Introduction

In the world of construction and engineering, the significance of structural support cannot be overstated. Galvanized guy wires play a crucial role in providing stability to various structures, ensuring they withstand environmental challenges while maintaining their integrity. But what is galvanized wire used for? This article will delve into the multifaceted applications of galvanized metal wire across different sectors, highlighting its importance.

Understanding Galvanized Guy Wires

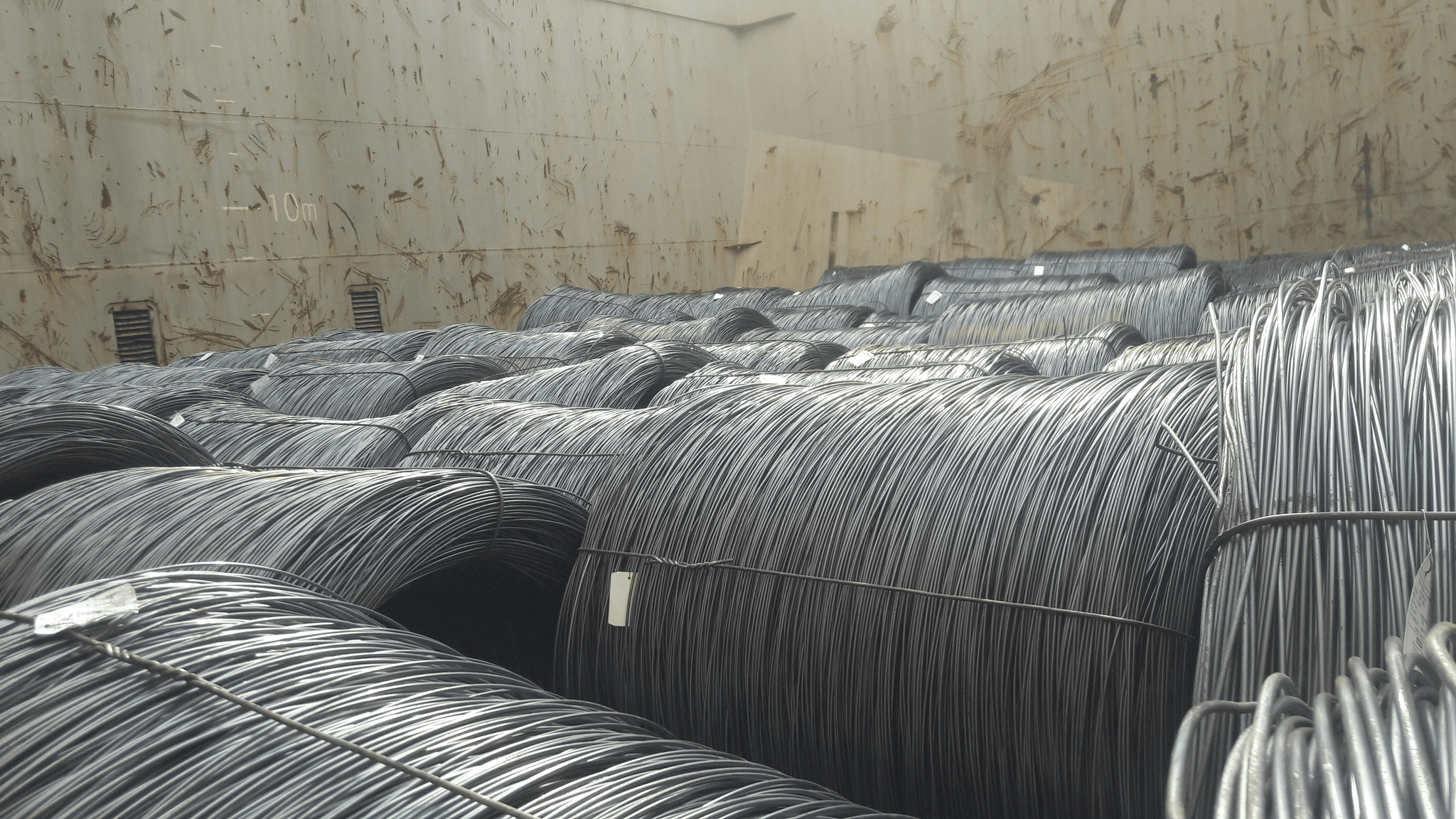

Galvanized metal wire is a type of steel wire that has undergone a protective coating process to enhance its resistance to rust and corrosion. This process involves dipping the steel in molten zinc, creating a barrier that is particularly effective in harsh weather conditions. When we ask, Is galvanized steel wire rust proof? it's important to note that while it significantly reduces rust formation, no material is entirely immune; however, its longevity makes it an excellent choice for structural applications.

The Importance of Structural Support

Structural support systems are essential for maintaining the safety and functionality of buildings and infrastructure. Galvanized guy wires provide necessary tension and stability, preventing structures from swaying or collapsing under stress from wind or other forces. With questions like How long does galvanized wire last? often arising, it's reassuring to know that when properly installed and maintained, these wires can provide decades of reliable service.

Applications Across Various Structures

The versatility of galvanized metal wire enables its use in diverse applications ranging from communication towers to bridges and wind turbines. In telecommunications, for example, 6 gauge galvanized steel wire ensures robust support for towers that must endure high wind loads while maintaining signal integrity. As we explore further into specific applications throughout this article, we will see how galvanized wires contribute significantly to modern engineering solutions.

Communication Towers

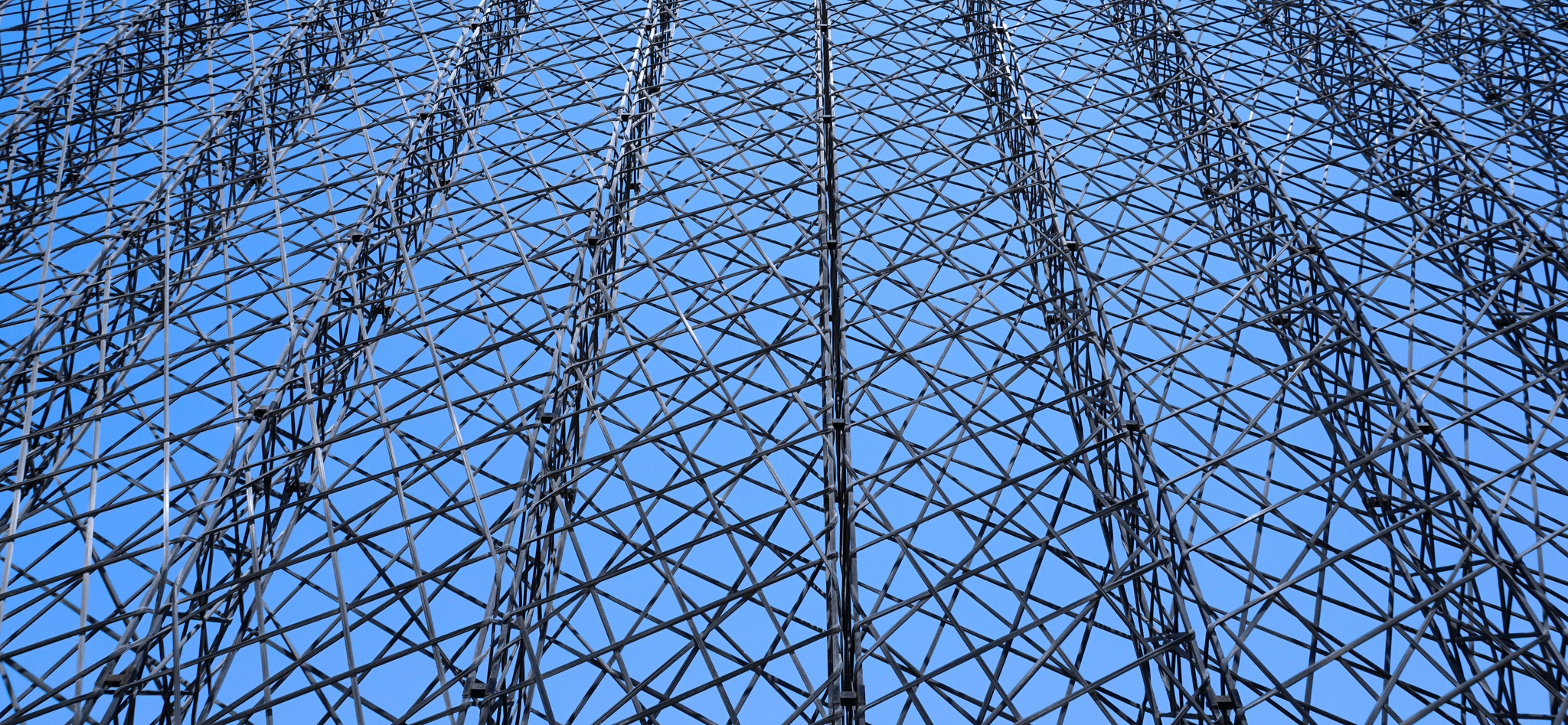

Communication towers are the backbone of our modern telecommunications infrastructure, providing essential support for transmitting signals over vast distances. These structures rely heavily on galvanized metal wire to maintain stability and integrity under various environmental conditions. Without robust support systems, the effectiveness of communication networks would significantly diminish.

Essential Support in Telecommunications

In the realm of telecommunications, communication towers serve as critical nodes for signal transmission, ensuring that our devices remain connected. The use of galvanized metal wire is paramount in these applications due to its strength and durability. What is galvanized wire used for? Primarily, it provides the necessary tension to keep antennas and other equipment securely in place while withstanding external forces like wind and weather.

Use of 6 Gauge Galvanized Steel Wire

Among the various options available, 6 gauge galvanized steel wire stands out as a popular choice for supporting communication towers. This specific gauge offers a perfect balance between flexibility and strength, allowing it to endure significant stress without compromising structural integrity. When considering whether galvanized steel wire is rust proof, it's important to note that while it is highly resistant to corrosion due to its zinc coating, it’s not completely impervious—regular maintenance can extend its lifespan considerably.

Longevity and Reliability in High Wind Areas

One of the key advantages of using galvanized metal wire in communication towers is its longevity and reliability, particularly in high wind areas where structural demands are amplified. How long does galvanized wire last? With proper installation and maintenance practices, it can endure for decades—making it an economical choice over time. Additionally, many engineers consider whether galvanized wire is waterproof; while the coating helps resist moisture-related deterioration, ensuring proper drainage around installations further enhances durability against elements like rain or snow.

Transmission Lines

Transmission lines are crucial for delivering electricity over long distances, and the choice of materials used in their construction significantly impacts their performance and longevity. One of the standout materials for this application is galvanized metal wire, renowned for its resilience against harsh environmental conditions. Understanding how galvanized wire functions in these demanding settings is essential for ensuring a reliable energy supply.

How Galvanized Metal Wire Stands Up to the Elements

Galvanized metal wire is specifically designed to withstand the rigors of outdoor exposure, making it an ideal choice for transmission lines. The galvanization process involves coating steel with a layer of zinc, which protects the wire from moisture and corrosion, ensuring durability even in extreme weather conditions. This robust nature means that when you ask, What is galvanized wire used for? you'll find it’s frequently employed in environments where wind, rain, and snow are prevalent.

Is Galvanized Steel Wire Rust Proof?

While galvanized steel wire isn't entirely rust-proof, it offers significant protection against corrosion compared to non-galvanized alternatives. The zinc coating acts as a sacrificial barrier; if scratched or damaged, it will corrode before the underlying steel does. So when pondering Is galvanized steel wire rust proof?, it's important to understand that while it's highly resistant to rusting, proper installation and maintenance remain key factors in maximizing its lifespan.

Spark Fittings and Custom Armor Rod Solutions

In addition to using galvanized metal wire itself, transmission lines often incorporate specialized fittings like armor rods that enhance structural integrity further. Spark Fittings provides customized armor rods made from aluminum wire or 6 Gauge Galvanized Steel Wire tailored to match the conductor's material—this avoids any potential corrosion issues between dissimilar metals. With color-coded options available for easy identification during installation, these armor rods are essential components that ensure reliability in electrical systems while answering the question: How long does galvanized wire last? by extending its operational life through thoughtful engineering.

Wind Turbines

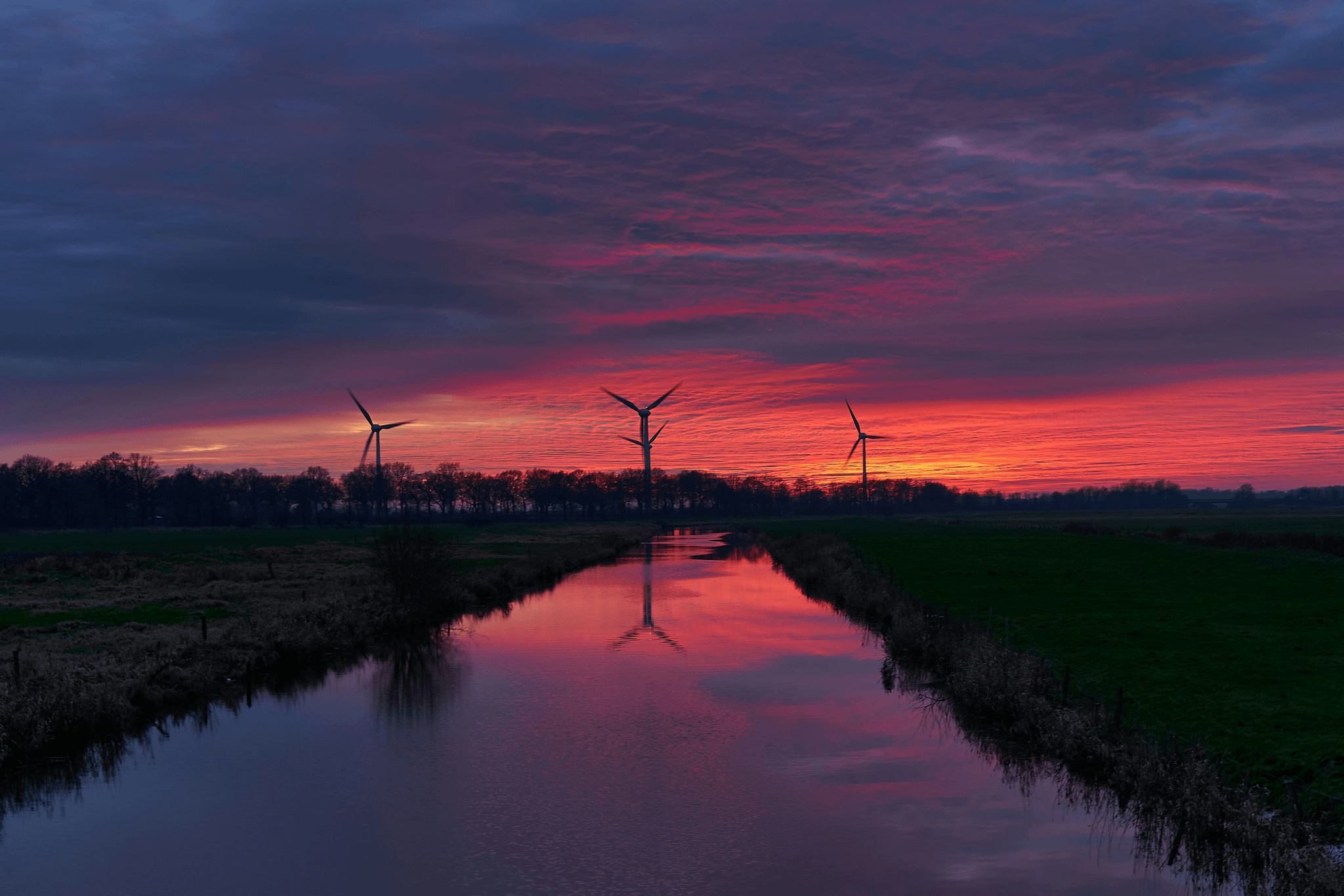

Wind turbines represent a significant leap toward sustainable energy, and they rely heavily on galvanized metal wire for structural integrity. The stability provided by this wire is crucial, especially in areas prone to high winds and turbulent weather conditions. Understanding the role of galvanized wire in these renewable energy structures helps us appreciate their engineering marvels.

Stabilizing Renewable Energy Structures

Galvanized metal wire plays a vital role in stabilizing wind turbines, ensuring they can withstand the forces of nature. These structures need to be robust enough to endure strong gusts while maintaining optimal performance levels. With the use of galvanized steel wire, especially 6 gauge galvanized steel wire, engineers can provide the necessary support that allows these colossal machines to function efficiently.

In addition to stability, it's essential for wind turbines to be lightweight yet strong; galvanized wires meet this requirement perfectly. Their resistance to corrosion and environmental wear ensures that the turbines remain operational over extended periods. This durability leads us to ask: Is galvanized steel wire rust proof? While not entirely rust-proof, its protective zinc coating significantly enhances its longevity against harsh elements.

What is Galvanized Wire Used For?

What is galvanized wire used for? In wind turbine applications, it secures various components such as blades and towers while also providing tension support where needed. This versatility makes it an indispensable material in modern engineering practices aimed at harnessing wind energy effectively.

Furthermore, the use of 6 gauge galvanized steel wire ensures that even under extreme conditions, the integrity of these structures remains intact. As a result, maintenance costs are reduced due to fewer repairs needed over time. So how long does galvanized wire last? Typically designed for long-term usage, it can last several decades when properly maintained.

Another common query is whether galvanized wire is waterproof? While it isn't entirely waterproof due to potential moisture retention in certain environments, its corrosion-resistant properties help mitigate damage from water exposure significantly.

The Role of Armor Rods in Wind Farm Operations

Armor rods are crucial components in wind farm operations because they offer additional protection and support for electrical conductors connected to turbines. Made from materials like aluminum and galvanized steel wire, armor rods prevent abrasion and enhance durability under mechanical stress conditions common with fluctuating wind patterns.

When selecting armor rod materials for specific applications within wind farms, it's essential that they correspond with the conductor's raw material—this avoids any corrosion between different elements that might compromise performance over time. Spark Fittings offers customized armor rods tailored specifically for various conductor sizes using an effective color code system for easy identification during installation.

In summary, both galvanization and spark fittings play integral roles in ensuring that our renewable energy sources remain stable and efficient throughout their operational lifespan—an investment well worth making as we transition into a greener future!

Radio Masts and Antennas

Radio masts and antennas play a crucial role in modern communication, requiring robust support structures to maintain signal integrity. One of the best materials for this purpose is galvanized metal wire, which provides both strength and durability. Understanding what galvanized wire is used for in these applications can help ensure a reliable communication network.

Ensuring Signal Integrity with Galvanized Wires

When it comes to radio masts, ensuring signal integrity is paramount, and galvanized wires are up to the task. The use of 6 gauge galvanized steel wire enhances the stability of these structures, allowing them to withstand various environmental challenges without compromising performance. Additionally, the corrosion resistance of galvanized steel wire means that even in adverse weather conditions, the signal remains clear and uninterrupted.

Importance of Waterproofing in Mast Construction

Waterproofing is another critical factor in mast construction; after all, no one wants their signal interrupted by rain or moisture! While many might wonder if galvanized wire is waterproof, it's essential to note that while it resists rust due to its zinc coating, proper waterproofing techniques must still be employed during installation. This approach not only protects the structural integrity but also prolongs the lifespan of components like 6 gauge galvanized steel wire.

How Long Does Galvanized Wire Last?

The longevity of galvanized metal wire often raises questions: how long does galvanized wire last? Generally speaking, when properly installed and maintained, it can last several decades—often upwards of 30 years! However, factors such as environmental conditions and exposure to pollutants can influence this lifespan significantly; thus regular inspections are vital for optimal performance.

Bridges and Large Structures

Bridges and large structures are marvels of modern engineering, often relying on the strength and stability provided by galvanized guy wires. These wires play a crucial role in maintaining the integrity of these massive constructions, enabling them to withstand various environmental stresses. When we ask, What is galvanized wire used for? the answer often leads us to its essential function in supporting these iconic structures.

Engineering Marvels Supported by Guy Wires

Guy wires are pivotal in supporting bridges, ensuring they remain stable against wind forces and other loads. The use of 6 gauge galvanized steel wire is common in these applications due to its superior tensile strength and durability. By anchoring the structure securely, these wires help maintain balance and prevent deformation over time.

The Corrosion Resistance of Galvanized Materials

One of the standout features of galvanized metal wire is its corrosion resistance, which is critical for outdoor applications like bridges exposed to moisture and varying weather conditions. Many people wonder, Is galvanized steel wire rust proof? While not entirely rust-proof, it has a protective zinc coating that significantly reduces corrosion risk. This makes it an ideal choice for long-term structural support where longevity is a concern—so you can expect your guy wires to last many years without significant degradation.

Spark Fittings for Specialized Applications

These armor rods are designed to match the conductor's material closely, preventing any corrosion between dissimilar metals—a vital consideration for structural integrity. With color-coded options available for easy identification during installation, Spark Fittings stands out as a leader in providing tailored solutions that enhance performance while ensuring safety.

Conclusion

In summary, galvanized guy wires are indispensable components in various structural applications, providing essential support and stability. Their versatility is evident across communication towers, transmission lines, wind turbines, radio masts, and even large bridges. Understanding the benefits of using galvanized metal wire can help engineers and builders make informed decisions for their projects.

Key Benefits of Using Galvanized Guy Wires

One of the standout features of 6 gauge galvanized steel wire is its remarkable strength-to-weight ratio, which allows it to withstand significant tension without compromising structural integrity. Additionally, the galvanization process protects the wire from rust and corrosion, making it a sustainable choice for long-term use in harsh environments. When asking What is galvanized wire used for?, it's clear that its applications extend far beyond mere aesthetics; it's about ensuring safety and reliability in engineering.

Factors Influencing the Lifespan of Guy Wires

The lifespan of galvanized guy wires largely depends on environmental factors such as exposure to moisture and temperature fluctuations. While you might wonder Is galvanized steel wire rust proof?, it's important to note that while it resists rust considerably better than untreated steel, no material is entirely immune to corrosion over time. Regular inspections can help determine How long does galvanized wire last?—often many years if properly maintained—allowing structures to remain stable and secure throughout their service life.

Choosing the Right Armor Rod Material

When selecting armor rod material for your project, compatibility with the conductor's raw material is crucial to prevent corrosion between different elements. Spark Fittings offers a range of options including aluminum wire, galvanized steel wire, and aluminum clad steel wire tailored to specific needs; this ensures optimal performance in various conditions. Remember that each type comes with a color code for easy identification during installation—a handy feature when dealing with multiple sizes!