Introduction

In the world of overhead transmission systems, the need for reliable and effective vibration dampeners cannot be overstated. Spiral vibration dampers play a crucial role in ensuring the stability and longevity of ADSS cables, which are often subjected to harsh environmental conditions. By mitigating vibrations caused by wind and other external forces, these cable dampers protect vital infrastructure and enhance overall performance.

Understanding Spiral Vibration Dampers

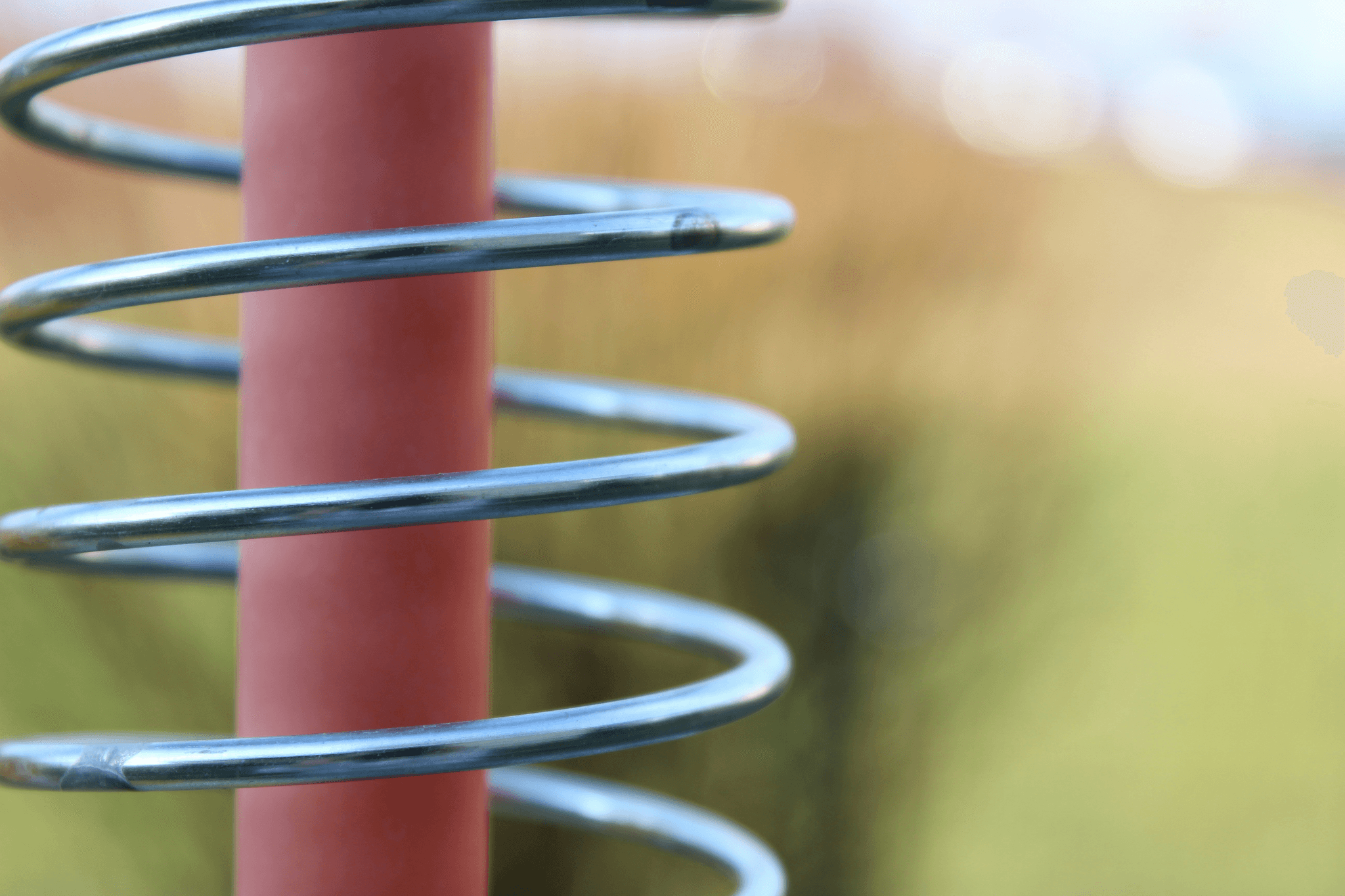

A spiral vibration damper is a specialized device designed to absorb and dissipate energy generated by vibrations in overhead cables. These innovative cable dampers work by utilizing a helical design that enhances their ability to counteract oscillations, thereby reducing stress on the cables themselves. Understanding how these dampers function is essential for anyone involved in maintaining or installing ADSS cables.

Importance of Vibration Dampeners for ADSS Cables

Vibration dampeners are particularly important for ADSS cables due to their unique positioning in transmission lines, which exposes them to various dynamic forces. Without proper cable dampers, these cables can experience excessive wear and tear, leading to potential failures that disrupt service. Investing in effective spiral vibration dampers not only extends the lifespan of ADSS cables but also ensures uninterrupted power delivery.

Overview of Spark Fittings Solutions

Spark Fittings offers a range of high-quality solutions tailored specifically for enhancing the performance of ADSS cables through advanced vibration damping technology. Their spiral vibration damper products are designed with innovation at their core, providing customizable options that cater to different cable specifications. With rigorous quality assurance processes in place, Spark Fittings stands out as a trusted provider committed to improving transmission line reliability.

What is a Spiral Vibration Damper?

In the world of overhead cable systems, especially when dealing with ADSS (All-Dielectric Self-Supporting) cables, understanding the role of a Spiral Vibration Damper is crucial. These innovative devices are specifically designed to mitigate vibrations that can adversely affect cable performance and longevity. By dampening these vibrations, they play a vital role in ensuring the reliability and safety of transmission lines.

Definition and Functionality

A Spiral Vibration Damper is essentially a specialized device attached to overhead cables to reduce oscillations caused by environmental factors such as wind and ice. Its unique spiral design allows it to effectively absorb and dissipate vibrational energy, preventing excessive movement that could lead to cable fatigue or failure. This functionality makes vibration dampeners indispensable in maintaining the integrity of ADSS cables over time.

How It Works in ADSS Applications

In ADSS applications, these cable dampers are strategically placed along the length of the cables where they are most susceptible to wind-induced vibrations. As wind flows over the cable, it can create oscillations; however, the Spiral Vibration Damper counteracts this motion by converting kinetic energy into thermal energy through its material properties and design structure. Thus, not only do these dampers protect against wear and tear, but they also enhance overall system performance by maintaining consistent tension in the cables.

Importance in Transmission Line Protection

Without these essential devices, cables may experience increased stress from vibrations leading to potential damage or even catastrophic failure during severe weather conditions. By incorporating vibration dampeners into transmission systems, utility providers can significantly improve reliability while reducing maintenance costs associated with repairs from vibration-related issues.

The Role of Vibration Dampeners

Vibration dampeners play a crucial role in maintaining the integrity and performance of ADSS cables, particularly in environments prone to wind-induced disturbances. By effectively mitigating vibrations, these cable dampers not only enhance the longevity of the cables but also ensure that they operate efficiently under various conditions. In this section, we’ll explore how these essential tools contribute to overall system reliability and safety.

Mitigating Wind-Induced Vibrations

Wind-induced vibrations can wreak havoc on overhead lines, leading to fatigue and potential failure over time. A well-designed vibration damper acts as a buffer, absorbing and dissipating energy caused by gusts or turbulent airflow around the cables. This is especially important for Spiral Vibration Dampers for ADSS Cable, as they are specifically engineered to reduce oscillations that could compromise the cable’s structural integrity.

By installing effective cable dampers along transmission lines, operators can significantly reduce the amplitude of vibrations caused by wind. This not only prolongs the lifespan of the cables but also minimizes maintenance interruptions due to adverse weather conditions. Ultimately, mitigating wind-induced vibrations ensures that energy transmission remains reliable even in challenging environments.

Enhancing Cable Longevity and Performance

The longevity of any cable system is directly linked to its ability to withstand environmental stresses without succumbing to wear or damage. Vibration dampeners serve as protective agents that enhance both performance and durability by reducing dynamic loads on ADSS cables during operation. With a properly installed cable damper, users can expect improved operational efficiency and reduced risk of failure.

Moreover, these dampers help maintain optimal tension within the cable structure, preventing sagging or excessive strain that could lead to premature degradation. As a result, utilizing Spiral Vibration Dampers for ADSS Cable translates into fewer service interruptions and lower lifetime costs associated with repairs or replacements. The added assurance provided by vibration dampeners allows operators to focus on delivering uninterrupted service rather than worrying about potential issues down the line.

Preventing Damage to Fiber Optic Cables

Fiber optic cables are particularly sensitive to mechanical stress; even minor vibrations can lead to significant performance degradation or complete failure of data transmission systems. By incorporating vibration dampeners into installation practices, operators can safeguard their fiber optic infrastructure against disruptive forces like wind or seismic activity. This proactive approach ensures that these delicate components remain intact and functional despite external pressures.

Cable dampers specifically designed for fiber optics help absorb shocks while maintaining proper alignment within their respective conduits or support structures. Utilizing a Spiral Vibration Damper for ADSS Cable not only protects against physical damage but also enhances signal quality by minimizing interference caused by unintended movement or oscillation patterns in nearby cables. In short, investing in high-quality vibration dampening solutions is essential for preserving both functionality and reliability in modern communication networks.

Benefits of Using a Spiral Vibration Damper for ADSS Cable

These innovative cable dampers play a pivotal role in enhancing the stability and efficiency of transmission systems. By mitigating vibrations caused by environmental factors, they contribute significantly to the overall reliability and longevity of cable installations.

Increased Reliability of Transmission Systems

One of the standout benefits of using a vibration dampener is the marked increase in reliability for transmission systems. By effectively reducing oscillations caused by wind or other external forces, these cable dampers maintain signal integrity and prevent disruptions. This enhanced stability translates into fewer outages and improved performance, making them essential for utilities aiming to deliver uninterrupted service.

Moreover, when ADSS cables are equipped with a Spiral Vibration Damper, they can better withstand extreme weather conditions that might otherwise compromise their functionality. The damper acts as a protective buffer, absorbing shocks and minimizing wear over time. As a result, operators can enjoy peace of mind knowing their transmission systems are fortified against unexpected challenges.

Reduced Maintenance Costs

Incorporating vibration dampeners into your infrastructure can lead to significant reductions in maintenance costs over time. With less wear and tear on cables due to vibrations being effectively managed, there’s less need for frequent repairs or replacements. This not only saves money but also reduces downtime associated with maintenance work—an added bonus for any utility company.

Additionally, when fiber optic cables remain intact thanks to effective cable dampers, there’s far less risk associated with costly outages or service interruptions. The durability provided by Spiral Vibration Dampers ensures that systems run smoothly without constant oversight or repairs needed due to environmental stressors. Consequently, companies can allocate resources more efficiently while enjoying long-term savings.

Improved Safety in Harsh Environments

Safety is paramount when dealing with high-voltage transmission lines and fiber optic cables; this is where spiral vibration dampers truly shine. By stabilizing cables against harsh wind conditions or seismic activity, these cable dampers enhance overall safety during operation and maintenance procedures alike. Workers on-site benefit from reduced risks associated with falling debris or sudden line failures.

Furthermore, in areas prone to extreme weather events—such as hurricanes or heavy storms—the presence of effective vibration dampeners can make all the difference in maintaining system integrity while keeping personnel safe from harm's way. The installation of these devices not only protects equipment but also prioritizes human safety during potentially hazardous situations involving electrical infrastructure.

In summary, utilizing a Spiral Vibration Damper for ADSS Cable offers numerous benefits ranging from increased reliability and reduced maintenance costs to improved safety standards in challenging environments—all vital components for successful operations within today’s demanding utility landscape.

Features of Spark Fittings' Vibration Dampers

Their Spiral Vibration Damper for ADSS Cable is designed not just for functionality but also for longevity, ensuring that your transmission systems remain reliable even in the harshest conditions. With a focus on both performance and user experience, these cable dampers are a game changer in the industry.

Innovative Design Elements

Spark Fittings’ vibration dampers boast cutting-edge design elements that set them apart from traditional options. Each cable damper is engineered using advanced materials that provide superior flexibility and strength, effectively absorbing vibrations caused by wind and other environmental factors. The unique spiral configuration enhances the damper's efficiency, allowing it to disperse energy more effectively than standard designs.

Moreover, these innovative features contribute to a lightweight yet robust structure that simplifies installation without compromising on performance. The careful engineering behind each Spiral Vibration Damper for ADSS Cable ensures optimal functionality while maintaining an aesthetically pleasing appearance. This blend of form and function is what makes Spark Fittings' products a top choice among professionals in the field.

Customization Options for Different Cables

Understanding that no two projects are alike, Spark Fittings offers extensive customization options for their cable dampers. Whether you need specific dimensions or unique material properties tailored to your project’s requirements, their team can create solutions that fit perfectly with various types of ADSS cables. This level of customization ensures that every vibration dampener performs optimally in its intended application.

Additionally, customers can choose from different colors and finishes to match their existing infrastructure or branding needs without sacrificing functionality. This attention to detail not only enhances the overall look but also reinforces the durability of the cable damper against environmental wear and tear. With Spark Fittings' customizable options, you can rest assured knowing your solution will meet both aesthetic and practical demands.

Quality Assurance and Testing Procedures

At Spark Fittings, quality assurance is paramount when it comes to manufacturing vibration dampeners. Each Spiral Vibration Damper undergoes rigorous testing procedures designed to evaluate performance under real-world conditions before it reaches customers’ hands. This thorough approach ensures reliability—important when considering how critical these cable dampers are in protecting sensitive fiber optic cables from damage.

The testing process includes simulations of wind-induced vibrations as well as assessments for material durability under extreme weather conditions—ensuring they stand up against Mother Nature's toughest challenges! By adhering to strict quality standards throughout production, Spark Fittings guarantees products that not only meet but exceed industry expectations for safety and reliability in transmission systems.

Installation and Maintenance Tips

When it comes to ensuring the longevity and effectiveness of your Spiral Vibration Damper for ADSS Cable, proper installation and maintenance are key. A well-installed cable damper can significantly reduce vibration-related issues, while regular upkeep keeps it functioning optimally. Here are some essential tips to guide you through the process.

Best Practices for Installing Cable Dampers

Installing cable dampers requires careful attention to detail to maximize their performance. First, ensure that the installation site is clean and free from debris; this will help avoid any interference with the vibration dampener's function. Next, follow manufacturer guidelines closely regarding placement and tension; improper installation can lead to inadequate vibration mitigation or even damage.

It's also crucial to use the right tools during installation. Using a torque wrench can help achieve the necessary tension without over-tightening, which could compromise the integrity of both the cable and the damper itself. Lastly, consider conducting a test run after installation to verify that everything is working as intended—this step can save you from future headaches.

Regular Monitoring for Optimal Performance

Once your Spiral Vibration Damper for ADSS Cable is installed, regular monitoring becomes essential in maintaining its effectiveness over time. Schedule periodic inspections to check for signs of wear or displacement; catching issues early can prevent costly repairs later on. Additionally, keep an eye on environmental factors such as wind speed and direction—these elements directly impact how well your cable dampers perform.

Another good practice is documenting inspection results in a maintenance log; this will help track performance trends over time and identify any recurring issues with specific installations. If you notice any unusual vibrations or movement in your cables during routine checks, don’t hesitate to investigate further; early intervention often leads to better outcomes.

Troubleshooting Common Issues

Even with diligent monitoring and proper installation, issues may occasionally arise with your vibration dampener system. One common problem is slippage; if you find that your cable damper has shifted from its original position, it may need re-tightening or repositioning according to manufacturer specifications.

Another issue could be visible wear or damage on either the damper or cable itself—if this occurs, it's best to replace affected components immediately rather than risk further complications down the line. Finally, if vibrations persist despite following all recommended practices, consider consulting with a professional who specializes in vibration mitigation solutions; they may offer insights that could resolve persistent problems effectively.

Conclusion

In summary, the importance of vibration dampeners, particularly the Spiral Vibration Damper for ADSS Cable, cannot be overstated. These innovative solutions not only enhance the performance of aerial cables but also contribute significantly to their longevity and reliability. As technology continues to evolve, the role of cable dampers will only become more critical in maintaining efficient transmission systems.

Enhancing ADSS Cable Performance

The application of a Spiral Vibration Damper for ADSS Cable plays a pivotal role in enhancing overall cable performance. By effectively mitigating wind-induced vibrations, these cable dampers ensure that transmission lines remain stable and operational even in harsh weather conditions. This stability translates into fewer disruptions and improved service reliability for end-users, making vibration dampeners an indispensable part of modern infrastructure.

The Future of Vibration Dampening Technology

Looking ahead, the future of vibration dampening technology is bright and full of potential innovations. Manufacturers are continuously exploring new materials and designs to create even more effective cable dampers that can withstand extreme environmental challenges while providing superior performance. As we embrace advancements in technology, we can expect smarter solutions that will further enhance the capabilities of vibration dampeners in various applications.

Choosing the Right Solutions from Spark Fittings

When it comes to selecting a reliable solution for your needs, Spark Fittings stands out as a leader in providing high-quality vibration dampeners tailored for specific applications. Their range includes customizable options designed to accommodate different types of cables while ensuring optimal performance under varied conditions. By choosing Spark Fittings' products, you’re not just investing in cable dampers; you’re ensuring peace of mind with proven reliability and safety.