Introduction

When it comes to the installation and maintenance of utility poles, the quality of pole line hardware and fasteners is crucial. From eye nuts to screws & bolts, every component plays a vital role in ensuring the safety and reliability of utility pole fittings. Understanding the importance of high-quality custom fastener manufacturers is essential for the longevity and performance of these structures. Utility pole bolts, in particular, are key components that require precision and durability to withstand various environmental factors.

Introduction to Pole Line Hardware and Fasteners

Pole line hardware refers to the various components used in the construction and maintenance of utility poles, including eye nuts, screws, bolts, and other fasteners. These elements are essential for securing conductors, insulators, cross arms, and other equipment to the pole structure.

Importance of High-Quality Custom Fastener Manufacturer

The significance of partnering with a high-quality custom fastener manufacturer cannot be overstated when it comes to pole line hardware. Custom fasteners are designed with precision to meet specific requirements for utility pole applications, ensuring safety, reliability, and longevity.

Understanding the Role of Utility Pole Bolts

Utility pole bolts are critical for securing cross arms and other hardware to the pole structure. They play a crucial role in maintaining the integrity and stability of utility poles in various weather conditions.

The Significance of Custom Fastener Manufacturer

When it comes to Pole Line Hardware, the significance of a custom fastener manufacturer cannot be overstated. These manufacturers play a crucial role in providing high-quality fasteners that are essential for the safety and reliability of utility poles. By understanding the importance of using high-quality fasteners, it becomes clear that custom fastener manufacturers are instrumental in ensuring the integrity of pole line hardware.

Importance of Using High-Quality Fasteners

High-quality fasteners are essential for the stability and longevity of utility poles. Custom fastener manufacturers produce specialized fasteners that are designed to withstand the unique demands placed on pole line hardware. These fasteners undergo rigorous testing to ensure their strength and durability, making them crucial for maintaining the safety and reliability of utility poles.

High-quality fasteners also play a crucial role in preventing costly and dangerous pole failures. By using fasteners specifically designed for the unique demands of utility poles, the risk of hardware failure due to corrosion, vibration, or extreme weather conditions is significantly reduced. This helps utility companies avoid the expense and inconvenience of emergency repairs and ensures that the poles can continue to provide reliable service to customers without interruption.

Ensuring Safety and Reliability in Pole Line Hardware

The use of high-quality fasteners from custom manufacturers is paramount in ensuring the safety and reliability of pole line hardware. These specialized fasteners provide secure fittings that can withstand environmental factors such as wind, rain, and temperature fluctuations. By utilizing these top-notch fasteners, utility companies can have confidence in the stability and resilience of their pole line hardware.

Furthermore, the use of high-quality fasteners also reduces the risk of hardware failure, which can lead to costly repairs and potential safety hazards. These custom fasteners are designed to provide a precise fit and maximum strength, ensuring that utility pole guy wires remain securely in place. This level of reliability is essential for maintaining uninterrupted power distribution and minimizing the risk of service disruptions for customers.

Impact of Substandard Fasteners on Utility Pole Guy Wire

Substandard fasteners can have a detrimental impact on utility pole guy wires, compromising their ability to support and stabilize poles. Custom fastener manufacturers offer solutions that prevent issues such as corrosion, loosening, or breakage which can result from using subpar fasteners. By choosing high-quality custom-made fasteners, utility companies can avoid costly repairs and ensure the longevity of their infrastructure.

Using substandard fasteners can also lead to safety hazards for utility workers and the public. If guy wires are not properly secured due to inferior fasteners, there is a risk of poles collapsing or wires snapping, potentially causing injury or property damage. Custom fastener manufacturers prioritize the safety and reliability of their products, providing peace of mind for utility companies and the communities they serve.

Pole Line Hardware and Eye Nuts

When it comes to Pole Line Hardware, Eye Nuts play a crucial role in ensuring secure fittings. These specialized nuts are designed to provide a reliable anchor point for attaching cables, wires, and other hardware to utility poles. By securely fastening these components, eye nuts help maintain the stability and integrity of the entire pole line system.

Role of Eye Nuts in Pole Line Hardware

Eye Nuts serve as essential components in Pole Line Hardware by providing a strong and secure anchor point for various attachments. Whether it's guy wires or cross arms, these nuts play a pivotal role in ensuring that all elements are firmly connected to the utility pole. Without the reliable support of eye nuts, the entire structure would be at risk of instability and potential failure.

Eye Nuts ensure secure fittings by their design, which features a circular eye at one end that allows for easy attachment of hardware such as bolts, hooks, or shackles. This design minimizes the risk of slippage or detachment, providing a reliable and stable connection for all attached components. Additionally, the durable material used in manufacturing eye nuts ensures that they can withstand the tension and weight of the attached hardware without compromising on safety.

How Eye Nuts Ensure Secure Fittings

The design of eye nuts allows for easy installation on utility poles, providing a stable connection point for hardware such as insulators or conductors. Their threaded hole enables screws or bolts to be inserted securely, ensuring that the attached components remain firmly in place even under extreme weather conditions or heavy loads. This level of security is essential for maintaining the safety and reliability of utility pole installations.

Eye nuts are available in a variety of materials, including stainless steel and galvanized steel, which offer excellent resistance to corrosion. This means that they can withstand exposure to the elements without deteriorating, ensuring long-lasting performance and reducing the need for frequent maintenance. By using high-quality eye nuts, utility pole installations can remain secure and reliable for extended periods, ultimately saving time and resources for utility companies.

Benefits of Utilizing High-Quality Eye Nuts

Choosing high-quality eye nuts from a reputable custom fastener manufacturer ensures that they are manufactured to precise specifications and meet industry standards for strength and durability. These superior quality eye nuts offer enhanced resistance to corrosion and wear, prolonging their lifespan and reducing maintenance requirements for pole line hardware installations.

In addition, high-quality eye nuts are designed to provide a secure and reliable connection for pole line hardware, ensuring the safety and stability of the installation. This can help prevent accidents and damage caused by loose or failing fasteners, saving time and money on repairs and replacements. Furthermore, utilizing top-notch eye nuts can also contribute to the overall efficiency and effectiveness of pole line hardware systems, allowing for smoother operations and reduced downtime.

Types of Screws & Bolts for Pole Line Hardware

Pole line hardware requires a variety of screws and bolts to ensure secure fittings and longevity. Understanding the different types available is crucial for selecting the right fasteners for utility pole installations.

Understanding the Varieties of Screws and Bolts

When it comes to pole line hardware, custom fastener manufacturers offer an array of screws and bolts designed to meet specific requirements. From lag screws to machine bolts, each type serves a unique purpose in utility pole construction.

Importance of Choosing the Right Fasteners

Selecting the appropriate screws and bolts is essential for maintaining the structural integrity of utility poles. Using high-quality fasteners from a reliable custom fastener manufacturer ensures that the hardware can withstand environmental factors and support the weight of power lines.

Impact of Quality Fasteners on the Longevity of Utility Poles

The quality of screws and bolts directly affects the longevity of utility poles. Inferior fasteners can lead to premature corrosion, weakening the overall structure and compromising safety. By choosing top-notch products from trusted suppliers, pole line hardware can withstand harsh conditions for years to come.

Spark Fittings is a leading company specializing in manufacturing equipment for preformed armor rods, tension clamps, and cable accessories for ADSS and OPGW. Our machines help customers produce high-quality preformed products for the transmission and distribution of electricity, as well as electrified railways.

Fastener Suppliers and Quality Assurance

When selecting fastener suppliers for pole line hardware, it's essential to consider factors such as experience, reputation, and ability to provide custom solutions. A reliable supplier should have a track record of delivering high-quality products that meet industry standards and specifications.

Factors to Consider When Selecting Fastener Suppliers

In the realm of pole line hardware, the importance of choosing a reputable and experienced custom fastener manufacturer cannot be overstated. The supplier's ability to offer tailored solutions for specific requirements is crucial in ensuring the safety and reliability of utility pole fastenings.

Importance of Quality Assurance in Fastener Manufacturing

Quality assurance is paramount in fastener manufacturing, especially when it comes to utility pole bolts and other critical components. A reputable custom fastener manufacturer will have stringent quality control measures in place to guarantee the durability and performance of their products.

How to Identify Reliable Fastener Suppliers

Identifying reliable fastener suppliers involves thorough research into their track record, certifications, and customer testimonials. A reputable supplier will also be transparent about their manufacturing processes and quality assurance measures, instilling confidence in their ability to provide high-quality custom fasteners.

By prioritizing these factors when selecting a custom fastener manufacturer for pole line hardware needs, you can ensure the safety and reliability of utility pole fastenings while maintaining industry standards.

The Role of Spark Fittings in Fastener Manufacturing

Spark Fittings plays a crucial role in the custom fastener manufacturing industry, offering specialized equipment for preformed armor rods, tension clamps, and cable accessories for ADSS and OPGW. Their machinery ensures the production of high-quality products for the transmission and distribution of electricity, as well as electrified railways.

Introduction to Spark Fittings

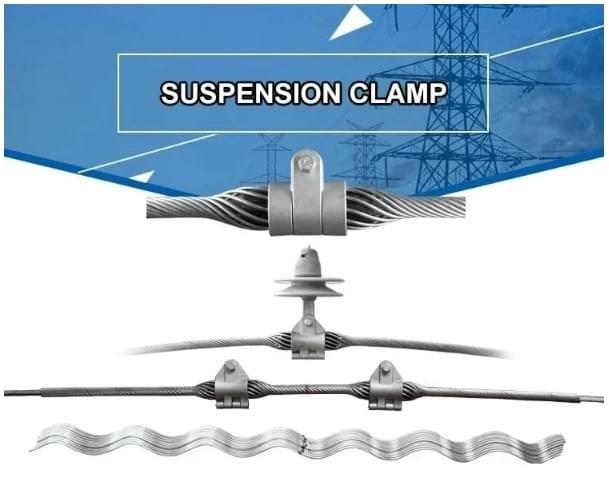

Spark Fittings is renowned for its expertise in manufacturing equipment tailored to the specific needs of the utility pole hardware industry. Their focus on producing top-notch preformed armor rods, tension clamps, and cable accessories has solidified their position as a key player in the fastener manufacturing sector.

Specialization in Manufacturing Equipment for Preformed Armor Rods

The company specializes in creating machinery designed specifically for preformed armor rods. This specialization allows them to cater to the unique requirements of utility pole hardware, ensuring that their products meet stringent quality standards and industry-specific regulations.

Contribution to High-Quality Custom Fastener Manufacturing

Spark Fittings' contribution to high-quality custom fastener manufacturing cannot be overstated. By providing state-of-the-art equipment for producing preformed armor rods and other essential components, they play a vital role in ensuring the safety and reliability of pole line hardware.

Remember that choosing a reliable custom fastener manufacturer is crucial for ensuring the safety and reliability of utility pole fastenings. With Spark Fittings' specialization in producing top-quality equipment for preformed armor rods and other essential components, they are an indispensable partner in the quest for high-quality custom fastener manufacturing.

Conclusion

In conclusion, when it comes to Pole Line Hardware, it is crucial to partner with a reputable custom fastener manufacturer that prioritizes safety and reliability. Choosing the right fastener supplier for utility pole bolts and ensuring the use of high-quality eye nuts, screws, and bolts is essential for the longevity and stability of utility poles. Quality assurance in fastener manufacturing cannot be overlooked, as substandard fasteners can compromise the integrity of utility pole guy wires.

Choosing the Right Fastener Supplier for Pole Line Hardware

Selecting a reliable custom fastener manufacturer is paramount to ensuring the safety and reliability of pole line hardware. It is imperative to partner with a supplier that offers high-quality products specifically designed for utility pole applications. By choosing a reputable supplier, you can guarantee the use of top-notch materials that meet industry standards.

Ensuring Safety and Reliability in Utility Pole Fastenings

The significance of using high-quality eye nuts, screws, and bolts cannot be overstated when it comes to utility pole fastenings. These components play a critical role in ensuring secure fittings that withstand environmental factors and operational demands. By prioritizing safety and reliability in utility pole fastenings, you can mitigate risks associated with substandard hardware.

Importance of Quality Assurance in Fastener Manufacturing

Quality assurance is an indispensable aspect of custom fastener manufacturing for pole line hardware. It involves stringent testing procedures and adherence to industry regulations to deliver reliable products that meet performance expectations. By emphasizing quality assurance, custom fastener manufacturers can instill confidence in their customers regarding the durability and effectiveness of their products.