Introduction

Understanding Guy Wire Basics

At its core, guy wiring refers to the use of tensioned cables (guy wires) that provide lateral support to structures, preventing them from toppling over due to wind or other forces. This technique is not just limited to electrical applications; it's widely used in construction and telecommunications as well. So when you ask yourself, “Is it guy wire or guidewire?” remember that while they sound similar, their functions are quite different—guy wires stabilize structures while guidewires assist in navigation.

Importance of Proper Installation

Proper installation of guy wires is paramount for ensuring stability and safety. Incorrectly installed wires can lead to catastrophic failures that not only jeopardize the structure but also pose serious risks to people nearby. Understanding what is the best angle for guy wire placement can greatly enhance stability and performance; this knowledge can be the difference between a secure installation and a disaster waiting to happen.

Tools and Materials Needed

Before embarking on your journey into guy wire installation, it's essential to gather all necessary tools and materials. You will typically need high-quality cables made from durable materials like stainless steel or galvanized steel for longevity and strength. Additionally, having appropriate tensioning devices, anchors, and safety gear on hand will ensure that you are fully prepared for both the installation process and any unexpected challenges along the way.

What is Guy Wiring?

When we talk about guy wiring, we're diving into a world of support and stability. Essentially, guy wires are tensioned cables used to reinforce structures, ensuring they stand tall against the elements. But what does guying mean in electrical terms? It refers to the practice of using these wires to stabilize tall structures like antennas and towers, preventing them from swaying or collapsing.

Guying Defined

Guying is the process of securing a structure using guy wires that are anchored to the ground or another stable surface. This technique is crucial for maintaining the integrity of tall installations, particularly in windy environments or when supporting heavy loads. In essence, it’s all about leveraging physics to keep your structures upright and safe.

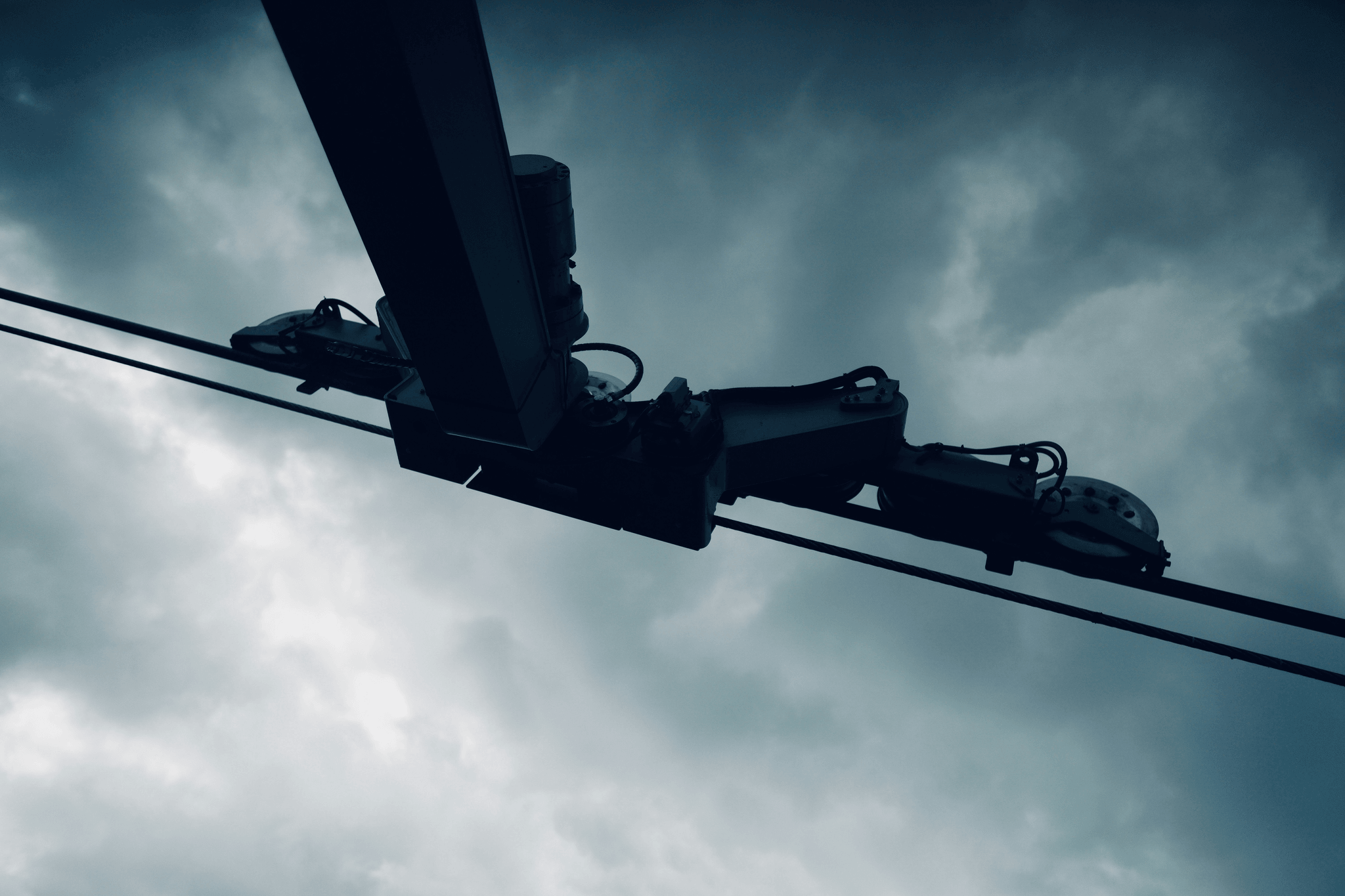

Applications of Guy Wires

Guy wires find their way into various applications—from telecommunications towers and radio antennas to utility poles and even large tents at events. Their versatility makes them an essential component for anyone involved in construction or installation projects that require additional support. Knowing how to use a guy wire effectively can make all the difference between a successful project and one that faces structural challenges.

Common Misconceptions

There are several misconceptions surrounding guy wiring that can lead to confusion during installation. One common myth is confusing guy wire with guidewire. While both serve important roles in their respective fields, they are distinctly different—guy wires stabilize structures while guidewires assist with navigation or control in medical settings. Understanding these differences can help you avoid pitfalls during your guy wire installation process.

How to Use a Guy Wire

Choosing the Right Wire

Choosing the right wire is essential for successful guy wire installation. The type of wire you select should be able to withstand environmental factors such as wind, tension, and corrosion. Typically, galvanized steel or high-tensile strength materials are preferred for durability; however, always consider specific requirements based on what does guying mean electrical in your context.

It's also important to consider the diameter of the wire; thicker wires can handle more load but may be harder to work with. Additionally, keep in mind that using high-quality materials can prevent frequent replacements and maintenance issues down the line. Ultimately, knowing how to use a guy wire starts with making informed choices about your materials.

Installation Techniques

Once you've chosen your wire, it's time to dive into effective installation techniques for your guy wires. Begin by assessing your site carefully—this includes identifying anchor points that can support tension without shifting over time. Properly marking these locations will ensure that you follow best practices when it comes to spacing and angles during installation.

When positioning your wires, remember that what is the best angle for guy wire typically ranges between 30° and 45° from horizontal for optimal stability without excessive strain on both anchor points and poles or towers themselves. Using tools such as levelers can help maintain this angle during installation; this precision is key in achieving a secure setup that meets manufacturer guidelines.

Don’t forget about tensioning! Ensuring each cable has appropriate tension is vital; too loose could lead to instability while too tight could cause damage or failure at connection points.

Safety Precautions

Safety should always be at the forefront when engaging in any form of construction or installation work—including guy wire installation! Make sure you're equipped with personal protective equipment (PPE) such as helmets, gloves, and eye protection before starting any tasks related to guy wiring.

Additionally, never underestimate environmental conditions like weather—windy days can turn an ordinary task into a hazardous endeavor if proper precautions aren’t taken! Always have a plan in place for securing loose wires during installations and avoid working near live electrical lines unless absolutely necessary.

Lastly, familiarize yourself with common mistakes people make when installing guys: overlooking measurements or ignoring manufacturer guidelines can lead not only to poor performance but also potential dangers down the road! By adhering strictly to safety protocols while understanding how to use a guy wire correctly, you'll minimize risks significantly.

The Best Angle for Guy Wire

Recommended Angles Explained

The general consensus in the world of guying is that a 30 to 45-degree angle is optimal for most installations. This range provides a balance between stability and tension, allowing the wire to effectively resist lateral forces without being overly taut or slack. Many professionals ask, Is it guy wire or guidewire? when discussing angles; however, it's crucial to remember that both terms refer to similar concepts in structural support.

Choosing an angle outside this recommended range can lead to complications. If you go too steep, you'll increase stress on both the anchor and the pole; too shallow an angle may not provide enough resistance against wind or other forces. Therefore, understanding what does guying mean in electrical contexts often ties back into these critical angles.

Impact on Stability

The impact of selecting the right angle cannot be overstated when discussing how to use a guy wire effectively. An improperly angled wire can lead not only to structural instability but also increased wear on equipment over time due to uneven tension distribution. This instability could result in catastrophic failures during storms or high winds if not properly addressed during installation.

Moreover, achieving optimal angles contributes significantly to overall safety during installations and maintenance work. When poles are well-guyed at appropriate angles, they are less likely to sway excessively or collapse under pressure—keeping workers safe while they perform tasks around them. Hence, understanding what is guy wiring goes beyond mere definitions; it directly affects performance and longevity.

Real-World Examples

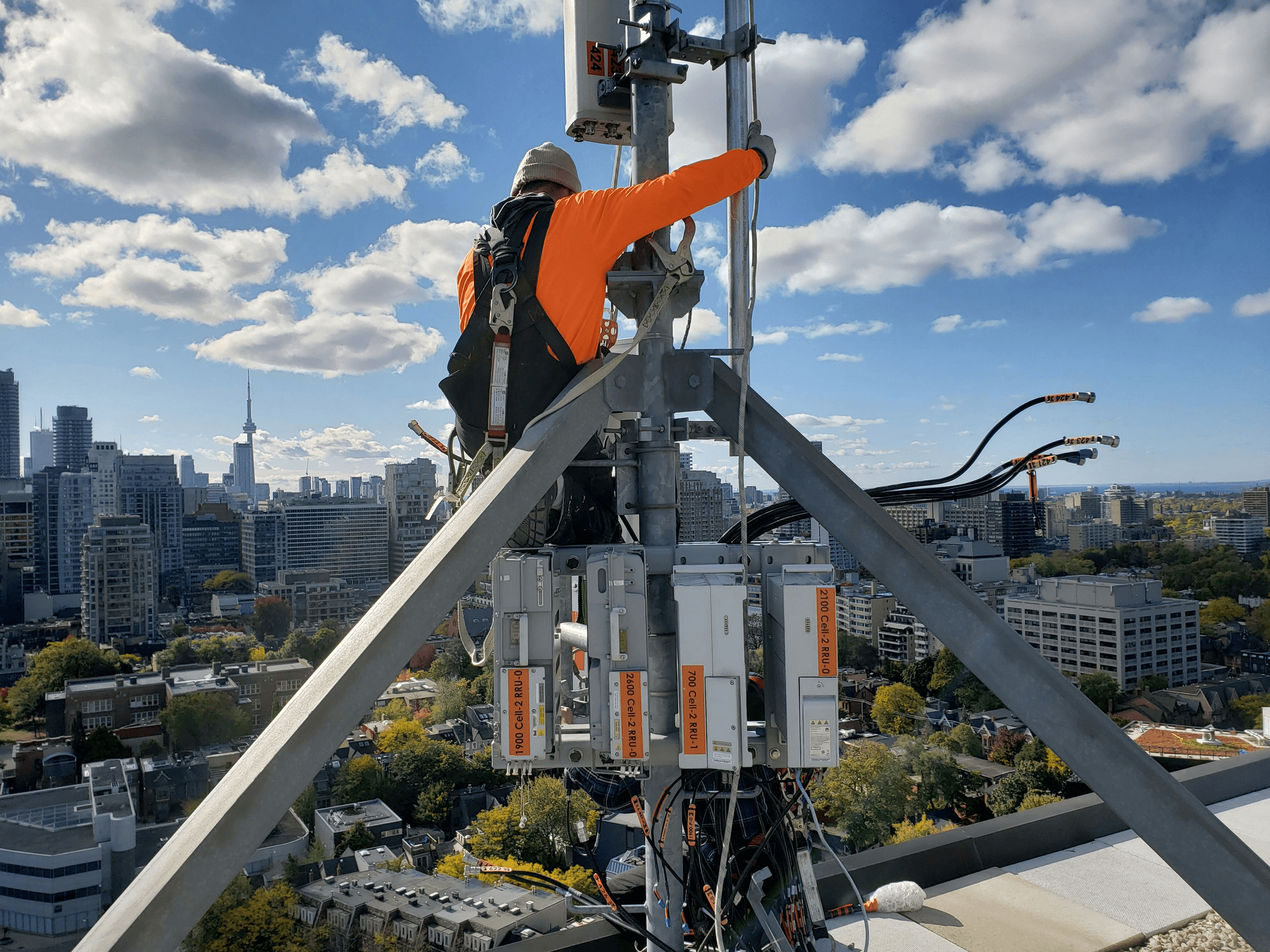

Let's consider some real-world applications where choosing the best angle for guy wire has made all the difference in stability and safety outcomes. For instance, telecommunications towers often employ precise angling techniques for their guy wires; engineers routinely adhere strictly to recommended angles of 30-45 degrees for maximum efficiency and support strength during adverse weather conditions.

Another example can be found in construction sites where temporary structures need robust support systems—here again, proper angling ensures that workers remain safe from unexpected collapses while maintaining equipment integrity throughout projects' durations. These scenarios illustrate why grasping how to use a guy wire correctly—including its optimal angles—is vital across various industries reliant on structural integrity.

Guy Wire Installation Step

Site Assessment

Before you even think about how to use a guy wire, a thorough site assessment is crucial. This involves evaluating the area where you plan to install your guy wires—look for potential obstructions, soil conditions, and the overall landscape. Understanding what does guying mean electrical-wise will help you determine if additional support structures are necessary for your installation.

During this phase, also consider environmental factors such as wind direction and potential hazards nearby. Proper site assessment not only ensures that your installation will be successful but also helps prevent common mistakes later on in the process. Remember, a solid foundation starts with knowing your surroundings!

Setting Up the Anchor

Once you've completed your site assessment, it's time to move on to setting up the anchor for your guy wire installation. The anchor is critical because it provides stability; without it, even the best angle for guy wire won't save you from disaster! Choose an appropriate anchoring method based on soil type—options include ground stakes or concrete blocks.

When installing anchors, make sure they are securely placed at a proper depth to withstand tension from the wires. It’s essential that both safety and performance are prioritized here; after all, nobody wants their structure swaying in the breeze like a flag! Remember that proper anchor placement can significantly affect how effective your guy wiring will be.

Tensioning the Wire

The final step in our guide on how to use a guy wire effectively is tensioning it properly after installation. This step is where many people overlook key measurements; getting this right ensures maximum stability for whatever structure you're supporting! Use a tension gauge or similar tool to achieve optimal tightness without over-stressing any components.

Achieving just the right amount of tension will not only enhance durability but also prolongs the life of both your wires and anchors—this means fewer headaches down the road! Make sure you're aware of what is considered best practice when it comes to maintaining this tension over time as environmental conditions may change its effectiveness.

In summary, successful guy wire installation hinges upon careful planning during each phase—from site assessment through anchor setup and finally finishing with precise tensioning of wires!

Common Guy Wire Installation Mistakes

Overlooking Measurements

One of the cardinal sins in guy wire installation is overlooking measurements. Accurate measurements are essential for determining the best angle for guy wire; a miscalculation can compromise stability and effectiveness. When you’re figuring out how to use a guy wire, always double-check your dimensions to ensure everything aligns perfectly

Forgetting Safety Gear

Safety gear is often an afterthought during any installation job, including guy wire installation, but it shouldn't be! Forgetting safety gear while working on structures can lead to serious injuries; don’t let your enthusiasm cloud your judgment. Equip yourself with helmets, gloves, and harnesses—these items are essential when you're navigating heights or handling heavy materials.

In addition to personal protection equipment (PPE), ensure that your workspace is free from hazards that could compromise safety while installing guy wires. After all, no one wants a mishap while trying to figure out what does guying mean in electrical contexts! Prioritizing safety will not only protect you but also enhance overall efficiency during the installation process.

Ignoring Manufacturer Guidelines

Ignoring manufacturer guidelines is like trying to bake a cake without following the recipe—likely messy and unappetizing! Each manufacturer provides specific instructions on how to use a guy wire effectively; neglecting these recommendations can result in subpar installations or even equipment failure down the line. Always consult these guidelines before diving into your project; they often contain valuable insights regarding tension settings and anchoring techniques.

Additionally, many people mistakenly assume that all types of wires are interchangeable without realizing that different materials require different handling approaches. For instance, is it guy wire or guidewire? Understanding these distinctions ensures you choose the right products for your specific needs and applications while adhering closely to what works best for stability and support structures. By respecting manufacturer guidelines, you'll set yourself up for success with each project!

Conclusion

In wrapping up our exploration of guy wire installation, it’s clear that understanding the fundamentals is crucial for ensuring stability and safety. Whether you're a seasoned pro or just starting out, knowing how to use a guy wire effectively can make all the difference in your projects. Remember, proper installation not only enhances performance but also mitigates risks associated with improper setups.

Key Takeaways on Guy Wire Installation

First and foremost, what does guying mean in electrical terms? It refers to the method of using guy wires to provide support and stability to structures like towers or poles. The best angle for guy wire installation typically falls between 30 and 45 degrees; this balance maximizes tension while minimizing stress on both the anchor points and the structure itself.

Additionally, common mistakes during guy wire installation often stem from overlooking measurements or neglecting safety gear. Always double-check your angles and ensure you have quality materials on hand—this can save you from costly errors down the line. Lastly, remember that following manufacturer guidelines is vital; they are there for a reason!

Benefit of Using Quality Gear like Spark Fittings

When it comes to guy wire installation, investing in quality gear pays off immensely. Products like Spark fittings are designed for durability and reliability, ensuring that your wires remain securely fastened under various conditions. This not only enhances safety but also prolongs the life of your installations.

Moreover, using high-quality components reduces maintenance needs over time—who doesn’t love less hassle? If you've ever experienced issues due to subpar materials, you know how frustrating it can be; avoid that headache by choosing trusted brands right from the start. Ultimately, quality gear contributes significantly to effective guy wiring practices.

Final Thoughts and Best Practices

As we conclude our discussion on what is guy wiring and its applications, it's essential to prioritize safety alongside functionality in every project you undertake. Always adhere to best practices: conduct thorough site assessments before starting any work and ensure you're equipped with all necessary tools and materials before diving into installation tasks.

Remember that learning how to use a guy wire is an ongoing journey—stay curious! Keep refining your techniques based on real-world experiences while sharing insights with fellow enthusiasts or professionals in your field. With these takeaways in mind, you'll be well-equipped for successful installations moving forward.