Introduction

When it comes to securing overhead lines and ensuring their stability, the GUY-GRIP Dead end is an essential component in the utility industry. Preformed Guy Grips offer a reliable solution for anchoring and supporting guy wires, providing numerous benefits over traditional methods. In this article, we will explore the importance of understanding the GUY-GRIP Dead end, the advantages of using Preformed Guy Grips, and delve into the installation process to ensure a secure and reliable setup.

Understanding the GUY-GRIP Dead end

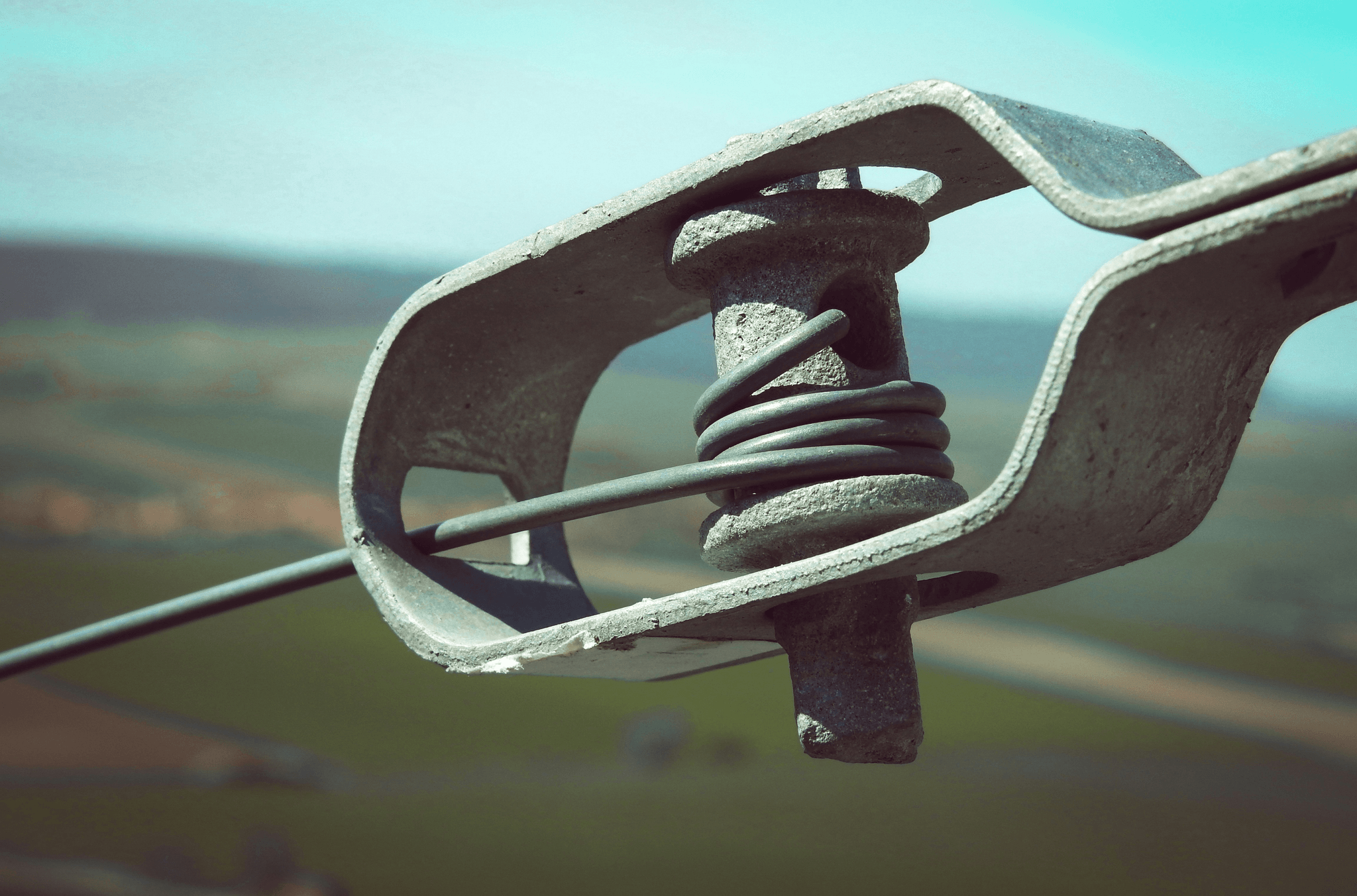

The GUY-GRIP Dead end is a crucial element in guy wire installations, designed to provide a secure termination point for guy wires while maintaining their strength and integrity. This innovative solution offers a high level of performance and durability, making it an ideal choice for various applications in the utility industry.

Benefits of using Preformed Guy Grips

Preformed Guy Grips offer several advantages over traditional methods of securing guy wires. They provide consistent performance, reduce installation time, and eliminate the need for special tools or skills. Additionally, they offer superior corrosion resistance and are reusable, making them a cost-effective solution for long-term use.

Exploring the installation process

The installation process of Preformed Guy Grips is straightforward and can be easily carried out by trained personnel. Proper installation is crucial to ensure the reliability and safety of guy wire setups, making it essential to follow manufacturer's guidelines and best practices during installation.

What are formed guy grips used to secure?

Formed guy grips are commonly used to secure overhead power lines, telecommunication cables, and antenna masts. These grips provide a reliable and durable means of supporting and tensioning these structures, ensuring their stability and longevity.

Importance of proper installation

Proper installation of formed guy grips is crucial for ensuring the safety and reliability of the supported structures. A secure installation prevents slippage or failure, which can lead to costly damage or service interruptions. It is essential to follow manufacturer guidelines and use the correct tools for a successful installation. Additionally, regular inspections and maintenance are necessary to ensure that the guy grips remain in optimal condition over time. This proactive approach can help identify any potential issues before they escalate into more significant problems, ultimately saving time and money in the long run.

Common applications of guy grips

Guy grips are widely used in various industries, including telecommunications, electric utilities, and construction. They are employed to support overhead cables, wires, and masts, providing stability in challenging environmental conditions such as high winds or extreme temperatures.

Guy grips are also commonly used in the marine industry to secure rigging on boats and ships. The durable construction of guy grips makes them well-suited for withstanding the harsh conditions of saltwater environments. Whether it's for supporting mast stays or securing lifelines, guy grips play a crucial role in maintaining the structural integrity of marine vessels.

Factors to consider when choosing guy grips

When selecting guy grips for a specific application, factors such as the type of cable or mast being supported, environmental conditions, and load requirements must be carefully considered. Choosing the right type and size of grip is essential for ensuring optimal performance and longevity. Additionally, it's important to take into account the installation process and whether the grips need to be easily removable or adjustable. This can impact the overall convenience and efficiency of the setup, especially in situations where maintenance or adjustments may be required over time.

GUY-GRIP Dead end: A Closer Look

Features and components of GUY-GRIP Dead end

The GUY-GRIP Dead end is a preformed guy grip dead-end designed to provide a secure and reliable termination for guy wires. It consists of a steel rod, preformed wire, and a unique torque tube that ensures proper installation and maximum holding strength. The design allows for easy installation without the need for special tools, making it a convenient choice for various applications.

In addition to its easy installation, the GUY-GRIP Dead end also offers exceptional durability and resistance to corrosion, ensuring a long-lasting and reliable termination for guy wires in various environmental conditions. The steel rod and preformed wire components are designed to withstand tension and harsh weather, making it a cost-effective solution for both temporary and permanent installations. This level of durability makes the GUY-GRIP Dead end a practical choice for telecommunications, utility, and construction applications where reliability is paramount.

Advantages of using GUY-GRIP Dead end

One of the key advantages of using the GUY-GRIP Dead end is its ability to provide superior holding strength compared to traditional methods. The preformed wire construction ensures consistent performance and reliability, even in harsh environmental conditions. Additionally, the ease of installation reduces labor costs and minimizes downtime during installation, making it a cost-effective solution for securing guy wires.

Furthermore, the GUY-GRIP Dead end offers a sleek and compact design, minimizing the need for additional hardware and reducing the overall footprint of the installation. This not only saves on material costs but also streamlines the appearance of the guy wire system. The modern and efficient design of the GUY-GRIP Dead end sets it apart from traditional methods, providing a more aesthetically pleasing solution for securing guy wires in various applications.

Comparing GUY-GRIP Dead end to other solutions

When comparing the GUY-GRIP Dead end to other solutions such as clamps or thimbles, it becomes evident that the preformed guy grip offers greater convenience and efficiency in securing guy wires. Its innovative design eliminates the need for multiple components and simplifies the installation process, resulting in time and cost savings for projects of all sizes.

Furthermore, the GUY-GRIP Dead end provides a more secure and reliable solution compared to clamps or thimbles. Its unique design ensures a strong grip on the guy wire, reducing the risk of slippage or failure. This added level of security is especially valuable in high-stress environments or areas prone to extreme weather conditions, giving project managers and engineers peace of mind knowing that their guy wires are well-protected.

Guy Grip Dead-End Installation Guide

Step-by-step instructions for installation

When installing a preformed guy grip dead end, start by ensuring that the guy grip is properly sized for the conductor. Next, position the guy grip on the conductor and make sure it is evenly distributed. Then, use a torque wrench to tighten the guy grip to the recommended torque value provided by the manufacturer.

After tightening the guy grip to the recommended torque value, double-check the installation to ensure that it is secure and reliable. Inspect the guy grip and conductor for any signs of damage or wear that could compromise the installation. Additionally, perform a pull test on the guy grip to confirm that it can withstand the necessary tension. By following these additional steps, you can have confidence in the durability and effectiveness of your preformed guy grip dead end installation.

Tips for ensuring a secure and reliable installation

To ensure a secure and reliable installation of the guy grip dead end, always follow the manufacturer's guidelines and recommendations. Additionally, inspect the guy grip for any signs of damage or wear before installation. Finally, make sure to properly tension the guy wire after installing the guy grip to achieve optimal performance.

Furthermore, it is important to use the correct tools and equipment for the installation to avoid any damage to the guy grip or the surrounding infrastructure. Using the wrong tools can lead to improper installation and compromise the security of the guy wire. Additionally, always double-check the connections and ensure that all components are properly secured before completing the installation process.

Common mistakes to avoid during installation

One common mistake to avoid during installation is over-tightening the guy grip, which can lead to damage or failure. Another mistake is using an improperly sized guy grip for the conductor, which can compromise its effectiveness. It's also important to avoid twisting or kinking the guy wire during installation to maintain its integrity.

Additionally, it's crucial to ensure that the guy grip is properly secured to the conductor to prevent any slippage or movement that could compromise its effectiveness. Using a torque wrench can help achieve the correct level of tightness without risking damage. Furthermore, avoiding sharp bends or angles in the guy wire during installation is essential to maintain its structural integrity and prevent weak points that could lead to failure over time.

Ensuring Safety and Reliability

Importance of following manufacturer's guidelines

It is crucial to adhere to the manufacturer's guidelines when using guy grips to ensure safety and reliability. Following the recommended installation procedures and specifications provided by the Preformed Guy Grip Dead End Manufacturer will help prevent accidents and ensure the longevity of the guy grip system. Additionally, proper maintenance of guy grips in accordance with the manufacturer's instructions will minimize wear and tear, reducing the risk of failure or malfunction. By staying up-to-date with maintenance schedules and inspections, you can catch any potential issues early on and address them before they become a safety hazard.

Proper maintenance of guy grips

Proper maintenance of guy grips is essential for their continued effectiveness. Regular inspections should be conducted to check for any signs of wear, corrosion, or damage. Any issues should be addressed promptly to avoid compromising the security of the installation.

Furthermore, it is important to ensure that guy grips are properly tightened to the recommended torque levels to maintain their effectiveness. Loose grips can lead to instability and potential failure, so regular checks and adjustments are crucial. Additionally, keeping the surrounding area clean and free from debris can help prevent damage and corrosion, extending the lifespan of the guy grips.

Understanding the role of Spark Fittings in installation

Spark Fittings plays a significant role in providing high-quality equipment for preformed armor rods, tension clamps, and cable accessories used in conjunction with guy grips. Their expertise in manufacturing products for electricity transmission and distribution ensures that installations are reliable and durable.

Spark Fittings also prides itself on its commitment to innovation and continuous improvement. With a team of experienced engineers and technicians, they are constantly researching and developing new products to meet the evolving needs of the electricity transmission and distribution industry. This dedication to staying ahead of the curve ensures that their installations not only meet current standards but also anticipate future requirements, providing peace of mind for their clients.

Conclusion

When it comes to choosing the right guy grip for your project, it's essential to consider the specific application and requirements. Whether it's for securing overhead lines, antennas, or communication towers, selecting the appropriate guy grip is crucial for ensuring safety and reliability.

Ensuring a secure and reliable installation of preformed guy grips is paramount in maintaining the integrity of the structure they are supporting. Proper installation techniques, adherence to manufacturer guidelines, and regular maintenance are key factors in guaranteeing the longevity and effectiveness of guy grips.

The role of Spark Fittings in the preformed products industry cannot be overstated. As a leading manufacturer of equipment for preformed armor rods and cable accessories, Spark Fittings plays a vital part in providing high-quality products that contribute to the safe and efficient transmission and distribution of electricity.