Introduction

When it comes to the efficient and safe distribution of electricity, understanding overhead power line components is crucial. From conductors and insulators to crossarms and hardware, each part plays a vital role in ensuring the reliable transmission of power. Overhead Power Line and Components are essential for delivering electricity from generating stations to consumers, making it important to comprehend their structure and function. Exploring Power Line Accessories further enhances the understanding of how these components work together to provide electricity to homes, businesses, and industries.

Understanding Overhead Power Line Components

Overhead power lines are designed with specific hardware to withstand various weather conditions and environmental factors. For example, conductors are typically made of aluminum or copper to ensure optimal electrical conductivity, while insulators are often made of materials like porcelain or glass to provide insulation and prevent electricity from leaking out. Additionally, crossarms are strategically placed along the length of the power line to support the conductors and maintain their spacing, ultimately contributing to the overall stability and functionality of the system.

Importance of Overhead Power Line Hardware

Power Line Hardware is essential for securing and supporting overhead power line components. Clamps, connectors, and grounding equipment are crucial in ensuring the stability and reliability of power lines.

Power line accessories such as insulators and cross arms are also crucial in maintaining the integrity of overhead power lines. Insulators prevent the flow of electricity to the supporting structures, while cross arms provide additional support for the conductors. These accessories work in conjunction with hardware to ensure that power lines remain secure and functional, even in adverse weather conditions.

Exploring Power Line Accessories

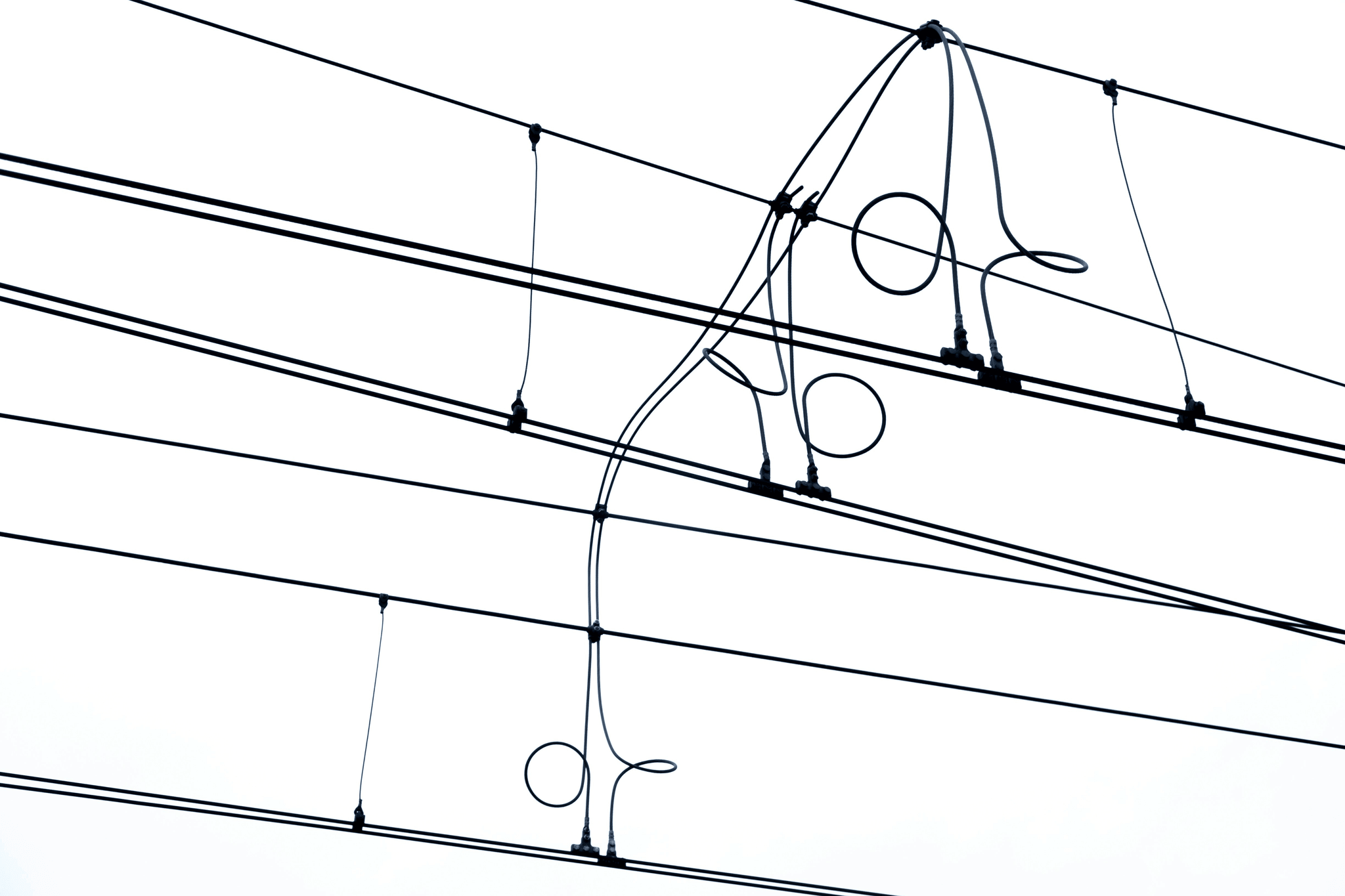

Overhead Power Line Accessories such as bird deterrents, warning markers, and spark fittings contribute to enhancing safety measures and protecting the integrity of power lines against environmental factors. In addition to these essential accessories, the use of vibration dampers can also play a crucial role in maintaining the stability of power lines during adverse weather conditions. These dampers absorb and dissipate the energy generated by wind-induced vibrations, reducing stress on the power line conductors and supporting structures.

Overhead Power Line Structure

When it comes to understanding overhead power line components, it's essential to grasp the structure of the lines themselves. The main components of overhead power lines include conductors, insulators, and crossarms. These elements work together to ensure the safe and efficient transmission and distribution of electricity.

Conductors

Conductors are the essential part of an overhead power line, as they carry the electrical current from one point to another. Typically made of aluminum or copper, these conductive materials are carefully chosen for their ability to efficiently transport electricity over long distances without significant power loss.

Insulators

Insulators play a crucial role in maintaining the integrity of overhead power lines by preventing electrical current from escaping and causing damage or injury. These components are typically made of materials such as glass or ceramic, providing a barrier between the conductor and the supporting structure.

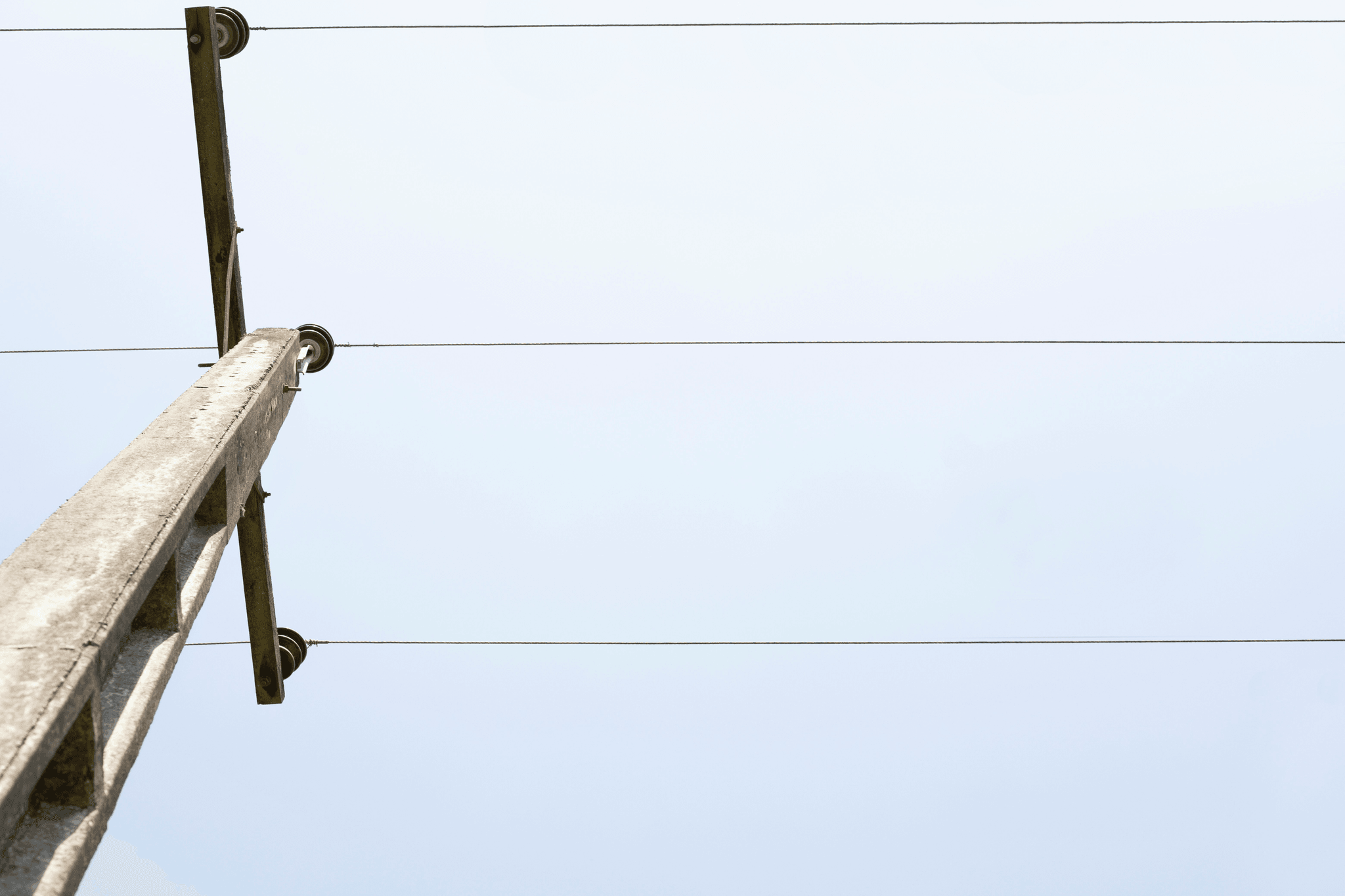

Crossarms

Crossarms serve as support structures for conductors and insulators, ensuring that they are properly spaced and secured along the length of the power line. These horizontal bars are commonly made from wood or metal and are strategically positioned to maintain the stability and functionality of the entire system.

In conclusion, understanding overhead power line components such as conductors, insulators, and crossarms is crucial for ensuring efficient transmission and distribution of electricity. By recognizing the importance of these elements in maintaining a safe and reliable power grid, we can work towards enhancing overall system performance while prioritizing safety measures for workers and communities alike.

Power Line Hardware

When it comes to overhead power line components, power line hardware plays a crucial role in ensuring the stability and functionality of the entire system. Clamps are essential components that secure conductors to the crossarms and ensure proper tension. These clamps come in various designs and materials, such as aluminum or steel, to accommodate different types of conductors and environmental conditions.

Clamps

Clamps are designed to withstand extreme weather conditions and provide a secure grip on the conductors. They are typically made of durable materials like aluminum or steel to prevent corrosion and ensure long-term reliability. The design of the clamp is tailored to the specific type and size of the conductor, providing a snug fit that prevents slippage or damage during operation.

In addition to their durability and secure grip, clamps are also designed with ease of installation in mind. Many clamps feature a quick and simple installation process, allowing for efficient deployment in the field. This saves time and labor costs, making them a practical choice for various applications. Additionally, the design of the clamp ensures that it can be easily adjusted or removed as needed, providing flexibility for maintenance or reconfiguration.

Connectors

Connectors play a crucial role in maintaining the integrity of the power distribution network by enabling the smooth and efficient transfer of electricity between various components. Compression connectors, for example, are known for their high conductivity and ability to withstand high temperatures, making them ideal for use in areas with heavy electrical loads. On the other hand, mechanical connectors provide a reliable and durable connection that is well-suited for applications where vibration and movement may be a concern, such as in overhead transmission lines. The choice of connector type depends on factors such as environmental conditions, voltage levels, and the specific requirements of the power line infrastructure.

Grounding Equipment

Grounding equipment is essential for protecting both the power line infrastructure and personnel from electrical faults or lightning strikes. It provides a path for excess electrical current to safely dissipate into the ground, preventing damage to equipment and minimizing safety hazards for workers and nearby residents. Grounding equipment includes ground rods, clamps, wires, and other specialized components designed to ensure effective grounding.

Transmission and Distribution Equipment

When it comes to overhead power line components, transmission and distribution equipment play a crucial role in ensuring the efficient flow of electricity. Transformers are essential for stepping up or stepping down voltage levels, switches help control the flow of electricity through different circuits, and circuit breakers protect the system from overloads and short circuits. These components work together to maintain a reliable power supply to homes and businesses.

Transformers

Transformers are vital components of overhead power lines, responsible for changing the voltage levels to facilitate efficient transmission and distribution of electricity. Step-up transformers increase voltage for long-distance transmission, while step-down transformers lower voltage for safe distribution to homes and businesses. With their ability to regulate voltage levels, transformers are indispensable in maintaining a stable power supply across various distances.

Switches

Switches are integral parts of overhead power line structures, allowing operators to control the flow of electricity through different circuits. By opening or closing electrical pathways, switches enable the rerouting of power during maintenance or repairs, as well as the isolation of faulty sections to prevent widespread outages. Their versatility in managing electrical currents is essential for ensuring a reliable supply of electricity.

Switches play a crucial role in maintaining the stability and reliability of the electrical grid. By allowing operators to control the flow of electricity through different circuits, switches enable seamless rerouting of power during maintenance or repairs. This flexibility ensures that any disruptions in the system can be quickly addressed without causing widespread outages, ultimately contributing to a more resilient power infrastructure.

Circuit Breakers

Circuit breakers serve as protective devices within overhead power line systems, interrupting the flow of electricity when an overload or short circuit occurs. By quickly disconnecting faulty circuits, circuit breakers prevent damage to equipment and minimize downtime due to electrical faults. Their ability to safeguard against electrical hazards makes them indispensable components in maintaining a safe and efficient power distribution network.

Circuit breakers are designed to detect and respond to electrical faults in a matter of milliseconds, ensuring that any potential damage is minimized. This rapid response time is crucial in preventing fires and other hazardous situations that can arise from overloaded circuits. Additionally, the versatility of circuit breakers allows for easy integration into various power distribution systems, making them a reliable and adaptable solution for safeguarding against electrical hazards.

Safety and Protective Gear

When it comes to ensuring the safety of overhead power lines, the use of bird deterrents is crucial in preventing avian-related incidents. These deterrents are designed to discourage birds from perching or nesting on power line structures, minimizing the risk of electrical outages and potential harm to the birds themselves.

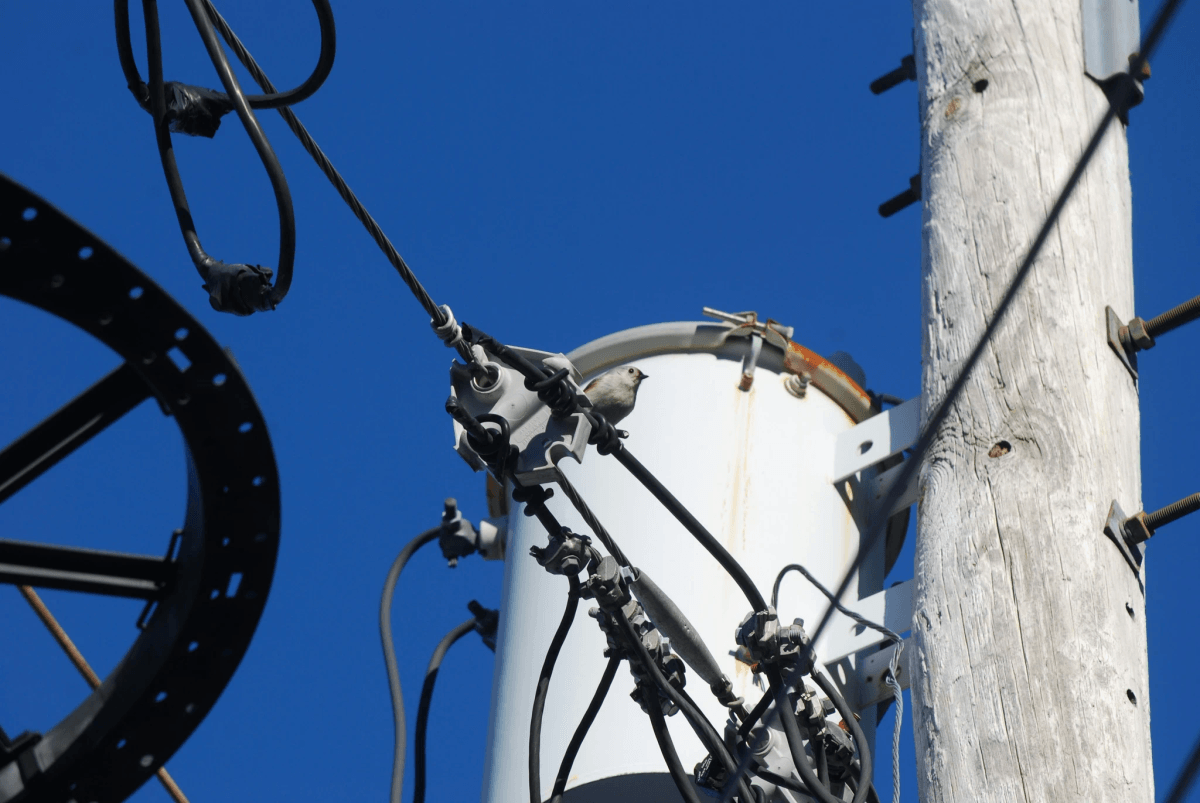

Bird Deterrents

Bird deterrents such as spikes, coils, and wires are commonly used to create an inhospitable environment for birds on overhead power line components. By installing these devices strategically along the power line structures, utility companies can significantly reduce the likelihood of bird-related issues while maintaining uninterrupted power supply for consumers.

Warning Markers

Warning markers are essential safety features that alert both aerial and ground-based workers about the presence of overhead power lines. These highly visible markers serve as a visual warning to prevent accidental contact with the lines during construction, maintenance, or any other activities near the power line structures.

Spark Fittings

Spark fittings play a vital role in safeguarding overhead power lines by providing effective protection against electrical arcing and sparking. These fittings are crucial components that help maintain the integrity of the power line system, minimizing potential fire hazards and ensuring reliable electricity transmission.

Maintenance and Inspection

When it comes to overhead power line components, maintenance and inspection are crucial for ensuring safety and reliability. Corrosion prevention is a key aspect of maintenance, as it helps to protect conductors, insulators, and other hardware from deterioration. Regular inspections and proactive measures can help identify and address corrosion issues before they escalate.

Corrosion Prevention

Corrosion prevention involves the use of protective coatings, such as zinc or aluminum, on metal components to shield them from environmental factors. Additionally, regular cleaning and maintenance can help remove corrosive substances like salt or pollutants that may accumulate on the equipment. By implementing effective corrosion prevention strategies, the lifespan of overhead power line components can be significantly extended.

Line Monitoring

Monitoring the condition of overhead power line components is essential for identifying potential issues early on. Advanced technologies like drones equipped with high-resolution cameras allow for thorough inspections of power lines, while sensors can provide real-time data on temperature, vibration, and other indicators of component health. By leveraging these monitoring tools, maintenance teams can stay ahead of potential problems and ensure the continued reliability of power lines.

Environmental Impact

The environmental impact of overhead power line components is an important consideration in maintenance efforts. Sustainable practices such as using eco-friendly coatings for corrosion prevention and minimizing waste during maintenance activities can help mitigate the impact on the environment. Additionally, proper disposal of old or damaged components is crucial for reducing environmental harm.

Now that we've explored the importance of maintenance and inspection in preserving overhead power line components, it's evident that proactive measures are essential for ensuring safety and reliability in electrical transmission systems. With a focus on corrosion prevention, effective line monitoring, and minimizing environmental impact, we can work towards enhancing the longevity and sustainability of our power infrastructure.

Conclusion

Overhead power line components play a crucial role in ensuring the safe and efficient transmission of electricity. From conductors to insulators, each part of the power line structure is essential for maintaining the integrity of the system. Regular maintenance is key to preventing outages and ensuring public safety around power lines. Additionally, innovations in power line technology continue to improve the reliability and performance of overhead power lines.

Enhancing Overhead Power Line Safety

Ensuring the safety of overhead power lines requires a comprehensive understanding of all components involved. By investing in high-quality hardware and accessories, such as bird deterrents and warning markers, utility companies can minimize risks and protect both workers and the public from potential hazards. Implementing proper grounding equipment and spark fittings can also help mitigate the risk of electrical fires and other accidents.

Importance of Regular Maintenance

Regular maintenance is essential for prolonging the lifespan of overhead power line components and preventing costly disruptions in service. Corrosion prevention measures, such as protective coatings and periodic inspections, are critical for preserving the structural integrity of conductors, insulators, and other hardware. Line monitoring technologies provide real-time data on system performance, enabling proactive maintenance to address potential issues before they escalate.

Innovations in Power Line Technology

Advancements in power line technology continue to drive improvements in efficiency, reliability, and safety within the industry. From smart grid systems that optimize energy distribution to innovative materials that enhance conductor performance, ongoing research and development are reshaping the future of overhead power lines. As utility companies embrace these innovations, they can deliver more reliable service while minimizing environmental impact.