Introduction

When it comes to construction and industrial projects, the choice of materials is crucial. Understanding the properties of galvanized rods and copper rods is essential for making informed decisions. These materials have distinct characteristics that can significantly impact the longevity and performance of a project.

Understanding Galvanized Rods

Galvanized rods are steel rods that have been coated with a layer of zinc to protect them from corrosion and rust. This process, known as galvanization, creates a durable and long-lasting material that is ideal for outdoor applications. The zinc coating provides an additional layer of protection against environmental factors, making galvanized rods a popular choice in construction and infrastructure projects.

Exploring Copper Rods

Copper rods, on the other hand, are known for their unique properties, including excellent conductivity and malleability. While copper is not as resistant to corrosion as galvanized steel, it offers other advantages such as aesthetic appeal and ease of manipulation. Copper rods are often used in electrical applications due to their superior conductivity.

Differences in Material Properties

The key differences between galvanized rods and copper rods lie in their material properties. Galvanized rods are prized for their durability and resistance to corrosion, making them suitable for outdoor use in harsh environments. On the other hand, copper rods offer superior conductivity but require additional protection against corrosion when used outdoors.

What is a Galvanized Rod?

Galvanized rods are steel rods that have been coated with a layer of zinc to prevent rust and corrosion. The composition of galvanized rods typically includes a base metal, such as steel, and a protective layer of zinc. This process creates a durable and long-lasting material that is ideal for outdoor use in various applications.

Definition and Composition

A galvanized iron rod is simply a steel rod that has been coated with a layer of zinc through the process of galvanization. This coating helps to protect the steel from corrosion and rust, making it ideal for use in outdoor or high-moisture environments. The composition typically includes a base metal, such as carbon steel, and a layer of zinc that is applied through either hot-dip galvanizing or electroplating.

Benefits of Galvanized Rods

One of the main benefits of using galvanized rods is their superior corrosion resistance. The zinc coating acts as a sacrificial anode, meaning it will corrode before the underlying steel does, providing long-lasting protection. Galvanized rods are also relatively low maintenance and have a lower initial cost compared to other corrosion-resistant materials like stainless steel.

Common Applications

Galvanized rods are commonly used in outdoor construction projects, such as building fences, handrails, and gates due to their ability to withstand harsh weather conditions without deteriorating. They are also used in electrical applications where moisture resistance is essential, such as grounding systems or lightning protection installations.

The Appeal of Copper Rods

Unique Properties of Copper

Copper rods are known for their exceptional conductivity, making them ideal for electrical applications. Additionally, copper possesses antimicrobial properties, making it a popular choice for medical equipment and fixtures. Its malleability and ductility also make it easy to work with in various projects.

Copper's unique properties extend beyond its conductivity and antimicrobial qualities. Its corrosion resistance makes it an excellent choice for outdoor applications, such as roofing and plumbing. The attractive patina that develops over time also adds to its aesthetic appeal, making it a popular choice for architectural elements like domes and statues. Additionally, copper's recyclability makes it an environmentally friendly option for sustainable building practices.

Advantages and Drawbacks

The main advantage of copper rods lies in their superior electrical conductivity, which is unmatched by other materials. However, copper is more expensive than galvanized rods and can be prone to corrosion over time if not properly maintained.

While copper rods may be more expensive than galvanized rods, their durability and longevity make them a worthwhile investment. When properly maintained, copper rods can last for decades without losing their electrical conductivity. Additionally, the high resistance to corrosion makes them ideal for outdoor or underground projects where exposure to moisture and other elements is a concern.

Practical Uses in Projects

Copper rods are commonly used in electrical wiring, plumbing systems, and architectural design elements due to their aesthetic appeal. They are also utilized in the manufacturing of industrial machinery and heat exchangers due to their excellent thermal conductivity.

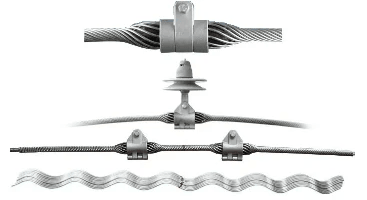

Remember that when considering material quality and cost for your project, Spark Fittings offers customized armor rods using high-quality aluminum wire, galvanized steel wire, or aluminum clad steel wire based on the conductor's raw material. With color-coded options available for easy identification during installation, Spark Fittings ensures the right fit for your specific project needs.

Galvanized Rod vs. Copper Rod: Durability and Corrosion Resistance

Comparing Longevity

When comparing the longevity of galvanized rods and copper rods, it's important to consider the corrosion resistance of each material. Galvanized rods are known for their exceptional durability, as they are coated with a layer of zinc that provides protection against rust and corrosion. On the other hand, copper rods also offer good longevity due to their natural resistance to corrosion, making them suitable for long-term use in various applications. Additionally, both materials are resistant to environmental factors such as moisture, humidity, and extreme temperatures, further contributing to their longevity and reliability in different settings.

Resistance to Environmental Factors

Both galvanized and copper rods exhibit strong resistance to environmental factors such as moisture, humidity, and extreme temperatures. Galvanized rods are specifically designed to withstand harsh outdoor conditions, making them ideal for outdoor construction projects or installations in areas prone to high humidity or salt exposure. Similarly, copper rods are known for their ability to resist corrosion in various environments, making them a reliable choice for both indoor and outdoor applications.

In addition to their resistance to environmental factors, both galvanized and copper rods also offer excellent durability, ensuring the longevity of any project they are used in. Galvanized rods are coated with a layer of zinc, which provides an extra layer of protection against corrosion and rust, making them a reliable choice for long-term outdoor installations. On the other hand, copper rods have a natural resistance to degradation, allowing them to maintain their structural integrity over time, even in challenging environments. This durability factor contributes significantly to the overall lifespan of any construction or installation using these materials.

Impact on Project Longevity

The choice between galvanized and copper rods can have a significant impact on the overall longevity of a project. Galvanized rods provide reliable protection against corrosion and can extend the lifespan of structures or equipment where they are used. Copper rods also contribute to project longevity by offering durable performance over time. Ultimately, the decision between galvanized and copper rods should be based on the specific environmental conditions and project requirements.

Hot Dipped Galvanized Threaded Rod and Galvanized Threaded Rod Kits

Hot Dipped Galvanized Threaded Rod and Galvanized Threaded Rod Kits are essential components in construction and electrical projects. The hot-dipping process involves coating the rod with a layer of zinc, providing excellent corrosion resistance. These rods come in various types, including fully threaded rods, double end rods, and bent anchor bolts, offering versatility for different project needs.

Overview of Types

Hot Dipped Galvanized Threaded Rods are available in different diameters and lengths to accommodate various project requirements. Additionally, Galvanized Threaded Rod Kits often include nuts, washers, and other accessories for comprehensive installation solutions. Whether it's for structural support or electrical grounding applications, these rods are designed to meet industry standards for reliability and durability.

In addition to their versatility in accommodating various project requirements, Hot Dipped Galvanized Threaded Rods are also known for their exceptional corrosion resistance, making them ideal for outdoor construction applications. The galvanization process creates a protective barrier that helps the rods withstand harsh environmental conditions, ensuring long-term performance and reliability. Whether used in building bridges, installing outdoor signage, or constructing fencing, these rods offer a durable solution for projects exposed to the elements.

Applications in Construction

In construction projects, Hot Dipped Galvanized Threaded Rods are commonly used for anchoring structural elements such as beams and columns. The galvanized coating provides protection against rust and corrosion, making them ideal for outdoor applications where exposure to moisture is a concern. These rods also play a crucial role in securing building foundations and ensuring structural stability.

In addition to their protective coating, Hot Dipped Galvanized Threaded Rods are also known for their high tensile strength, making them capable of withstanding heavy loads and providing long-term structural support. This makes them a reliable choice for construction projects where durability is a top priority. Furthermore, their threaded design allows for easy installation and adjustment, saving time and labor during the construction process. As a result, these rods are a popular choice among contractors and builders looking for efficient and effective anchoring solutions.

Considerations for Project Planning

When planning a construction project, it's important to consider the use of Hot Dipped Galvanized Threaded Rods as part of the overall material selection. Their superior corrosion resistance compared to standard steel rods makes them a valuable investment in long-term project durability. Additionally, the inclusion of Galvanized Threaded Rod Kits can streamline the procurement process by providing all necessary components in one package.

In addition to their corrosion resistance, Hot Dipped Galvanized Threaded Rods are also known for their high strength and durability, making them an ideal choice for construction projects that require reliable structural support. By incorporating these rods into your material selection, you can ensure that your project meets safety standards and withstands the test of time. Furthermore, the use of Galvanized Threaded Rod Kits simplifies the procurement process by providing a comprehensive solution for securing all necessary components in one convenient package.

Price Comparison: Galvanized Rod vs. Copper Rod

Galvanized rod price is a key factor to consider when weighing the options between galvanized and copper rods for your project. The cost of galvanized rods is generally lower than that of copper rods, making them a more budget-friendly option for many construction and industrial projects.

Evaluating Cost Factors

When evaluating cost factors, it's important to consider not only the initial purchase price of the rods but also the long-term maintenance and replacement costs. Galvanized rods are known for their durability and resistance to corrosion, which can result in lower maintenance and replacement expenses over time compared to copper rods. Additionally, the installation process for galvanized rods is often simpler and requires less specialized equipment, saving both time and money during construction projects. This makes galvanized rods a cost-effective choice for projects with tight budgets.

Budget Considerations for Projects

For projects with tight budgets, choosing galvanized rods over copper can make a significant impact on overall costs. The lower price point of galvanized rods allows for more flexibility in budget allocation, potentially freeing up funds for other essential project components or upgrades.

By choosing galvanized rods over copper for projects with tight budgets, teams can allocate funds more effectively, potentially freeing up resources for other essential project components or upgrades. This strategic decision can lead to a more efficient use of budget and resources, allowing for a higher overall project value. Additionally, the long-term investment in galvanized rods can provide durability and reliability, ensuring that the project remains cost-effective over time.

Value for Long-Term Investment

In terms of long-term investment, galvanized rods offer excellent value due to their longevity and low maintenance requirements. While the initial cost may be lower than that of copper rods, the extended lifespan and minimal upkeep needed make galvanized rods a wise investment choice for many projects.

Spark Fittings offers customized armor rod solutions tailored to specific project needs, ensuring that the chosen material aligns with conductor surface materials to prevent corrosion issues. With a focus on quality and longevity, Spark Fittings provides reliable options for armor rod materials in construction and industrial applications.

Conclusion

Making the Right Choice for Your Project

When considering whether to use a galvanized rod or a copper rod for your project, it's important to weigh the benefits and drawbacks of each material. Galvanized rods offer excellent corrosion resistance and durability, making them ideal for outdoor applications, while copper rods have unique properties that make them suitable for specific projects. It's crucial to assess the specific needs of your project and choose the material that best aligns with those requirements.

Considering Material Quality and Cost

In addition to material properties, cost is also a significant factor in decision-making. Galvanized rods are generally more cost-effective than copper rods, making them a practical choice for projects with budget constraints. However, it's essential to prioritize material quality and longevity when making your decision, as investing in high-quality materials can contribute to the overall success and longevity of your project.

Spark Fittings: Your Source for Customized Armor Rods

If you're looking for customized armor rods tailored to your project's specific needs, Spark Fittings is your go-to source. They offer a wide range of armor rod materials, including aluminum wire, galvanized steel wire, and aluminum clad steel wire. With their expertise in preformed armor rods manufacturing and production line equipment supply, Spark Fittings can provide you with high-quality solutions for your project requirements.

With their commitment to quality and customization options, Spark Fittings is dedicated to meeting the unique needs of every project. Whether you require hot dipped galvanized threaded rod or galvanized threaded rod kits, Spark Fittings has the expertise and resources to deliver reliable solutions that align with your project goals.