Introduction

Guide wires play a crucial role in the structural integrity of electrical poles, ensuring stability and safety in various environments. Understanding guide wire power poles is essential for anyone involved in construction, utility maintenance, or simply curious about how power lines are supported. This introduction will address common questions about guide wires, including their differences from guy wires and their specific applications in electrical pole structures.

Understanding Guide Wire Power Poles

When we talk about guide wire power poles, we're referring to the essential components that help keep these towering structures upright and secure against environmental stresses like wind and ice. Unlike guy wires that provide lateral support, guide wires serve a different purpose: they stabilize the pole itself while allowing for some flexibility during adverse weather conditions. Understanding this distinction is vital for anyone looking to grasp the mechanics behind utility infrastructure.

The Importance of Guide Wires

The importance of guide wires cannot be overstated; they enhance the durability of electrical poles and ensure reliable service delivery across vast distances. Without them, utility poles would be more susceptible to collapse under heavy loads or extreme weather conditions, leading to potential outages and safety hazards. Therefore, knowing what kind of wire is on power poles can help inform decisions regarding installation and maintenance.

Common Questions About Guide Wires

Many people often ask: What is the guide wire for electrical poles? or Is it guy wire or guide wire? These questions highlight a common confusion between these two types of support systems used in construction and utility applications. Additionally, understanding utility pole guy wire requirements can clarify why certain materials are chosen over others—factors like strength, durability, and environmental resistance all come into play when selecting the right type of wire.

What is a Guide Wire?

When discussing the infrastructure that supports our electrical systems, the term guide wire frequently comes up. But what exactly is a guide wire for electrical poles? Simply put, it’s a crucial component designed to provide stability and support to utility poles, ensuring they remain upright and functional against environmental forces. Often confused with guy wires, guide wires serve a distinct purpose in maintaining the integrity of power pole structures.

Definition and Purpose

A guide wire is a tensioned wire that connects to utility poles to enhance their stability and prevent swaying or tipping due to wind or other external forces. Its primary purpose is to anchor the pole securely, allowing for safe transmission of electricity over long distances. In construction, understanding what a guide wire is can help in designing safer and more resilient infrastructures.

Differences from Guy Wires

Is it guy wire or guide wire? While both terms are often used interchangeably, they have specific differences in application and design. Guy wires typically provide lateral support to tall structures like towers or masts, while guide wires specifically stabilize vertical elements like power poles by securing them at an angle. Recognizing these distinctions helps clarify their roles in electrical pole systems.

Key Features of Guide Wires

Guide wires have distinctive features that set them apart from other types of wiring used in construction. They are usually made from high-tensile strength materials that can withstand significant stress without breaking or stretching excessively. Additionally, many manufacturers offer customization options for these wires based on specific utility pole guy wire requirements, ensuring optimal performance tailored to various environmental conditions.

What is the Guide Wire for Electrical Poles?

Guide wires play a crucial role in the stability and safety of electrical poles. These wires, often confused with guy wires, are specifically designed to provide support and prevent structural failure under various conditions. Understanding what is the guide wire for electrical poles helps clarify their importance in maintaining reliable power distribution systems.

Functionality of Guide Wires

The primary functionality of guide wires is to stabilize electrical poles by counteracting lateral forces such as wind and ice load. They anchor the pole securely, ensuring that it remains upright and functional even during severe weather conditions. This leads to reduced maintenance costs and improved safety for both utility workers and the public.

In essence, guide wire power poles are essential for maintaining the integrity of electrical distribution networks. They help distribute stress evenly across pole structures, preventing any single point from becoming overloaded. This is particularly important in areas prone to extreme weather where utility pole guy wire requirements must be met rigorously.

Components of Electrical Pole Structures

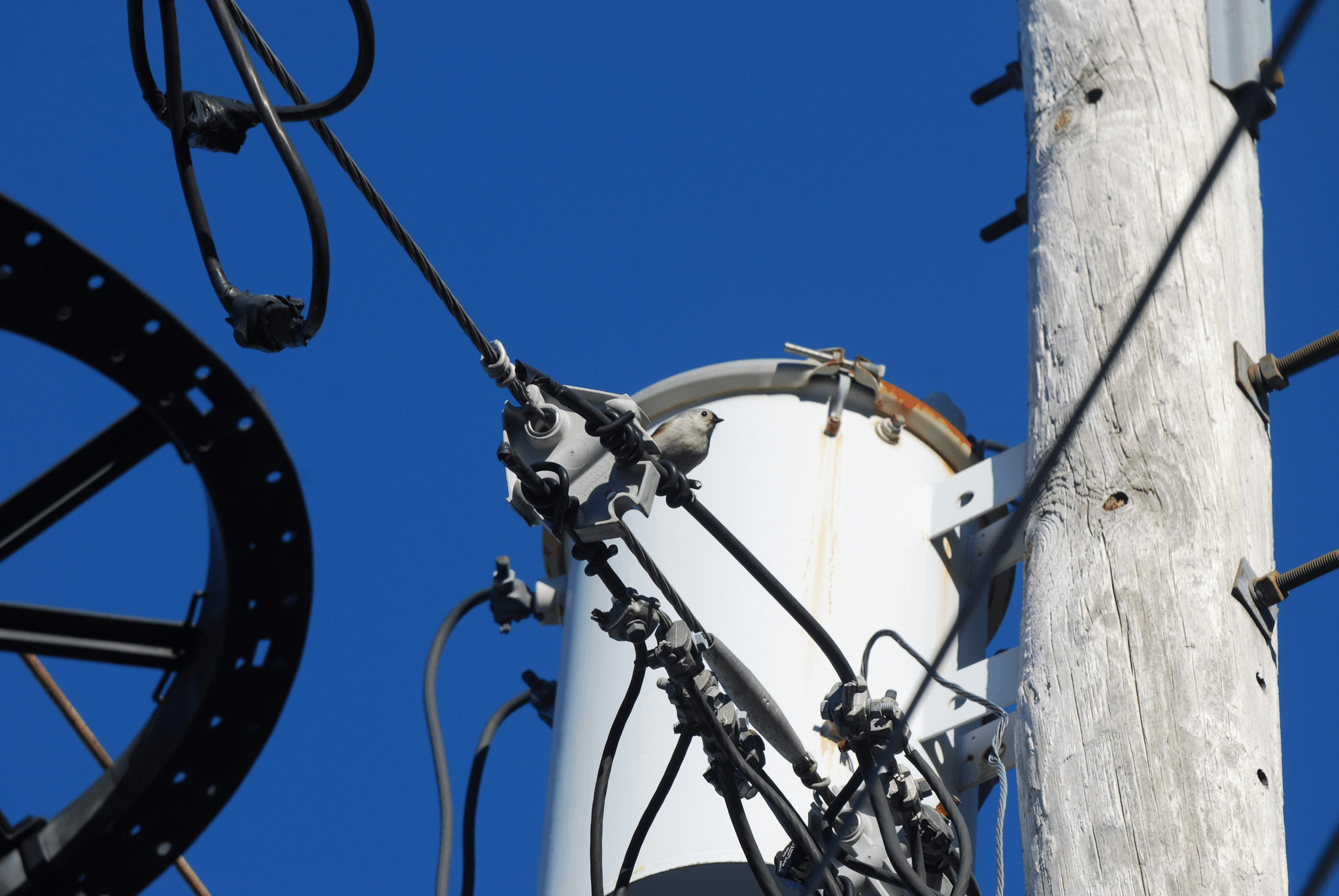

Electrical pole structures consist of several key components that work together to ensure stability and functionality, including the pole itself, insulators, crossarms, and guide wires. The combination of these elements creates a robust framework capable of withstanding environmental challenges while supporting electrical lines safely above ground.

Understanding what kind of wire is on power poles can also shed light on how these components interact; typically made from high-strength materials like galvanized steel or aluminum, they provide both durability and flexibility in harsh conditions. Each component has its specific role but collectively contributes to the effectiveness of guide wires in supporting electrical infrastructure.

Benefits of Using Guide Wires

The benefits of using guide wires extend beyond mere stability; they enhance overall system reliability by minimizing risks associated with pole collapse or failure during adverse weather events. By providing additional support where needed, these wires help reduce service interruptions caused by downed lines or damaged equipment—issues that can be costly for utility companies.

Moreover, proper installation according to utility pole guy wire requirements ensures compliance with safety standards while optimizing performance over time. This proactive approach not only protects infrastructure but also enhances public safety by reducing hazards associated with fallen power lines or compromised poles.

How Guide Wires Enhance Stability

Guide wires play a crucial role in maintaining the stability of structures, particularly in construction and electrical applications. A well-designed guide wire power pole system ensures that poles remain upright and withstand various environmental forces, such as wind and ice loading. Understanding how guide wires function can help stakeholders make informed decisions about their construction projects.

Importance in Construction

In construction, the importance of guide wires cannot be overstated. They are essential for ensuring that structures remain stable during and after installation, especially when dealing with tall or heavy components like power poles. Without adequate support from guide wires, these structures could lean or collapse under stress, posing safety risks to both workers and the public.

Application in Power Poles

When we ask, What is the guide wire for electrical poles?, we're referring to a critical component that enhances the overall integrity of utility pole systems. These wires are strategically positioned to counteract lateral forces acting on the poles, ensuring they remain vertical despite harsh weather conditions. The application of guide wires in power poles is not just about aesthetics; it significantly contributes to the longevity and reliability of electrical distribution networks.

Examples of Effective Use

To illustrate effective use, consider utility companies that adhere to strict utility pole guy wire requirements when installing new power poles. They often rely on seasoned professionals who understand what kind of wire is on power poles and how it should be configured to maximize stability. For example, using high-tensile strength materials for guide wires can dramatically reduce sagging over time while improving resistance against environmental challenges—an investment that pays dividends in safety and performance.

Choosing the Right Wire for Power Poles

Types of Wires Used

In the realm of electrical poles, various types of wires are utilized, each serving distinct purposes. Commonly used wires include galvanized steel wire and aluminum wire, both known for their strength and resistance to corrosion—essential traits for any guide wire in construction or utility applications. When pondering What kind of wire is on power poles?, it's important to note that these materials often come in different gauges tailored to specific load requirements.

Guy wires are another frequent choice when discussing stability in pole structures; they provide lateral support that complements guide wires effectively. The interplay between these two types can enhance overall structural integrity while ensuring safety standards are met. Ultimately, selecting the right wire type is vital not just for performance but also for compliance with utility pole guy wire requirements.

Utility Pole Guy Wire Requirements

When considering what makes a suitable utility pole guy wire, several key factors come into play to ensure optimal performance and safety. These requirements often include tensile strength specifications, resistance to environmental elements like UV radiation and moisture, as well as adherence to local regulations regarding installation practices. Therefore, when asking Is it guy wire or guide wire? it's essential to understand that both serve unique roles but must meet stringent criteria.

In addition to material properties, proper installation techniques must be followed according to utility guidelines; this helps maintain tension and alignment over time. Regular inspections also contribute significantly toward meeting these utility pole guy wire requirements by identifying wear or damage before they become problematic. Understanding these nuances ensures that your choice in guide wires translates into reliable support systems.

Factors to Consider for Durability

Durability is a paramount consideration when choosing a guide wire power pole solution; after all, no one wants a wobbly structure swaying in the wind! Several factors influence this aspect: material composition plays a major role—galvanized steel offers excellent rust resistance while aluminum provides lightweight options without compromising strength. Additionally, environmental conditions such as humidity levels or exposure to saltwater can affect how long your chosen materials last.

Another critical element includes maintenance practices; regular inspections can help catch any signs of wear before they escalate into more significant issues that could jeopardize structural integrity or lead to costly repairs down the line. Lastly, understanding how different components interact—like armor rods from Spark Fittings—can further enhance durability by minimizing corrosion risks between dissimilar metals used in construction projects like electrical poles.

Spark Fittings and Armor Rods

When it comes to the structural integrity of guide wire power poles, spark fittings and armor rods play a pivotal role. These components not only enhance the performance of guide wires but also ensure that electrical poles remain stable under various conditions. Understanding their function and materials can significantly impact the longevity and reliability of power pole installations.

Overview of Spark Fittings

Spark fittings are specialized hardware used in conjunction with guide wires to secure them effectively to electrical poles. They serve as connectors that help maintain tension in the guide wire, ensuring that it remains taut and functional over time. This is crucial for maintaining stability in power pole structures, especially when subjected to environmental stresses like wind or ice accumulation.

Importance of Material Selection

Choosing the right materials for spark fittings is essential for ensuring durability and resistance against corrosion. The raw materials typically include aluminum wire, galvanized steel wire, and aluminum clad steel wire; each has its unique advantages based on the conductor’s composition. Selecting a material similar to that of the conductor surface helps avoid corrosion between different elements, thereby enhancing overall performance.

Customization Options for Armor Rods

Armor rods are another critical component associated with guide wires in construction applications, particularly on utility poles. Spark Fittings offers customization options for armor rods to meet specific project requirements, which can be tailored based on conductor size or environmental factors. Each type of armor rod comes with a color code that not only facilitates easy identification during installation but also ensures compatibility with various conductor materials.

Conclusion

In the world of construction and electrical infrastructure, understanding guide wires is key to ensuring stability and safety. These essential components, often referred to as guide wire power poles, play a vital role in maintaining the integrity of electrical systems. By exploring their applications, we can appreciate their impact on our everyday lives.

Guide Wire Applications in Everyday Life

Guide wires are not just limited to electrical poles; they find use in various construction projects across different sectors. From supporting telecommunications towers to stabilizing bridges, these wires ensure that structures remain upright and secure against environmental forces. Whether you’re aware of it or not, every time you see a power pole standing tall, there’s likely a guide wire working behind the scenes to keep it steady.

Benefits of Understanding Guide Wires

Knowing what a guide wire is for electrical poles can empower individuals involved in construction and maintenance projects. It helps clarify the differences between guy wires and guide wires—two terms often confused but serving distinct purposes. Furthermore, understanding utility pole guy wire requirements allows professionals to select the right materials and techniques for enhanced durability and safety.

Making Informed Decisions on Power Poles

When it comes to choosing what kind of wire is on power poles, informed decisions are crucial for long-term performance. Factors such as material selection—like aluminum or galvanized steel—play an important role in ensuring that your guide wire can withstand harsh weather conditions without compromising structural integrity. With companies like Spark Fittings offering customized armor rods that match conductor materials, making educated choices has never been easier.