Introduction

In the realm of electrical systems, the durability and protection of conductors are paramount. This is where preformed armor rods come into play, providing essential support and safeguarding against various environmental factors. Understanding what an armor rod is used for and its critical role in transmission lines can help ensure the longevity and efficiency of electrical infrastructure.

Understanding the Function of Preformed Armor Rods

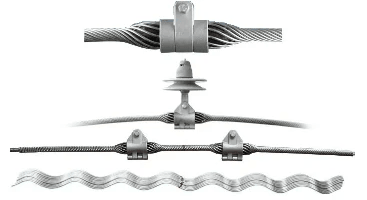

Preformed armor rods are specialized components designed to protect electrical conductors from abrasion, enhance insulation, and provide mechanical stability. These rods are engineered to fit snugly around conductors, acting as a shield against wear caused by weather conditions or physical interactions. By understanding how preformed armor rods function, we can appreciate their significance in maintaining the integrity of transmission lines.

Importance of Durability in Electrical Systems

Durability is a key factor in the reliability of electrical systems, particularly when it comes to minimizing maintenance costs and preventing outages. The environmental wear that conductors face can lead to significant issues if not properly managed; hence, investing in high-quality solutions like preformed armor rods is crucial. Ensuring that your system is equipped with robust components helps safeguard operations for years to come.

Overview of Spark Fittings’ Contribution

Spark Fittings stands at the forefront of manufacturing equipment for preformed armor rods, tension clamps, and cable accessories tailored for ADSS and OPGW applications. Their commitment to quality ensures that customers receive top-notch products designed specifically for the transmission and distribution of electricity across various landscapes—including electrified railways. With their innovative machinery aiding in producing high-quality preformed products, Spark Fittings plays a pivotal role in enhancing the durability and efficiency of electrical systems worldwide.

What is an Armor Rod Used For?

Preformed armor rods serve a vital role in the electrical industry, particularly for transmission lines. These specialized components are designed to enhance the durability and reliability of conductors, ensuring they withstand various environmental challenges. Understanding what an armor rod is used for can significantly impact the longevity and efficiency of electrical systems.

Protecting Conductors from Abrasion

One of the primary functions of preformed armor rods is to protect conductors from abrasion caused by wind, ice, and other environmental factors. By encasing the conductor in a protective layer, these rods minimize wear and tear that can lead to costly outages or failures. In regions where extreme weather conditions prevail, using high-quality preformed armor rods becomes essential for maintaining system integrity.

The abrasion protection offered by these rods is particularly crucial in areas with heavy vegetation or rugged terrain, where physical contact could damage conductors over time. Additionally, using China preformed armor rods ensures you have access to cost-effective solutions without compromising on quality or performance. Ultimately, protecting conductors from abrasion not only prolongs their lifespan but also enhances overall system reliability.

Enhancing Electrical Insulation

Another significant benefit of preformed armor rods is their ability to enhance electrical insulation around conductors. This added layer of protection helps prevent short circuits and electrical faults that could arise due to moisture or other contaminants infiltrating the conductor's surface. By improving insulation properties, these rods contribute to safer and more efficient electrical systems.

With robust insulation provided by preformed armor rods, utility companies can significantly reduce maintenance costs associated with repairs or replacements caused by electrical failures. Furthermore, understanding what an armor rod is used for extends beyond mere protection; it plays a crucial role in ensuring compliance with safety standards and regulations within the industry as well. Therefore, investing in high-quality products such as those offered by Spark Fittings ensures that your transmission lines remain safe and efficient over time.

Supporting Mechanical Stability

Preformed armor rods also play a critical role in supporting mechanical stability for overhead conductors. They help distribute tension evenly across the conductor's length while minimizing stress at critical connection points during installation or under load conditions. This mechanical support reduces the risk of sagging or breakage that can occur due to excessive weight from ice accumulation or wind loads on transmission lines.

When considering what is the difference between armor rod and line guard? It's essential to note that while line guards may provide some level of protection against debris impacts, they do not offer the same comprehensive mechanical support as preformed armor rods do for transmission lines. Choosing preformed armor rods not only enhances stability but also contributes positively towards reducing maintenance demands over time—saving both time and money for utility providers.

In conclusion, understanding how preformed armor rods function serves as a foundation for making informed decisions regarding their application in your projects—especially when it comes down to effective installation techniques like how to roll an armor rod. With such versatile benefits ranging from abrasion protection to enhanced insulation and mechanical stability under your belt (or should we say conductor?), you’re well-equipped for success!

The Difference Between Armor Rods and Line Guards

When discussing protective equipment for electrical conductors, many people wonder about the differences between preformed armor rods and line guards. Both serve essential roles in safeguarding electrical systems, but they are designed with distinct functionalities that cater to specific needs. Understanding these differences can help in making informed choices for transmission line protection.

Key Functional Variations

Preformed armor rods primarily focus on protecting conductors from abrasion and mechanical stress while enhancing electrical insulation. They are specifically engineered to distribute mechanical loads evenly across the conductor, preventing wear over time. In contrast, line guards are designed to prevent birds and other wildlife from perching on lines, minimizing interference and potential damage caused by external factors.

While both products contribute to the longevity of transmission lines, their core functions set them apart significantly. Armor rods excel in providing direct protection against physical wear caused by environmental factors or installation stresses. On the other hand, line guards address concerns related to wildlife interactions with overhead lines but do not offer the same level of conductor support as preformed armor rods.

Design and Application Distinctions

The design of preformed armor rods is tailored to wrap around conductors snugly, ensuring a secure fit that can withstand dynamic loads during operation. These rods often feature a streamlined profile that minimizes wind resistance while maintaining structural integrity under various weather conditions. Conversely, line guards typically have a more robust design aimed at deterring animals rather than supporting conductors directly.

Application methods also differ between these two products; installing preformed armor rods requires careful attention to ensure proper placement along the conductor's length for maximum effectiveness. In contrast, line guards are generally installed at specific points along transmission lines where animal activity is anticipated. This distinction highlights the importance of selecting the right product based on specific operational needs.

Why Choose Armor Rods for Transmission Lines

Choosing preformed armor rods for transmission lines offers several advantages that enhance overall system durability and reliability. Their ability to provide robust mechanical support ensures that conductors remain stable even in adverse weather conditions or during heavy load scenarios—essential for maintaining uninterrupted service delivery in electrical systems like those supported by Spark Fittings’ quality manufacturing processes.

Moreover, investing in high-quality China preformed armor rods can lead to significant cost savings over time due to reduced maintenance requirements and fewer replacements needed throughout a system's lifespan. The longevity provided by these protective measures means fewer disruptions caused by conductor failure or damage from environmental wear—an attractive proposition for any utility company looking to optimize their infrastructure investments.

The Role of Preformed Armor Rods in Transmission Lines

Preformed armor rods play a crucial role in enhancing the performance and longevity of transmission lines. By providing robust protection to conductors, these components help ensure that electrical systems remain functional even under challenging conditions. Understanding the significance of preformed armor rods can lead to better maintenance practices and improved overall system reliability.

Ensuring Longevity for Conductors

One of the primary functions of preformed armor rods is to ensure the longevity of conductors used in transmission lines. These rods act as a protective layer, shielding conductors from mechanical wear and tear that can occur over time. With high-quality preformed armor rods, such as those manufactured by Spark Fittings, utilities can significantly extend the lifespan of their electrical infrastructure.

Moreover, when asking What is an armor rod used for? it’s essential to recognize that these components not only provide physical protection but also enhance electrical insulation properties. This dual functionality contributes to reduced risk of failures and outages, ultimately leading to a more reliable power supply for consumers.

Mitigating Weather Impact and Environmental Wear

Weather conditions can be particularly harsh on transmission lines, causing wear due to wind, rain, snow, and temperature fluctuations. Preformed armor rods are designed to mitigate these environmental impacts effectively, providing a barrier against abrasion caused by ice or debris accumulation during storms. This resilience helps maintain conductor integrity even when faced with severe weather events.

In regions where extreme weather is common, choosing high-quality China preformed armor rods becomes increasingly important for utilities looking to safeguard their investments. By incorporating these robust components into their systems, companies can minimize damage caused by environmental wear while ensuring optimal performance throughout various seasons.

Cost-Efficiency Through Reduced Maintenance

Investing in preformed armor rods also leads to significant cost-efficiency through reduced maintenance needs over time. When installed correctly during the initial setup—following proper armor rod installation techniques—these products help prevent frequent repairs or replacements due to damage or degradation. This translates into lower operational costs for utility companies while ensuring continuous service delivery.

Additionally, understanding What is the difference between armor rod and line guard? can aid decision-makers in selecting suitable protective measures for their infrastructure needs. While both serve protective roles, preformed armor rods are specifically engineered for enhanced durability against mechanical stress and environmental factors compared to line guards.

With effective use of tools and knowledge on How to roll an armor rod?, technicians can streamline installation processes further, maximizing efficiency while minimizing downtime during maintenance activities. Ultimately, investing in quality preformed products like those offered by Spark Fittings pays off through long-term savings and improved service reliability.

Armor Rod Installation: A Step-by-Step Guide

Installing preformed armor rods is crucial for ensuring the longevity and durability of electrical conductors. This guide will walk you through the essential steps, focusing on preparing the conductors, applying the armor rods correctly, and conducting post-installation inspections. Understanding these steps will help you maximize the benefits of using preformed armor rods in your transmission line projects.

Preparing the Conductors for Installation

Before diving into armor rod installation, it’s vital to prepare your conductors properly. Start by cleaning the conductor surfaces to remove any dirt or debris that could interfere with adhesion or fit. Additionally, inspect for any signs of wear or damage; this is especially important when asking yourself, What is an armor rod used for? The answer lies in its ability to protect and enhance conductor performance.

Next, ensure that all necessary tools are readily available—this includes gloves, safety goggles, and any specific equipment required for handling China preformed armor rods. Proper preparation not only ensures a smooth installation process but also contributes to achieving maximum efficiency from your preformed armor rod for transmission line applications.

Techniques for Proper Application

One common question is: What is the difference between an armor rod and a line guard? Armor rods are specifically designed for protecting conductors against abrasion and environmental factors while maintaining mechanical stability; understanding this distinction will help you appreciate their unique application during installation.

For effective application of China preformed armor rods, consider using a rolling technique that allows even distribution of force across the surface area of both components. This method minimizes stress points which could lead to premature wear or failure.

Post-Installation Inspection and Testing

Once you've installed your preformed armor rods, it's time to evaluate your work through thorough inspection and testing procedures. Start by visually checking each installation point; look out for any irregularities such as misalignment or gaps between the rod and conductor that could compromise performance over time.

After visual checks are complete, perform functional tests where applicable—this might include tension tests or electrical continuity checks depending on your specific setup. These evaluations should reassure you that everything has been installed correctly and adheres to safety standards commonly expected in projects involving transmission lines.

Finally, remember that regular maintenance checks should follow initial installations; keeping track of how well your preformed line products hold up under varying environmental conditions will ensure long-term success in protecting your electrical systems effectively.

How to Roll an Armor Rod Effectively

Rolling a preformed armor rod might seem like a straightforward task, but mastering the technique can significantly impact its performance and longevity. Proper rolling ensures that the armor rod fits securely on the conductor, providing optimal protection against abrasion and environmental wear. Let’s break down how to roll these essential components effectively.

Necessary Tools and Equipment

To roll an armor rod efficiently, you’ll need a few essential tools and equipment at your disposal. First, gather your preformed armor rods, ensuring they are compatible with your specific application—whether for transmission lines or other electrical systems. Additionally, you’ll require a pair of gloves for safety, a measuring tape to ensure correct placement, and possibly some lubricant if specified by the manufacturer to ease installation.

Best Practices for a Successful Roll

Start by carefully positioning the preformed armor rod over the conductor; it should be aligned properly to prevent any misalignment during installation. Next, apply even pressure while rolling from one end of the rod to the other; this helps ensure that it wraps snugly around the conductor without gaps that could compromise its protective function.

Another tip is to periodically check your progress as you roll; this allows you to make adjustments if needed before fully securing it in place. Also, consider using tools specifically designed for this purpose—these can help maintain even tension and prevent damage during installation.

Common Mistakes to Avoid

While learning how to roll an armor rod effectively, it's important to be aware of common pitfalls that may arise during installation. One frequent mistake is rushing through the process without proper alignment; misalignment can lead not only to ineffective protection but also potential damage down the line—literally!

Another error often made is applying too much force while rolling; excessive pressure can deform or damage both the armor rod and conductor itself. Lastly, neglecting post-installation inspection is a significant oversight—always check that everything has been applied correctly before moving on with your project.

By avoiding these common mistakes and adhering closely to best practices in armor rod installation, you'll enhance not only durability but also efficiency in electrical systems using preformed armor rods.

Conclusion

In conclusion, preformed armor rods are indispensable components in the realm of electrical systems, particularly for transmission lines. Their ability to protect conductors from abrasion, enhance electrical insulation, and provide mechanical stability cannot be overstated. The durability and reliability offered by these rods ensure that they play a crucial role in maintaining the integrity of electrical infrastructures.

The Essential Nature of Preformed Armor Rods

Preformed armor rods serve multiple essential functions that are critical to the longevity of transmission lines. They not only safeguard conductors against environmental wear and tear but also improve overall mechanical strength. Understanding what is an armor rod used for is key to appreciating its role in enhancing the reliability of electrical systems.

Spark Fittings: Leaders in Quality Manufacturing

When it comes to manufacturing high-quality preformed armor rods, Spark Fittings stands out as a leader in the industry. Specializing in equipment for preformed products, they provide innovative solutions tailored for the transmission and distribution of electricity as well as electrified railways. Their commitment to quality ensures that customers receive dependable products that meet rigorous standards.

Investing in Durability for Future Projects

Investing in durable components like preformed armor rods is crucial for any future projects involving electrical systems. By choosing quality materials from trusted manufacturers such as Spark Fittings, project managers can mitigate long-term maintenance costs and ensure system reliability over time. Understanding how to roll an armor rod properly during installation further enhances this investment by maximizing performance and lifespan.