Introduction

In the realm of manufacturing, formed wire products hold a significant place, serving as the backbone for various applications across multiple industries. From construction to electronics, these products are integral to modern engineering solutions. As we delve into the world of wire forming, it becomes evident that understanding what products are made of wire is crucial for anyone involved in these sectors.

Importance of Formed Wire Products

Formed wire products are essential components in countless applications, providing strength and versatility that few materials can match. Their ability to be shaped into intricate designs makes them invaluable in industries ranging from automotive to telecommunications. By exploring what is wire forming and its benefits, businesses can better appreciate how formed wire products contribute to efficiency and innovation.

Overview of Wire Forming Techniques

Wire forming involves various techniques that manipulate metal wires into specific shapes and configurations for diverse uses. These processes can include bending, coiling, and welding, each tailored to meet unique requirements in manufacturing. Understanding what products are made from MS wire or wire rods further highlights the importance of mastering these techniques in producing high-quality formed wire products.

Key Players in Wire Manufacturing

Within the landscape of wire manufacturing, several key players stand out due to their commitment to quality and innovation. Companies like Spark Fittings specialize in creating equipment for preformed armor rods and tension clamps essential for electrical transmission systems. By examining their contributions alongside other manufacturers, we gain insight into how formed wire products continue to evolve and shape our infrastructure today.

What is Wire Forming?

Wire forming is a crucial manufacturing process that shapes and transforms wire into specific configurations for various applications. This technique encompasses a range of methods that allow manufacturers to create formed wire products tailored to meet diverse industry needs. By understanding what wire forming entails, we can appreciate its significance in producing everything from simple hooks to complex assemblies.

Definition and Process Explained

Wire forming refers to the process of bending, twisting, and shaping wire into desired forms using specialized machinery and techniques. The process typically begins with selecting the appropriate type of wire, which may include materials such as stainless steel, aluminum, or MS (mild steel) wire. Once the material is chosen, it undergoes various operations—like coiling, bending, or cutting—to produce finished products that serve specific functions across different sectors.

The beauty of wire forming lies in its versatility; manufacturers can create an array of items ranging from everyday tools to intricate components used in advanced machinery. This adaptability makes it an essential technique in answering the question: What products are made of wire? From automotive parts to decorative items, the possibilities are virtually limitless when it comes to formed wire products.

Benefits of Wire Forming Techniques

One significant advantage of wire forming techniques is their ability to produce custom solutions efficiently and cost-effectively. By utilizing automated processes and precision machinery, manufacturers can achieve high levels of accuracy while minimizing waste—a win-win for both businesses and the environment. Additionally, formed wire products often exhibit enhanced strength and durability due to the careful selection of materials and engineering practices involved in their creation.

Another benefit lies in the rapid prototyping capabilities offered by modern technology; companies can quickly develop samples or small batches before committing to larger production runs. This agility allows businesses to respond swiftly to market demands while ensuring product quality meets stringent standards. When considering what products are made from MS wire or what products are made from wire rods, it's clear that these techniques foster innovation across industries.

Applications of Wire Forming in Industries

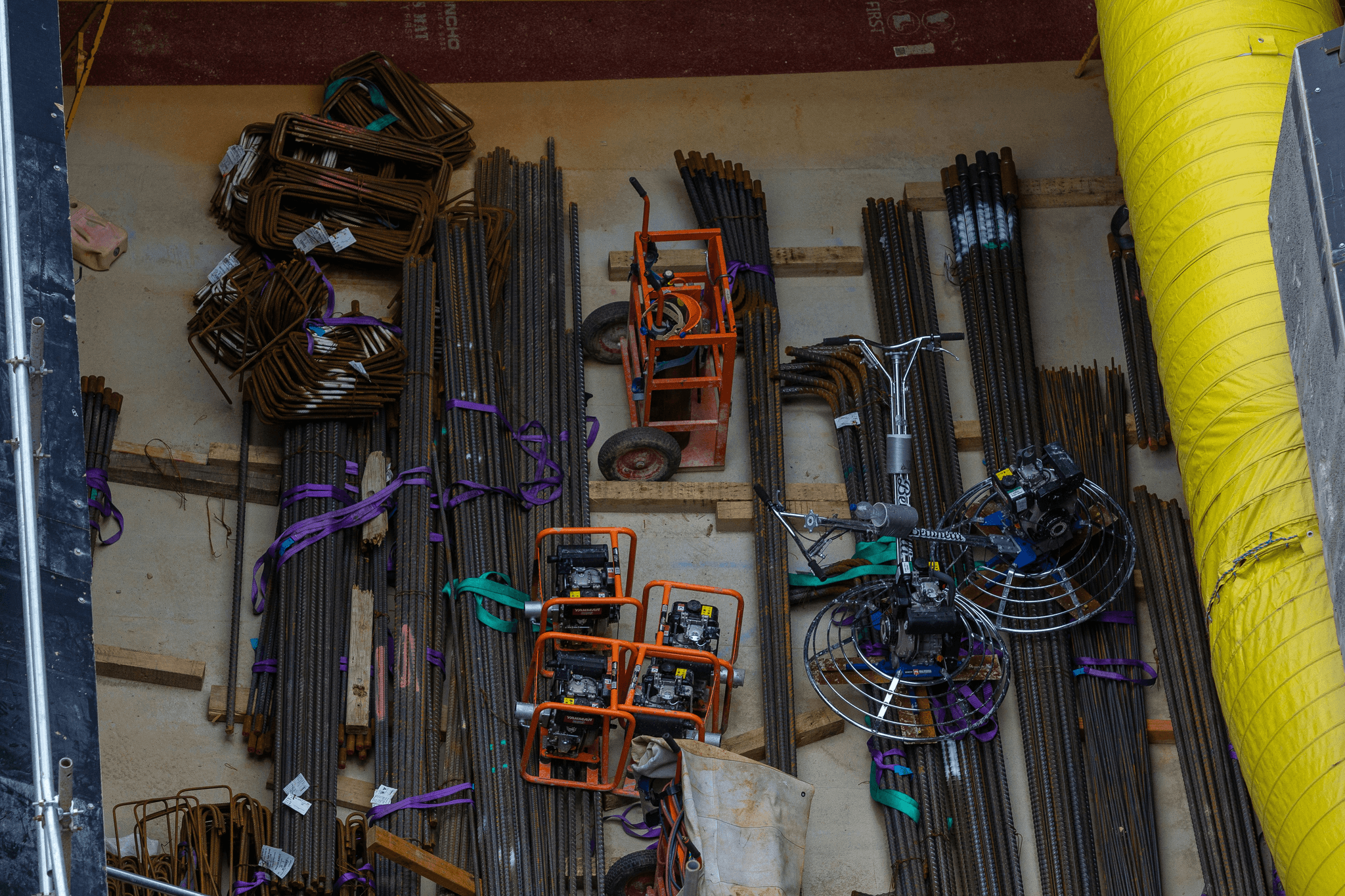

Wire forming finds applications across a multitude of industries due to its inherent flexibility and efficiency in producing formed wire products tailored for specific uses. In construction, for example, formed wires serve as essential components for reinforcing concrete structures or creating safety barriers on job sites. Similarly, sectors like automotive manufacturing leverage custom-formed wires for everything from electrical connections to structural supports.

Moreover, electronics manufacturers utilize precisely shaped wires in circuit boards and other critical components where reliability is paramount. The healthcare industry also benefits significantly from this technology; medical devices often incorporate specialized formed wires designed for optimal performance under rigorous conditions. As we explore further into what products are made from MS wire or what products are made from wire rods later on, it's evident that these applications highlight just how integral this process is across various fields.

What Products are Made of Wire?

Wire is an incredibly versatile material that serves as the backbone for a multitude of products across various industries. From everyday items to specialized equipment, formed wire products play a crucial role in modern manufacturing and engineering. Understanding what products are made of wire not only highlights its importance but also showcases the breadth of applications it encompasses.

Common Products and Their Uses

When we think about common products made from wire, several items come to mind, including hangers, fences, and springs. These formed wire products serve essential functions in our daily lives; for instance, wire hangers help keep our clothes organized while providing durability and strength. Additionally, wire fencing is widely used in agriculture and construction to create boundaries or protect livestock, showcasing the versatility of what products are made from wire.

In more specialized applications, we find components like brackets and clips that are integral to various machinery and equipment. These items often undergo processes defined by what is wire forming to achieve their desired shapes and functionalities. The adaptability of formed wire products means they can be tailored for specific uses across different sectors—whether it's automotive, aerospace, or consumer goods.

Insights into Custom Wire Products

Custom wire products have become increasingly popular as industries demand unique solutions tailored to their specific needs. Companies often seek out custom manufacturing options when off-the-shelf solutions won't cut it; this is where understanding what is wire forming becomes essential. By employing advanced techniques like bending, coiling, or welding during the forming process, manufacturers can create intricate designs that meet exact specifications.

For example, custom brackets or clips can be designed for particular machinery requirements without compromising on strength or durability. This flexibility allows businesses to innovate continuously while ensuring their operational efficiency remains intact—proving once again how essential formed wire products are in modern manufacturing landscapes. Furthermore, custom solutions often lead to cost savings by reducing waste material during production.

The Role of Wire in Modern Engineering

Wire plays a pivotal role in modern engineering by providing structural support and functionality across diverse applications—from construction projects to electrical installations. Understanding what products are made from MS wire can reveal its significance; MS (Mild Steel) offers excellent tensile strength while remaining cost-effective for various applications such as rebar ties or safety barriers.

Moreover, when considering what products are made from wire rods—such as cables used in suspension bridges—the impact becomes even clearer: these components ensure safety while enabling complex designs that were once thought impossible. The engineering world relies heavily on formed wire products not just for their physical properties but also for the innovative possibilities they present within design parameters.

In summary, whether it's through standard offerings or bespoke creations tailored via custom processes—formed wire products remain indispensable players across numerous industries today!

What Products are Made from MS Wire?

MS Wire and Its Versatility

MS wire is renowned for its adaptability across various industries, which is precisely why it’s a favorite among manufacturers. It can be easily formed into different shapes and sizes through various wire forming techniques, allowing for the creation of both standard and custom formed wire products. Whether you're in construction, automotive, or even electronics, MS wire has the potential to meet diverse engineering needs.

Examples of Products Using MS Wire

The list of products made from MS wire is extensive and impressive. Common examples include fencing materials that provide security without compromising aesthetics, springs that serve vital functions in machinery and everyday items like mattresses or pens, and hooks used in countless applications—from home organization to industrial settings. Additionally, custom formed wire products such as brackets or specialized components can be tailored to specific requirements in various industries.

Advantages of Using MS Wire in Manufacturing

Using MS wire offers several advantages that make it an attractive option for manufacturers looking at efficiency and cost-effectiveness. First off, its malleability allows for easy manipulation during the forming process; this means less time spent on production without sacrificing quality—an essential factor when considering what is wire forming? Moreover, its resistance to wear makes it ideal for long-lasting products that withstand daily use while keeping maintenance costs low. In summary, incorporating MS wire into manufacturing not only enhances product performance but also streamlines production processes.

What Products are Made from Wire Rods?

Wire rods are the unsung heroes in the world of formed wire products, serving as the foundational material for a plethora of applications. These long, cylindrical pieces of metal are produced through a process called wire drawing, which enhances their strength and versatility. In industries ranging from construction to automotive manufacturing, wire rods play a crucial role in creating both structural and functional components.

Understanding Wire Rods and Their Applications

Wire rods are typically made from steel or other alloys and come in various diameters to suit different manufacturing needs. They find extensive use in producing various formed wire products such as nails, screws, and even high-strength cables used in construction projects. The flexibility of wire rods allows manufacturers to create items that meet specific engineering requirements while maintaining durability.

Applications of wire rods extend beyond simple fasteners; they are also integral to making springs, wires for electrical applications, and reinforcement materials for concrete structures. When considering What products are made from wire rods?, one can identify an impressive range that includes everything from fencing materials to intricate machinery components. This versatility makes them indispensable across multiple sectors.

Differentiating Wire Rod Products

Differentiating between various types of wire rod products is essential for understanding their specific uses and benefits. For instance, some wire rods may be cold drawn for enhanced tensile strength, while others might be hot rolled for improved ductility during forming processes. Additionally, the coating applied to these products can vary significantly; galvanized options offer corrosion resistance ideal for outdoor applications.

In terms of size and shape, wire rod products can range from thin wires used in electronics to thick cables designed for heavy lifting or anchoring purposes. Understanding What products are made of wire? involves recognizing how these differences cater to distinct industry requirements—be it automotive parts or building infrastructures like bridges and skyscrapers.

The Impact of Wire Rods in Construction and More

The impact of wire rods on construction is monumental; they provide the backbone for many structural elements within buildings and infrastructure projects. Reinforcing bars (rebar) made from wire rod help strengthen concrete structures by providing tensile support where needed most. Moreover, their application extends into creating safety features such as barriers or fencing around construction sites.

Beyond construction, industries like telecommunications rely heavily on formed wire products derived from high-quality wire rods—think telephone lines or overhead cables that keep our connected world running smoothly! Spark Fittings exemplifies this impact by specializing in equipment that utilizes preformed armor rods specifically designed for tension clamps used in electricity transmission systems.

In conclusion, understanding what products are made from wire rods reveals their critical role across numerous sectors—from providing structural integrity in buildings to facilitating communication through electrical infrastructure. As we continue exploring innovations within formed wire products with leading manufacturers like Spark Fittings at the forefront, it's clear that the future holds exciting developments driven by these versatile materials.

Leading Manufacturers: Spotlight on Spark Fittings

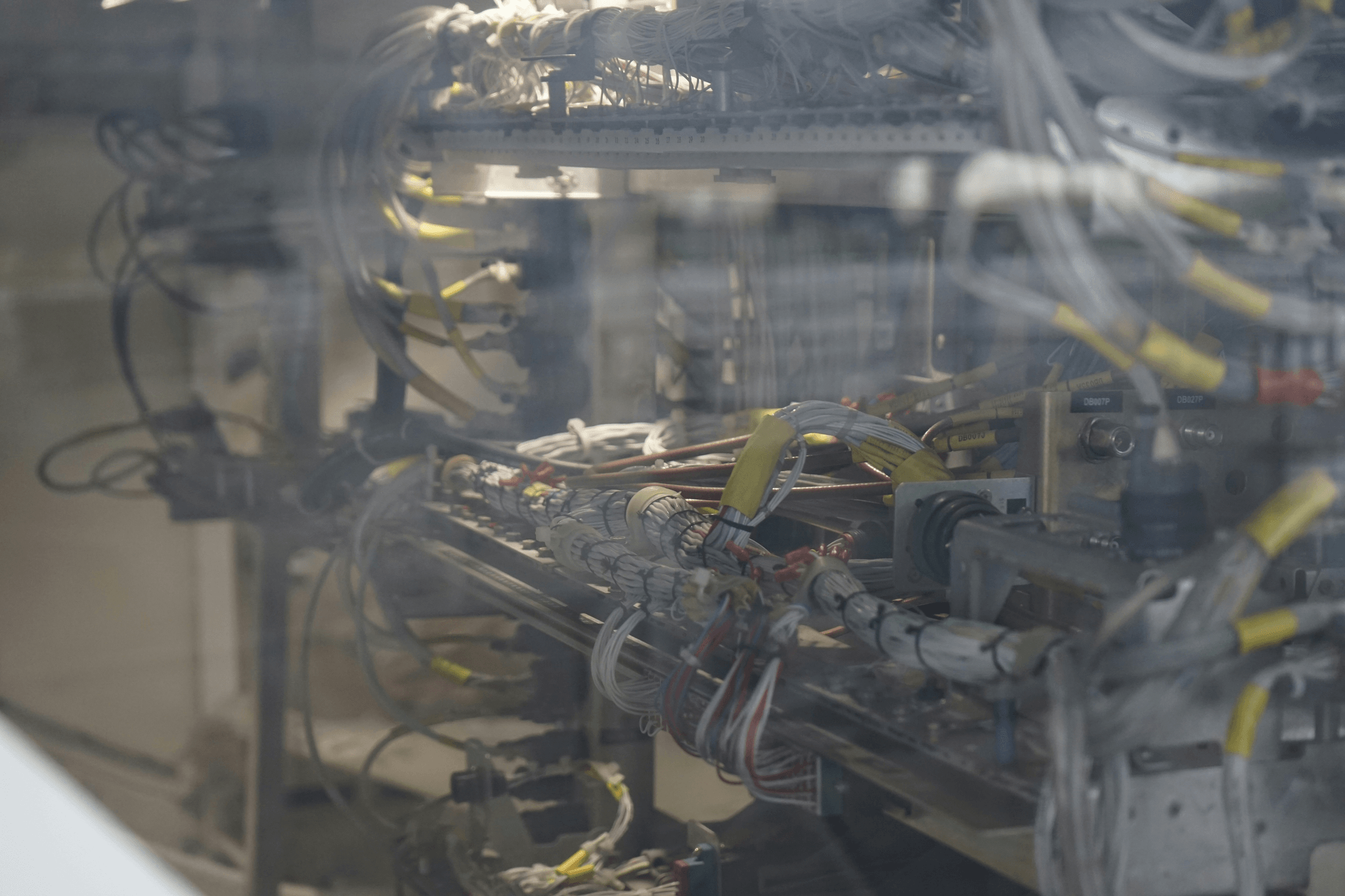

Overview of Spark Fittings’ Product Range

Spark Fittings offers an impressive array of formed wire products designed to meet various industry needs. Their product line encompasses essential components such as preformed armor rods that protect cables from environmental stressors, tension clamps that secure wires, and specialized cable accessories that ensure seamless connectivity. By focusing on what products are made from wire, they cater to sectors like electrified railways and power distribution networks.

The versatility of their offerings illustrates the wide-ranging applications of formed wire products across different industries. From telecommunications to energy production, each product is engineered for durability and performance. Customers can rely on Spark Fittings not just for standard solutions but also for custom designs tailored specifically to their operational requirements.

Innovations in Formed Wire Product Manufacturing

Innovation is at the heart of Spark Fittings' approach to manufacturing formed wire products. The company employs cutting-edge technology and advanced machinery to streamline production processes while maintaining high quality standards. By integrating modern techniques into what is wire forming?, they enhance both efficiency and precision in creating intricate wire components.

Moreover, their commitment to research and development ensures that they stay ahead of industry trends while continuously improving their product offerings. This proactive stance allows them to introduce new features that enhance functionality—such as improved load-bearing capabilities or corrosion resistance—making their formed wire products even more appealing to customers across various sectors.

Commitment to Quality and Sustainability

Quality assurance is a fundamental principle at Spark Fittings; they meticulously monitor every aspect of production to guarantee exceptional performance in all their formed wire products. This dedication extends beyond just meeting industry standards; it reflects a broader commitment to customer satisfaction through reliable solutions tailored for specific needs.

In addition, Spark Fittings prioritizes sustainability within its manufacturing processes by utilizing eco-friendly materials whenever possible and implementing energy-efficient practices throughout production lines. Their focus on what products are made from MS wire? highlights how responsibly sourced materials contribute positively towards environmental conservation efforts without compromising product integrity or performance.

By choosing Spark Fittings as your supplier for formed wire products, you’re not just investing in quality; you’re supporting a company dedicated to sustainable practices that benefit both customers and the planet alike.

Conclusion

In conclusion, formed wire products are essential components across various industries, showcasing their versatility and adaptability. As we look to the future, advancements in technology and manufacturing processes promise even more innovative applications for these products. Understanding what products are made of wire can help businesses leverage their potential to meet evolving demands.

The Future of Formed Wire Products

The future of formed wire products is bright, with increasing demand driven by technological advancements and sustainability initiatives. Industries are continually exploring new applications for wire forming techniques, resulting in enhanced product performance and reduced environmental impact. As companies invest in research and development, we can expect to see a wider variety of custom solutions emerging from the question: what is wire forming?

Choosing the Right Formed Wire Manufacturer

When it comes to selecting a manufacturer for formed wire products, quality and reliability should be top priorities. Researching potential partners involves understanding their capabilities in producing various items—like those derived from MS wire or wire rods—and evaluating their commitment to innovation. Spark Fittings stands out as a premier choice with its specialization in manufacturing equipment for preformed armor rods and cable accessories that cater specifically to the needs of electric transmission systems.

Exploring Opportunities in Wire Product Supply

Exploring opportunities within the supply chain for formed wire products can lead to significant benefits for businesses looking to enhance their offerings. By understanding what products are made from MS wire or what products are made from wire rods, manufacturers can better tailor their inventory to meet market demands effectively. With companies like Spark Fittings leading the charge in quality production methods, there has never been a better time to tap into this growing sector.