Introduction

In the world of electrical infrastructure, understanding line construction material distribution is crucial for ensuring safety and efficiency. The backbone of this distribution lies in Pole Line Hardware, which encompasses a variety of components essential for maintaining reliable power delivery systems. This introduction serves to highlight the significance of these materials and their role in the broader context of cable accessories.

Understanding Line Construction Material Distribution

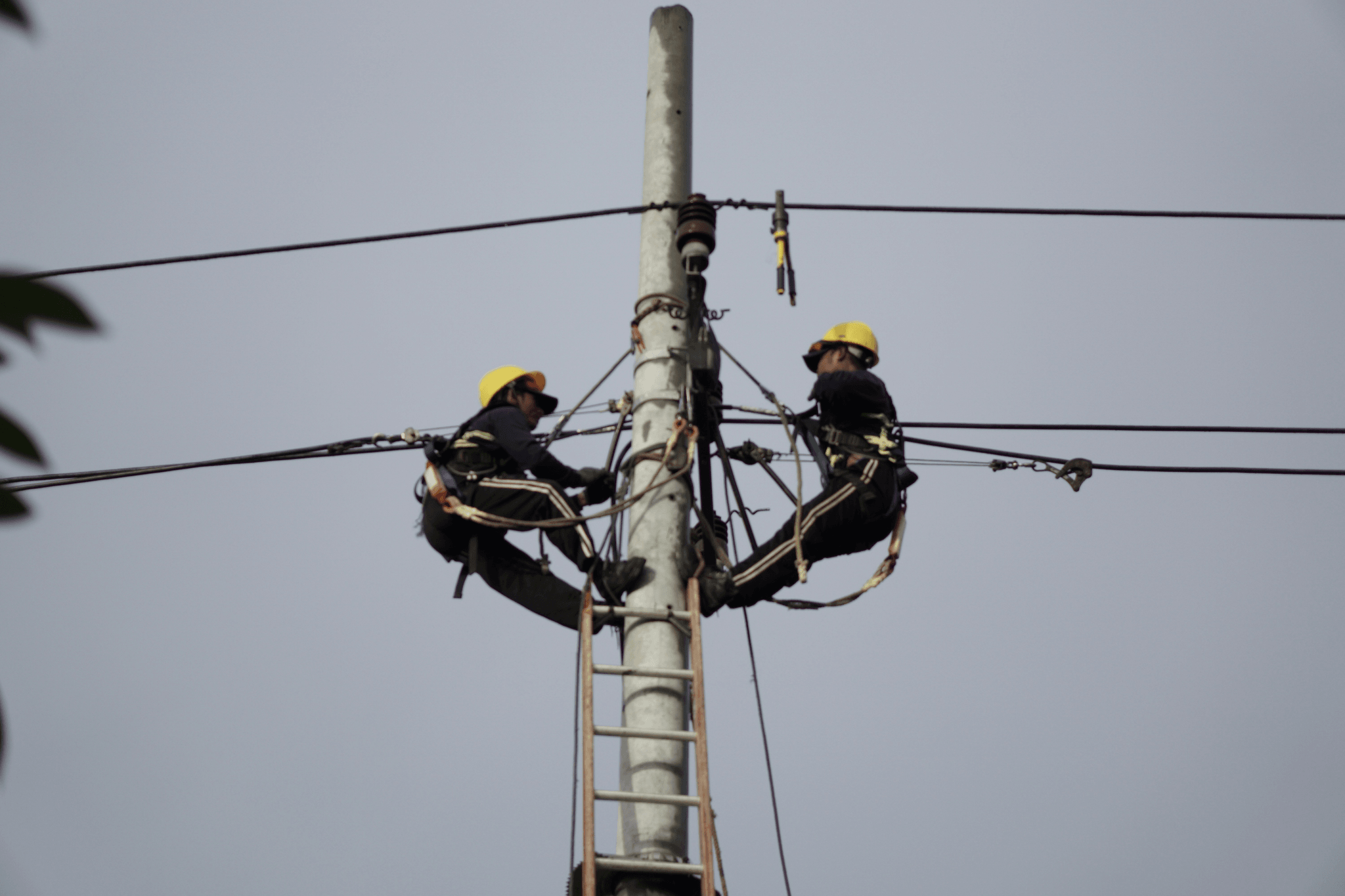

Line construction material distribution involves the systematic supply and management of various components necessary for constructing and maintaining power lines. This includes everything from cables to Pole Hardware & Accessories that support the entire structure. Proper understanding ensures that projects are completed on time, within budget, and adhere to safety standards.

Importance of Pole Line Hardware

Pole Line Hardware plays a pivotal role in supporting overhead power lines, ensuring they remain stable under various environmental conditions. High-quality hardware not only enhances the durability of installations but also minimizes maintenance costs over time. By investing in reliable Pole Line Hardware Accessories, utilities can enhance their operational efficiency while safeguarding against potential disruptions.

Overview of Cable Accessories

Cable accessories are integral components that complement pole line hardware by providing necessary functionalities such as insulation, protection, and connectivity for electrical cables. These accessories ensure seamless integration within the overall system while facilitating easy maintenance and upgrades when needed. Understanding the diverse range of cable accessories available can help stakeholders make informed decisions when selecting materials for line construction projects.

Essentials of Pole Line Hardware

When it comes to constructing and maintaining power lines, the importance of pole line hardware cannot be overstated. This hardware forms the backbone of any electrical distribution system, ensuring safety and reliability in delivering power. Understanding the essentials of pole line hardware is crucial for anyone involved in line construction or maintenance.

Types of Pole Hardware & Accessories

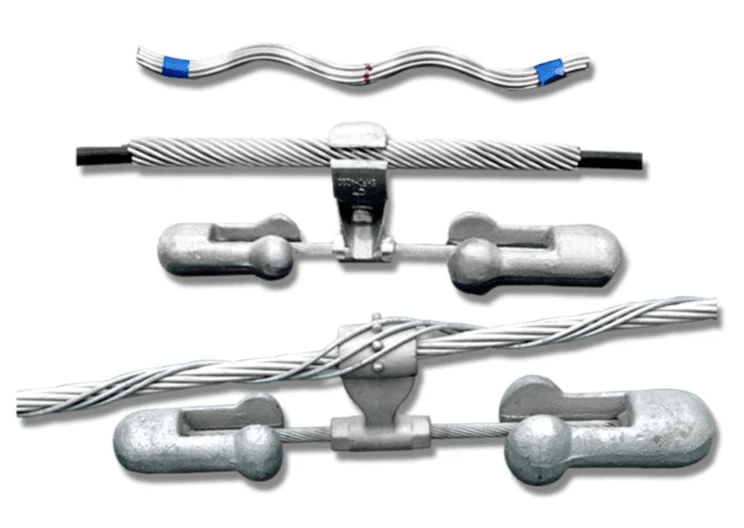

Pole hardware encompasses a variety of components designed to support overhead lines effectively. Common types include insulators, crossarms, brackets, and various fasteners that work together to secure wires and cables in place. Additionally, pole line hardware accessories such as grounding kits and protective covers play a vital role in enhancing system performance and safety.

In the realm of cable accessories, you'll find specialized connectors, splices, and terminations that ensure seamless integration between different sections of wiring. Each type serves a distinct purpose; for example, insulators prevent electrical leakage while connectors facilitate easy assembly and disassembly during maintenance. With so many options available from leading pole line hardware manufacturers like Spark Fittings, selecting the right components is essential for optimal performance.

Key Features of Quality Hardware

Quality pole line hardware should exhibit durability, corrosion resistance, and high tensile strength to withstand environmental stresses such as wind or ice loads. These key features ensure that the materials can endure harsh conditions without compromising safety or functionality over time. Moreover, reliable pole hardware & accessories are designed with precision engineering to provide a perfect fit during installation.

Another important aspect is ease of installation; quality hardware should come with clear instructions or pre-assembled parts that simplify setup processes for crews on-site. This efficiency not only saves time but also reduces labor costs associated with prolonged installations. When evaluating products from various pole line hardware manufacturers, it's crucial to look for certifications that guarantee adherence to industry standards.

Benefits of Using Reliable Materials

Investing in reliable materials for your pole line construction projects pays off significantly in terms of longevity and performance. High-quality pole line hardware minimizes the risk of failures such as breakages or malfunctions that could lead to costly outages or safety hazards down the road. Furthermore, dependable materials often require less frequent replacements or repairs—saving both time and money in long-term operational expenses.

Using trusted brands also enhances overall project credibility; clients are more likely to trust systems built with top-notch components from reputable manufacturers like Spark Fittings—known for their innovative cable accessories tailored for ADSS (All-Dielectric Self-Supporting) applications among others. Ultimately, choosing quality over cost when selecting your materials ensures peace-of-mind knowing you’ve taken steps toward safer installations.

Insights into Pole Line Hardware Manufacturers

In the world of line construction, understanding pole line hardware manufacturers is crucial for ensuring quality and reliability in projects. These manufacturers play a significant role in the production of pole hardware & accessories that are essential for effective distribution systems. By delving into their innovations and offerings, we can better appreciate how they contribute to the overall efficiency and safety of electrical infrastructure.

Leading Manufacturers and Their Innovations

Among the key players in the pole line hardware market, several manufacturers stand out due to their commitment to innovation and quality. Companies like Spark Fittings are renowned for their advanced manufacturing processes that focus on cable accessories designed for both traditional utilities and modern electrified railways. Their production of preformed armor rods and tension clamps exemplifies how cutting-edge technology can enhance the performance of pole hardware & accessories.

Moreover, other leading manufacturers have also embraced innovative materials that improve durability while reducing environmental impacts. By incorporating sustainable practices into their operations, these companies not only meet industry standards but also cater to a growing demand for eco-friendly solutions in line construction material distribution. The emphasis on innovation ensures that pole line hardware remains robust enough to withstand various environmental conditions while maintaining efficiency.

Comparison of Leading Brands

When comparing leading brands in the realm of pole line hardware manufacturers, several factors come into play, including product range, quality assurance processes, and customer support services. Some brands excel in offering a diverse array of pole line hardware accessories tailored for specific applications, while others may focus on niche products with specialized functions. This variety allows contractors to select materials that best fit their project requirements without compromising on quality.

Additionally, brand reputation plays a significant role in influencing purchasing decisions among contractors and utility companies alike. A manufacturer known for its reliable cable accessories will likely be favored over one with less consistent product performance records. Thorough research into customer reviews and case studies can help illuminate which brands consistently deliver high-quality products necessary for successful installations.

Enhancing Efficiency with Quality Suppliers

Choosing quality suppliers is paramount when it comes to enhancing operational efficiency within line construction projects involving pole line hardware & accessories. Reliable suppliers not only provide superior products but also offer valuable insights into best practices in installation techniques and maintenance strategies—an often-overlooked aspect that can significantly impact project longevity.

Furthermore, establishing strong relationships with reputable manufacturers ensures timely access to essential materials needed during peak construction periods or emergency repairs. This reliability fosters smoother workflows and minimizes downtime caused by equipment failures or supply chain disruptions—critical factors when dealing with electrical infrastructure where safety is paramount.

In conclusion, understanding the landscape of pole line hardware manufacturers—including leading innovators like Spark Fittings—can greatly influence project outcomes by ensuring access to high-quality materials tailored for specific needs within the industry.

The Role of Spark Fittings in Line Construction

In the world of line construction, Spark Fittings stands out as a crucial player, particularly in the realm of cable accessories and pole line hardware. Their innovative solutions not only enhance the efficiency of electrical transmission but also ensure that installations are safe and reliable. By focusing on high-quality materials and cutting-edge technology, Spark Fittings contributes significantly to the overall integrity of pole hardware & accessories.

Overview of Spark Fittings Contributions

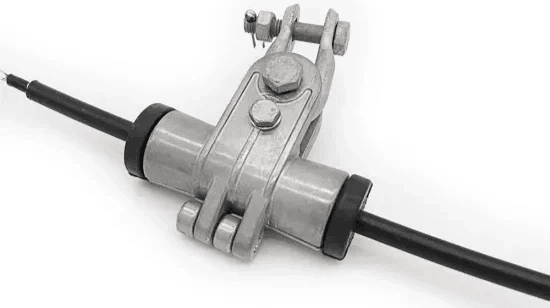

Spark Fittings plays a pivotal role in the line construction industry by providing specialized equipment designed for preformed armor rods, tension clamps, and various cable accessories. Their products are tailored for applications involving ADSS (All-Dielectric Self-Supporting) and OPGW (Optical Ground Wire), ensuring that electricity can be transmitted efficiently across vast distances. The company’s commitment to quality means that their pole line hardware accessories are not just functional but also durable, helping to reduce maintenance costs over time.

Key Products Offered by Spark Fittings

Among the standout offerings from Spark Fittings are their preformed armor rods, which provide excellent protection for overhead cables against environmental stressors. Tension clamps manufactured by them ensure secure connections between cables and poles, minimizing risks associated with sagging or breakage. Furthermore, their range of cable accessories is designed to facilitate easy installation while maintaining optimal performance levels—essential features when considering pole line hardware.

Real-World Applications of Spark Fittings

The applications of Spark Fittings' products can be seen across various sectors including utilities, telecommunications, and electrified railways. For instance, their tension clamps play a vital role in securing overhead power lines in urban environments where space is limited yet reliability is paramount. Additionally, as cities expand and electrification projects grow more complex, incorporating high-quality cable accessories from trusted pole line hardware manufacturers like Spark Fittings becomes increasingly essential for successful project outcomes.

Selecting the Right Line Construction Material

Choosing the right line construction material is a critical step in ensuring the reliability and longevity of electrical distribution systems. The selection process involves evaluating various factors, including material properties, compatibility with existing infrastructure, and specific application needs. Understanding these elements can significantly impact the overall performance of Pole Line Hardware and its accessories.

Factors to Consider when Choosing Materials

When selecting materials for line construction, several key factors come into play. First, one must consider the environmental conditions where the Pole Hardware & Accessories will be installed; factors like temperature fluctuations, humidity levels, and exposure to corrosive substances can affect material performance. Additionally, assessing the mechanical strength required for different applications ensures that chosen materials can withstand operational stresses while maintaining safety standards.

Another crucial aspect is compatibility with existing Pole Line Hardware and accessories. Materials should seamlessly integrate with current systems to avoid complications during installation or maintenance. Finally, understanding local regulations regarding electrical installations can guide decisions on suitable materials that comply with safety codes and standards.

The Impact of Quality on Longevity

Quality plays a pivotal role in determining how long construction materials will last under various operating conditions. High-quality Pole Line Hardware typically exhibits superior resistance to wear and tear compared to lower-grade alternatives; this durability translates into reduced maintenance costs over time. Investing in reliable cable accessories not only enhances performance but also minimizes disruptions caused by equipment failure.

Moreover, quality materials often feature advanced manufacturing processes that improve their structural integrity and performance characteristics. For instance, products from reputable Pole line hardware manufacturers undergo rigorous testing to ensure they meet industry standards before reaching consumers. This attention to detail results in longer-lasting solutions that provide peace of mind throughout their operational lifespan.

Balancing Cost and Quality

While it may be tempting to opt for cheaper alternatives when selecting line construction materials, it’s essential to strike a balance between cost-effectiveness and quality assurance. Lower-priced options might save money upfront but often lead to higher long-term expenses due to frequent replacements or repairs of inferior Pole Hardware & Accessories. Therefore, investing in high-quality cable accessories becomes a wise financial decision over time.

Furthermore, evaluating total cost ownership is crucial; this approach considers not just purchase price but also maintenance costs associated with each option over its lifecycle. By prioritizing quality from reputable suppliers like Spark Fittings—known for manufacturing top-notch preformed armor rods and tension clamps—customers can enhance both functionality and longevity while avoiding hidden costs down the road.

In conclusion, selecting the right line construction material requires thoughtful consideration of various factors including environmental conditions, compatibility with existing systems, quality assurance measures from manufacturers like Spark Fittings that specialize in cable accessories—and ultimately finding an ideal balance between cost efficiency without compromising on reliability or safety standards.

Trends in Line Construction Material Distribution

The landscape of line construction material distribution is evolving rapidly, driven by technological advancements and a growing focus on sustainability. As industries recognize the importance of reliable Pole Line Hardware and accessories, manufacturers are innovating to meet the demands of modern infrastructure. This section explores emerging technologies, sustainability efforts, and future directions for cable accessories in the market.

Emerging Technologies in Hardware Distribution

Emerging technologies are transforming how Pole Hardware & Accessories are distributed, making processes more efficient and user-friendly. Digital platforms are streamlining inventory management and order fulfillment, allowing customers to access a wider range of Pole Line Hardware with ease. Innovations such as automated warehousing and AI-driven supply chain solutions enhance accuracy while reducing lead times for essential cable accessories.

Moreover, manufacturers like Spark Fittings are leveraging advanced machinery to produce high-quality pole line hardware that meets stringent industry standards. By adopting cutting-edge technologies, these companies can ensure that their products, including cable accessories for ADSS and OPGW systems, remain competitive in a rapidly changing market. The integration of smart technology not only improves operational efficiency but also enhances customer satisfaction through timely deliveries and superior product quality.

Sustainability in Pole Line Hardware

Sustainability has become a crucial consideration for manufacturers of Pole Line Hardware Accessories as environmental concerns rise globally. Companies are increasingly focusing on sourcing materials responsibly and minimizing waste throughout the production process. Innovations such as recyclable materials and eco-friendly manufacturing practices contribute to reducing the carbon footprint associated with line construction.

Additionally, sustainable practices extend beyond manufacturing; they also encompass distribution methods that prioritize energy efficiency and reduced emissions. Leading pole line hardware manufacturers are now investing in green logistics solutions to ensure that their products reach customers with minimal environmental impact. As consumers become more conscious of sustainability issues, having eco-friendly cable accessories can significantly enhance brand reputation while meeting regulatory requirements.

Future Directions for Cable Accessories

Looking ahead, the future of cable accessories is poised for exciting developments driven by both technological advancements and evolving market needs. Manufacturers will likely focus on creating smarter products that integrate seamlessly with existing infrastructure while enhancing performance through improved design features. This includes innovations aimed at increasing durability and reliability in harsh environments where pole line hardware is deployed.

Furthermore, collaboration among industry stakeholders will play a vital role in shaping the future landscape of pole line hardware distribution—enabling knowledge sharing about best practices related to installation techniques or maintenance protocols for cable accessories. As trends shift towards greater customization options tailored to specific project requirements, suppliers must be agile enough to adapt their offerings accordingly while maintaining high-quality standards synonymous with leading brands like Spark Fittings.

In conclusion, staying ahead in line construction material distribution requires an understanding of emerging technologies alongside a commitment to sustainability—ensuring that both current needs and future challenges are addressed effectively through innovative solutions.

Conclusion

In the realm of line construction, the significance of quality hardware cannot be overstated. The reliability and durability of Pole Line Hardware directly influence the overall performance and safety of electrical distribution systems. Investing in superior Pole Hardware & Accessories ensures that projects are not only completed efficiently but also stand the test of time.

The Impact of Quality Hardware

Quality hardware serves as the backbone for any successful line construction project. When you choose high-grade Pole Line Hardware, you’re essentially choosing longevity and resilience, which are crucial for maintaining operational integrity over years of service. Moreover, using top-tier materials reduces maintenance costs and minimizes downtime, allowing for smoother operations in the long run.

Choosing the Right Manufacturers

Selecting reputable Pole line hardware manufacturers is vital for ensuring that you receive dependable products tailored to your specific needs. Leading brands often invest in research and development to innovate their offerings, making them a smart choice for contractors looking to enhance their projects' efficiency. By partnering with trusted manufacturers like Spark Fittings, known for their high-quality cable accessories and pole hardware solutions, you can feel confident in your material choices.

Final Thoughts on Line Construction Essentials

In summary, understanding the essentials surrounding line construction materials is key to achieving successful outcomes in any project. From selecting reliable Pole Line Hardware Accessories to staying updated on industry trends, every decision impacts performance and safety standards. Ultimately, prioritizing quality over cost can lead to substantial benefits in both immediate project execution and long-term operational success.