Introduction

When it comes to protecting your gear, rod armor is essential for ensuring longevity and durability. Choosing the right armor rod material is crucial in preventing corrosion and maintaining the integrity of your equipment. Spark Fittings plays a key role in providing high-quality armor rods that offer maximum protection for your gear.

The Importance of Rod Armor

Rod armor serves as a protective layer for your equipment, shielding it from external elements and potential damage. Whether it's for electrical conductors or other industrial applications, the use of armor rods is vital in maintaining the longevity of your gear.

Choosing the Right Armor Rod Material

Selecting the appropriate material for your armor rods is essential in ensuring compatibility with your equipment. The raw materials used, such as aluminum wire, galvanized steel wire, and aluminum clad steel wire, play a crucial role in preventing corrosion and maintaining the integrity of your gear.

The Role of Spark Fittings

Spark Fittings offers customized options for armor rods to meet specific requirements, ensuring a perfect fit for various types of equipment. Their expertise in manufacturing preformed armor rods and other cable accessories makes them a trusted source for high-quality protection solutions.

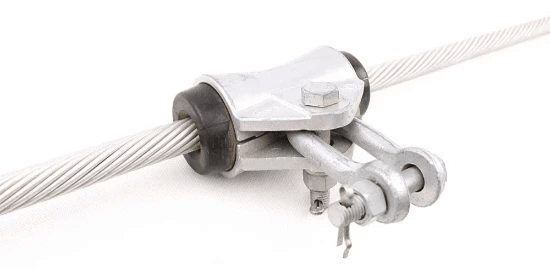

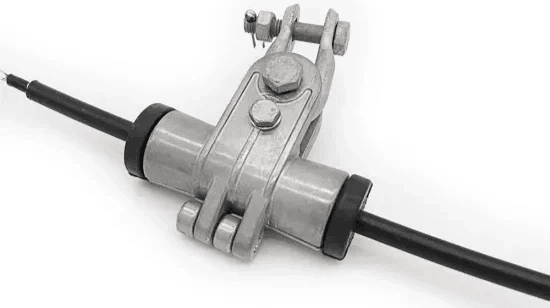

What is an Armor Rod?

An armor rod is a protective covering that is wrapped around the gear, such as a fishing rod, to prevent corrosion and increase durability. The armor rod material should be chosen carefully to match the conductor's surface material, ensuring longevity and preventing corrosion between different elements. Spark Fittings offers customized armor rods with color coding for easy identification during installation.

Protection for Your Gear

Armor rods provide essential protection for your gear, such as fishing rods, by preventing corrosion and increasing durability. By choosing the right armor rod material that matches the conductor's surface material, you can ensure long-term protection and avoid damage to your valuable equipment. Spark Fittings offers high-quality armor rods made from aluminum wire, galvanized steel wire, and aluminum clad steel wire to protect your gear effectively.

Preventing Corrosion

One of the key functions of an armor rod is to prevent corrosion on the gear it protects. By choosing the right material for your armor rod, you can ensure that it acts as a barrier against environmental factors that may cause corrosion over time. The color coding provided by Spark Fittings makes it easy to identify the size of the conductor during installation, ensuring proper protection against corrosion.

Choosing the Right Material

When selecting an armor rod material, it's crucial to consider the surface material of the conductor it will be protecting. Matching these materials will prevent corrosion between different elements and ensure effective long-term protection for your gear. Spark Fittings offers a range of high-quality materials for armor rods and provides customized options to meet specific requirements, ensuring that you choose the right material for your needs.

How to Install Armor Rods

Armor rods are essential for protecting your gear and preventing corrosion. Proper installation is crucial to ensure the longevity and durability of your equipment.

Step-by-Step Guide

To install armor rods, start by cleaning the conductor surface thoroughly to remove any dirt or grease. Next, wrap the armor rod around the conductor in a helical pattern, ensuring a snug fit. Finally, secure the ends of the armor rod with tape or clamps to prevent unraveling.

After securing the armor rod in place, double-check the tightness and alignment to ensure it is properly installed. It's important to inspect the entire length of the conductor to make sure there are no gaps or loose areas. Once you have confirmed that everything is secure, you can proceed with confidence knowing that your conductor is protected from damage and wear.

Color Coding for Easy Identification

All armor rods come with a color code that corresponds to different conductor sizes, making it easy to identify the right fit for your gear. This color coding system simplifies the installation process and ensures that you choose the correct armor rod for your specific needs. In addition to standard color-coding options, Spark Fittings also offers customized color-coding solutions to meet your unique requirements. Whether you need a specific color for easy identification in a particular environment or want to match your company's branding, we can create a tailored solution for you. Our customized options ensure that your armor rods not only provide protection but also seamlessly integrate into your overall setup.

Customized Options from Spark Fittings

Spark Fittings understands that every project has unique requirements, which is why they offer customized armor rod options. Whether you need a specific size for a particular application or a specific material to meet certain environmental conditions, Spark Fittings can tailor their armor rods to fit your exact specifications. This level of customization ensures that you get the perfect solution for your needs, without having to compromise on quality or performance.

Benefits of Using Armor Rods

Armor rods provide numerous benefits for your gear, ensuring longevity, increased durability, and a cost-effective solution for protection. When properly installed, armor rods can extend the lifespan of your equipment, saving you time and money in the long run.

Longevity of Your Gear

By providing a protective layer around your gear, armor rods shield it from environmental factors such as moisture and corrosion. This helps to prolong the life of your equipment, reducing the need for frequent replacements and maintenance.

Increased Durability

Armor rods add an extra layer of defense against wear and tear, preventing damage to your gear from external elements. This increased durability ensures that your equipment remains in optimal condition for longer periods of time.

Cost-Effective Solution

Investing in high-quality armor rods is a cost-effective way to protect your valuable gear. By minimizing the need for frequent repairs or replacements, armor rods help save on maintenance costs and reduce downtime.

Spark Fittings offers customizable options for armor rods made from aluminum wire, galvanized steel wire, or aluminum clad steel wire to suit different conductor materials. The color-coded design simplifies identification during installation and ensures compatibility with various conductor sizes.

Installation Instructions for Armor Rods are provided by Spark Fittings to ensure proper fitting and maximum protection for your equipment. These instructions include step-by-step guidance on how to wrap armor rods securely around the gear to prevent corrosion and extend its lifespan.

With Spark Fittings' expertise in manufacturing preformed accessories like armor rods, customers can trust in the quality and reliability of these essential components for their gear's protection.

Why Quality Matters

When it comes to rod armor, the importance of high-quality materials cannot be overstated. Using premium materials ensures that the armor rods provide effective protection for your gear, preventing corrosion and ensuring long-term durability. At Spark Fittings, we understand the significance of quality materials and offer a range of options to suit your specific needs.

Importance of High-Quality Materials

Choosing the right material for your armor rods is crucial in ensuring their effectiveness. At Spark Fittings, we offer armor rods made from aluminum wire, galvanized steel wire, and aluminum clad steel wire, allowing you to select the material that best matches your conductor's surface material. This helps avoid corrosion between different elements and ensures optimal performance. Additionally, high-quality materials also contribute to the durability and longevity of the armor rods, reducing the need for frequent replacements and maintenance. By investing in high-quality materials, you can save time and money in the long run while ensuring reliable protection for your conductors.

Avoiding Corrosion

Using high-quality materials for your armor rods is essential for avoiding corrosion and maintaining the integrity of your gear. By selecting the appropriate material that matches your conductor surface, you can effectively prevent corrosion and extend the lifespan of your equipment. Additionally, regular inspections and maintenance can help identify any signs of corrosion early on, allowing for prompt action to be taken to prevent further damage. Furthermore, investing in protective coatings or treatments for your armor rods can provide an extra layer of defense against corrosion, ensuring long-term protection for your equipment in even the harshest environments. With these proactive measures in place, you can have peace of mind knowing that your gear is well-equipped to withstand the test of time.

Ensuring Long-Term Protection

When it comes to rod armor, long-term protection is key. By choosing high-quality materials for your armor rods, you can ensure that they provide reliable protection for an extended period. At Spark Fittings, we prioritize quality in our manufacturing process to guarantee that our armor rods deliver long-term protection for your gear. Additionally, our rigorous testing procedures ensure that each rod meets the highest standards of durability and performance, giving you peace of mind knowing that your equipment is well-protected in the long run.

FAQs About Armor Rods

How to Twist Armor Rods

When it comes to twisting armor rods, it's important to follow the proper technique. Start by wrapping the armor rod tightly around the conductor, ensuring that it is securely in place. Use a twisting tool to achieve the desired level of tension, and make sure to evenly distribute the pressure along the length of the rod for optimal performance.

After achieving the desired level of tension, it's important to secure the armor rod in place with a locking clip or tape. This will ensure that the rod remains in position and provides long-lasting protection to the conductor. Additionally, be sure to inspect the twisted armor rods regularly to check for any signs of wear or damage. This proactive approach can help prevent potential issues and maintain the integrity of the installation.

Proper Installation Techniques

Proper installation of armor rods is crucial for their effectiveness in protecting your gear. Begin by thoroughly cleaning the conductor surface to remove any dirt or debris. Then, carefully wrap the armor rod around the conductor, ensuring a tight and secure fit. Finally, use a twisting tool to achieve the recommended tension level for maximum durability.

After achieving the recommended tension level, it's important to inspect the armor rods for any signs of damage or wear. Regular maintenance and inspection can help identify any issues early on and prevent potential damage to your gear. Additionally, make sure to follow manufacturer guidelines and recommendations for installation to ensure the best performance and longevity of the armor rods.

Common Misconceptions Debunked

One common misconception about armor rods is that they are only suitable for industrial applications. In reality, these versatile tools can be used to protect a wide range of gear, including fishing rods and other equipment prone to wear and tear. Additionally, some may believe that wrapping armor rods is a complicated process, but with proper guidance and tools, installation can be straightforward and hassle-free.

Furthermore, another misconception about armor rods is that they are bulky and heavy, making them impractical for everyday use. However, advancements in technology have led to the development of lightweight and durable armor rods that are easy to handle and transport. This makes them ideal for protecting a variety of equipment without adding unnecessary weight or bulk. With these modern options, users can enjoy the benefits of armor rods without any inconvenience.

Conclusion

Protect Your Gear with Premium Rod Armor

When it comes to protecting your gear, nothing beats the reliability of premium rod armor. Whether it's preventing corrosion or providing durability, armor rods are essential for keeping your equipment in top condition. With the right material and proper installation, you can ensure that your gear stays safe and secure for the long haul.

Ensure Longevity and Durability

By investing in high-quality armor rods, you're ensuring the longevity and durability of your equipment. With the right protection in place, you can avoid costly replacements and repairs down the line. Properly wrapped and twisted armor rods provide an added layer of defense against wear and tear, giving you peace of mind when it comes to the safety of your gear.

Trust Spark Fittings for Quality Armor Rods

When it comes to choosing the right armor rods, trust Spark Fittings for quality materials and expert guidance. With a range of customizable options and color-coded identification, Spark Fittings ensures that you get the perfect fit for your specific needs. From installation instructions to choosing the right material, Spark Fittings has everything you need to protect your gear with confidence.