Introduction

When it comes to the protection of power lines, armor rods play a crucial role in maintaining their durability and longevity. But what exactly is an armor rod? How does it differ from a line guard? And how do you go about installing and twisting these essential components? In this comprehensive guide, we will explore the significance of line protection, the different types of armor rods available, and the key factors to consider when choosing the right ones for your transmission line.

Understanding the Importance of Line Protection

The primary purpose of armor rods is to provide mechanical protection to overhead power lines. They help prevent damage caused by vibration, wind-induced oscillation, and other external factors that could compromise the integrity of the conductors. Essentially, they act as a shield for the transmission line, ensuring that it remains resilient in various environmental conditions.

Exploring the Different Types of Armor Rods

There are several types of armor rods to choose from, including aluminum wire, galvanized steel wire, and aluminum clad steel wire variations. Each type offers unique benefits and is suited for different applications within transmission lines. Understanding these differences is essential in selecting the most suitable armor rod for your specific needs.

When choosing armor rods, it's important to consider the environmental factors that may impact their performance. For example, if the transmission line is located in a coastal area with high levels of salt in the air, galvanized steel wire armor rods may be more suitable due to their corrosion resistance. On the other hand, aluminum wire armor rods are lightweight and ideal for areas with high wind loads. Understanding the specific environmental conditions of your transmission line will help you make an informed decision when selecting armor rods.

Factors to Consider When Choosing Armor Rods

Selecting the right armor rod involves considering various factors such as conductor material compatibility, corrosion prevention between different elements, and proper identification of conductor size during installation. These considerations are crucial in ensuring that the chosen armor rods effectively protect and enhance the durability of your power lines.

In addition to the factors mentioned above, it is also important to consider the environmental conditions in which the armor rods will be installed. Different locations may have varying levels of exposure to elements such as salt, moisture, and UV radiation, which can impact the performance and longevity of the armor rods. Choosing armor rods that are specifically designed to withstand these environmental factors can help ensure their effectiveness in protecting power lines over time.

Types of Armor Rods

When it comes to line protection, armor rods play a crucial role in maintaining the durability of transmission lines. But what exactly is an armor rod? An armor rod is a preformed helical wire that is used to protect the conductor from damage caused by vibration, abrasion, and friction during operation. It provides mechanical protection to the conductor and helps in maintaining the integrity of the transmission line.

Aluminum Wire Armor Rods

Aluminum wire armor rods are widely used for protecting transmission lines due to their lightweight and corrosion-resistant properties. They are easy to install and provide excellent mechanical protection to the conductor surface. The aluminum material ensures that the armor rods do not add excessive weight to the transmission line while still providing reliable protection.

Additionally, aluminum wire armor rods are cost-effective, making them a popular choice for protecting transmission lines. Their durability and resistance to environmental factors make them a reliable option for long-term use. The lightweight nature of aluminum also means that installation is quick and easy, saving both time and labor costs for transmission line projects.

Galvanized Steel Wire Armor Rods

Galvanized steel wire armor rods are known for their strength and durability. They are ideal for protecting transmission lines in harsh environmental conditions where corrosion is a concern. The galvanized steel material provides superior mechanical protection, making these armor rods suitable for long-term use in challenging settings.

In addition to their exceptional strength and durability, galvanized steel wire armor rods offer a cost-effective solution for protecting transmission lines. The galvanized steel material not only provides superior mechanical protection but also offers resistance to corrosion, reducing the need for frequent maintenance. This makes them an ideal choice for long-term use in challenging settings, providing a reliable and low-maintenance solution for protecting transmission lines.

Aluminum Clad Steel Wire Armor Rods

Aluminum clad steel wire armor rods are designed to withstand harsh environmental conditions, including high winds, extreme temperatures, and heavy precipitation. This makes them an ideal choice for transmission lines located in diverse geographic regions. The combination of aluminum and steel also ensures that the armor rods can effectively dissipate electrical energy, reducing the risk of power outages and equipment damage during storms or other adverse weather events.

Choosing the Right Material

When it comes to choosing the right armor rod material, it's essential to match it with the conductor surface material. This ensures a secure and reliable fit, preventing any potential damage or corrosion. The color code on armor rods is also crucial for easy identification of conductor size during installation, making the process more efficient and accurate. Spark Fittings offers customized armor rods to meet specific requirements, providing a tailored solution for line protection.

Matching Armor Rod Material to Conductor Surface

Matching the armor rod material to the conductor surface material is vital for ensuring a secure and durable fit. By selecting an armor rod material that is similar to the conductor's raw material, you can prevent any potential corrosion or damage between different elements. This compatibility ensures that the armor rod effectively protects the transmission line without causing any adverse effects on its components.

Matching the armor rod material to the conductor surface material is vital for ensuring a secure and durable fit. By selecting an armor rod material that is similar to the conductor's raw material, you can prevent any potential corrosion or damage between different elements. This compatibility ensures that the armor rod effectively protects the transmission line without causing any adverse effects on its components.

Avoiding Corrosion Between Different Elements

Avoiding corrosion between different elements is a key consideration when choosing armor rods. By selecting materials that are compatible with each other, you can prevent any chemical reactions or degradation that could compromise the integrity of the transmission line. This proactive approach helps maintain the overall durability and performance of the line, ensuring long-term reliability and safety.

Importance of Color Code for Conductor Size Identification

The color code on armor rods serves as a visual identifier for conductor size during installation. This simple yet effective system streamlines the installation process by allowing workers to quickly and accurately identify which armor rod corresponds to each conductor size. This not only saves time but also reduces the likelihood of errors during installation, enhancing overall efficiency and precision.

With Spark Fittings' expertise in preformed armor rods manufacturing and customization services, customers can benefit from tailored solutions that meet their specific line protection needs. By offering customized options and specialized equipment for various cable accessories, Spark Fittings ensures that transmission lines are equipped with high-quality armor rods designed for optimal performance and longevity.

Customizing Armor Rods

Armor rods are essential components for protecting transmission lines from damage and wear. What is an armor rod? It is a preformed rod designed to protect the conductor from abrasion, bending, and compression. The difference between armor rod and line guard lies in their design and purpose. While armor rods are used to protect conductors, line guards are used to support them.

Benefits of Customized Armor Rods

Customized armor rods offer several advantages over standard ones. They can be tailored to fit specific conductor sizes and shapes, ensuring a perfect fit for maximum protection. Additionally, customized armor rods can be designed to match the color of the conductor, providing a seamless and aesthetically pleasing look.

Customized armor rods also offer the benefit of improved durability and longevity. By fitting perfectly to the conductor, they provide a secure and stable layer of protection, reducing wear and tear on the conductor itself. This can ultimately extend the lifespan of the entire system, saving time and money on maintenance and replacements in the long run.

How Spark Fittings Offers Customization Services

Spark Fittings specializes in providing customized armor rods tailored to meet the unique needs of each project. With extensive expertise in preformed armor rods manufacturing, they have the capability to produce customized solutions that perfectly align with the requirements of their clients. Whether it's matching the material to the conductor surface or creating color-coded options, Spark Fittings offers comprehensive customization services.

Role of Spark Fittings

When it comes to preformed armor rods manufacturing, Spark Fittings stands out with its expertise in producing high-quality armor rods. The company offers a wide range of options, including aluminum wire, galvanized steel wire, and aluminum clad steel wire armor rods to suit different transmission line needs. With their extensive knowledge and experience in this field, Spark Fittings ensures that their armor rods are tailored to match the conductor surface material, preventing corrosion between different elements.

Expertise in Preformed Armor Rods Manufacturing

Spark Fittings takes pride in their expertise in preformed armor rods manufacturing. They understand the importance of choosing the right material for armor rods and ensuring that it matches the conductor's raw material. By specializing in this area, they are able to provide top-notch solutions for line protection with their high-quality armor rods.

By focusing on preformed armor rods manufacturing, Spark Fittings has been able to hone their skills and knowledge in this specialized area. This expertise allows them to stay ahead of industry trends and developments, ensuring that they are always using the most advanced materials and techniques in their manufacturing process. As a result, their clients can trust that they are receiving the most innovative and effective solutions for line protection with high-quality armor rods.

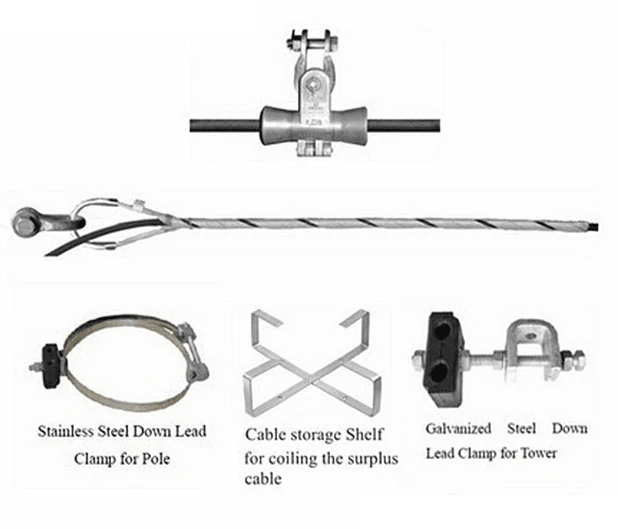

Providing Preformed Tension Clamp/Armor Rods Machines

In addition to manufacturing preformed armor rods, Spark Fittings also offers preformed tension clamp/armor rods machines. These machines are essential for installing and securing armor rods onto transmission lines effectively. With their reliable and durable equipment, Spark Fittings makes it easier for utility companies and contractors to ensure the durability and safety of their transmission lines.

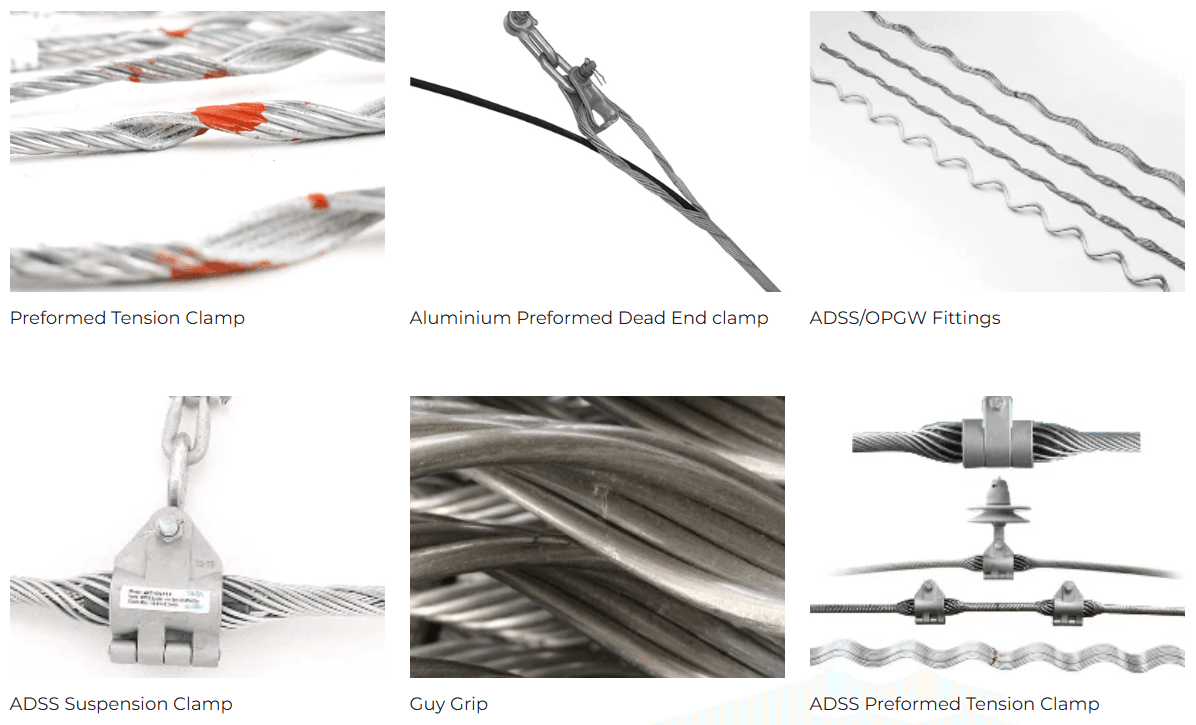

Manufacturing Equipments for Preformed ADSS & OPGW Cable Accessories

Furthermore, Spark Fittings is a leading supplier of manufacturing equipment for preformed ADSS & OPGW cable accessories. Their commitment to providing comprehensive solutions for line protection extends beyond just armor rods, as they also offer a range of equipment designed specifically for ADSS & OPGW cable accessories. This demonstrates their dedication to offering a complete suite of products that cater to the diverse needs of transmission line projects.

Conclusion

Armor rods are essential for protecting transmission lines and enhancing their durability. By choosing the right armor rod material and customizing them to fit specific needs, line protection can be optimized. Partnering with Spark Fittings ensures access to quality line protection accessories and expertise in manufacturing preformed armor rods.

Making the Best Choice for Line Protection

Selecting the appropriate armor rod is crucial for ensuring the longevity of transmission lines. Understanding the differences between armor rods and line guards is key in making an informed decision. Proper installation of armor rods is also vital in maximizing their effectiveness.

Enhancing Line Durability with the Right Armor Rods

The process of twisting armor rods onto conductors must be done correctly to ensure a secure fit that provides optimal protection. The use of armor rod clamps can aid in this process, providing additional stability and support to the transmission line.

Partnering with Spark Fittings for Quality Line Protection Accessories

Spark Fittings offers a wide range of preformed armor rods, as well as customization services to meet specific requirements. Their expertise in manufacturing equipment for preformed ADSS & OPGW cable accessories ensures high-quality products that enhance line durability.