Introduction

In the world of manufacturing, innovation drives efficiency and productivity, and one of the unsung heroes of this revolution is the wire bending machine. Understanding wire bending machines is crucial for businesses looking to optimize their production processes. These machines come in various forms, with automatic wire bending machines leading the charge in high-performance capabilities.

Understanding Wire Bending Machines

So, what is a wire bending machine? At its core, a wire bending machine is a piece of equipment designed to shape and manipulate metal wires into desired forms and configurations. This functionality is essential across numerous applications, from automotive parts to intricate artistic designs, making it a vital tool in many industries.

Importance of High Performance in Manufacturing

High performance in manufacturing isn't just a buzzword; it's a necessity for staying competitive. High Performance Wire Bending Machines enhance production speed while maintaining accuracy, which translates to reduced operational costs and increased output quality. In an era where efficiency can make or break a business, investing in advanced machinery like CNC wire bending machines becomes paramount.

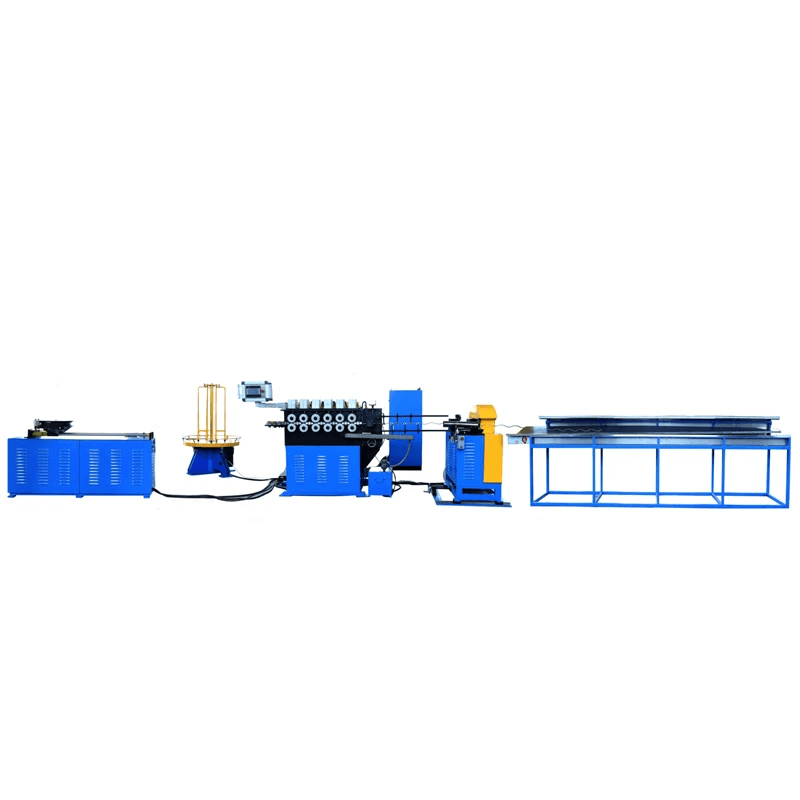

Overview of Automatic Wire Bending Machines

Automatic wire bending machines represent the pinnacle of technology in this field, offering unparalleled precision and speed compared to their manual counterparts. These machines are designed to handle complex tasks with minimal human intervention, ensuring consistent results that meet stringent industry standards. As manufacturers continue to seek ways to streamline operations and reduce waste, automatic options are increasingly becoming the go-to solution for steel wire bending machine applications.

What is a Wire Bending Machine?

When delving into the world of manufacturing, one might wonder, What is a wire bending machine? These machines are specialized tools designed to bend wire into specific shapes and configurations. They play a crucial role in various industries, such as automotive, construction, and electronics, where precision and efficiency are paramount.

Definition and Functionality

A wire bending machine is an automated device that shapes wire by applying force to manipulate its form without breaking it. The functionality of these machines varies widely; they can produce simple bends or intricate designs depending on the complexity of the required application. Automatic wire bending machines enhance productivity by allowing for mass production with minimal human intervention while ensuring consistent quality.

Types of Wire Bending Machines

There are several types of wire bending machines available on the market today, each catering to different needs and specifications. Among them, High Performance Wire Bending Machines stand out for their speed and precision in handling complex tasks like creating custom components for machinery or decorative items. Additionally, CNC Wire Bending Machines offer advanced capabilities by utilizing computer numerical control technology to achieve high levels of accuracy in bending steel wires.

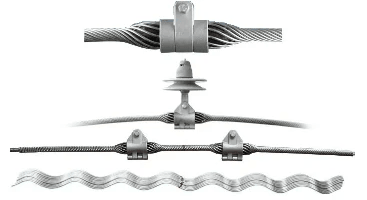

Applications in Various Industries

Wire bending machines find applications across numerous sectors due to their versatility and efficiency. In the automotive industry, they are used to create components such as brackets and frames that require precise bends for proper fitment. Similarly, in construction, Steel Wire Bending Machines play a vital role in producing rebar supports that enhance structural integrity—demonstrating just how integral these machines are to modern manufacturing processes.

High Performance Wire Bending Machines Explained

High performance wire bending machines are revolutionizing the manufacturing landscape, particularly in sectors that require precision and efficiency. These machines stand out due to their advanced technology, allowing for complex wire shapes and designs to be produced with minimal human intervention. With the integration of features like CNC (Computer Numerical Control) technology, these models offer unparalleled accuracy compared to traditional methods.

Features of High Performance Models

High performance wire bending machines come equipped with a suite of innovative features that enhance their functionality. One standout characteristic is the ability to execute intricate bends and twists in various types of wire materials, including steel, copper, and aluminum. Moreover, many automatic wire bending machines incorporate user-friendly interfaces and programmable settings that allow operators to customize designs easily—making it simpler than ever to achieve desired specifications.

Another significant feature is the speed at which these machines operate; high performance models can produce components much faster than manual or less advanced options. Most high performance wire bending machines also boast real-time monitoring capabilities, ensuring consistent quality control throughout production runs. This combination of speed, precision, and adaptability makes them indispensable tools in modern manufacturing environments.

Benefits of Utilization in Production

Utilizing high performance wire bending machines can lead to substantial benefits in production efficiency and output quality. By reducing cycle times through automation—thanks to features found in CNC wire bending machines—manufacturers can significantly increase their throughput while maintaining high standards of accuracy. This not only helps meet growing market demands but also allows businesses to optimize their resources more effectively.

Additionally, the reduction in labor costs associated with using an automatic wire bending machine cannot be overlooked; fewer operators are needed for complex tasks when machinery handles most functions autonomously. The consistency provided by high performance models also minimizes errors during production runs, resulting in less waste and rework time—a win-win scenario for any manufacturer striving for lean operations.

Case Studies of Efficiency Gains

Several case studies illustrate how companies have reaped the rewards from investing in high performance steel wire bending machines. For instance, a leading automotive parts manufacturer integrated a CNC bending machine into its production line and witnessed a 30% increase in output within just three months due to improved cycle times and reduced downtime caused by manual setups.

In another example, a furniture manufacturer adopted an automatic wire bending machine that enabled them to streamline their design processes significantly; they were able to launch new products faster while also cutting material waste by nearly 25%. These success stories underscore not only the transformative impact of these technologies but also highlight what is possible when manufacturers choose cutting-edge solutions tailored for efficiency gains.

The Role of CNC Wire Bending Machines

In the realm of modern manufacturing, CNC wire bending machines have revolutionized how we approach wire forming tasks. These machines are not just tools; they are sophisticated systems that enhance both efficiency and precision in production lines. Understanding what a CNC bending machine is can help businesses leverage its capabilities to maximize output.

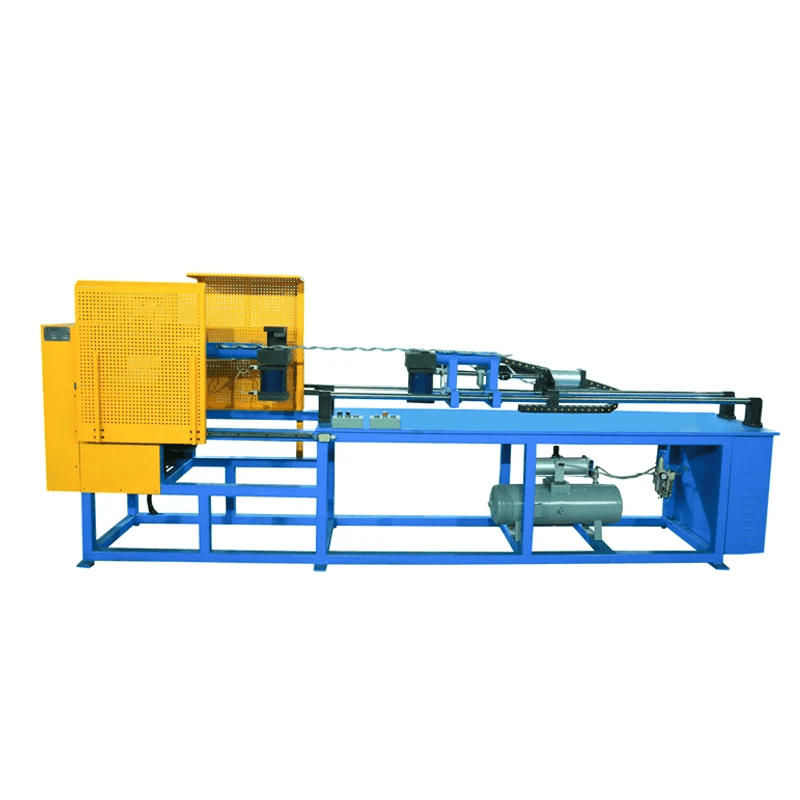

What is a CNC Bending Machine?

At its core, a CNC bending machine is an advanced piece of equipment designed for shaping and forming metal wires with precision. Unlike traditional wire bending machines, which often require manual intervention, a CNC wire bending machine automates the process through computer numerical control (CNC). This means that once programmed, the machine can execute complex bends and shapes consistently without human error.

The functionality of these machines extends beyond simple bends; they can perform intricate designs and repetitive tasks with ease. This capability makes them ideal for various applications across industries such as automotive, aerospace, and construction. By understanding what a wire bending machine can do, manufacturers can better appreciate the advantages of integrating CNC technology into their operations.

Advantages of CNC Technology

The advantages of utilizing CNC technology in wire bending are manifold, making it a preferred choice for many manufacturers seeking high performance wire bending machines. One significant benefit is increased efficiency; these machines reduce setup times and allow for faster production cycles compared to manual alternatives. Additionally, the automation provided by a CNC wire bending machine minimizes labor costs while ensuring consistent quality across all produced items.

CNC technology also enhances flexibility in design modifications; programming changes can be made quickly without needing extensive downtime or retooling. This adaptability allows businesses to respond swiftly to customer demands or market trends without sacrificing quality or speed. Furthermore, high performance models equipped with advanced features ensure that even complex geometries are achieved with remarkable accuracy.

Precision and Automation in Wire Bending

Precision is paramount when it comes to manufacturing components from steel wires or other materials; this is where automatic wire bending machines truly shine. The combination of automation and precise control over every aspect of the bend ensures that products meet stringent specifications every time they are produced. With minimal human intervention required during operation, manufacturers experience fewer errors leading to higher quality outputs.

Moreover, automation facilitates continuous production runs without fatigue-related issues that might affect manual laborers over time—this means greater reliability in meeting delivery schedules too! As industries increasingly move towards smart manufacturing solutions, investing in a steel wire bending machine equipped with cutting-edge CNC technology becomes not just advantageous but essential for staying competitive in today's market landscape.

Spark Fittings: Innovating Wire Bending Solutions

In the realm of wire bending, Spark Fittings has emerged as a beacon of innovation, pushing the boundaries of what is possible with automatic wire bending machines. Their dedication to quality and performance is evident in their diverse offerings tailored for various industrial needs. With a focus on high performance wire bending machines, they are redefining efficiency and precision in manufacturing.

Overview of Spark Fittings' Offerings

Spark Fittings boasts an impressive catalog that includes cutting-edge CNC wire bending machines designed for optimal functionality. These products cater to a wide array of applications, ensuring that manufacturers can find the perfect fit for their specific requirements. By integrating advanced technology into their designs, Spark Fittings stands out as a leader in the industry, providing solutions that enhance productivity and streamline operations.

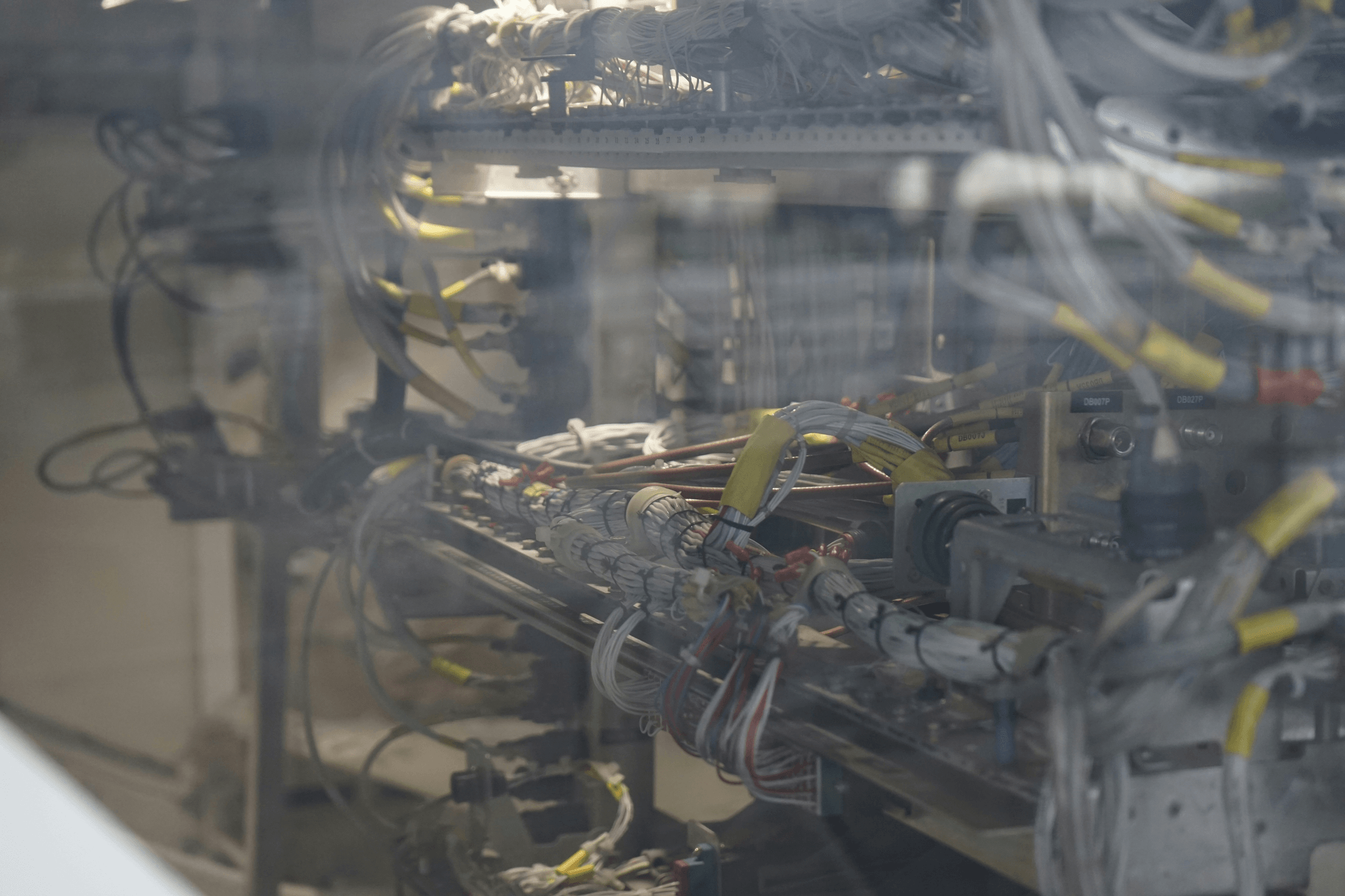

Twisted Wire Folding Labeling Machine Explained

One standout product from Spark Fittings is the Twisted Wire Folding Labeling Machine, which exemplifies what is a wire bending machine at its finest. This machine not only bends but also labels twisted wires with remarkable accuracy and speed, making it an invaluable asset for manufacturers dealing with steel wire bending applications. Its innovative design simplifies complex tasks while ensuring consistent quality across production lines.

Advantages for Steel Wire Bending Machine Applications

The advantages of utilizing Spark Fittings' solutions in steel wire bending machine applications are manifold. First and foremost, these high performance wire bending machines significantly reduce production time while maintaining exceptional precision—key factors in today’s fast-paced manufacturing environment. Additionally, by incorporating features typical of CNC technology into their designs, users can expect enhanced automation that translates into fewer errors and lower operational costs.

Choosing the Right Steel Wire Bending Machine

Selecting the right Steel Wire Bending Machine is crucial for optimizing production efficiency and ensuring high-quality output. With various options available, understanding the differences between automatic and manual machines can significantly impact your manufacturing process. This section will guide you through key considerations, comparisons, and future trends in wire bending technology.

Key Factors to Consider

When choosing a wire bending machine, several key factors should be at the forefront of your decision-making process. First, assess the volume of production; if you're dealing with high volumes, an automatic wire bending machine might be more suitable due to its speed and efficiency. Additionally, consider the types of materials you'll be working with; some machines are specifically designed for certain steel grades or thicknesses.

Another important factor is precision—what is a CNC bending machine if not a tool that offers unparalleled accuracy? High Performance Wire Bending Machines often come equipped with advanced features such as programmable controls that ensure every bend meets strict specifications. Finally, think about maintenance requirements; machines that are easier to service can save you time and money in the long run.

Comparing Automatic vs. Manual Options

The debate between automatic and manual options for wire bending machines often boils down to specific needs within your operation. Automatic wire bending machines offer superior speed and consistency, making them ideal for large-scale production runs where time is money. On the other hand, manual machines may provide greater flexibility for small batch jobs or custom projects where intricate designs are required.

CNC Wire Bending Machines represent a middle ground by combining automation with precision control over complex shapes and sizes—perfect for industries requiring both speed and accuracy. While manual options may have lower upfront costs, consider whether their slower pace could hinder your overall productivity compared to investing in a high-performance model that streamlines operations. Ultimately, understanding what is a wire bending machine capable of in terms of capabilities will help you make an informed choice.

Future Trends in Wire Bending Technology

The landscape of wire bending technology is evolving rapidly thanks to advancements in automation and digitalization. Future trends indicate a growing reliance on smart technologies such as IoT integration within CNC Wire Bending Machines that allow real-time monitoring and diagnostics—enhancing both efficiency and predictive maintenance capabilities. This means manufacturers can maximize uptime while reducing unexpected breakdowns.

Moreover, sustainability is becoming increasingly important; many manufacturers are now focusing on energy-efficient designs that minimize waste during production processes associated with steel wire bending machines. As we look ahead, expect innovations like AI-driven software solutions that optimize bend sequences based on historical data—further pushing the boundaries of what an automatic wire bending machine can achieve while maintaining quality standards.

Conclusion

In conclusion, the evolution of wire bending technology has paved the way for remarkable advancements in manufacturing efficiency. High Performance Wire Bending Machines, particularly automatic wire bending machines, have revolutionized production processes across various industries. By integrating features like precision and automation, these machines not only enhance productivity but also ensure consistent quality in output.

Maximizing Efficiency with High Performance Machines

Maximizing efficiency with High Performance Wire Bending Machines is no longer just a goal; it's a necessity in today’s competitive landscape. These machines are designed to streamline operations, reduce waste, and minimize downtime—making them indispensable for manufacturers aiming to optimize their workflows. The integration of CNC technology further elevates this efficiency by allowing for precise control and rapid adjustments during production.

The Future of Automatic Wire Bending Technology

The future of automatic wire bending technology looks incredibly promising as innovations continue to emerge at a rapid pace. As we explore what is a CNC bending machine and its capabilities, it becomes clear that automation will play an increasingly vital role in the industry. With advancements in artificial intelligence and machine learning, we can anticipate even smarter Steel Wire Bending Machines that adapt to varying production needs seamlessly.

Investing in Quality for Long-Term Gains

Investing in quality when choosing a wire bending machine pays off significantly over time. Whether you opt for an automatic wire bending machine or a manual one, the long-term benefits of high-performance models are undeniable—lower maintenance costs and increased reliability stand out among them. Ultimately, understanding what is a wire bending machine and selecting the right model tailored to your specific needs will lead you towards sustained success and profitability.