controls that allow operators to create complex bends with minimal setup time.

Differences Between Manual and CNC Bending

When discussing what is a wire bending machine, it's important to distinguish between manual and CNC (Computer Numerical Control) options. Manual bending machines require skilled operators who physically manipulate the wire using hand tools or simple jigs; this method can be labor-intensive and less precise than automated alternatives. In contrast, CNC coiling and bending machines utilize computer programming for precise control over the entire process, resulting in higher accuracy and repeatability—key factors when considering what is a CNC wire cut machine for your operations.

High Performance Wire Bending Machines for Steel Bars

Features of High Performance Machines

High Performance Wire Bending Machines are equipped with cutting-edge technology that enhances their operational capabilities. These machines often feature CNC coiling and bending machines, which allow for automated processes that minimize human error and maximize output quality. Additionally, many come with user-friendly interfaces, programmable settings, and advanced safety features that ensure a smooth operation while maintaining high standards of productivity.

Another notable feature is their versatility; they can bend steel bars into complex shapes required in various industries such as automotive, construction, and manufacturing. The integration of software solutions allows operators to design custom wire forms quickly, making adjustments on-the-fly without significant downtime. With robust construction materials, these machines are built to withstand heavy-duty use while ensuring longevity in performance.

Benefits of Using Steel in Wire Forms

Using steel in wire forms has its advantages that cannot be overlooked—strength being the foremost among them. Steel wire forms are not only durable but also offer excellent resistance against deformation under stress, making them ideal for structural applications where reliability is crucial. Moreover, steel's inherent properties allow it to be easily manipulated by what is known as a wire bending machine—whether manual or CNC—enabling intricate designs without compromising on strength.

Another benefit is cost-effectiveness; while steel may have a higher upfront cost compared to other materials like aluminum or plastic, its longevity often translates into savings over time due to reduced maintenance needs and replacement frequency. This makes it an attractive option for businesses looking to optimize both performance and budgetary constraints when considering what is a CNC wire cut machine or any other equipment related to wire form production.

Lastly, steel’s recyclability adds an eco-friendly aspect that appeals to modern manufacturing standards focused on sustainability—a key consideration as industries continue shifting towards greener practices.

Case Studies of Successful Applications

There are numerous case studies showcasing the effectiveness of High Performance Wire Bending Machines for Steel Bars across different sectors. For instance, a leading automotive manufacturer successfully integrated CNC coiling and bending machines into their production line to create custom brackets that could withstand harsh conditions without failure—a crucial factor in vehicle safety standards.

In another example within the construction industry, a company utilized these advanced bending machines to produce rebar ties efficiently at scale; this not only sped up project timelines but also improved overall structural integrity thanks to precise bends tailored specifically for each application type—showing just how vital understanding what are wire forms can be when selecting machinery.

Lastly, an innovative furniture designer employed high-performance bending technologies in crafting unique metal furniture pieces that stand out in both aesthetics and durability—a testament to how creative applications can thrive with proper machinery support like what is known as a bending machine called? In each case study mentioned above, the benefits realized underscore why investing in high-performance equipment pays dividends over time.

What is a CNC Wire Cut Machine?

CNC wire cut machines represent a significant advancement in the world of wire form production, streamlining the process of creating intricate shapes and designs. By employing Computer Numerical Control (CNC) technology, these machines automate the cutting process, ensuring precision and consistency that manual methods simply cannot achieve. This innovation has revolutionized how manufacturers approach wire forms, leading to enhanced efficiency and reduced production times.

Overview of CNC Technology

At its core, CNC technology allows for precise control over machinery through computer programming. In the context of wire form machines, this means that operators can input detailed specifications into the system, which then guides the machine in executing cuts with exceptional accuracy. The result? A more efficient workflow where even complex designs can be produced with minimal human intervention.

Advantages of CNC in Wire Form Production

The advantages of using CNC technology in wire form production are manifold. First and foremost, it enhances precision; each cut made by a CNC wire cut machine is executed according to exact specifications, reducing waste material and errors significantly. Additionally, these machines can operate continuously without fatigue—something manual operators can't claim—which leads to increased productivity and faster turnaround times for projects involving high-performance wire bending machines for steel bars or other materials.

Moreover, the versatility offered by CNC coiling and bending machines allows manufacturers to adapt quickly to changing design needs or customer demands without extensive downtime or retooling requirements. This adaptability makes them an invaluable asset in any production line focused on creating high-quality wire forms.

Popular CNC Models in the Market

Brands like XYZ Corp’s ProCut series are known for their user-friendly interfaces and robust build quality—ideal for those venturing into automated wire form production for the first time. Another noteworthy contender is ABC Industries' FlexiWire model, which excels at handling various materials while maintaining precision during both cutting and bending processes.

These popular models not only embody what a modern wire bending machine should offer but also highlight how far we've come from traditional methods of crafting what are wire forms? Today’s market demands efficiency paired with quality—qualities that these advanced machines deliver seamlessly.

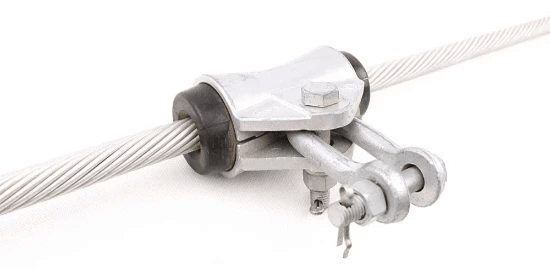

Comparing Twisted Wire Folding Labeling Machines

When it comes to the production of wire forms, choosing the right machine can significantly impact your efficiency and product quality. Among these machines, Spark Fittings’ Twisted Wire Machine stands out for its innovative features designed to enhance productivity. Understanding what sets this machine apart is crucial for businesses looking to optimize their wire form production processes.

Features of Spark Fittings’ Twisted Wire Machine

Spark Fittings’ Twisted Wire Machine boasts a variety of impressive features that make it a top choice in the realm of wire form machines. This high-performance machine is engineered to handle intricate designs with precision, allowing for seamless bending and coiling of wire forms. Additionally, the integration of advanced CNC technology ensures consistent results, making it an ideal option for producing high-quality wire forms.

Another notable feature is its user-friendly interface, which allows operators to easily program and adjust settings according to specific project needs. The machine’s ability to produce multiple twisted wire configurations without extensive downtime enhances overall productivity. Furthermore, its robust construction ensures durability and reliability in demanding manufacturing environments.

Advantages of Automated Labeling

Automated labeling systems integrated into twisted wire folding machines offer significant advantages over traditional methods. For starters, automated labeling reduces human error, ensuring that every product is accurately labeled according to specifications—crucial when considering what are wire forms? This accuracy not only improves compliance but also enhances customer satisfaction by providing clear and consistent information on products.

Moreover, automated systems can operate at high speeds without sacrificing quality, allowing manufacturers to keep up with increasing demand while maintaining efficiency. This capability is especially beneficial in industries where rapid turnaround times are essential. By incorporating automated labeling into their processes, companies can streamline production lines and reduce labor costs associated with manual labeling.

Integrating Twisted Wire Machines into Production Lines

Integrating twisted wire machines into existing production lines requires careful planning but can yield substantial benefits when executed correctly. First and foremost, assessing current workflows helps identify how a new machine will fit within existing operations—especially when considering what is a CNC wire cut machine? Ensuring compatibility with other equipment will facilitate smoother transitions and minimize disruptions during implementation.

Furthermore, training staff on how these machines operate—particularly regarding their advanced features—is vital for maximizing productivity from day one. A well-trained workforce will be able to leverage the capabilities of high-performance wire bending machines for steel bars effectively while minimizing errors during operation. As businesses adapt their production lines to incorporate new technologies like Spark Fittings' Twisted Wire Machine, they position themselves at the forefront of innovation in manufacturing.

Conclusion

In wrapping up our exploration of wire form machines and their various applications, it becomes clear that selecting the right equipment is crucial for achieving optimal results in production. Whether you're considering high performance wire bending machines for steel bars or CNC coiling and bending machines, understanding your specific needs will guide your decision-making process. The world of wire forms is diverse, and knowing what a wire bending machine can do for you will empower your operations.

Making the Best Choice for Your Needs

When it comes to choosing a wire form machine, it's essential to assess the specific requirements of your project. Factors such as material type, production volume, and desired precision all play significant roles in determining which machine suits you best. Remember that high performance wire bending machines for steel bars offer unique benefits that may align perfectly with your goals, while CNC technology can enhance efficiency and accuracy.

Future Trends in Wire Form Technology

The future of wire form technology is bright and brimming with innovation. As industries continue to evolve, we can expect advancements in automation and smart manufacturing processes that will redefine what we know about wire forms. With developments like next-generation CNC wire cut machines becoming more prevalent, the landscape of manufacturing is set to change dramatically.

Resources for Further Learning on Wire Forms

For those eager to dive deeper into the world of wire forms, a wealth of resources awaits you. Industry publications, online courses, and manufacturer websites provide valuable insights into what are wire forms? and what is a wire bending machine? Additionally, engaging with forums or local workshops can help you connect with experts who can share firsthand knowledge about the latest trends in CNC coiling and bending machines.