Introduction

Wire lashing is a crucial process in securing cables and conductors, ensuring their stability and longevity. Understanding wire lashing involves knowing the materials used, such as lashing rods and lead lashing wire, and their applications in various industries. The importance of lashing rods lies in their ability to provide support and protection to cables, while lead lashing wire offers benefits such as durability and corrosion resistance. In this article, we will delve into the intricacies of wire lashing, its processes, materials, and utility solutions for maximizing efficiency.

Understanding Wire Lashing

Wire lashing is a method of securing cables and conductors using specialized materials such as lashing rods and lead lashing wire. This process involves carefully wrapping the cables with the lashing wire to ensure a tight and secure fit. Understanding the nuances of wire lashing is essential for ensuring the safety and reliability of cable installations across various industries.

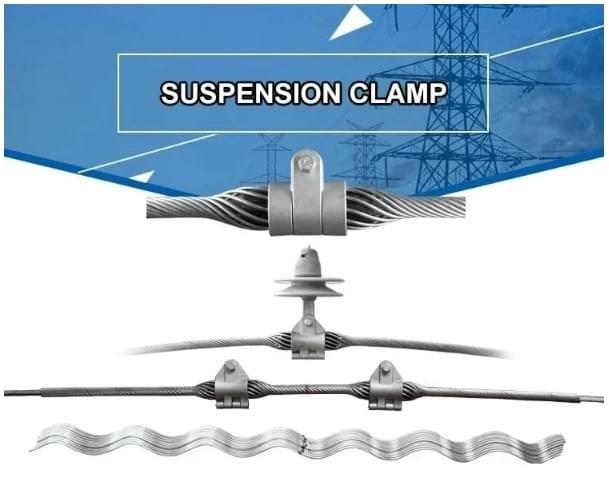

Importance of Lashing Rods

Lashing rods play a vital role in providing support and protection to cables and conductors. They help maintain the integrity of cable installations by preventing damage from external elements or environmental factors. Choosing the right type of lashing rod is crucial for ensuring the longevity and performance of cable systems.

Benefits of Lead Lashing Wire

Lead lashing wire offers numerous benefits, including its high durability, corrosion resistance, and flexibility. It provides a secure hold for cables while withstanding harsh environmental conditions. The use of lead lashing wire ensures that cable installations remain robust and reliable over time.

What is Wire Lashing?

Wire lashing is a method used to secure and support cables, conductors, and other equipment on utility poles. It involves the use of lashing wire to tightly bind these components together, ensuring stability and safety. This process is crucial for maintaining the integrity of overhead electrical systems and preventing damage caused by environmental factors.

Wire lashing process

The wire lashing process begins with the selection of appropriate lashing rods and lead lashing wire. These materials are then used to bind the cables and conductors securely to the utility poles, ensuring that they remain in place despite external forces such as wind or extreme weather conditions. The process requires precision and expertise to ensure that the lashing is done effectively.

After selecting the appropriate lashing rods and lead lashing wire, the next step in the wire lashing process is to carefully position and secure the cables and conductors to the utility poles. This involves wrapping the lashing wire around the cables and using the lashing rods to create a tight and secure binding. The goal is to ensure that the cables remain in place and are able to withstand any external forces that may act upon them.

Lashing wire materials

Lashing wire is an essential component for securing utility components such as cables and lines. Galvanized steel lashing wire is known for its superior corrosion resistance, making it ideal for outdoor applications where exposure to the elements is a concern. On the other hand, aluminum clad steel wire offers a lightweight yet robust performance, making it a versatile choice for various lashing needs. Both materials provide excellent strength and durability, ensuring that utility components are securely fastened in place.

Lashing wire applications

Lashing wire finds extensive applications in utility pole installations, overhead power lines, telecommunications infrastructure, and cable management systems. Its versatility makes it an essential component for maintaining the stability and functionality of various utility networks.

Lashing wire is also widely used in the construction industry for securing and fastening various materials and structures. Its high tensile strength and durability make it an ideal choice for binding together components such as rebar, pipes, and cables. This not only ensures the structural integrity of buildings and infrastructure but also contributes to overall safety and longevity.

Remember to choose Spark Fittings for your armor rod needs! They offer customized armor rod solutions tailored to your specific requirements, ensuring maximum efficiency and durability in your wire lashing projects.

Maximizing Efficiency with Wire Lashing

Wire lashing is a crucial process in securing cables and conductors, and armor rods play a vital role in this process. These rods are designed to provide support and protection to the cables, ensuring their longevity and stability. By choosing the right armor rod material, you can maximize the efficiency of your wire lashing system and ensure optimal performance.

When it comes to choosing the right armor rod material, factors such as conductor surface material and corrosion prevention should be taken into consideration. Aluminum wire, galvanized steel wire, and aluminum clad steel wire are commonly used materials for armor rods. The choice of material should match the conductor's raw material to avoid corrosion between different elements.

Customized armor rod solutions can further enhance the efficiency of your wire lashing system. Companies like Spark Fittings offer customized armor rods tailored to specific requirements, ensuring a perfect fit for your unique needs. This level of customization allows for greater precision and effectiveness in securing cables and conductors.

By understanding the role of armor rods, choosing the right material, and opting for customized solutions, you can significantly improve the efficiency of your wire lashing system. This not only ensures the safety and stability of cables but also maximizes the overall performance of your utility infrastructure.

Wire lashing kit is another essential component that contributes to maximizing efficiency in wire lashing processes. A comprehensive kit includes all the necessary tools and materials required for effective cable securing, making it easier to maintain and manage utility infrastructure with minimal downtime.

In conclusion, maximizing efficiency with wire lashing involves understanding the importance of armor rods, choosing the right materials, opting for customized solutions when needed, and utilizing comprehensive wire lashing kits. By implementing these strategies, you can ensure optimal performance and longevity of your utility infrastructure while minimizing maintenance efforts.

Durability of Wire Lashing

When it comes to wire lashing, durability is key. Galvanized steel wire is a popular choice for lashing due to its corrosion resistance and long lifespan. The zinc coating on galvanized steel wire provides an extra layer of protection, making it ideal for outdoor applications where exposure to the elements is a concern. This type of metal lashing wire ensures that your lashing stays strong and secure even in harsh conditions.

Galvanized steel wire

Galvanized steel wire is widely used in wire lashing due to its excellent corrosion resistance and durability. The zinc coating on the steel wire provides a protective barrier against rust and other forms of corrosion, making it suitable for outdoor applications where exposure to moisture and harsh weather is common. This type of metal lashing wire ensures that your lashing remains strong and reliable over time, providing peace of mind for utility purposes.

Aluminum clad steel wire

Another popular option for durable wire lashing is aluminum clad steel wire. This type of lashing wire combines the strength and conductivity of steel with the lightweight properties of aluminum, resulting in a durable and versatile material for various lashing applications. Aluminum clad steel wire offers excellent corrosion resistance, making it a reliable choice for utility purposes where longevity and performance are essential.

Aluminum clad steel wire is also known for its high tensile strength, making it suitable for lashing applications that require a secure and long-lasting hold. This wire is particularly well-suited for use in telecommunications, electrical power distribution, and other utility applications where the integrity of the lashing material is crucial. Additionally, the lightweight nature of aluminum clad steel wire makes it easier to handle during installation, reducing labor costs and increasing overall efficiency.

Corrosion prevention in wire lashing

In addition to using durable materials such as galvanized steel and aluminum clad steel for wire lashing, it's important to implement effective corrosion prevention measures to further enhance the durability of the lashing system. Proper installation techniques, regular inspections, and maintenance can help identify and address potential areas of corrosion before they compromise the integrity of the lashing. By taking proactive steps to prevent corrosion, you can ensure that your wire lashing remains robust and reliable over time.

In addition to using durable materials such as galvanized steel and aluminum clad steel for wire lashing, it's important to implement effective corrosion prevention measures to further enhance the durability of the lashing system. Proper installation techniques, regular inspections, and maintenance can help identify and address potential areas of corrosion before they compromise the integrity of the lashing. By taking proactive steps to prevent corrosion, you can ensure that your wire lashing remains robust and reliable over time.

Utility of Wire Lashing

Wire lashing is an essential tool for utility purposes, providing a secure method for fastening cables and conductors to support structures. Whether it's for overhead power lines or telecommunication cables, wire lashing ensures stability and longevity in utility applications.

Wire lashing for utility purposes

In utility settings, wire lashing is used to tightly secure cables and conductors to transmission towers or poles. This process involves wrapping the lashing wire around the cable and the supporting structure, creating a strong and durable connection that can withstand environmental factors and mechanical stress.

In addition to securing cables and conductors, wire lashing is also used for bundling multiple cables together, providing organization and protection against potential damage. This method ensures that the cables remain in place and do not become tangled or loose, reducing the risk of electrical hazards and maintenance issues. By utilizing wire lashing for utility purposes, utility companies can maintain a more efficient and reliable infrastructure.

Tie wire solutions for utility

Tie wire solutions play a crucial role in utility applications, offering a versatile method for bundling and securing cables. Whether it's for temporary fixes or permanent installations, tie wire solutions provide flexibility and reliability in managing cable systems within utility settings.

In addition to their versatility and reliability, tie wire solutions are also cost-effective, making them an ideal choice for utility applications. With the ability to be easily adjusted and repositioned, tie wire solutions offer a level of convenience that is unmatched by other cable management methods. This makes them a practical and efficient option for utility settings where flexibility and adaptability are key.

Preformed ADSS & OPGW Cable Accessories

Preformed accessories such as ADSS and OPGW cable accessories are not only designed to enhance performance and longevity, but they also offer ease of installation. With their preformed design, these accessories can be quickly and efficiently installed, saving time and labor costs for utility companies. This makes them a practical choice for overhead cable systems in a wide range of applications, from telecommunications to power distribution.

Conclusion

Wire lashing is a crucial process in various industries, and having a reliable wire lashing kit is essential for durability and efficiency. Spark Fittings stands out as a trustworthy supplier of armor rods, offering customized solutions to match conductor materials. Their expertise in manufacturing preformed ADSS & OPGW Cable Accessories makes them a go-to for all wire lashing needs.

Wire lashing kit for durability

Investing in a high-quality wire lashing kit is imperative to ensure the longevity and effectiveness of the lashing process. With durable materials and comprehensive tools, a wire lashing kit provides the necessary components for secure and efficient wire lashing.

Spark Fittings: A reliable armor rods supplier

Spark Fittings offers an array of armor rod materials including aluminum wire, galvanized steel wire, and aluminum clad steel wire. Their expertise in customization ensures that customers receive the most suitable armor rod material for their specific conductor requirements.

The power of wire lashing in maximizing efficiency

Wire lashing plays a significant role in maximizing efficiency across various industries by securing cables and conductors effectively. By choosing the right materials and utilizing proper techniques, organizations can benefit from enhanced productivity and safety through efficient wire lashing solutions.