Introduction

Rubber is a fascinating material with a wide range of properties that make it incredibly versatile. From its elasticity to its resistance to heat and chemicals, rubber has found its way into countless applications. However, one of the most intriguing aspects of rubber is its role in electrical conductivity. Despite being widely known as an insulator, there are misconceptions about whether electricity can run through rubber. In this article, we will explore the unique properties of rubber, understand its role in electrical conductivity, and debunk common misconceptions surrounding its use in electrical systems.

Exploring the properties of rubber

Rubber is known for its ability to stretch and return to its original shape, making it an ideal material for various applications such as tires, seals, and gaskets. Its insulating properties also make it valuable in electrical systems where preventing the flow of electricity is crucial for safety.

Understanding its role in electrical conductivity

The question Is rubber a conductor or insulator for electricity? often arises due to conflicting information about how it interacts with electric current. Understanding the science behind why rubber is a bad conductor of electricity will shed light on why it's used as an insulator in many electrical applications.

Debunking common misconceptions

One common misconception is whether an eraser can act as an insulator due to its rubber composition. We'll address this and other misconceptions surrounding the use of rubber as an insulating material in electrical systems.

What makes a material a conductor or insulator?

When it comes to understanding the conductivity of materials, it's essential to differentiate between conductors and insulators. Conductors allow electricity to flow through them easily, while insulators resist the flow of electrical current. This fundamental principle is crucial in determining the suitability of materials for various electrical applications.

Conductivity vs. insulation: the basic principles

Conductivity refers to a material's ability to conduct electricity, allowing electrons to move freely within its structure. On the other hand, insulation prevents the flow of electrical current by restricting the movement of electrons. Understanding this distinction is vital in selecting the right materials for specific electrical purposes.

Factors that determine a material's conductivity

Several factors influence a material's conductivity, including its atomic structure, temperature, and impurities present. Metals are generally good conductors due to their free-flowing electrons, while non-metals like rubber have tightly bound electrons that hinder electrical conduction.

The role of electrons in electrical conduction

Electrical conduction relies on the movement of electrons within a material. In conductors, such as metals, there are free electrons that can move easily under an electric field, facilitating the flow of electricity. In contrast, insulators like rubber have tightly bound electrons that do not permit easy electron movement.

Is rubber a conductor or an insulator?

Investigating the conductivity of rubber

Rubber is widely known as an insulator, meaning it does not conduct electricity. This is due to its molecular structure, which lacks free-flowing electrons necessary for electrical conduction. When tested, rubber consistently shows high resistance to electrical current, confirming its insulating properties.

Rubber's insulating properties make it a valuable material for a wide range of applications, from electrical insulation in wiring and cables to protective gear for electrical workers. Its ability to resist the flow of electricity helps prevent accidents and ensures the safety of both equipment and personnel. Despite its non-conductive nature, rubber can still be used in conjunction with conductive materials to create effective insulating layers, demonstrating its versatility in the realm of electrical conductivity.

The unique properties of rubber in relation to electricity

Rubber's insulating properties make it a valuable material for electrical applications. Its ability to resist the flow of electricity makes it ideal for use in insulation, protecting against electrical shocks and short circuits. Additionally, rubber's flexibility and durability make it suitable for various electrical components and wiring.

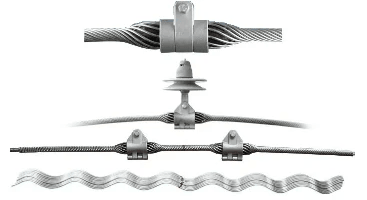

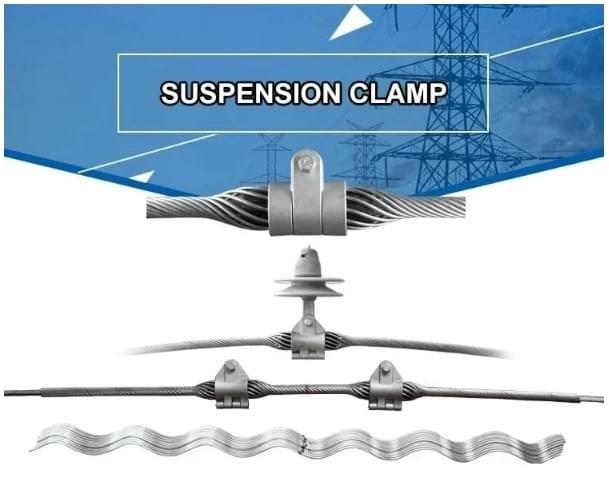

Real-life applications of rubber as an insulator

Rubber's role as an insulator is evident in everyday items such as power cords, electrical cables, and protective gloves used by electricians. It also plays a crucial role in the manufacturing of electrical equipment, providing insulation for wires and components to ensure safe and reliable operation. Additionally, rubber is used in the construction of insulation mats for electrical substations and switchyards, where it provides a protective barrier against electrical current. This helps prevent accidents and ensures the safety of workers who may come into contact with live electrical equipment.

Conductivity testing methods for rubber

Rubber's electrical conductivity is a topic of great interest, leading to the establishment of industry standards for testing rubber conductivity. These standards ensure that accurate and reliable measurements are obtained, allowing for a better understanding of rubber's behavior as a conductor or insulator. Spark Fittings is at the forefront of conducting these tests, utilizing state-of-the-art equipment to assess the electrical properties of rubber with precision.

Industry standards for testing rubber conductivity

Industry standards dictate specific procedures and parameters for testing rubber conductivity, ensuring consistency and comparability across different studies and applications. These standards cover aspects such as sample preparation, test conditions, and measurement techniques to guarantee reliable results. Adhering to these standards is crucial in determining whether rubber can effectively function as an insulator in electrical systems.

The importance of accurate conductivity measurements

Accurate conductivity measurements are essential in determining whether electricity can run through rubber or if it serves as an effective insulator. Precise data enables engineers and researchers to make informed decisions regarding the use of rubber in electrical applications, ultimately contributing to the safety and efficiency of various systems.

The role of Spark Fittings in conducting electrical tests

Spark Fittings plays a pivotal role in conducting electrical tests on rubber materials, leveraging their expertise in manufacturing equipment for the transmission and distribution of electricity. Their state-of-the-art machines facilitate precise measurements and analysis, supporting advancements in rubber technology for electrical use.

Safety considerations with rubber in electrical applications

When it comes to ensuring safety in electrical installations with rubber components, it's crucial to understand the properties of rubber as an insulator. Rubber's high resistance to electrical current makes it a reliable choice for preventing electric shocks and short circuits. By using rubber insulation, the risk of accidental contact with live wires is significantly reduced, providing a safer environment for both professionals and consumers.

Ensuring safety in electrical installations with rubber components

In electrical installations, using rubber components such as insulating gloves, mats, and sleeves is essential for protecting workers from electric shock. These rubber materials act as barriers that prevent the flow of electricity through the body, significantly reducing the risk of injury or fatality. By following industry standards and guidelines for using rubber insulation in electrical systems, companies can ensure the safety of their employees while working with live electricity.

Common safety hazards related to rubber insulation

Despite its effectiveness as an insulator, improper handling or damage to rubber insulation can lead to safety hazards. Over time, exposure to extreme temperatures, chemicals, or physical wear can degrade the insulating properties of rubber, increasing the risk of electrical accidents. It's important to regularly inspect and maintain rubber components in electrical systems to identify any signs of damage or deterioration that could compromise their insulating capabilities.

Best practices for using rubber in electrical systems

To maximize safety when using rubber in electrical systems, it's crucial to follow best practices for installation and maintenance. This includes proper storage and handling of insulated tools and equipment to prevent damage to the rubber insulation. Additionally, regular testing and certification of rubber components ensure that they meet industry standards for electrical insulation performance. By implementing these best practices, companies can minimize risks associated with using rubber in electrical applications.

By prioritizing safety considerations when utilizing rubber in electrical applications, businesses can create a secure working environment while minimizing the potential for accidents or injuries related to electric shock incidents.

Future developments in rubber technology for electrical use

Innovations in rubber materials for improved conductivity

The ongoing research and development in rubber technology are focused on enhancing the conductivity of rubber materials. By incorporating conductive fillers such as carbon black or graphene into rubber compounds, scientists aim to improve the electrical properties of rubber. These innovations will enable rubber to serve as a more effective conductor in various electrical applications.

The potential impact of advanced rubber technology in electrical engineering

The advancements in rubber technology have the potential to revolutionize electrical engineering by expanding the range of applications for rubber materials. With improved conductivity, rubber can be utilized in new ways within electrical systems, providing enhanced insulation and even serving as a viable conductor in specific scenarios. This could lead to more efficient and versatile electrical designs.

The role of Spark Fittings in developing cutting-edge rubber products

As a leading company specializing in manufacturing equipment for the transmission and distribution of electricity, Spark Fittings plays a crucial role in advancing the development of cutting-edge rubber products for electrical use. Their expertise and innovative solutions contribute to the creation of high-quality, reliable rubber components that meet the evolving needs of modern electrical engineering.

By leveraging these future developments in rubber technology, engineers and manufacturers can harness the unique properties of this versatile material to create more efficient and sustainable electrical systems. With ongoing innovation, the question Is Rubber a Conductor or Insulator for Electricity? may soon have an even more complex and intriguing answer.

Conclusion

Rubber plays a crucial role as an insulator in modern electrical systems, providing safety and reliability in various applications. Its unique properties make it a bad conductor of electricity, ensuring that electricity cannot run through rubber, thus preventing electrical hazards. As an expert in rubber technology for electrical use, Spark Fittings continues to leverage its expertise to develop innovative solutions for the future.

The role of rubber as an insulator in modern electrical systems

Rubber is widely used as an insulator in electrical systems due to its high resistance to the flow of electric current. This makes it a safe choice for applications where insulation is critical, such as wiring and cable jackets. The ability of rubber to resist the flow of electricity protects against shocks and short circuits, making it essential for ensuring safety in electrical installations.

Exploring the possibilities of rubber as a conductor in the future

While rubber is currently known for its insulating properties, there is ongoing research into developing advanced rubber materials with improved conductivity. This opens up exciting possibilities for using rubber as a conductor in the future, potentially revolutionizing electrical engineering with new applications and innovations.

Leveraging Spark Fittings' expertise in rubber technology for electrical applications

As a leading company specializing in manufacturing equipment for the transmission and distribution of electricity, Spark Fittings continues to play a vital role in advancing rubber technology for electrical use. With a focus on producing high-quality preformed products for various electrical applications, Spark Fittings is at the forefront of driving innovation and progress in the industry.