Introduction

Understanding the Importance of Stability

Stability is a cornerstone of any construction project, especially when it involves tall or heavy structures that require additional support. Guy wire grips are designed specifically to provide this necessary support by securing guy wires effectively. By utilizing products like Big Grip Dead Ends or Guy Wire Dead End Grips, engineers can significantly enhance the structural integrity and longevity of their projects.

Exploring Different Types of Guy Wire Grips

The market offers a variety of guy wire grips tailored for different applications and requirements. From standard grips to specialized options like Big Grip Dead Ends, each type serves a unique function in stabilizing structures. Understanding these differences can help you choose the right grip for your specific needs, ensuring optimal performance and safety.

The Role of Spark Fittings in Stability

Spark Fittings stands out as a leading manufacturer specializing in equipment for preformed armor rods, tension clamps, and cable accessories used in transmission systems. Their products are integral to achieving high-quality stability solutions like preformed guy grip dead ends that cater to various electrical infrastructure needs. By investing in reliable fittings from Spark Fittings, you ensure that your guy wire grip systems are not only effective but also durable over time.

What is a Guy Wire Grip?

A guy wire grip is a crucial component in the world of telecommunications and utility pole installations, providing essential support and stability to overhead lines. These grips are designed to securely hold guy wires, which are tensioned cables that help stabilize structures like poles and towers. Understanding the function and types of guy wire grips can greatly enhance the safety and efficiency of your projects.

Definition and Function

At its core, a guy wire grip is a device that attaches to a guy wire, allowing it to maintain tension while securing it in place. This function is vital as it prevents any slack in the wire, ensuring that structures remain upright and stable under various weather conditions. Without an effective guy wire grip, the integrity of utility poles or communication towers could be compromised, leading to potential failures or hazards.

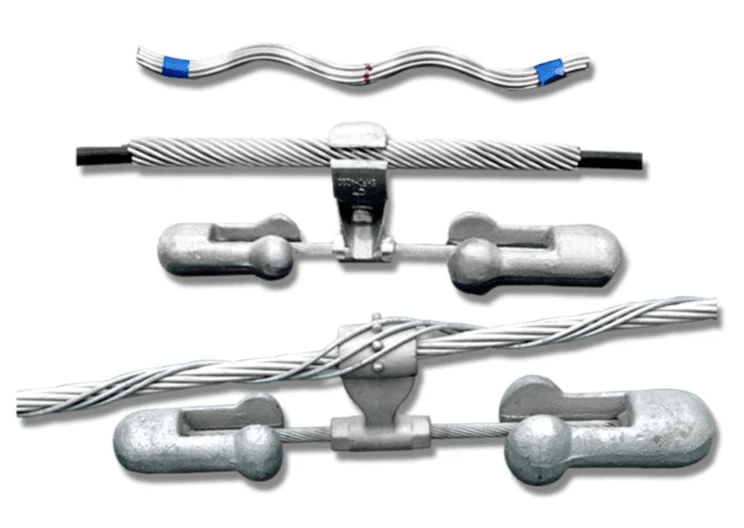

Types of Guy Wire Grips

There are several types of guy wire grips available on the market, each designed for specific applications and environments. One popular option is the Big Grip Dead End, which provides maximum stability by distributing loads evenly across larger areas. Another type includes Guy Wire Dead End Grips, which are specifically engineered for anchoring purposes in various installations.

Additionally, pulling grips for wire play an essential role when installing new lines or replacing existing ones; they facilitate smooth handling during installation processes. Each type varies not only in design but also in size—guy wire grip sizes can significantly impact their effectiveness depending on the application at hand.

Applications in the Field

Guy wire grips find their applications across multiple sectors including telecommunications, power distribution, and construction industries. For instance, they are commonly used in securing telephone poles or radio towers where stability is paramount due to environmental pressures like wind or snow load. Furthermore, understanding what is the difference between guy wire and stay wire can help professionals choose appropriate systems based on their project requirements.

In addition to this distinction between wires—such as what is the difference between wire rope and guy wire?—the right choice of grip ensures not only safety but also longevity of installations under various operational stresses. Spark Fittings stands out as a preformed guy grip dead end manufacturer known for high-quality products that meet industry standards for durability and reliability.

Big Grip Dead Ends: A Closer Look

Big Grip Dead Ends are an essential component in the world of guy wire grips, providing robust solutions for stabilizing structures like towers and poles. These grips are designed to securely anchor guy wires, ensuring that they can withstand significant tension and environmental challenges. Understanding how these grips function is crucial for anyone involved in construction or maintenance of overhead lines.

Overview of Big Grip Dead Ends

Big Grip Dead Ends are specialized devices used to terminate guy wires effectively. They feature a preformed design that allows them to grip the wire securely without slipping, making them ideal for high-stress applications. When installed correctly, Big Grip Dead Ends provide a reliable connection point that enhances overall stability in various projects.

Benefits for Maximum Stability

One of the primary benefits of using Big Grip Dead Ends is their ability to distribute loads evenly across the wire, which significantly reduces stress on both the wire and the anchoring structure. This feature is particularly important when considering factors such as wind load and ice accumulation, which can compromise stability if not properly managed. Additionally, these grips help prevent wear and tear on guy wires over time, making them a cost-effective choice for long-term use.

Choosing the Right Grip for Your Needs

Selecting the right Big Grip Dead End involves understanding your specific project requirements and conditions. Factors such as wire size, environmental conditions, and load specifications play critical roles in determining which grip will provide optimal performance. Consulting with manufacturers like Spark Fittings can help you identify appropriate options tailored to your needs while ensuring compliance with industry standards.

Guy Wire Dead End Grips Explained

Guy wire dead end grips are essential components in ensuring the stability and integrity of structures that rely on guy wires for support. These grips securely anchor the ends of guy wires, preventing slippage and providing a robust connection that can withstand environmental stresses. Understanding how these grips function is crucial for anyone involved in installation or maintenance of tensioned wire systems.

How Guy Wire Dead End Grips Work

Guy wire dead end grips operate by utilizing a series of tapered strands that conform tightly to the wire as tension is applied. This design allows them to effectively grip the wire without causing damage, distributing load evenly across the surface area. When installed correctly, they ensure that the forces acting on the guy wire do not compromise its structural integrity, which is vital for maintaining stability in various applications.

The gripping mechanism relies on friction and mechanical interlock to secure the guy wire in place. As tension increases, these features enhance their hold, making them reliable under significant loads. This functionality distinguishes Guy Wire Dead End Grips from other types of grips, emphasizing their importance in construction and utility projects where stability is paramount.

Comparing with Other Grip Types

When comparing Guy Wire Dead End Grips with other grip types, such as Big Grip Dead Ends or standard cable clamps, several factors come into play regarding performance and application suitability. While Big Grip Dead Ends offer enhanced strength for larger cables or extreme conditions, Guy Wire Dead End Grips are specifically designed for optimal performance with standard-sized guy wires. This targeted design makes them a preferred choice when precise anchoring is necessary.

Another key distinction lies in installation ease; Guy Wire Dead End Grips often require less adjustment than other grip types due to their straightforward design and effective gripping action. In contrast, some alternative grip solutions may necessitate more complex setups or additional components to achieve similar levels of security and stability. Ultimately, choosing between these options depends on specific project requirements and environmental factors.

Best Practices for Installation

To ensure maximum effectiveness when installing Guy Wire Dead End Grips, following best practices is crucial. First and foremost, it's essential to choose the correct size from available guy wire grip sizes; using an improperly sized grip can lead to failure under load conditions. Additionally, always inspect both the grip and the associated hardware before installation to confirm they are free from defects or wear.

Proper alignment during installation also plays a critical role in achieving optimal performance; misaligned grips can lead to uneven load distribution and potential failure points over time. It's advisable to consult manufacturer guidelines—such as those provided by Spark Fittings—to understand specific recommendations related to installing preformed products like dead end grips effectively. Lastly, regular maintenance checks will help ensure long-term reliability by identifying any issues before they escalate into serious problems.

What is the Difference Between Guy Wire and Stay Wire?

Definitions and Applications

Guy wire, often referred to as a guy line or tether, is a tensioned cable that supports a vertical structure by anchoring it to the ground or another structure. It plays a vital role in maintaining structural integrity, particularly for tall installations like radio towers or utility poles. On the other hand, stay wire is typically used to provide lateral support for structures such as masts or antennas; it helps resist sideways forces that could lead to instability.

Both wires can be equipped with various components like Big Grip Dead Ends or Guy Wire Dead End Grips for enhanced stability. These fittings ensure that the wires remain securely attached while accommodating tension changes over time. Understanding these applications helps in selecting the appropriate type of wire based on specific structural requirements.

Key Differences in Usage

The primary difference between guy wire and stay wire lies in their application: guy wires are primarily vertical supports while stay wires are horizontal stabilizers. Guy wires tend to be more robust due to the significant forces they need to withstand when supporting tall structures; hence they often require larger guy wire grip sizes for effective anchoring. Conversely, stay wires usually experience less tension since they counteract lateral forces rather than vertical loads.

In terms of installation practices, using Pulling Grips for Wire can facilitate easier handling of both types of cables but may differ based on their specific characteristics and required tensions. For instance, installing Big Grip Dead Ends on guy wires demands careful attention due to their critical role in maintaining overall stability compared to stay wires which might not require such robust fittings.

Choosing the Right Wire for Your Project

When selecting between guy wire and stay wire for your project, consider factors such as load requirements, environmental conditions, and structural design specifications. If you're working on a tall structure that requires significant vertical support, opting for a high-quality guy wire with appropriate grips—like Guy Wire Dead End Grips—will be essential for ensuring stability under load conditions.

Conversely, if your project involves lateral stabilization—such as with masts—you'll want to focus on choosing suitable stay wires that meet your project's specific needs without oversizing them unnecessarily.

Additionally, consulting with manufacturers like Spark Fittings can provide insights into choosing preformed products tailored specifically for either type of wiring system you plan on using; this ensures you have reliable equipment designed specifically for optimal performance under varying conditions.

Guy Wire Grip Sizes and Their Importance

Finding the Right Size for Your Needs

To find the right size of a guy wire grip, you must first consider the specifications of your project. The diameter of the wire being used is essential; using a grip that fits snugly around your guy wire ensures optimal performance. Additionally, factors such as environmental conditions and load requirements should influence your choice, as they may affect how much tension your guy wire grip will need to withstand.

Common Sizes Available

Guy wire grips come in various sizes to accommodate different diameters of wires and cables. Common sizes typically range from 1/4 inch up to 1 inch or more, catering to both light-duty and heavy-duty applications. For specialized needs, manufacturers like Spark Fittings offer custom solutions through their preformed guy grip dead end manufacturing process.

How Size Impacts Stability

The size of a guy wire grip directly impacts its ability to maintain stability under load. A properly sized grip ensures that there is sufficient contact area with the cable, allowing for maximum friction and resistance against slippage. Conversely, an oversized or undersized grip can lead to failure points; thus understanding what is the difference between wire rope and guy wire? becomes critical when selecting grips for specific applications.

Pulling Grips for Wire: An Essential Tool

What Are Pulling Grips?

Pulling grips are devices that attach to wire or cable, allowing for effective handling and tensioning during installation processes. They are typically made from durable materials that can withstand significant force while maintaining a secure grip on the wire. When you ask yourself, What is the difference between guy wire and stay wire? remember that pulling grips can be tailored to suit various types of wires, including both guy wires and stay wires.

How They Assist in Stability

The primary function of pulling grips is to provide a stable connection point when tensioning cables or wires. By securely holding onto the wire, they help maintain alignment and reduce the risk of slippage during installation, which is critical when using Guy Wire Dead End Grips or Big Grip Dead Ends. This stability not only ensures proper setup but also contributes to long-term structural integrity by minimizing wear on equipment caused by improper tensioning.

Best Brands and Recommendations

When selecting pulling grips for your project, it's essential to choose reliable brands known for quality and durability. Spark Fittings stands out as a leading manufacturer specializing in preformed products like armor rods and tension clamps—ideal companions for your pulling grips needs. Additionally, look into other reputable companies that offer a range of sizes suitable for different guy wire grip sizes; this ensures you find the perfect fit for your specific applications.

Conclusion

In summary, guy wire grips are essential components in ensuring structural stability across various applications. Understanding the different types, such as Big Grip Dead Ends and Guy Wire Dead End Grips, can significantly impact your project's success. By choosing the right equipment and grip sizes, you can enhance safety and performance in your installations.

Key Takeaways on Guy Wire Grips

Guy wire grips serve a critical function in stabilizing structures like towers and poles. Big Grip Dead Ends provide maximum stability by securely anchoring guy wires, while Guy Wire Dead End Grips offer reliable solutions for various applications. Familiarity with the differences between guy wire and stay wire is vital for selecting the appropriate grip for your specific needs.

The Importance of Choosing Quality Equipment

When it comes to guy wire grips, quality matters immensely; subpar equipment can lead to failures that jeopardize safety. Spark Fittings stands out as a preformed guy grip dead end manufacturer known for producing high-quality products that meet industry standards. Investing in reliable pulling grips for wire ensures you have durable solutions that withstand environmental challenges.

Final Thoughts on Stability Solutions

Stability is paramount in construction and telecommunications sectors, making the proper selection of guy wire grip sizes crucial to maintaining structural integrity. Understanding what is the difference between wire rope and guy wire will help you make informed decisions about your project requirements. Ultimately, prioritizing quality equipment from reputable manufacturers like Spark Fittings will lead to successful outcomes and peace of mind.