Introduction

When it comes to overhead line insulation products, understanding the different types of insulators is crucial for ensuring the safety and reliability of transmission lines. From insulator strings on transmission lines to cover insulated tubing, there are various Types of Overhead Lines Insulators to consider. Choosing the right insulator is essential for maintaining the integrity of the system and preventing outages. Key Factors in Insulator Selection include environmental conditions, voltage levels, and mechanical loads, making it a complex decision that requires careful consideration.

Understanding Overhead Line Insulator Types

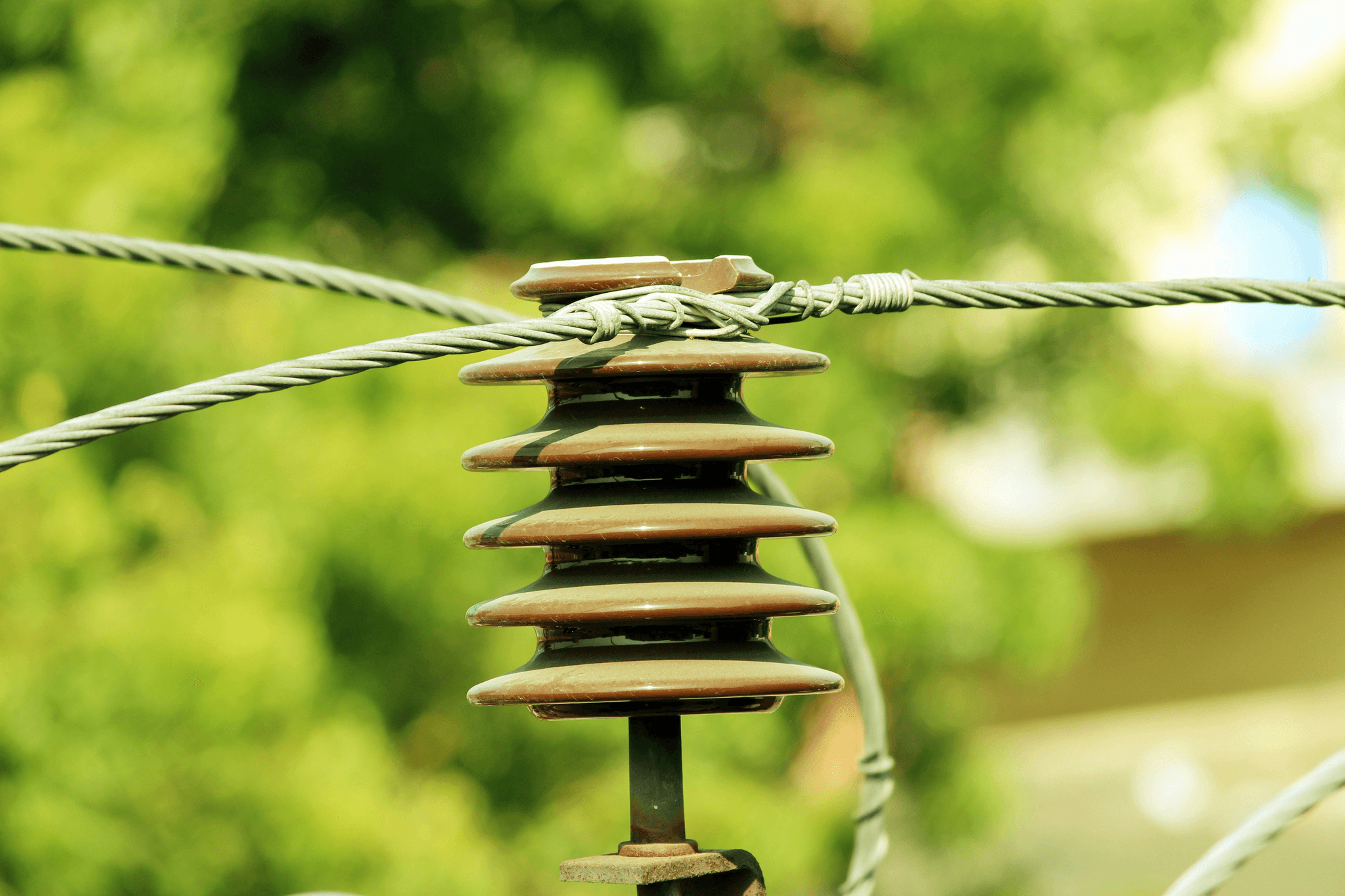

Insulators on the overhead transmission lines serve a critical role in preventing power outages and ensuring the safety of personnel. These insulators come in various forms, including porcelain, polymer, glass, and composite materials. Each type offers unique benefits and considerations based on their application in high voltage transmission lines.

Importance of Choosing the Right Insulator

The significance of selecting the right insulator cannot be overstated. The performance and longevity of overhead line insulation products depend on this decision. Whether it's for overhead power lines or electrified railways, utilizing appropriate insulators is crucial for maintaining reliable electrical distribution systems.

Key Factors in Insulator Selection

Factors such as pollution resistance, mechanical strength, and resistance to tracking and erosion play a vital role in determining which type of insulator is best suited for a particular application. Additionally, understanding why Are Overhead Power Lines Uninsulated can shed light on the importance of proper insulation selection.

Porcelain Insulators

Porcelain insulators are one of the most commonly used overhead line insulation products due to their excellent electrical and mechanical properties. Their high resistance to electrical tracking and erosion make them ideal for use in high voltage transmission lines, where they provide reliable insulation for the conductors. In addition, their robust construction allows them to withstand harsh environmental conditions, ensuring a long lifespan and minimal maintenance requirements.

Advantages of Porcelain Insulators

The advantages of porcelain insulators lie in their ability to maintain insulation integrity even in the presence of contaminants or pollutants, making them suitable for a wide range of applications. Their high mechanical strength and resistance to thermal shock also contribute to their durability, allowing them to withstand extreme temperature variations without compromising performance. Furthermore, porcelain insulators offer excellent resistance to surface damage and cracking, ensuring reliable long-term operation.

In addition, the design flexibility of porcelain insulators allows for customization to meet specific project requirements, making them a versatile choice for high voltage transmission lines. This adaptability enables engineers to optimize the performance and efficiency of the insulators, leading to improved overall system reliability. Moreover, the aesthetic appeal of porcelain insulators adds a visually pleasing element to transmission line infrastructure, enhancing the overall appearance of the landscape without compromising functionality.

Applications in High Voltage Transmission Lines

Porcelain insulators are commonly used in insulator strings transmission lines for high voltage power distribution and transmission systems. Their ability to provide effective electrical insulation at elevated voltages makes them well-suited for use in overhead line cover insulated tubing, where they help prevent current leakage and ensure safe and reliable power delivery. Additionally, their robust design allows them to support heavy conductor loads without compromising performance or safety.

Porcelain insulators also offer excellent resistance to environmental factors such as moisture, UV radiation, and pollution, which can degrade the performance of other materials. This makes them particularly well-suited for use in outdoor transmission line applications where they are exposed to harsh weather conditions. Their ability to withstand these elements ensures a longer lifespan and reduces the frequency of maintenance and replacement, ultimately contributing to cost savings for power utilities.

Considerations for Maintenance and Lifespan

When considering porcelain insulators on the overhead transmission lines, it's important to factor in maintenance requirements and expected lifespan. Regular inspection and cleaning can help ensure optimal performance and longevity, while proactive measures such as applying protective coatings can further enhance their resistance to environmental factors. By addressing these considerations, operators can maximize the reliability of their overhead line insulation products while minimizing downtime and maintenance costs.

In addition to regular inspection and cleaning, operators should also consider the potential for mechanical damage to porcelain insulators. Factors such as vibration, wind, and ice can all contribute to wear and tear on the insulators, potentially leading to cracks or other forms of damage. By implementing measures such as vibration dampers or protective shields, operators can mitigate the risk of mechanical damage and prolong the lifespan of the insulators. This proactive approach can help minimize the need for unscheduled maintenance and reduce the likelihood of unexpected downtime.

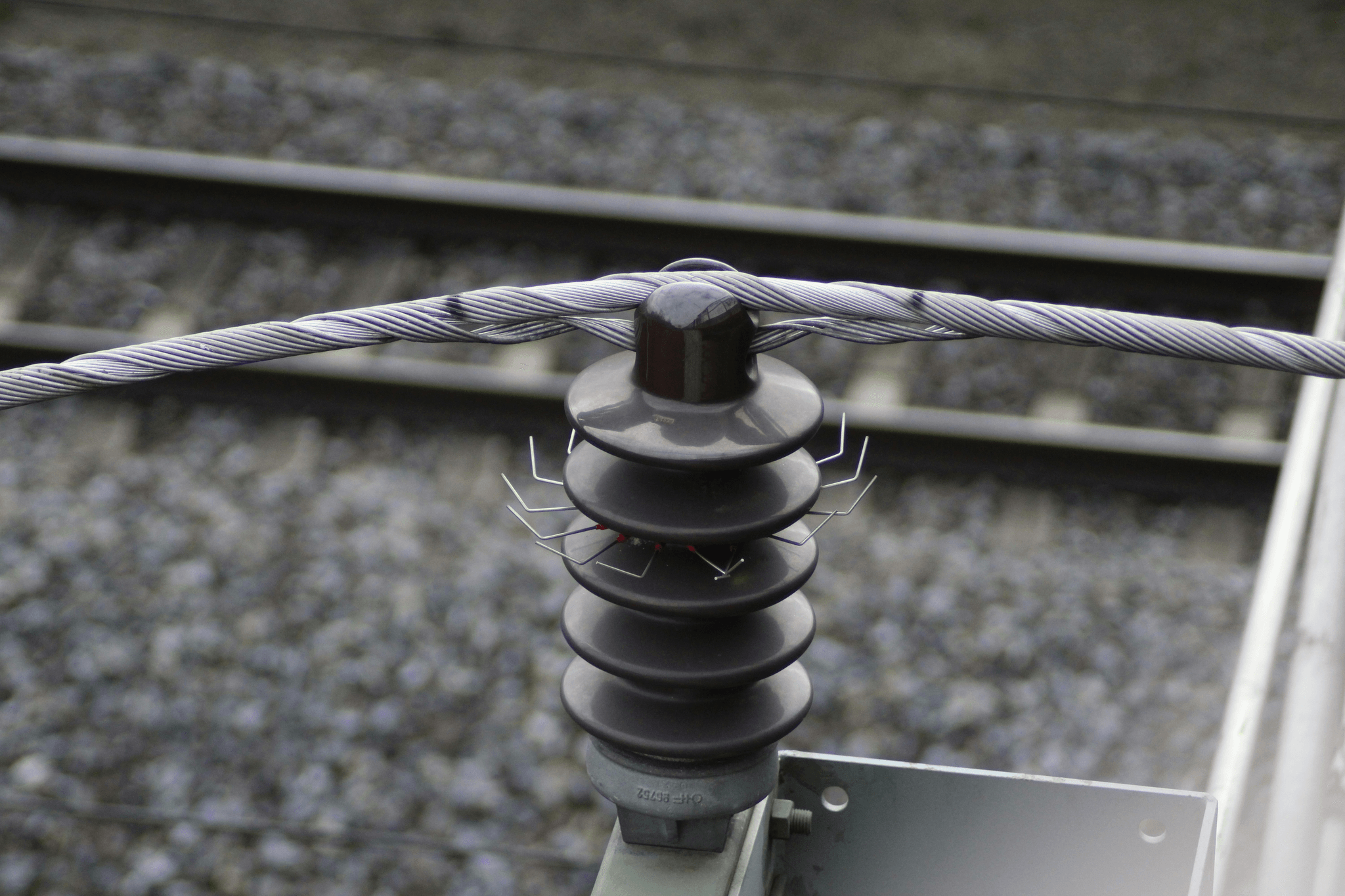

Polymer Insulators

Benefits of Polymer Insulators

Polymer insulators offer numerous advantages as overhead line insulation products. They are lightweight, reducing the strain on support structures and making installation easier. Their resistance to tracking and erosion also ensures long-term performance, while their flexibility allows for greater resistance to mechanical stress.

Utilization in Harsh Environmental Conditions

Polymer insulators are ideal for use in harsh environmental conditions, such as coastal areas or industrial zones. Their non-porous surface prevents moisture ingress, making them highly resistant to pollution and contamination. This makes them a reliable choice for overhead line cover insulated tubing in challenging settings.

Comparison with Porcelain Insulators

When comparing polymer insulators with porcelain insulators on the overhead transmission lines, polymer insulators stand out due to their superior performance in contaminated environments and their lighter weight. Additionally, they require less maintenance and have a longer lifespan compared to porcelain insulators, making them a cost-effective choice for various applications.

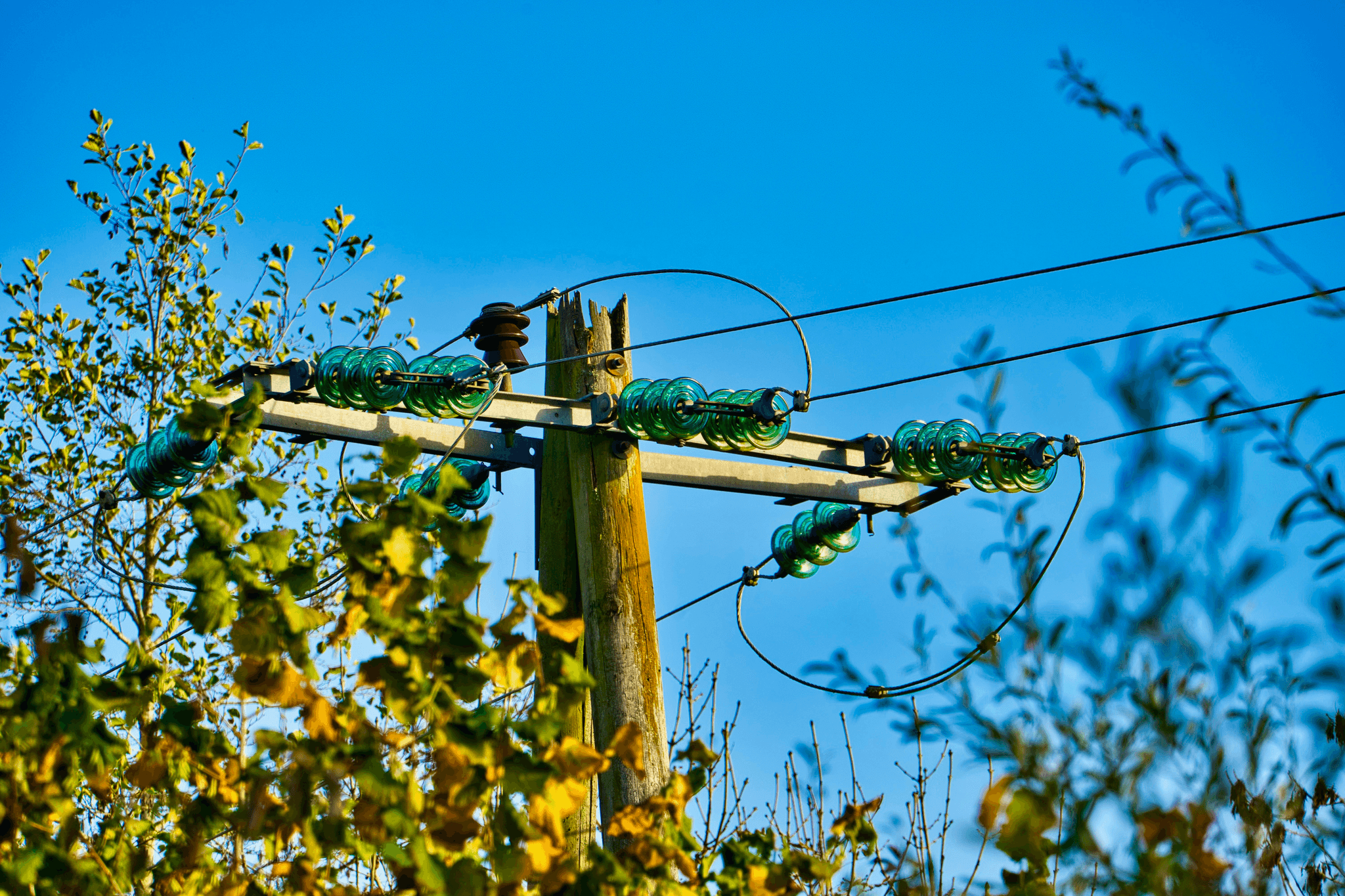

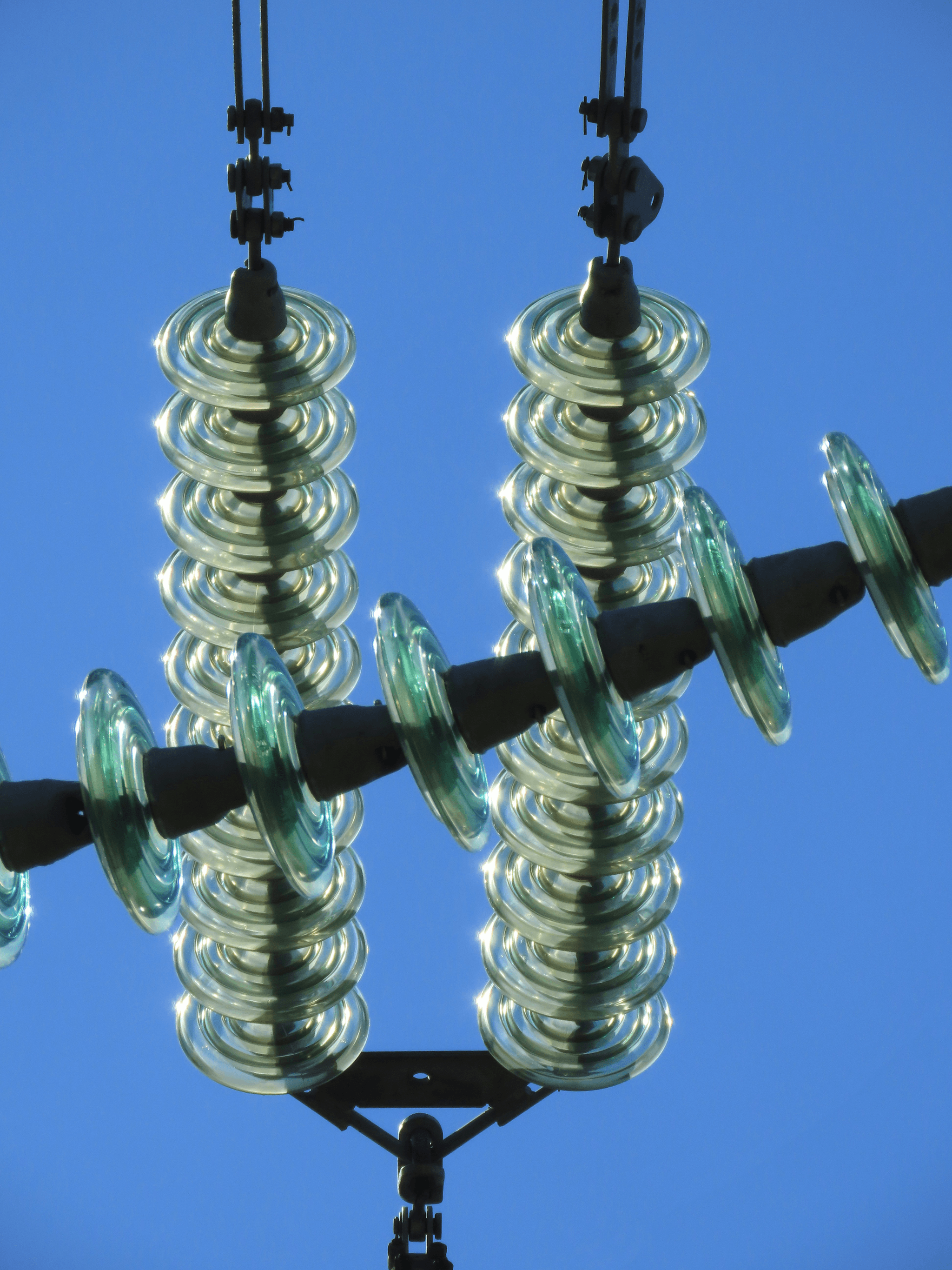

Glass Insulators

Glass insulators are a crucial component of overhead line insulation products, offering unique properties that make them ideal for high voltage transmission lines. These insulator strings transmission lines are designed to provide reliable insulation and support, ensuring the safe and efficient distribution of electricity. Glass insulators on the overhead transmission lines have been used for decades due to their exceptional durability and resistance to environmental factors.

Unique Properties of Glass Insulators

Glass insulators are known for their excellent electrical and mechanical properties, making them an ideal choice for overhead line cover insulated tubing. Their high resistance to electrical current and ability to withstand extreme weather conditions make them a reliable option for long-term use in transmission lines. Additionally, glass insulators offer superior resistance to pollution and contamination, ensuring consistent performance in various environments.

Glass insulators have a rich historical significance in power distribution, as they were widely used in early electrical systems to support and insulate overhead power lines. Their durable and long-lasting nature allowed for the efficient transmission of electricity over long distances, revolutionizing the way power was distributed. This historical legacy adds to the allure of glass insulators, making them a unique and nostalgic choice for modern-day applications.

Historical Significance in Power Distribution

The historical significance of glass insulators in power distribution dates back to the early days of electricity transmission. These durable and reliable insulators played a crucial role in establishing the infrastructure for electrification, enabling the widespread distribution of power across vast distances. Their proven track record in power distribution has solidified their reputation as a trusted solution for overhead line insulation products.

The design and production of glass insulators have evolved over time to meet the changing needs of power distribution. Innovations in materials and manufacturing processes have led to insulators that are lighter, stronger, and more resistant to environmental factors such as pollution and extreme weather conditions. These advancements have allowed for more efficient and reliable power transmission, contributing to the overall improvement of electricity infrastructure.

Modern Applications and Innovations

In modern times, glass insulators continue to be widely utilized in transmission lines due to their proven performance and longevity. With advancements in manufacturing processes and materials, modern glass insulators offer enhanced durability and reliability, meeting the evolving needs of power distribution systems. Additionally, innovative designs and configurations have expanded the applications of glass insulators, allowing for greater versatility in various installation scenarios.

When it comes to choosing the right overhead line insulation products for your application, it's essential to consider the unique properties and historical significance of glass insulators. By understanding their benefits and modern innovations, you can make an informed decision that ensures long-term performance and safety for your power distribution system.

Composite Insulators

Composite insulators have seen significant advancements in technology, providing improved performance and durability for overhead line insulation products. These insulators are designed to resist pollution and contamination, ensuring long-term reliability in harsh environmental conditions. Additionally, composite insulators are being integrated into smart grid systems, offering enhanced functionality and efficiency for modern power transmission networks.

Advancements in Composite Insulator Technology

In recent years, composite insulator technology has made great strides in improving the overall performance of overhead line insulation products. These advancements have resulted in insulators that offer superior strength, flexibility, and resistance to environmental factors. As a result, composite insulators are becoming increasingly popular for use in high voltage transmission lines due to their ability to withstand extreme weather conditions and heavy loads.

In addition to their physical properties, composite insulators also offer superior resistance to pollution and contamination. This is a crucial advantage for overhead line insulation products, as they are constantly exposed to environmental factors such as dust, dirt, and chemical pollutants. The ability of composite insulators to repel these contaminants ensures that they maintain their performance and longevity over time, reducing maintenance costs and downtime for high voltage transmission lines.

Resistance to Pollution and Contamination

One of the key benefits of composite insulators is their inherent resistance to pollution and contamination. Unlike traditional porcelain or glass insulators, composite materials do not provide a surface for contaminants to adhere to, making them ideal for use in areas with high levels of air pollution or industrial emissions. This resistance ensures that the insulators maintain their electrical properties over time, reducing the need for frequent maintenance and cleaning.

In addition to their resistance to pollution and contamination, composite insulators also offer the advantage of being lightweight and easy to handle. This makes them more cost-effective to transport and install compared to traditional insulators, saving time and resources during the installation process. The lightweight nature of composite insulators also reduces the strain on support structures, contributing to overall system reliability and longevity.

Integration into Smart Grid Systems

As power transmission networks continue to evolve towards smart grid systems, the integration of composite insulators has become increasingly important. These modern insulators offer advanced features such as built-in sensors for monitoring temperature and vibration, as well as improved connectivity for data collection and analysis. This integration allows for more efficient management of power distribution networks while enhancing overall reliability and safety.

Furthermore, the integration of composite insulators into smart grid systems also enables more accurate fault detection and quicker response times. With the ability to monitor temperature and vibration in real-time, these insulators can identify potential issues before they escalate, allowing for proactive maintenance and minimizing downtime. This proactive approach ultimately leads to cost savings for power distribution companies and ensures a more reliable supply of electricity for consumers.

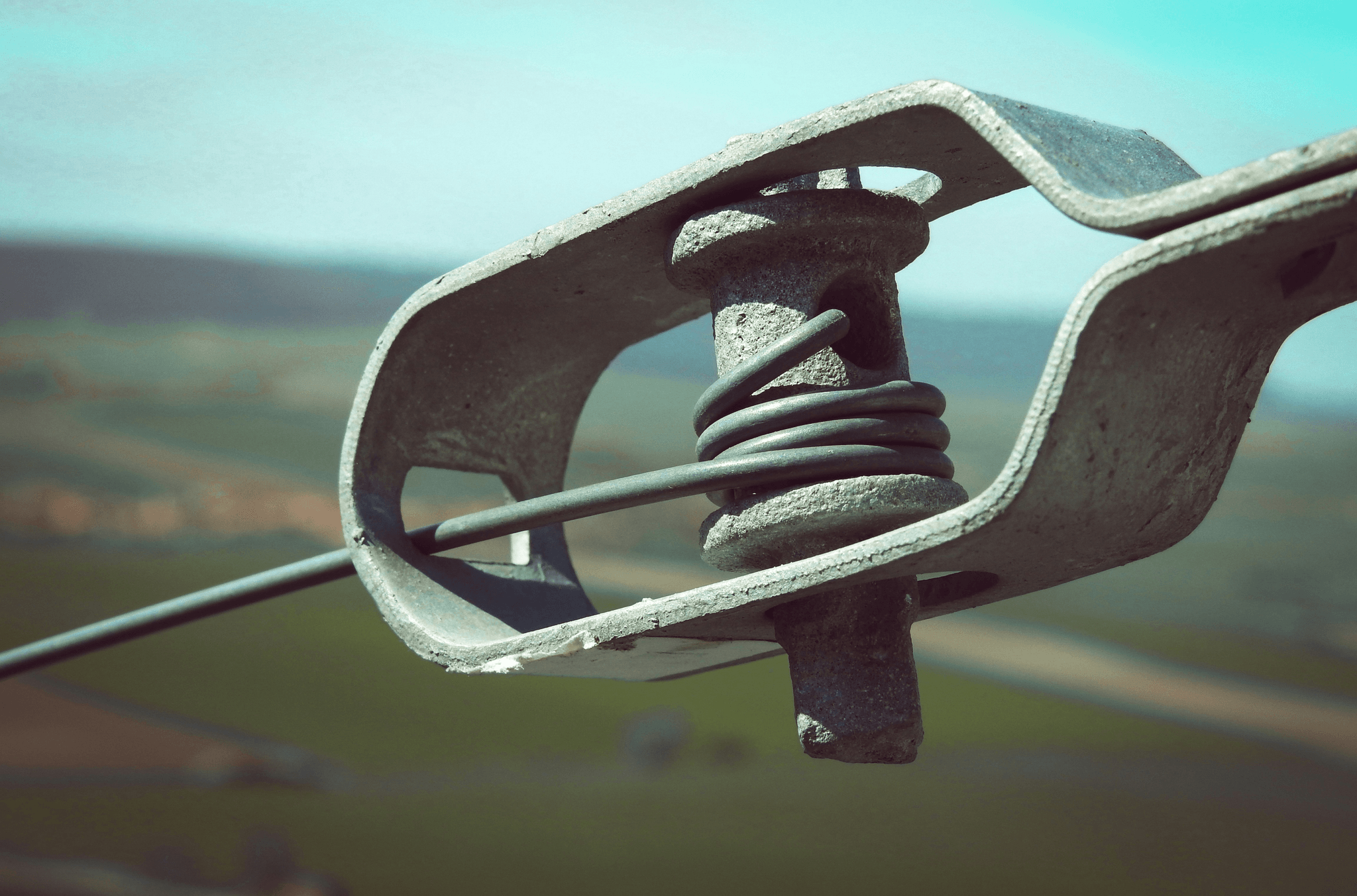

Insulator Fittings

When it comes to overhead line insulation products, the quality of fittings is crucial for optimal performance. Properly designed and manufactured fittings ensure that insulator strings on transmission lines are securely attached and can withstand harsh environmental conditions. Spark Fittings, a leading manufacturer in this field, plays a vital role in ensuring the reliability and safety of overhead line cover insulated tubing.

Importance of Quality Fittings for Insulator Performance

The effectiveness of insulators on the overhead transmission lines heavily relies on the quality of fittings used to secure them in place. High-quality fittings contribute to the overall durability and longevity of the insulation system, reducing the need for frequent maintenance and replacement. Choosing reliable fittings is essential for maintaining the integrity of the transmission lines.

Role of Spark Fittings in Ensuring Proper Installation

Spark Fittings specializes in manufacturing equipment that facilitates the proper installation of insulators on transmission lines. Their expertise in producing preformed armor rods and tension clamps ensures that insulator strings are securely fastened, minimizing the risk of damage or failure due to improper installation practices.

Impact on Overall Reliability and Safety

The use of high-quality fittings from companies like Spark Fittings has a direct impact on the overall reliability and safety of overhead power lines. By providing durable and dependable components for insulator installations, these companies contribute to maintaining uninterrupted power supply and reducing potential hazards associated with faulty insulation systems.

Conclusion

When it comes to choosing the right insulator for your application, it's crucial to consider the specific requirements of your overhead line insulation products. Whether you're looking at insulator strings for transmission lines or overhead line cover insulated tubing, understanding the types of insulators in transmission lines is key to ensuring long-term performance and safety.

Ensuring long-term performance and safety of your overhead line insulation products is a top priority. With the right maintenance and consideration of factors like environmental conditions, you can maximize the lifespan and reliability of your insulators on the overhead transmission lines.

Partnering with industry-leading manufacturers like Spark Fittings can make all the difference in the quality and performance of your insulators. Spark Fittings specializes in manufacturing equipment for preformed armor rods, tension clamps, and cable accessories for ADSS and OPGW, providing high-quality solutions for overhead line insulation products.