Introduction

Power line insulators are crucial components in electrical power systems, serving the vital role of preventing leakage of electricity and ensuring efficient transmission. Understanding the different types of insulators used in power transmission is essential for maintaining reliable power supply. There are various types of power line insulators, each with its unique function and material composition.

Understanding Power Line Insulators

Power line insulators are devices that prevent the flow of electric current between the conductor and the tower or pole they are mounted on. They play a critical role in maintaining the integrity of power transmission lines by isolating them from their support structures. Different types of power line insulators are used based on voltage levels, environmental conditions, and other factors.

Importance of Insulators in Power Systems

The insulators used in power systems are essential for maintaining a safe and reliable electrical supply. They help to prevent short circuits and ensure that electricity flows efficiently through transmission lines without loss or interruption. Without proper insulation, power systems would be vulnerable to outages and safety hazards.

Common Types of Power Line Insulators

There are several common types of power line insulators used in power transmission, including disc insulators, pin type insulators, suspension insulators, and porcelain insulators. Each type has its unique design and application based on specific requirements such as voltage levels and environmental conditions.

What are Power Line Insulators?

Power line insulators are essential components in electrical power systems that prevent the flow of electric current to the earth, thereby ensuring the safety and efficiency of power transmission. These insulators are designed to withstand high voltages and provide insulation between the conductor and the supporting structure, such as poles or towers.

Definition and function of power line insulators

Power line insulators are devices used to support and electrically isolate transmission lines from the ground or supporting structures. They play a crucial role in preventing electrical leakage, which can lead to power loss, equipment damage, or even safety hazards. By providing a high-resistance path for electricity, insulators help maintain the integrity of the power system.

Importance of insulators in preventing electricity leakage

The primary function of power line insulators is to prevent electricity from leaking out of the transmission lines and causing disruptions or hazards. Without proper insulation, power loss and potential safety risks can occur due to current flowing into unintended paths. Insulators effectively block this leakage by creating a barrier that maintains the electrical flow within the designated conductors.

Different materials used for insulators

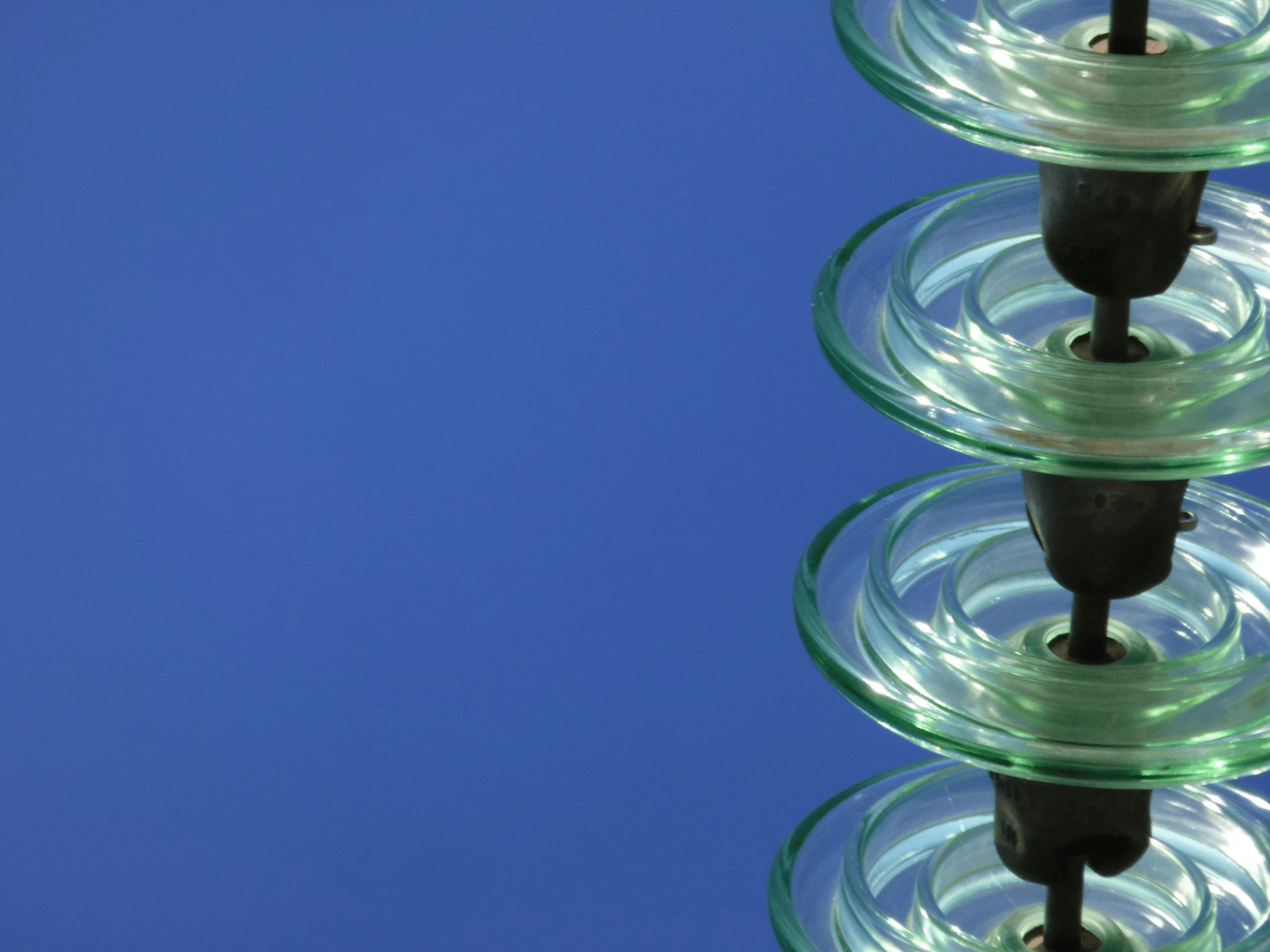

Insulators are made from various materials such as glass, porcelain, polymer, or composite materials like fiberglass reinforced plastic (FRP). Each material offers unique properties that make it suitable for specific applications based on factors like voltage requirements, environmental conditions, and mechanical strength. The choice of material depends on factors such as cost-effectiveness, durability, and performance in different operating conditions.

Insulators made from glass are known for their high mechanical strength and resistance to harsh environmental conditions, making them ideal for use in high voltage transmission lines. Porcelain insulators, on the other hand, are valued for their excellent electrical properties and long-term reliability, making them suitable for applications where consistent performance is crucial. Polymer insulators offer lightweight and corrosion-resistant options, making them a popular choice for areas with high pollution levels or coastal regions where salt spray can be a concern.

Types of Power Line Insulators

When it comes to power line insulators, there are four main types used in power transmission systems. Disc insulators, also known as suspension insulators, are commonly used for high voltage transmission lines. Pin type insulators are typically used in low and medium voltage distribution lines. Suspension insulators are designed to support the conductors and are commonly used in overhead power lines. Porcelain insulators are widely used due to their high mechanical strength and resistance to weathering.

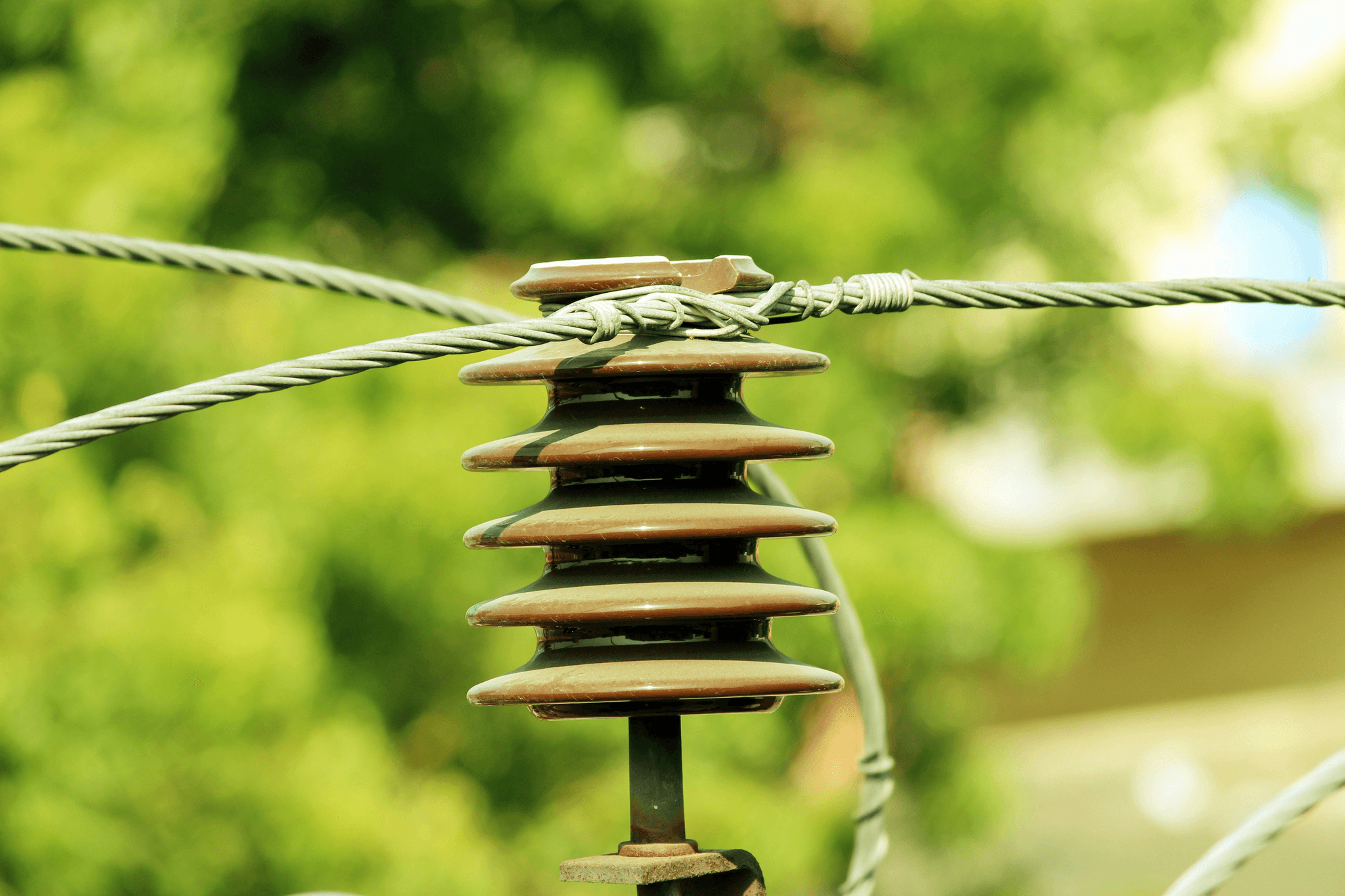

Disc insulators

Disc insulators, also known as suspension insulators, are a popular choice for high voltage transmission lines due to their ability to support heavy loads and withstand electrical stress. These insulators consist of several porcelain discs connected in series by metal links, providing a reliable means of supporting the conductors while preventing leakage currents.

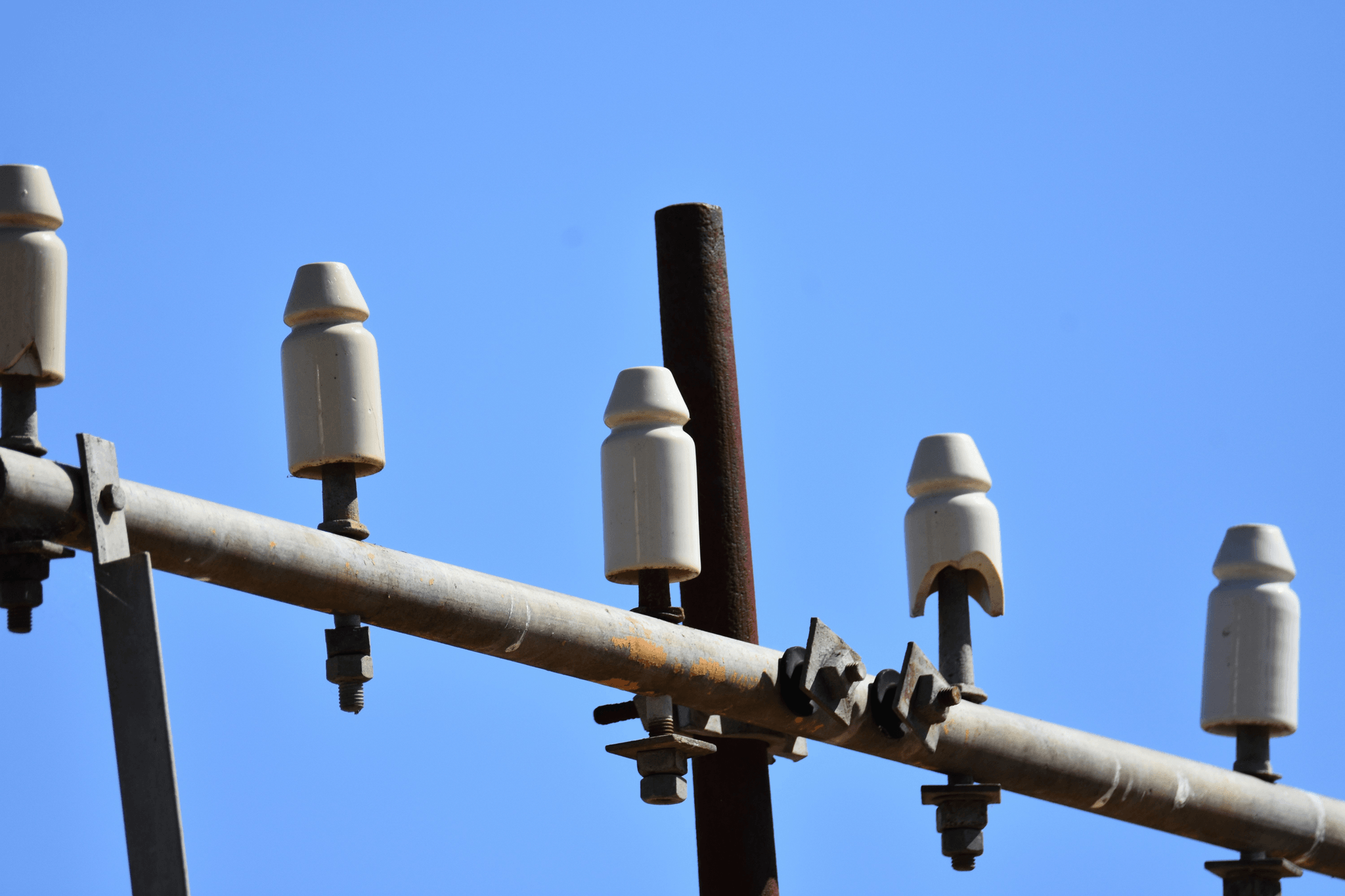

Pin type insulators

Pin type insulators are commonly used in low and medium voltage distribution lines to support the conductors on the cross-arm of the pole. These insulators have a simple design with a single piece of porcelain or glass, making them cost-effective and easy to install. They play a crucial role in preventing electricity leakage and ensuring the safe distribution of power.

Suspension insulators

Suspension insulators are designed to support the conductors on overhead power lines by suspending them from the cross-arm or pole structure. These insulators consist of several units connected in series, providing both mechanical support and electrical insulation for the transmission line.

Porcelain insulators

Porcelain insulators are widely used in power transmission systems due to their excellent mechanical strength, resistance to weathering, and high dielectric strength. They can be found in various configurations such as disc, pin type, and suspension designs, making them versatile for different applications within the power system.

Role of Power Line Insulators in Transmission

Power line insulators play a crucial role in ensuring the efficiency of power transmission. By preventing the flow of electrical current to the ground, insulators help maintain the integrity of the power lines and reduce energy loss during transmission.

Insulators' impact on power transmission efficiency

The use of insulators on power lines is essential for maintaining high levels of electrical conductivity and reducing energy loss. By effectively isolating the conductive materials, insulators help to minimize leakage and ensure that a maximum amount of electricity reaches its intended destination.

Insulators also play a crucial role in protecting power lines from environmental factors such as rain, snow, and wind. Without insulators, these elements could cause the conductive materials to deteriorate or become damaged, leading to potential power outages and safety hazards. By providing a barrier between the conductors and the surrounding environment, insulators help to maintain the structural integrity of power lines and ensure continuous electricity transmission.

How insulators protect power lines from environmental factors

Insulators are designed to withstand various environmental factors such as rain, wind, and extreme temperatures. They provide a protective barrier that prevents moisture and contaminants from compromising the integrity of the power lines, ensuring reliable performance in all weather conditions.

Insulators also play a crucial role in preventing power outages by reducing the risk of electrical faults caused by environmental factors. By providing a barrier between the power lines and the surrounding elements, insulators help maintain the flow of electricity without interruption. Proper installation and maintenance of insulators are essential to ensure their effectiveness in protecting power lines from environmental factors. This includes regular inspections to identify any signs of wear or damage, as well as ensuring that insulators are securely attached to the power lines.

Importance of proper installation and maintenance

Proper installation and regular maintenance are critical for ensuring the effectiveness of power line insulators. Inspectors must regularly check for signs of wear or damage, as well as ensure that insulators are correctly installed to maintain their ability to withstand environmental stressors.

Spark Fittings' Contribution to Insulator Production

Spark Fittings is a leading company specializing in manufacturing equipment for preformed armor rods, tension clamps, and cable accessories for ADSS and OPGW. Our machines help customers produce high-quality preformed products for the transmission and distribution of electricity, as well as electrified railways.

Quality equipment for manufacturing insulator components

At Spark Fittings, we provide state-of-the-art machinery for the production of insulator components such as disc insulators, pin type insulators, suspension insulators, and porcelain insulators. Our equipment ensures precision and efficiency in the manufacturing process, resulting in reliable and durable power line insulators.

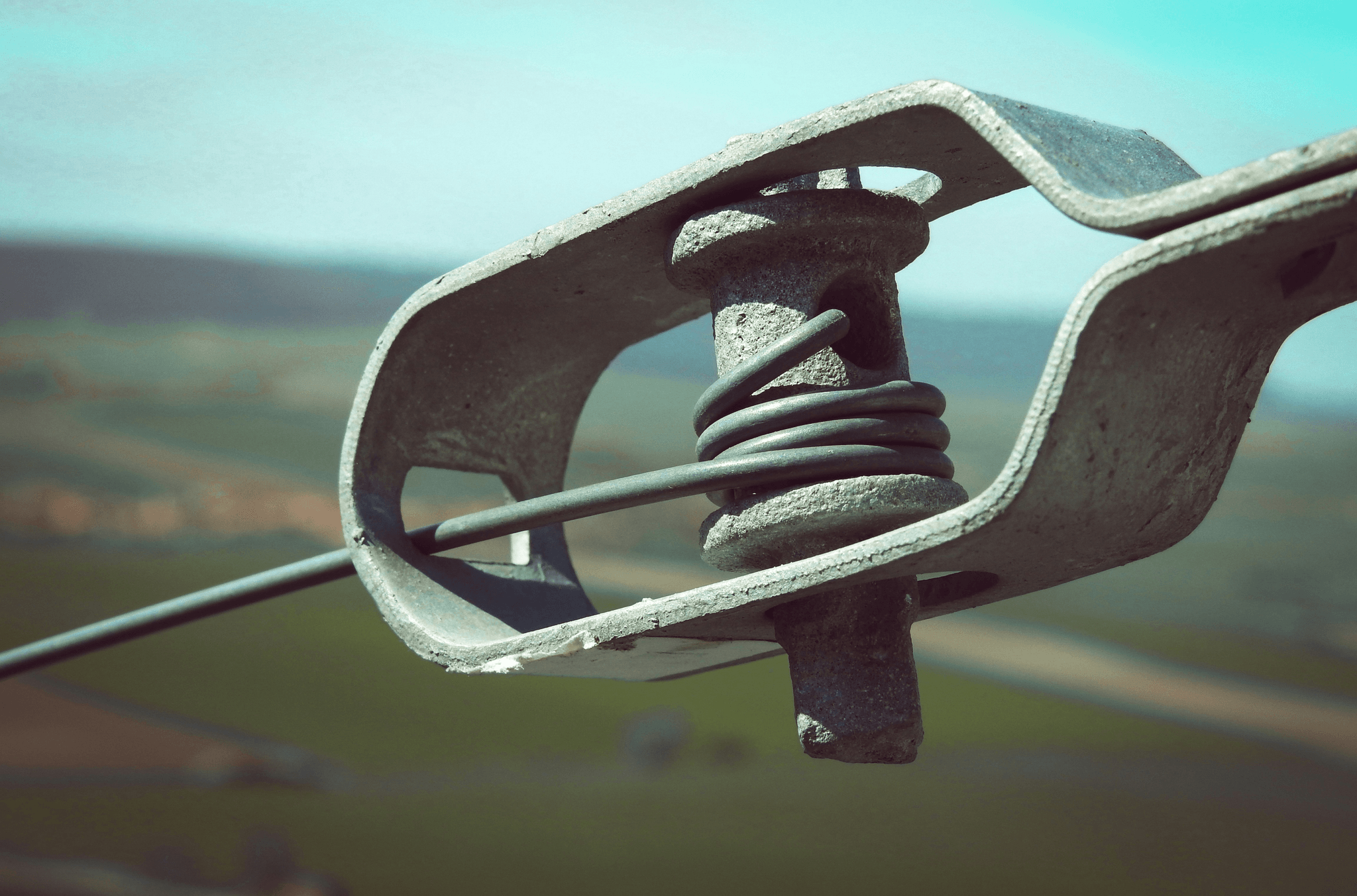

Importance of high-quality preformed armor rods and tension clamps

Our focus on producing high-quality preformed armor rods and tension clamps is crucial in ensuring the stability and longevity of power line insulators. These components play a vital role in securing insulators to power lines, preventing electrical leakage, and maintaining the integrity of the entire power system.

Furthermore, our commitment to producing high-quality preformed armor rods and tension clamps directly contributes to enhancing the reliability and performance of power line insulators. By using durable and well-designed components, we can minimize the risk of insulator failure due to environmental factors such as extreme weather conditions or physical stress. This ultimately leads to a more resilient power grid that can better withstand unforeseen challenges, ensuring uninterrupted electricity supply for consumers.

Enhancing the reliability and performance of power line insulators

By utilizing Spark Fittings' top-notch equipment for manufacturing preformed products, power system operators can enhance the reliability and performance of their power line insulators. High-quality components contribute to minimizing maintenance needs, reducing downtime, and ultimately improving the efficiency of power transmission. In addition to these benefits, investing in top-notch equipment also ensures a longer lifespan for the insulators, providing a cost-effective solution for power system operators in the long run. Furthermore, the use of high-quality materials and precision manufacturing techniques can also improve the insulators' resistance to environmental factors such as extreme temperatures and weather conditions.

Conclusion

When it comes to reliable power transmission, power line insulators play a crucial role in preventing electricity leakage and protecting power lines from environmental factors. Choosing the right insulators for your power system is essential to ensure efficient transmission and minimize downtime. Proper maintenance of power line insulators is also vital to prolong their lifespan and optimize performance.

Ensuring Reliable Power Transmission with Insulators

Power line insulators are essential for maintaining reliable power transmission by preventing electricity leakage and ensuring the safety of the power lines. With the right insulators, you can minimize the risk of outages and maintain a consistent flow of electricity through the transmission lines.

Choosing the Right Insulators for Your Power System

Selecting the appropriate insulators for your power system is crucial to ensure efficient transmission and minimize downtime. Understanding the different types of insulators used in power transmission, such as disc, pin type, suspension, and porcelain insulators, will help you make an informed decision based on your specific requirements. It's important to consider the environmental conditions in which the insulators will be placed, as this can affect their performance and longevity. Factors such as pollution levels, temperature variations, and mechanical stress should all be taken into account when choosing the right insulators for your power system.

Importance of Proper Maintenance for Power Line Insulators

Proper maintenance of power line insulators is essential to prolong their lifespan and optimize their performance. Regular inspections and cleaning can help identify any issues or damage early on, allowing for timely repairs or replacements to prevent potential disruptions in power transmission.

Spark Fittings' contribution to insulator production plays a significant role in enhancing the reliability and performance of power line insulators through quality equipment for manufacturing components like preformed armor rods and tension clamps. By utilizing high-quality products from Spark Fittings, customers can ensure efficient transmission and minimal downtime in their power systems.