Introduction

In the world of construction and infrastructure, understanding steel galvanized guy wire is crucial for ensuring stability and reliability in various projects. This robust material, often used in tensioning applications, serves as an essential component in many industries. When you delve into the realm of galvanized wire fence systems, it becomes clear that quality manufacturing is paramount to achieving optimal performance and longevity.

Understanding Steel Galvanized Guy Wire

Steel galvanized guy wire is a high-strength cable coated with a layer of zinc to prevent corrosion and enhance durability. This protective coating makes it ideal for outdoor applications, where exposure to the elements can lead to rapid degradation of unprotected metal. In addition to its resilience, multi-purpose galvanized steel wire offers versatility across numerous applications, from telecommunications to agriculture.

Importance of Quality Manufacturing

When it comes to steel guy wire manufacturer & supplier options, quality manufacturing cannot be overstated. The strength and reliability of these products directly impact their performance in critical applications such as utility poles and communication towers. Utilizing high-grade materials like 10 gauge galvanized wire or 12 gauge galvanized wire diameter ensures that the final product meets industry standards while providing peace of mind for end-users.

Exploring Spark Fittings Role

Spark Fittings plays a pivotal role in the landscape of guy wire production by offering innovative solutions tailored to specific needs. Their expertise includes manufacturing custom armor rods made from aluminum or galvanized steel wire, which are designed to fit various conductor materials seamlessly. By focusing on corrosion resistance and utilizing color-coded identification systems during installation, Spark Fittings stands out as a reliable partner in the industry.

Overview of Steel Galvanized Wire

Steel galvanized wire is a vital component in various applications, known for its durability and resistance to corrosion. This type of wire undergoes a galvanization process, where it is coated with zinc to enhance its protective qualities. The result is a robust material that can withstand harsh environmental conditions, making it ideal for long-term use.

What is Steel Galvanized Wire

Steel galvanized wire refers to steel wire that has been treated with zinc to prevent rust and corrosion. This process involves dipping the steel into molten zinc, creating a protective layer that shields the metal from moisture and other corrosive elements. Available in various gauges, including 10 gauge galvanized wire and 12 gauge galvanized wire diameter, this versatile product caters to different industrial needs.

Benefits of Using Steel Galvanized Wire

One of the primary benefits of using steel galvanized wire is its exceptional durability. The galvanization process significantly extends the lifespan of the wire compared to non-galvanized alternatives, making it an economical choice over time. Additionally, steel galvanized wire offers excellent tensile strength and flexibility, which are crucial characteristics for applications such as guy wires or fencing systems.

Applications in Various Industries

Steel galvanized wire finds applications across multiple sectors due to its strength and resistance properties. In construction, it's commonly used in Guy Wire Fence Systems to provide stability and support structures like telecommunications towers or utility poles. Moreover, industries ranging from agriculture to manufacturing utilize multi-purpose galvanized steel wire for fencing solutions, reinforcement materials, and even crafting intricate designs.

Finding a Reliable Steel Guy Wire Manufacturer & Supplier

Key Qualities to Look For

First and foremost, transparency is essential; a trustworthy supplier should openly share information about their manufacturing processes, material sourcing, and quality control measures. Look for manufacturers that offer a diverse range of products, including Multi Purpose Galvanized Steel Wire and different gauges such as 10 Gauge Galvanized Wire and 12 gauge galvanized wire diameter options. Additionally, customer service matters—prompt responses to inquiries and willingness to collaborate on custom projects can set apart the best suppliers from the rest.

Another critical aspect is industry experience; companies with a long-standing presence often have proven track records in delivering high-quality products consistently. They should also be able to provide references or testimonials from previous clients who have successfully utilized their steel galvanized wire in various applications. Lastly, consider the flexibility of their offerings; whether you need standard sizes or custom solutions like armor rods or specialized fencing systems, adaptability speaks volumes about a manufacturer’s capabilities.

Top Manufacturers in the Market

Several manufacturers stand out in the crowded market of steel guy wire production. Companies like Spark Fittings have carved out a niche by specializing in innovative solutions tailored specifically for guy wire applications, including preformed armor rods made from aluminum or galvanized steel wire. Their commitment to quality ensures that customers receive products designed for durability while reducing corrosion risks between different materials.

Other notable names include established giants known for their extensive product lines that encompass everything from basic steel galvanized wire to advanced Galvanized Wire Fence Systems tailored for agricultural use or industrial settings. These companies often invest heavily in R&D to develop new technologies aimed at improving performance and longevity of their wires—keeping them ahead of competitors while meeting evolving industry needs.

Don’t overlook smaller manufacturers either; they often focus on niche markets with personalized service that larger companies may lack. These suppliers might offer customized options such as specific lengths or gauges like 12 gauge galvanized wire diameter based on unique project requirements—making them valuable partners for specialized tasks.

Industry Certifications and Standards

Certifications play an essential role when evaluating potential suppliers of steel galvanized wire; they indicate adherence to industry standards regarding safety, quality, and environmental practices. Look for certifications such as ISO 9001 which demonstrates commitment towards maintaining consistent quality management systems across all operations—from raw material procurement through manufacturing processes down to delivery logistics.

Additionally, compliance with ASTM (American Society for Testing Materials) standards ensures that your selected supplier’s products meet rigorous testing criteria related specifically to strength properties relevant within various applications involving Multi Purpose Galvanized Steel Wire or fencing systems alike. Suppliers should readily provide documentation verifying compliance with these standards upon request—if they hesitate, it may be time to reconsider your options!

Lastly, consider any environmental certifications such as LEED (Leadership in Energy and Environmental Design) which could further assure you that your chosen manufacturer takes sustainability seriously—a vital aspect given today’s growing emphasis on eco-friendly practices within construction industries worldwide.

Product Range: Galvanized Wire Fence Systems

Types and Features of Galvanized Wire Fences

There are several types of **Galvanized Wire Fence Systems**, each tailored for specific needs. For instance, barbed wire fences offer an extra layer of security, while chain-link fences provide visibility without compromising strength. Moreover, the use of different gauges like **10 Gauge Galvanized Wire** or **12 gauge galvanized steel wire** allows for customization based on the required tensile strength and application.

The features that set these fences apart include resistance to rust and corrosion due to their galvanized coating, making them ideal for outdoor use. Additionally, many systems come with easy installation options that cater to both DIY enthusiasts and professional installers alike. The right choice in fencing can significantly impact property security and aesthetics.

How to Choose the Right System

Choosing the right **Galvanized Wire Fence System** hinges on understanding your specific requirements. Start by assessing the purpose—are you looking for security, containment, or aesthetic appeal? Factors such as location, climate conditions, and intended use will dictate whether you should opt for a lighter gauge like **12 gauge galvanized wire diameter** or a heavier-duty option like **10 Gauge Galvanized Wire**.

It's also essential to consider local regulations regarding fencing materials and heights before making a decision. Consulting with a reliable **Steel Guy Wire Manufacturer & Supplier** can provide insights into which system best meets your needs while ensuring compliance with industry standards. Ultimately, investing time in selecting the appropriate fence will yield long-term benefits.

Real-World Applications

The applications of **Galvanized Wire Fence Systems** are practically limitless! In agriculture, these systems are commonly used to protect livestock from predators while keeping them contained within safe boundaries. In urban settings, they're employed in parks and playgrounds for safety without obstructing views.

Moreover, commercial properties often utilize these fences as part of their perimeter security measures due to their robust nature when constructed with high-quality materials such as **multi-purpose galvanized steel wire**. Whether it's protecting crops or securing industrial sites, choosing the right galvanized fencing system ensures reliability across various environments.

Spotlight on Spark Fittings

Innovative Solutions in Guy Wire Manufacturing

Spark Fittings has revolutionized the landscape of guy wire manufacturing with cutting-edge techniques and materials. Their focus on innovation means that they are constantly exploring new ways to enhance the durability and effectiveness of steel galvanized wire products. This approach not only benefits their customers but also elevates industry standards overall.

One notable innovation is their use of advanced machinery for producing Multi Purpose Galvanized Steel Wire, which allows for greater precision and consistency in every coil produced. By investing in state-of-the-art technology, Spark Fittings ensures that their offerings meet the rigorous demands of various industries while maintaining affordability. As a result, consumers can trust that they are receiving high-quality products designed to withstand even the toughest conditions.

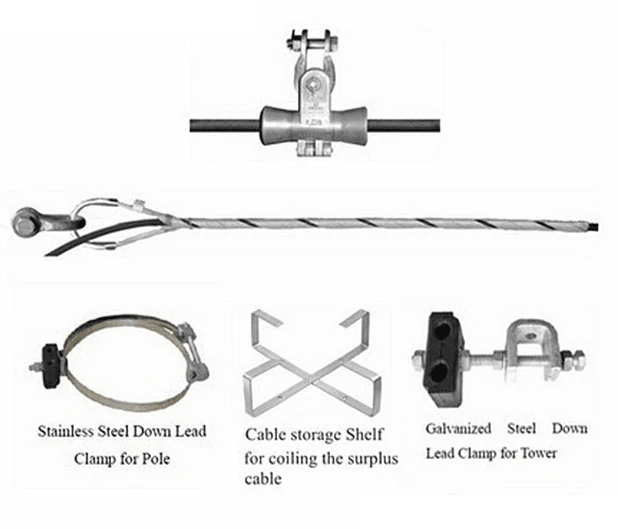

Custom Armor Rods for Specific Needs

In addition to standard offerings, Spark Fittings specializes in creating custom armor rods tailored to specific requirements. The raw materials used—aluminum wire, galvanized steel wire, and aluminum clad steel wire—are chosen based on the conductor’s material to minimize corrosion risks between different elements. This attention to detail ensures optimal performance while prolonging the lifespan of installations.

The importance of matching armor rod material with conductor surface material cannot be overstated; it significantly reduces wear and tear over time. Furthermore, each armor rod comes with a color code that simplifies identification during installation—a thoughtful touch appreciated by many contractors working with 10 Gauge Galvanized Wire or 12 gauge galvanized wire diameter specifications. With such customization options available, clients can confidently select solutions that align perfectly with their unique project needs.

The Importance of Corrosion Resistance

Corrosion resistance is paramount when discussing steel galvanized wire applications, especially in environments exposed to harsh weather conditions or corrosive elements. Spark Fittings understands this necessity and prioritizes corrosion-resistant materials in its product line-up. By utilizing high-quality coatings and alloys within their Multi Purpose Galvanized Steel Wire offerings, they ensure longevity without sacrificing performance.

The durability brought forth by these materials not only protects investments but also enhances safety across various applications—from telecommunications towers using 12 gauge galvanized steel wire to agricultural fences made from Galvanized Wire Fence Systems. Ultimately, choosing products from a reputable Steel Guy Wire Manufacturer & Supplier like Spark Fittings guarantees you’re getting top-notch solutions built to withstand time's test while keeping corrosion at bay.

Technical Specs: Understanding Wire Gauges

When it comes to steel galvanized wire, understanding wire gauges is crucial for ensuring the right application and performance. The gauge of the wire affects its strength, flexibility, and overall suitability for various projects, including Galvanized Wire Fence Systems. Choosing the correct gauge can make all the difference in achieving durability and efficiency in your construction or fencing needs.

Analyzing 10 Gauge Galvanized Wire

10 Gauge Galvanized Wire is a popular choice among builders and contractors due to its robust characteristics. This wire diameter provides excellent tensile strength, making it ideal for applications that require high levels of support, such as tensioning systems or security fences. Additionally, 10 gauge galvanized steel wire is resistant to corrosion thanks to its protective zinc coating, extending its lifespan in outdoor environments.

In practical terms, 10 gauge galvanized wire is often used in agricultural fencing and construction projects where heavy-duty performance is necessary. Its thickness allows it to withstand significant loads without bending or breaking under pressure. When selecting a steel guy wire manufacturer & supplier, ensure that they offer high-quality 10 gauge options that meet industry standards.

The Role of 12 Gauge Galvanized Wire Diameter

The 12 gauge galvanized wire diameter serves as a versatile alternative for various applications while still maintaining considerable strength. This size strikes a balance between flexibility and durability, making it suitable for lighter fencing needs or temporary structures where ease of installation is paramount. The use of 12 gauge galvanized steel wire in projects like garden fencing or trellises showcases its adaptability across different contexts.

Moreover, this gauge offers enough resistance against wear and tear while remaining manageable during installation processes. It's essential to understand how the properties of 12 gauge galvanized wire can impact your specific project requirements; thus consulting with trusted suppliers can provide valuable insights into which option best suits your needs.

Choosing the Right Gauge for Your Project

Selecting the appropriate gauge for your project hinges on several factors including load requirements, environmental conditions, and intended use of the steel galvanized wire. For instance, if you're constructing a robust fence designed to withstand harsh weather conditions or animal pressure, opting for thicker wires like 10 Gauge Galvanized Wire may be more beneficial. Conversely, if you're working on lighter applications such as decorative fencing or garden supports, then utilizing 12 gauge galvanized wire may suffice.

It's also wise to consider future maintenance when choosing between gauges; heavier wires typically require less upkeep due to their enhanced durability over time. Ultimately, collaborating with reputable manufacturers who specialize in Multi Purpose Galvanized Steel Wire will help you navigate these choices effectively while ensuring you receive materials that align with your project goals.

Conclusion

In summary, steel galvanized wire is a versatile and essential material across various industries. Its durability, resistance to corrosion, and strength make it an ideal choice for applications ranging from construction to agriculture. Understanding the benefits of galvanized wire fence systems and the importance of selecting the right manufacturer can significantly impact project success.

Key Takeaways on Steel Galvanized Wire

Steel galvanized wire offers numerous advantages, including enhanced longevity and lower maintenance costs due to its protective zinc coating. The use of 10 gauge galvanized wire or 12 gauge galvanized steel wire can provide different levels of strength suited for specific applications. Moreover, multi-purpose galvanized steel wire serves as an adaptable solution that meets diverse needs in both residential and industrial settings.

The Role of Trustworthy Suppliers

Finding a reliable steel guy wire manufacturer & supplier is crucial for ensuring quality materials that meet industry standards. Trustworthy suppliers not only provide high-quality products but also offer guidance on selecting the appropriate gauge and type of steel galvanized wire for your projects. Their expertise can help you navigate through options like 12 gauge galvanized wire diameter or other specifications to ensure optimal performance.

Future of Steel Guy Wire Manufacturing

The future of steel guy wire manufacturing looks promising as innovations continue to emerge in material science and production techniques. Companies like Spark Fittings are leading the charge with customized solutions such as armor rods designed specifically for unique requirements, ensuring compatibility with various conductor materials while preventing corrosion issues between different elements. As industries evolve, the demand for high-quality products like galvanized wire fence systems will likely grow, emphasizing the importance of reliable manufacturers in this sector.