Introduction

Choosing the right dead end clamp is crucial for ensuring the safety and efficiency of electrical transmission systems. A well-selected dead end clamp not only secures conductors effectively but also contributes to the overall performance and longevity of the infrastructure. With various options available, understanding how to choose the best dead end clamp can make all the difference in your project’s success.

Importance of Choosing the Right Dead End Clamp

The importance of selecting an appropriate dead end clamp cannot be overstated, as it plays a pivotal role in maintaining tension and stability within overhead lines. Using a compatible dead end clamp ensures that cables remain securely fastened, reducing the risk of sagging or failure during adverse weather conditions. Additionally, investing in high-quality clamps can lead to long-term cost savings by minimizing maintenance needs and enhancing system reliability.

Understanding Different Types of Dead End Clamps

There are several types of dead end clamps available on the market, each designed for specific applications and environments. The most common types include suspension clamps, strain clamps, and compression dead-ends, each serving unique functions in supporting overhead lines. Familiarizing yourself with these variations will help you determine which type best suits your project's requirements.

Factors Impacting Dead End Clamp Performance

When evaluating dead end clamps, several factors influence their performance and suitability for particular applications. Material composition is vital; different materials offer varying levels of strength and corrosion resistance that directly affect durability over time. Additionally, load-bearing capacity must be considered to ensure that the chosen clamp can withstand environmental stresses without compromising safety or performance.

What is a Dead End Clamp?

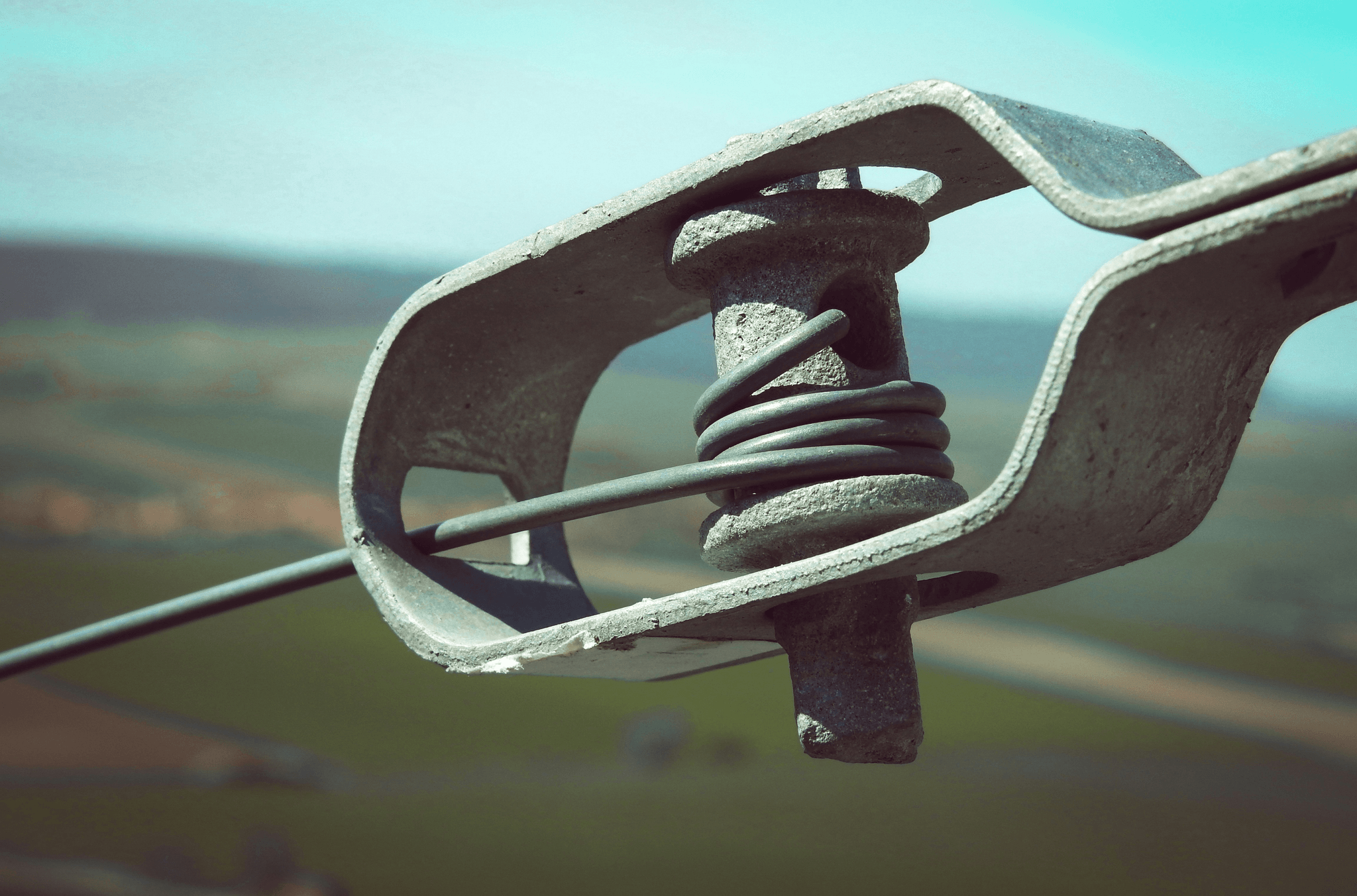

A dead end clamp is a crucial component in electrical transmission systems, designed to secure the end of an overhead conductor. This device plays a vital role in maintaining the integrity and stability of power lines by preventing slippage and ensuring that the conductor remains firmly anchored. Understanding its definition and functionality is essential for anyone involved in electrical infrastructure.

Definition and Functionality

At its core, a dead end clamp serves to hold the ends of conductors firmly in place at their termination points, particularly in overhead line installations. It functions by gripping the conductor tightly while distributing stress evenly along its length, which minimizes wear and tear over time. This functionality is critical for maintaining safety and reliability within electrical transmission networks.

Types of Dead End Clamps

There are several types of dead end clamps available, each tailored to specific applications and installation conditions. The most common types include the Dead End Clamp Overhead Line, Strain clamps, Suspension clamps, and Compression Dead-End clamps. Each type varies in design and application; for instance, suspension clamps are typically used where vertical support is required, while strain clamps are ideal for high-tension scenarios.

Applications in Electrical Transmission

Dead end clamps find extensive use across various applications within electrical transmission systems. They are primarily employed to secure conductors at pole or tower terminations where tension forces are present—this ensures that lines remain stable even under adverse weather conditions or heavy loads. Additionally, these clamps play a significant role in railway electrification projects by providing reliable connections for overhead wires that power trains efficiently.

Key Features of Dead End Clamps

Material Considerations

The material used in dead end clamps plays a significant role in their overall performance and durability. Most dead end clamps are made from high-strength aluminum or steel alloys that offer a balance of lightweight properties and structural integrity. Choosing the right material can enhance the clamp's load-bearing capacity while minimizing the risk of corrosion over time.

For instance, aluminum clamps are often favored for their resistance to oxidation, making them suitable for various environmental conditions. On the other hand, steel clamps may be preferred for heavy-duty applications where strength is paramount. Regardless of your choice between options like Strain clamp or Compression Dead-End types, always consider how material affects both performance and long-term maintenance costs.

Load-Bearing Capacity

Load-bearing capacity is another critical feature that directly impacts the effectiveness of dead end clamps in electrical transmission systems. This metric indicates how much weight or tension a clamp can withstand without failing, which is vital when securing overhead cables under varying weather conditions or during peak load times.

When comparing different types like Suspension Clamp versus Compression Dead-End options, it's essential to assess their respective load capacities to ensure they meet your project requirements. A well-chosen dead end clamp will not only secure cables effectively but also contribute to overall system reliability by preventing sagging or breakage under stress.

Corrosion Resistance and Durability

Corrosion resistance is an indispensable feature when selecting a dead end clamp since these components are often exposed to harsh environmental conditions such as rain, snow, and salt spray from coastal areas. High-quality materials with protective coatings can significantly improve a clamp's lifespan by reducing wear from corrosion over time.

Durability goes hand-in-hand with corrosion resistance; a robust dead end clamp must endure mechanical stresses while maintaining its integrity throughout its service life. When evaluating Dead End Clamp Price options on the market, consider investing in higher-quality products that offer better corrosion protection and durability—this will save you money on replacements down the line.

Comparing Dead End Clamp Types

Dead End Clamp Overhead Line vs. Suspension Clamp

The Dead End Clamp Overhead Line is specifically designed to secure conductors at the end of a span, ensuring that they remain taut and properly positioned. This clamp type effectively absorbs tension and minimizes stress on the conductor due to environmental factors like wind or ice accumulation. On the other hand, a Suspension Clamp is intended for hanging conductors from a support structure without exerting significant stress on them; it allows for some movement while still maintaining stability.

While both clamps serve essential roles in electrical transmission systems, their applications differ significantly. The Dead End Clamp Overhead Line is ideal for locations where tension must be maintained at the end of a line, while Suspension Clamps are better suited for stretches where flexibility is needed without compromising safety or functionality. Understanding these distinctions can help you choose wisely based on your project requirements.

Differences Between Strain Clamp and Compression Dead-End

Strain clamps are designed to withstand high tensile loads by gripping conductors tightly and distributing forces evenly across their surface area. They often feature adjustable components that allow for customization based on specific installation needs or environmental conditions. In contrast, Compression Dead-Ends utilize a crimping mechanism to secure conductors firmly in place; this method provides excellent conductivity but may not accommodate as much flexibility as strain clamps.

Both types have unique advantages depending on your project’s demands. For instance, if you're working with long spans needing robust support against dynamic loads like wind or seismic activity, strain clamps would be more advantageous due to their adaptability under tension. However, if your focus is on reliability with minimal maintenance requirements over time, Compression Dead-Ends might be your best bet.

Ideal Use Cases for Each Type

Choosing between these dead end clamp types ultimately depends on specific application scenarios and environmental factors involved in your project. The Dead End Clamp Overhead Line shines in situations where conductor ends need firm anchoring at terminal points—think power lines extending through rugged terrain or urban environments where stability is paramount. Conversely, Suspension Clamps work best when there’s a need for movement allowance along wires—such as in areas prone to temperature fluctuations causing expansion or contraction.

Strain clamps are perfect when dealing with high-tension lines that require enhanced grip during adverse weather conditions; they provide peace of mind against potential sagging or snapping under pressure from strong winds or heavy ice loads. Meanwhile, Compression Dead-Ends are ideal for installations prioritizing longevity and low maintenance costs—like those found in rural areas with less frequent inspections needed over time.

In summary, understanding these differences can lead you toward making informed decisions regarding dead end clamp selections tailored specifically for your electrical transmission projects.

Evaluating Dead End Clamp Price

Understanding Cost Factors

The price of a dead end clamp is influenced by several key factors that should be considered when shopping around. First, the materials used in construction play a significant role; high-quality metals or composites will typically drive up the cost but offer enhanced durability and performance. Additionally, manufacturing techniques—such as whether the clamp is produced through casting or machining—can also impact pricing; more intricate designs often come with higher production expenses.

Another factor to consider is the type of clamp itself; for instance, a Dead End Clamp Overhead Line may have different pricing dynamics compared to a Suspension Clamp or Strain Clamp due to their specific applications and load requirements. Furthermore, market conditions and supplier competition can affect prices as well; keeping an eye on industry trends may yield better deals over time. Ultimately, understanding these cost factors will empower you to make smarter purchasing decisions.

Quality vs. Price: Finding the Balance

When evaluating dead end clamp prices, striking the right balance between quality and cost is essential for optimal performance in electrical transmission systems. While it might be tempting to opt for cheaper options like compression dead-ends or strain clamps that fit your budget better initially, sacrificing quality could lead to long-term issues such as premature wear or failure under load conditions.

Investing in high-quality dead end clamps ensures reliability and safety in your electrical infrastructure, which can save you money on repairs down the line. Always remember that while lower-priced options might seem appealing at first glance, they could result in higher overall costs if they fail prematurely or require frequent replacements—so choose wisely!

Best Value Options Available

When searching for best value options for dead end clamps, it's important to consider both performance and price without compromising on quality. Brands like Spark Fittings are known for their commitment to producing reliable equipment tailored specifically for preformed armor rods and tension clamps used in various applications—including overhead lines where both suspension clamps and compression dead-ends are commonly employed.

To find great value options among different types of clamps available on the market today, compare features such as load-bearing capacity and corrosion resistance alongside their respective prices from multiple suppliers. By doing thorough research into your choices while keeping an eye out for reputable brands like Spark Fittings that prioritize quality assurance standards through compliance checks—you'll be well-equipped to make a purchase that offers excellent long-term value without breaking your budget.

Choosing the Right Supplier

Why Spark Fittings Stands Out

Spark Fittings is a leading company specializing in manufacturing equipment for preformed armor rods, tension clamps, and cable accessories tailored for ADSS and OPGW applications. Their expertise extends to producing high-quality dead end clamps that cater to various electrical transmission needs, including both suspension clamp and strain clamp varieties. With a focus on innovation and customer satisfaction, Spark Fittings ensures that their products meet rigorous industry standards while offering excellent performance at competitive prices.

Evaluating Supplier Reputation

When searching for a reliable supplier of dead end clamps, reputation is key. Look for suppliers with proven track records in providing high-quality products such as compression dead-ends or suspension clamps; customer reviews and testimonials can be invaluable in this regard. A reputable supplier will also be transparent about their manufacturing processes and adhere to industry regulations, ensuring that you receive a product that meets all necessary compliance standards.

Ensuring Quality and Compliance

Quality assurance should never be an afterthought when selecting your dead end clamp supplier. Ensure that your chosen provider has stringent quality control measures in place throughout their manufacturing processes—this is particularly important when dealing with critical components like strain clamps or overhead line attachments. Additionally, check if they comply with relevant safety regulations; this not only protects your investment but also ensures reliability during operation.

Conclusion

In conclusion, the significance of choosing the right dead end clamp cannot be overstated. These components are essential for ensuring the stability and reliability of electrical transmission systems, whether through a Dead End Clamp Overhead Line or other applications. By understanding the various types of clamps available and their specific functionalities, you can make an informed choice that supports your project’s success.

Recap of Dead End Clamp Importance

Dead end clamps play a crucial role in maintaining tension within overhead lines and ensuring that cables remain securely anchored. Their performance directly impacts the safety and efficiency of electrical transmission, making it vital to select the appropriate type for your specific needs. Whether you’re considering a Suspension Clamp, Strain clamp, or Compression Dead-End, each has its unique benefits tailored to different applications.

Future Trends in Dead End Clamp Technology

The future of dead end clamp technology is poised for exciting advancements as innovations continue to emerge in materials and design. Manufacturers are increasingly focusing on enhancing load-bearing capacity while improving corrosion resistance to extend product lifespan significantly. As industry standards evolve, we can expect more eco-friendly options that not only meet performance requirements but also reduce environmental impact.

Final Thoughts on Choosing Wisely

When it comes to selecting a dead end clamp, knowledge is power—making an informed decision ensures optimal performance and safety in your electrical systems. Balancing factors such as Dead End Clamp Price with quality is essential; investing wisely now can save costs associated with replacements or failures down the line. As you explore options from reputable suppliers like Spark Fittings—known for their high-quality preformed armor rods and tension clamps—remember that choosing wisely today will pave the way for reliable electrical transmission tomorrow.