Introduction

In the industrial world, the pole lashing rod plays a crucial role in ensuring the stability and reliability of various structures. Whether it's for securing electrical poles, telecom towers, or other utility infrastructure, lashing rods are indispensable tools that provide essential support. Understanding the significance of pole lashing in industrial settings is key to maximizing efficiency and safety. Let's delve into the practical uses and benefits of pole lashing rods to appreciate their importance in various applications.

Understanding the Pole Lashing Rod

Lashing rods, also known as lashing bars, are essential components used to secure and stabilize utility poles and other structures. These rods are designed to withstand high tension and provide robust support, ensuring the stability of overhead lines and cables. Available in various materials such as steel or aluminum, lashing rods come in different lengths and diameters to accommodate specific requirements for different applications.

Importance of Pole Lashing in Industrial Settings

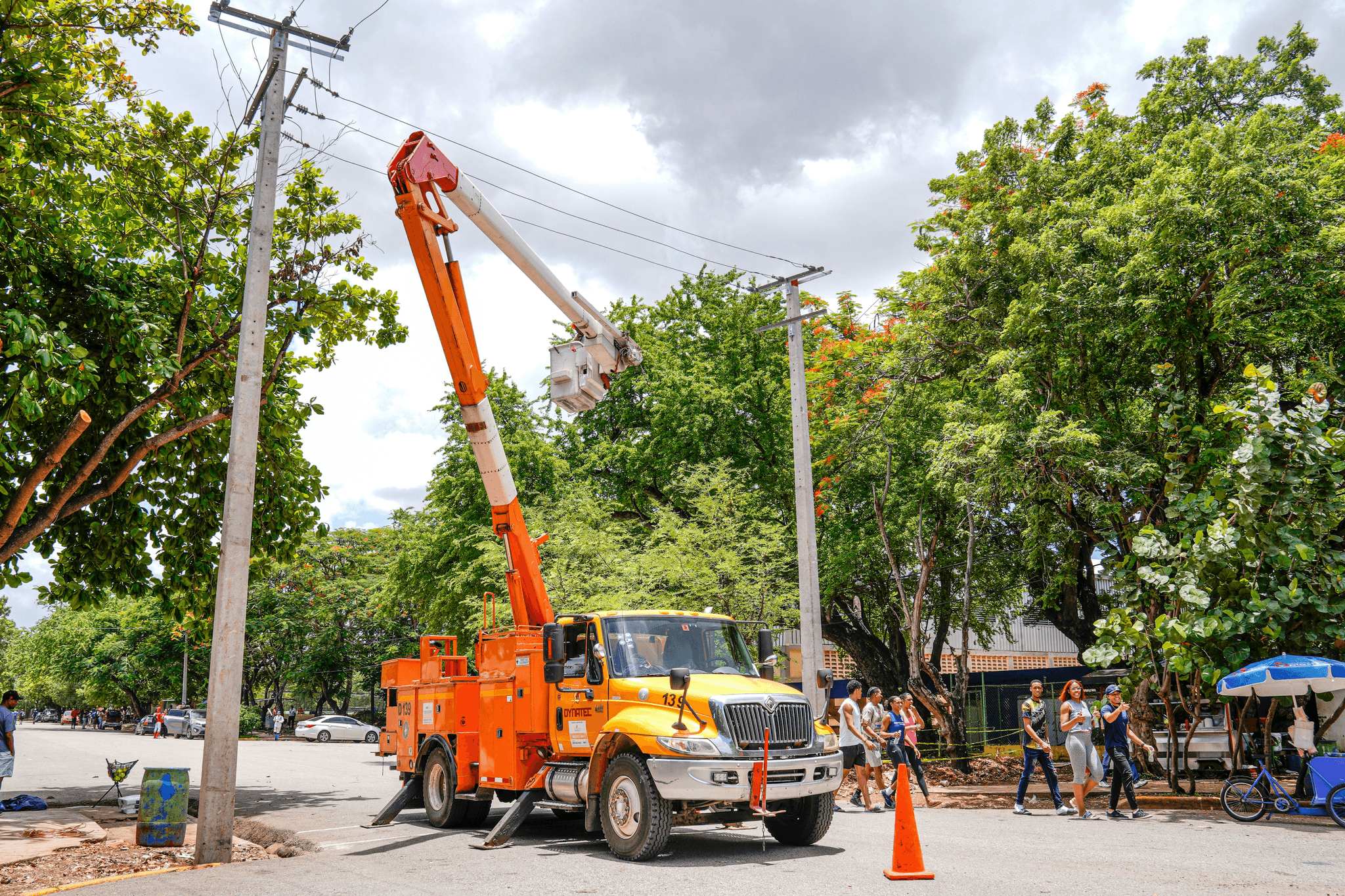

The importance of pole lashing in industrial settings cannot be overstated. Properly secured utility poles are critical for maintaining reliable power distribution, telecommunication networks, and other essential services. Without effective pole lashing, structures may be vulnerable to damage from environmental factors such as strong winds or heavy loads, leading to potential safety hazards and service disruptions.

Exploring the Practical Uses of Pole Lashing Rod

Pole lashing rods have a wide range of practical uses across various industries. From supporting overhead power lines to securing communication infrastructure, these versatile components play a vital role in maintaining the integrity and functionality of essential utilities. Understanding how to effectively utilize pole lashing rods is key to optimizing their performance and ensuring long-term reliability.

What is a Pole Lashing Rod?

Lashing rods are essential tools used in industrial settings to secure and support utility poles. These rods are designed to withstand the weight and tension of overhead cables, ensuring the stability and safety of the entire infrastructure. By providing a strong and reliable connection between the pole and the cables, lashing rods play a crucial role in maintaining the integrity of power lines and communication networks.

Definition and Function of a Lashing Rod

A lashing rod, also known as a pole lashing rod, is a durable metal bar typically made of steel or aluminum. It is specifically designed to be wrapped around utility poles to secure overhead cables in place. The primary function of a lashing rod is to provide support and stability to the cables, preventing them from sagging or coming loose due to external forces such as wind or heavy loads.

Lashing rods come in various types and variations to accommodate different utility pole sizes and cable configurations. Some lashing rods are designed with adjustable lengths to fit poles of varying diameters, while others are equipped with specialized hooks or clamps for securing specific types of cables. Additionally, there are lashing rods that feature anti-corrosion coatings to withstand harsh weather conditions, ensuring long-term durability and reliability. These variations allow for flexibility in choosing the most suitable lashing rod for specific utility pole and cable arrangements, making them an essential component in maintaining a secure and efficient overhead cable network.

Types and Variations of Lashing Rods

There are several types of lashing rods available in the market, each tailored to specific industrial requirements. Common variations include solid steel lashing rods, hollow core lashing rods, and lightweight aluminum lashing rods. The choice of material and design depends on factors such as load capacity, environmental conditions, and installation preferences.

Benefits of Using Lashing Rods in Industrial Applications

The use of lashing rods offers numerous benefits in industrial applications. Firstly, they provide a cost-effective solution for securing utility poles and overhead cables, reducing maintenance expenses in the long run. Additionally, lashing rods enhance safety by preventing cable sagging or disconnection, minimizing the risk of power outages or communication disruptions.

Furthermore, lashing rods contribute to the overall aesthetic appeal of the industrial landscape by providing a clean and organized appearance. This attention to detail can enhance the professional image of a company and instill confidence in clients and customers. Additionally, the use of lashing rods demonstrates a commitment to quality and safety, which can be a valuable selling point for businesses looking to attract new partnerships or contracts.

How to Tie Pole Lashing?

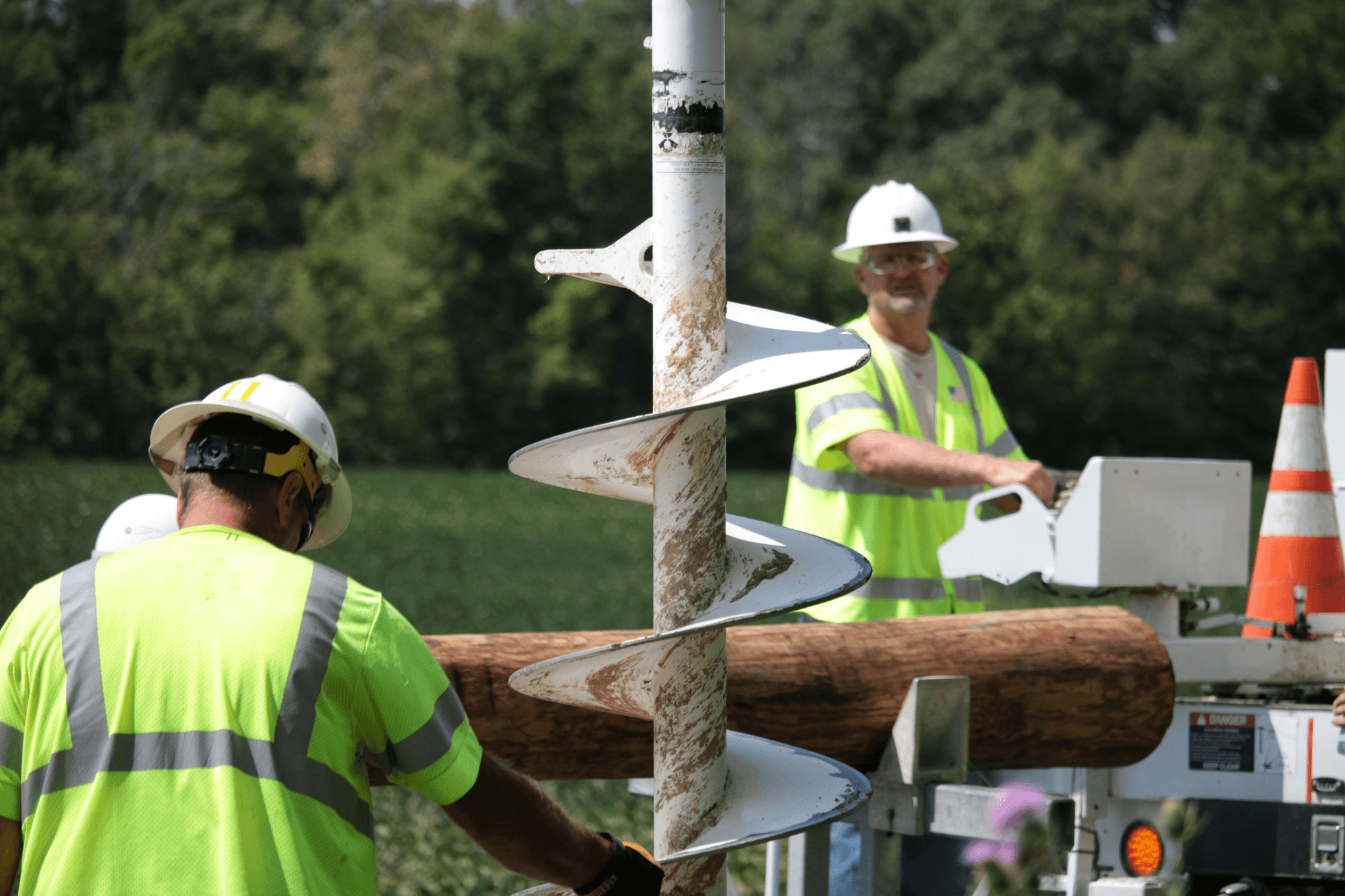

Start by positioning the lashing rod around the pole and securing it with a clove hitch knot. Then, wrap the wire around the rod and pole in a figure-eight pattern, ensuring each wrap is tight and secure.

Step-by-Step Guide to Properly Tie Pole Lashing

To properly tie pole lashing, begin by placing the lashing rod against the pole and wrapping the wire around both in a figure-eight pattern. Use a come-along tool to maintain tension as you continue wrapping, ensuring that each loop is snug against the previous one. Finally, finish with another clove hitch knot to secure the end of the wire.

Best Practices for Ensuring Secure Lashing

To ensure secure lashing, it's essential to use high-quality lashing rods and wires that can withstand environmental factors and heavy loads. Regular inspections of the lashing are also important to detect any signs of wear or damage that could compromise its strength and stability.

Common Mistakes to Avoid When Tying Pole Lashing

One common mistake when tying pole lashing is using insufficient tension, which can lead to loose or unstable lashing over time. Additionally, using low-quality materials or improper techniques can result in weak or ineffective lashing that poses safety risks in industrial settings.

The Weight of a Lashing Rod

Understanding the Weight Range of Lashing Rods

Lashing rods typically range in weight from 2 to 5 pounds, depending on the specific application and material composition. The weight of a lashing rod directly impacts its handling and maneuverability, making it essential to select the right weight for the job at hand. In addition to considering the physical demands of the job, it's important to think about the strength and endurance of the person using the lashing rod. A heavier rod may be more difficult to handle for someone with less upper body strength, while a lighter rod may not provide enough stability for a larger project.

Factors to Consider When Choosing the Right Weight

When choosing a lashing rod, several factors come into play when considering weight. The type of material used in the construction of the rod, as well as the intended use and environmental conditions, will all influence the ideal weight for your specific needs. Additionally, considering the strength and endurance of workers who will be using the lashing rods is vital in ensuring safety and efficiency.

Impact of Weight on Industrial Use and Durability

The weight of a lashing rod has a significant impact on its industrial use and durability. A lighter rod may be more suitable for overhead applications or situations requiring extended use, reducing strain on workers' arms and shoulders. On the other hand, heavier lashing rods may offer increased stability and strength in demanding conditions such as extreme weather or high-tension installations.

A lashing rod's weight also affects its portability and ease of handling. A lighter rod can be more convenient for transportation and maneuvering in tight spaces, making it ideal for on-the-go installations or projects that require frequent repositioning. Conversely, a heavier rod may be better suited for stationary applications where stability and resistance to movement are crucial, providing a reliable solution for long-term use in fixed locations.

Pole Line Hardware Suppliers

Finding Reliable Suppliers for Lashing Rods

When looking for reliable suppliers of pole lashing rods, it's essential to consider factors such as reputation, experience, and product range. Spark Fittings, a leading company specializing in manufacturing equipment for preformed armor rods and cable accessories, is a trusted supplier with a proven track record of delivering high-quality products to industrial clients. Their expertise in the field makes them an ideal choice for sourcing lashing rods.

Evaluating Quality and Reliability of Lashing Rods

When evaluating the quality and reliability of lashing rods from different suppliers, it's crucial to consider factors such as material durability, load capacity, and corrosion resistance. Spark Fittings' lashing rods are known for their superior strength and durability, making them a reliable choice for industrial applications. Their commitment to quality assurance ensures that their products meet industry standards and specifications.

Exploring Options for Purchasing Lashing Rods

When exploring options for purchasing lashing rods, it's important to consider factors such as pricing, delivery lead times, and customer support. Spark Fittings offers a wide range of lashing rod options to suit different industrial requirements. With competitive pricing and efficient delivery services, they provide convenient solutions for businesses looking to acquire high-quality pole lashing rods.

Practical Applications of Lashing Rods in Industrial Settings

Examples of Industries Benefiting from Lashing Rods

Lashing rods are widely used in the telecommunications industry for securing utility poles and overhead lines, ensuring the safety and reliability of communication networks. Additionally, the electrical power industry relies on lashing rods to support power lines and maintain uninterrupted transmission of electricity. Furthermore, the railway industry utilizes lashing rods to secure electrified railways, contributing to efficient and safe operations.

Real-World Case Studies of Successful Lashing Rod Implementation

In a recent case study, a telecommunications company implemented lashing rods to secure utility poles in high-wind areas, resulting in a significant reduction in pole damage and service disruptions during adverse weather conditions. Similarly, an electrical power provider utilized lashing rods to reinforce power lines in challenging terrains, leading to improved resilience against environmental factors such as heavy snow and strong winds.

Future Trends and Innovations in Lashing Rod Technology

As technology continues to advance, there is a growing focus on developing lightweight yet durable lashing rods that offer enhanced strength and flexibility for various industrial applications. Moreover, innovations in corrosion-resistant materials and advanced manufacturing processes are driving the evolution of lashing rod technology, promising extended lifespan and reduced maintenance requirements for utility infrastructure.

Conclusion

Maximizing Industrial Efficiency with Lashing Rods

Lashing rods play a crucial role in maximizing industrial efficiency by providing secure support for poles and lines. With their ability to withstand heavy loads and harsh environmental conditions, lashing rods ensure the uninterrupted flow of electricity and communication signals, ultimately enhancing productivity and reliability in industrial settings.

Lashing rods are not only essential for maintaining the structural integrity of industrial poles and lines, but they also contribute to cost savings by minimizing the need for frequent repairs and replacements. By partnering with trusted suppliers like Spark Fittings, industrial businesses can ensure that they are investing in high-quality lashing rods that are built to last. This long-term durability translates to reduced downtime and maintenance costs, allowing companies to allocate their resources more efficiently and focus on core operations.

Advantages of Partnering with Trusted Suppliers like Spark Fittings

Their expertise in manufacturing equipment for pole line hardware ensures high-quality products that meet industry standards. By choosing reliable suppliers, industrial companies can benefit from durable and reliable lashing rods that contribute to the overall efficiency of their operations.

Harnessing the Full Potential of Pole Lashing Rods

To fully harness the potential of pole lashing rods, it's important for industrial professionals to understand the various aspects of these essential components. From knowing how to properly tie pole lashing to choosing the right weight and evaluating suppliers, maximizing the benefits of lashing rods requires attention to detail and a commitment to quality.

Understanding the different types of pole lashing rods available in the market is crucial for industrial professionals. Each type has its own unique features and benefits, and choosing the right one can make a significant impact on the efficiency and safety of your operations. From fiberglass to composite materials, knowing the strengths and weaknesses of each type will help you make an informed decision when selecting lashing rods for your specific needs.