Introduction

In recent years, the landscape of industrial processes has been reshaped by the rise of sandblasting automation. This advancement not only streamlines operations but also enhances the overall efficiency of sandblasting techniques, making them more accessible and effective for various applications. As businesses look to maximize productivity and minimize costs, embracing technology in sandblasting is becoming a crucial strategy.

The Rise of Sandblasting Automation

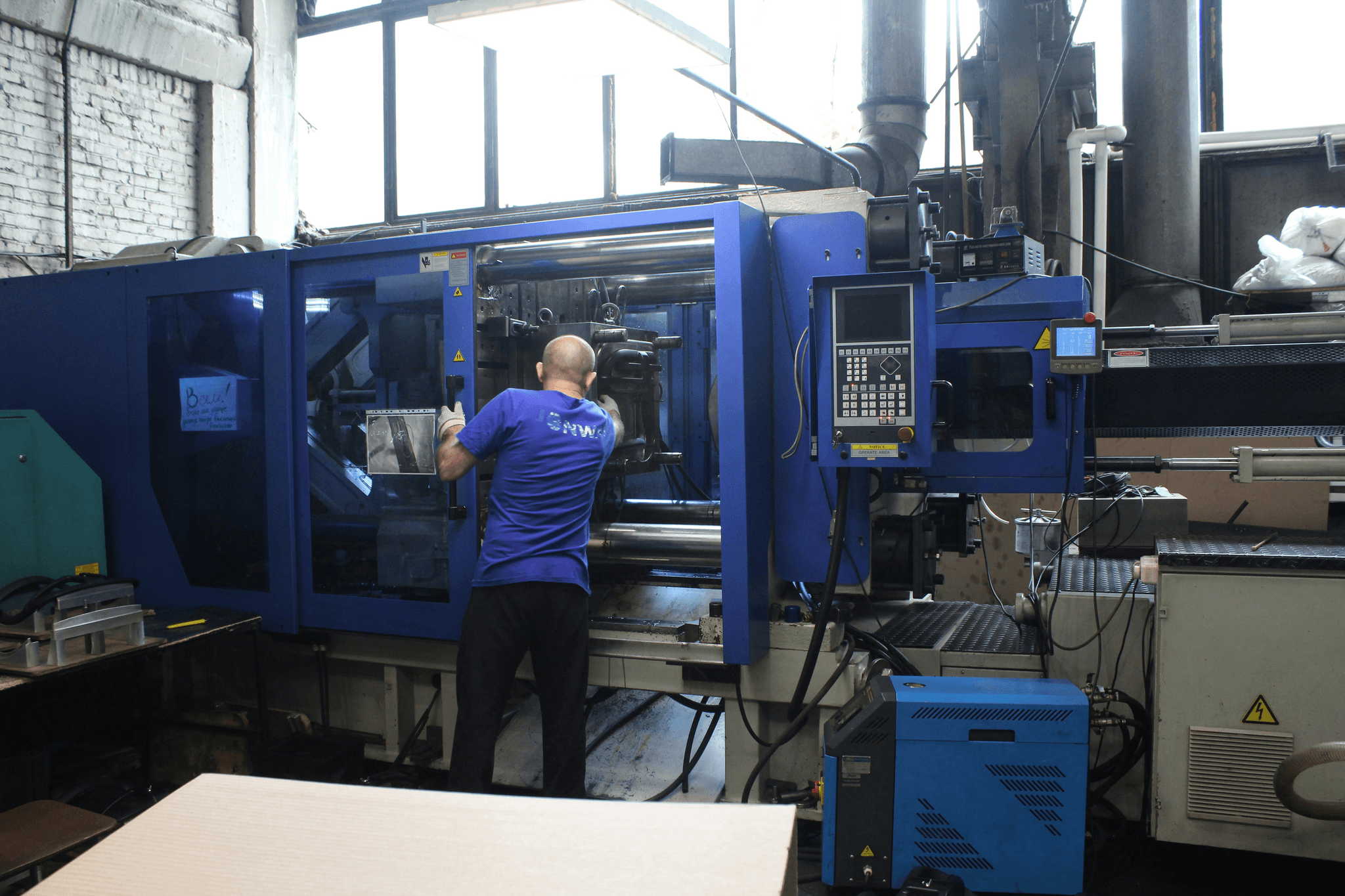

Sandblasting automation has transformed traditional methods into sophisticated systems that leverage cutting-edge technology. Automated blasting systems enable consistent results while reducing manual labor, which can lead to significant improvements in production speed and quality. The evolution from manual to automated processes raises questions like, What is automated blasting?—a method that utilizes machines for precision and efficiency in surface preparation.

Benefits of Embracing Technology

The benefits of embracing sandblasting automation extend beyond mere efficiency; they encompass cost savings, enhanced safety, and improved product quality. By integrating automatic sandblasting machines into their operations, companies can reduce labor costs while achieving higher output levels with less waste. Additionally, with increased focus on worker safety, these automated systems help mitigate risks associated with traditional sandblasting methods.

Key Players in the Industry

As the demand for industrial sandblasting continues to grow, several key players have emerged at the forefront of this technological revolution. Companies like Spark Electronic Technology Wuxi Co., Ltd., known for their automatic glue sand blasting machine among other innovative equipment, are leading the charge in providing tailored solutions for diverse industrial needs. With a commitment to quality and innovation, these players are essential in shaping the future landscape of sandblasting automation.

Understanding Sandblasting Automation

In the world of industrial processes, sandblasting automation has emerged as a game-changer, offering efficiency and precision that manual methods simply cannot match. This section will delve into what automated blasting entails, the key components that make up these systems, and the numerous advantages they bring to businesses in need of sandblasting services.

What is automated blasting?

Automated blasting refers to the use of machines and technology to perform sandblasting tasks without human intervention. This process utilizes programmed systems to control the blasting operation, ensuring consistent results while reducing labor costs and errors. As industries evolve and seek ways to optimize productivity, understanding what automated blasting means becomes essential for anyone considering entering or expanding in this field.

Key components of automated systems

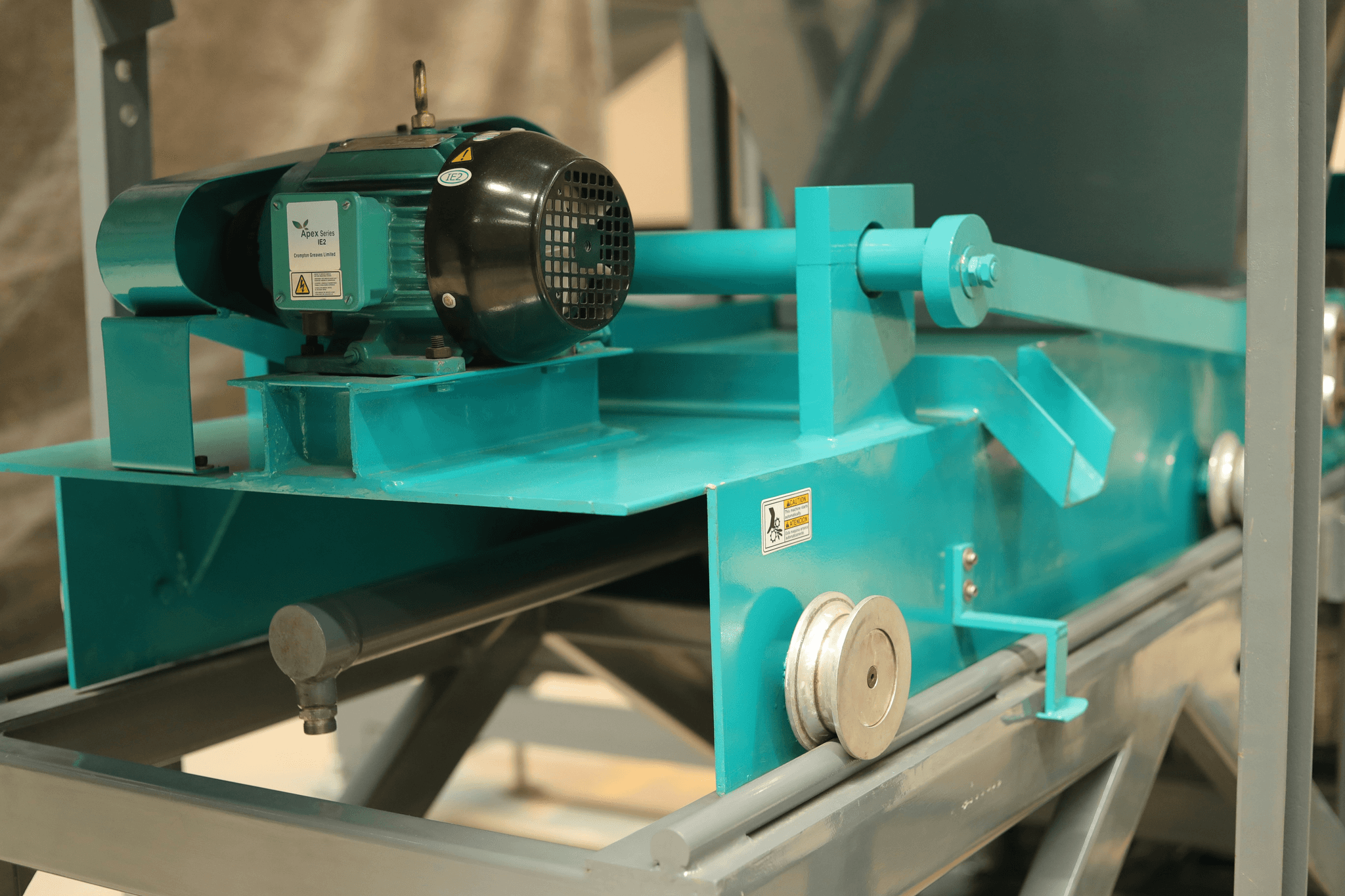

The backbone of any effective sandblasting automation system lies in its key components, which typically include a control panel, blast cabinet, abrasive delivery system, and dust collection unit. The control panel allows operators to program settings for pressure and duration while monitoring performance metrics in real-time. Meanwhile, an efficient abrasive delivery system ensures that materials are dispensed accurately for optimal results—crucial when considering whether sandblasting is a profitable business venture.

Advantages of automatic sandblasting machines

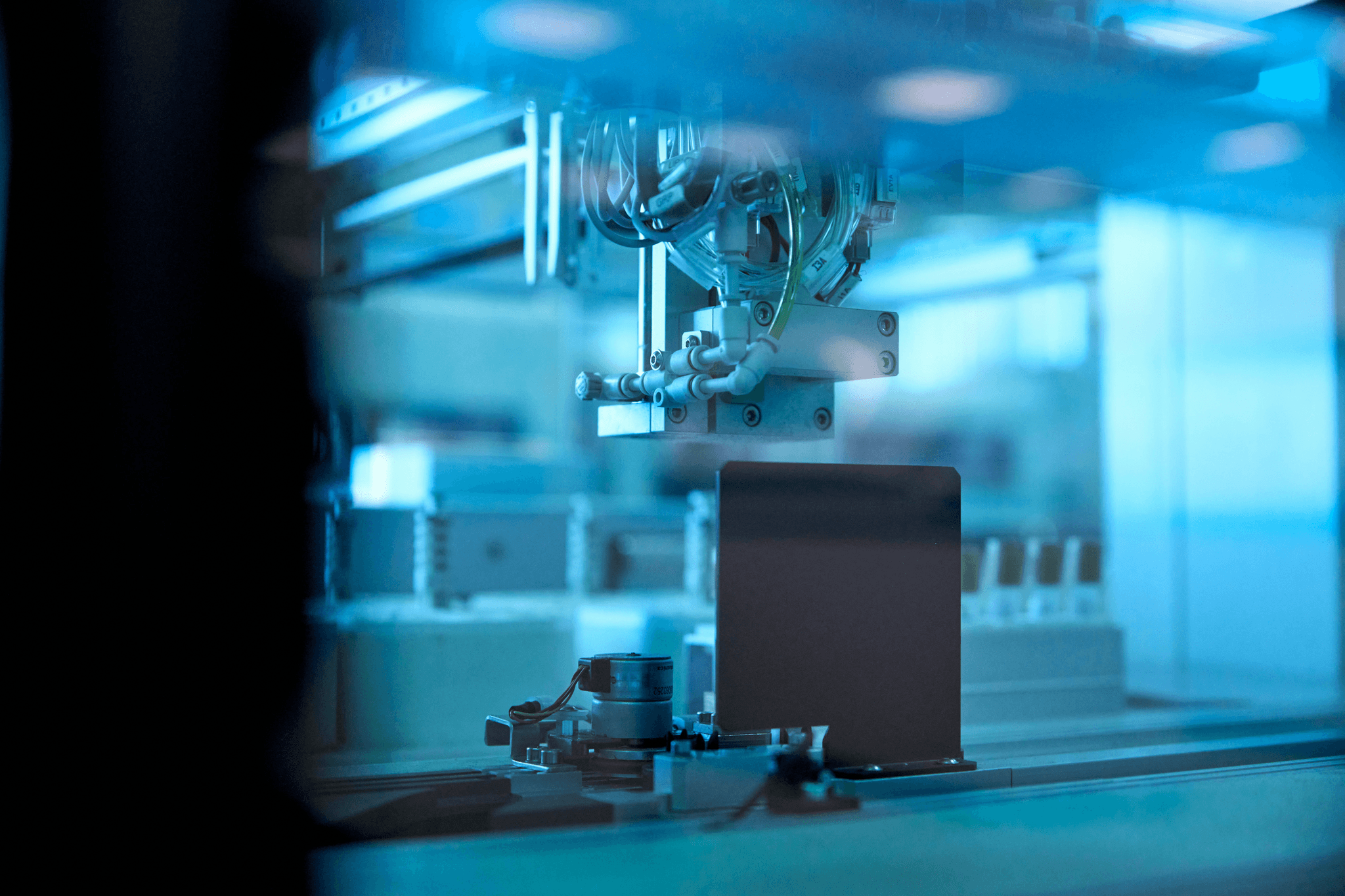

The advantages of automatic sandblasting machines are manifold; they not only enhance efficiency but also improve safety in industrial environments. By minimizing human involvement in potentially hazardous conditions—such as exposure to harmful dust—automated & robotic blast systems significantly reduce workplace accidents. Furthermore, these machines can operate continuously with minimal downtime, making them an attractive investment for businesses looking for an automatic sandblasting machine for sale.

Is Sandblasting a Profitable Business?

Sandblasting automation has revolutionized the industry, making it more efficient and cost-effective. Many businesses are now asking themselves, Is sandblasting a profitable business? The answer largely depends on several key factors that influence profitability, including operational costs, market demand, and the effectiveness of automated systems.

Factors Influencing Profitability

Several elements contribute to the profitability of sandblasting operations. First and foremost is the initial investment in automated & robotic blast systems, which can be substantial but pays off in efficiency gains over time. Additionally, labor costs play a critical role; with automation reducing manual labor needs, companies can allocate resources more effectively and boost their bottom line.

Market conditions also significantly impact profitability. If demand for industrial sandblasting services remains high and competition is manageable, profit margins can be quite favorable. Conversely, fluctuations in raw material prices or regulatory changes—such as when was sandblasting banned in certain contexts—can affect overall profits.

Cost Savings Through Automation

One of the most compelling reasons to embrace sandblasting automation is the potential for significant cost savings. Automated systems streamline processes that were once labor-intensive and time-consuming, leading to reduced operational costs over time. For instance, an automatic sandblasting machine for sale may seem like a hefty upfront investment but often leads to lower maintenance costs and increased throughput.

Moreover, these machines enhance precision and reduce waste by optimizing material usage during blasting operations. This efficiency not only saves money but also minimizes environmental impact—an increasingly important factor for many businesses today looking to improve their sustainability practices.

Industry Demand for Sandblasting Services

The demand for industrial sandblasting services remains robust across various sectors such as construction, automotive manufacturing, and metal fabrication. As industries continue to evolve with new technologies—including advancements in what is automated blasting?—the need for effective surface preparation methods has never been higher.

Furthermore, companies are increasingly recognizing that investing in an automatic glue sand blasting machine can set them apart from competitors by providing superior quality finishes at faster rates. This growing industry trend suggests that businesses willing to adapt through technology stand poised to benefit from increased demand while enjoying improved profitability.

The Evolution of Sandblasting Technology

The journey of sandblasting technology has been nothing short of revolutionary. From its inception as a manual task to the advanced systems we see today, the evolution reflects a broader trend towards efficiency and safety in industrial processes. This section explores the historical context, regulatory changes, and the rise of automation in sandblasting.

Historical overview of sandblasting

Sandblasting was first introduced in 1870 by Benjamin Tilghman, who patented the process as a means to clean surfaces and prepare them for painting or finishing. Initially, it involved manually directing a stream of abrasive material at high pressure onto surfaces, which required significant labor and time. Over decades, advancements in technology led to more efficient methods and machinery that enhanced productivity—setting the stage for what we now refer to as sandblasting automation.

When was sandblasting banned?

While sandblasting has been pivotal in various industries, its use has not been without controversy due to health concerns related to silica dust exposure. In many regions, regulations began tightening around the late 20th century, leading to bans on traditional dry sandblasting practices that utilized silica-based abrasives. These bans pushed manufacturers and service providers toward safer alternatives and ultimately paved the way for automated & robotic blast systems that minimize human exposure while maintaining effectiveness.

Transition to automated & robotic blast systems

The transition from manual sandblasting to automated & robotic blast systems marks a significant milestone in industrial practices. What is automated blasting? It involves using machines equipped with advanced controls that allow for precise application of abrasives without direct human involvement—a game changer for productivity and safety. With automatic sandblasting machines now available for sale from companies like Spark Electronic Technology Wuxi Co., Ltd., industries can enjoy enhanced efficiency while meeting stringent safety standards.

Exploring the Sandblasting Mechanism

The sandblasting mechanism is a fascinating process that combines pressure, abrasives, and technology to achieve optimal results in surface preparation. Essentially, it involves propelling abrasive materials at high speeds to clean or finish surfaces, making it an essential technique in industries ranging from automotive to construction. Understanding this mechanism is crucial for those considering investing in automated systems or exploring whether sandblasting is a profitable business.

What is sandblasting mechanism?

At its core, the sandblasting mechanism utilizes compressed air or water to propel abrasive materials against a surface. This process effectively removes contaminants like rust, paint, and dirt while also smoothing out rough surfaces. With the rise of sandblasting automation, machines are now able to perform these tasks more efficiently and consistently than ever before.

Automated blasting systems have revolutionized traditional methods by integrating advanced technologies that enhance precision and control during the blasting process. By utilizing computer-driven controls and sensors, these systems can adjust parameters in real-time for optimal performance. As a result, businesses can significantly reduce labor costs while improving output quality—key factors when assessing if sandblasting is a profitable business.

The role of pressure and abrasives

Pressure plays a pivotal role in the effectiveness of the sandblasting mechanism; it determines how fast and forcefully abrasives are projected onto surfaces. Typically measured in PSI (pounds per square inch), higher pressure levels lead to more aggressive cleaning actions but may also increase wear on equipment if not managed properly. Balancing pressure with appropriate abrasive materials ensures efficient operation without compromising safety or equipment longevity.

Abrasives come in various forms—from silica sand to glass beads—each offering unique benefits depending on the application at hand. Selecting the right abrasive material can enhance efficiency while minimizing potential damage to delicate surfaces during industrial sandblasting operations. As automated & robotic blast systems continue to evolve, they provide tailored solutions for varying pressures and abrasives that cater specifically to industry needs.

Innovations in efficiency and safety

Recent innovations have made significant strides toward enhancing both efficiency and safety within the realm of sandblasting automation. For instance, automatic sandblasting machines now incorporate features such as dust collection systems that capture harmful particles generated during blasting processes—protecting workers' health while maintaining compliance with environmental regulations like those related to when was sandblasting banned?

Moreover, advancements in smart technology allow for real-time monitoring of blasting conditions, enabling operators to make data-driven decisions that improve workflow efficiency dramatically. Companies like Spark Electronic Technology Wuxi Co., Ltd., known for their automatic glue sand blasting machine among other specialized equipment offerings, exemplify this trend by providing custom solutions designed specifically for industrial applications.

As we look ahead into the future of industrial practices involving automated & robotic blast systems, it's clear that ongoing innovations will continue shaping how we approach surface preparation tasks—making them safer and more efficient than ever before.

Spotlight on Spark Electronic Technology

In the realm of sandblasting automation, Spark Electronic Technology Wuxi Co., Ltd. stands out as a beacon of innovation and quality. Specializing in manufacturing equipment for preformed armor rods, tension clamps, and cable accessories, they have become a trusted partner for industries reliant on efficient sandblasting solutions. Their impressive lineup includes machines like the automatic glue sand blasting machine, which is designed to enhance productivity and precision in industrial applications.

Overview of Spark Electronic’s offerings

Spark Electronic offers an array of advanced machinery tailored to meet the demands of modern industrial sandblasting processes. Their products include not just the automatic glue sand blasting machine but also essential equipment like chamfering machines and hydraulic bending machines that cater to various aspects of production. This comprehensive approach ensures that businesses can find everything they need under one roof, making it easier to implement automated & robotic blast systems into their operations.

Benefits of their automatic glue sand blasting machine

The automatic glue sand blasting machine from Spark Electronic is a game-changer for those exploring whether sandblasting is a profitable business venture. With its ability to significantly reduce labor costs while increasing efficiency, this machine has become an essential tool for manufacturers aiming for high-quality finishes without sacrificing speed. Moreover, its user-friendly interface allows even novice operators to achieve professional results, further solidifying its place in the market for automatic sandblasting machines for sale.

Custom solutions for industrial sandblasting

Recognizing that every business has unique needs, Spark Electronic excels at providing custom solutions tailored specifically for industrial sandblasting applications. Whether it's modifying existing equipment or developing entirely new systems, their team works closely with clients to ensure that each solution meets precise specifications—making them a key player in the evolution of automated blasting technology. By focusing on customer satisfaction and innovation, they help companies navigate challenges such as when was sandblasting banned by adhering to safety regulations while maximizing output through effective use of what is the sandblasting mechanism.

Conclusion

In conclusion, sandblasting automation has revolutionized the industry, enhancing efficiency and precision in various applications. The shift towards automated blasting systems not only streamlines operations but also significantly reduces labor costs and human error. As businesses increasingly recognize the benefits of what is automated blasting?, investing in these advanced technologies has become a strategic move to stay competitive.

Enhancing Efficiency with Automation

The integration of sandblasting automation into industrial processes has led to remarkable improvements in efficiency. Automated & robotic blast systems allow for consistent results that manual methods simply cannot match, leading to higher quality finishes on products. Furthermore, these systems enable companies to maximize productivity by operating continuously without the fatigue associated with human workers.

Future Prospects in Sandblasting

Looking ahead, the future prospects in sandblasting are bright as technology continues to advance at a rapid pace. With ongoing innovations and research into more effective techniques, we can expect even greater improvements in safety and efficiency within the industry. Additionally, as environmental regulations tighten—especially considering when was sandblasting banned?—the demand for cleaner and more sustainable practices will likely drive further adoption of automated solutions.

Investing in Automatic Sandblasting Machines

For those pondering whether sandblasting is a profitable business?, investing in automatic sandblasting machines can be a game-changer. With options like an automatic sandblasting machine for sale from reputable manufacturers such as Spark Electronic Technology Wuxi Co., Ltd., businesses can enhance their operational capabilities while reaping significant cost savings over time. By focusing on industrial sandblasting automation now, companies position themselves well for future growth and success.