Introduction

When it comes to protecting power lines, line guards play a crucial role in ensuring safety and reliability. Understanding the importance of line guards is essential for maintaining the integrity of transmission lines. Additionally, exploring different types of line guards and addressing frequently asked questions can provide valuable insights into their usage and benefits.

Understanding the Importance of Line Guards

Line guards are essential components that provide protection to overhead power lines from various environmental factors and external threats. They help prevent damage to the conductors, insulators, and other vital components, ultimately ensuring uninterrupted power supply.

Line guards come in a variety of types, each designed to address specific threats and environmental conditions. For instance, bird flight diverters are used to prevent birds from colliding with power lines, while spacer dampers are installed to minimize the effects of wind-induced vibrations. Additionally, tree wire guards are used to protect power lines from vegetation interference. Understanding these different types of line guards is crucial in selecting the most suitable ones for specific locations and conditions.

Exploring Different Types of Line Guards

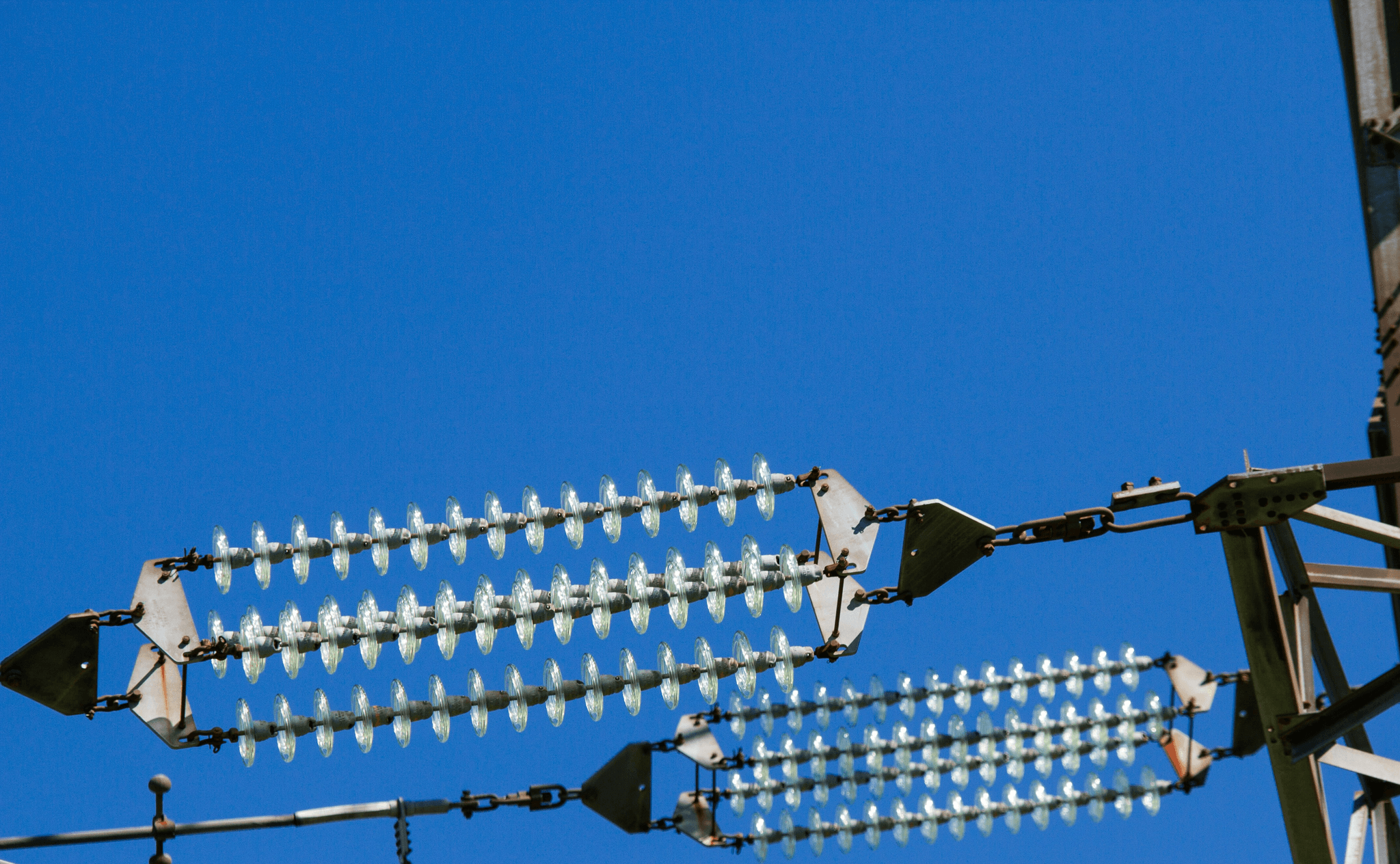

There are various types of line guards available, each designed to cater to specific needs and requirements. From porcelain to polymer line guards, understanding their differences and applications is crucial for selecting the most suitable option for a particular power line infrastructure.

Understanding the specific environmental conditions and potential threats to power lines is essential for choosing the right type of line guard. For example, in areas with high levels of pollution or chemical exposure, porcelain line guards may be more suitable due to their resistance to corrosion and degradation. On the other hand, polymer line guards are lightweight and flexible, making them ideal for areas prone to extreme weather conditions such as strong winds or heavy snowfall.

FAQs About Line Guards

Addressing common questions about line guards can help clarify misconceptions and provide valuable information about their installation, maintenance, and effectiveness in safeguarding power lines against adverse conditions.

Line guards are protective devices designed to shield power lines from various environmental hazards such as tree branches, animals, and severe weather. They are typically made of durable materials such as plastic or metal and are installed along the length of the power line to provide a physical barrier against potential threats. Line guards play a crucial role in preventing power outages and reducing the risk of electrical fires caused by contact with foreign objects or vegetation. Additionally, they help maintain the integrity of the power grid by minimizing disruptions and ensuring continuous electricity supply to consumers.

What is a Line Guard?

Definition and Purpose of Line Guards

A line guard is a protective device used in overhead power lines to prevent damage to insulators from wildlife, vegetation, or other external factors. The primary purpose of a line guard is to maintain the integrity of the power line and ensure uninterrupted electrical transmission.

Line guards are typically made from durable materials such as metal, plastic, or composite materials. These materials are chosen for their ability to withstand harsh weather conditions and resist corrosion, ensuring the longevity of the line guard. Additionally, line guards are designed to be lightweight yet sturdy, allowing for easy installation and maintenance without compromising on their protective capabilities.

Common Materials Used in Line Guards

Line guards are typically made from durable materials such as galvanized steel, aluminum, or composite materials. These materials are chosen for their ability to withstand harsh weather conditions and provide long-lasting protection for the power lines.

Line guards made from galvanized steel offer exceptional strength and corrosion resistance, making them ideal for protecting power lines in areas with extreme weather conditions. Aluminum line guards are lightweight yet sturdy, providing a cost-effective solution for ensuring the safety and longevity of power lines. Additionally, composite materials offer a versatile option for line guards, as they can be customized to meet specific requirements while still delivering durability and reliability.

Benefits of Using Line Guards

The use of line guards offers several benefits, including increased reliability of the power grid by reducing the risk of outages caused by animal interference or environmental factors. Additionally, line guards help extend the lifespan of insulators and minimize maintenance costs for power utilities.

Line guards also contribute to the overall safety of the power grid by reducing the risk of electrical fires and other hazardous incidents. By providing an additional layer of protection for power lines, line guards help prevent potential damage or accidents that could result in significant harm to people and property. This added safety measure not only benefits power utilities but also enhances the well-being of communities that rely on a stable and secure electrical infrastructure.

The Difference Between Line Guard and Armor Rod

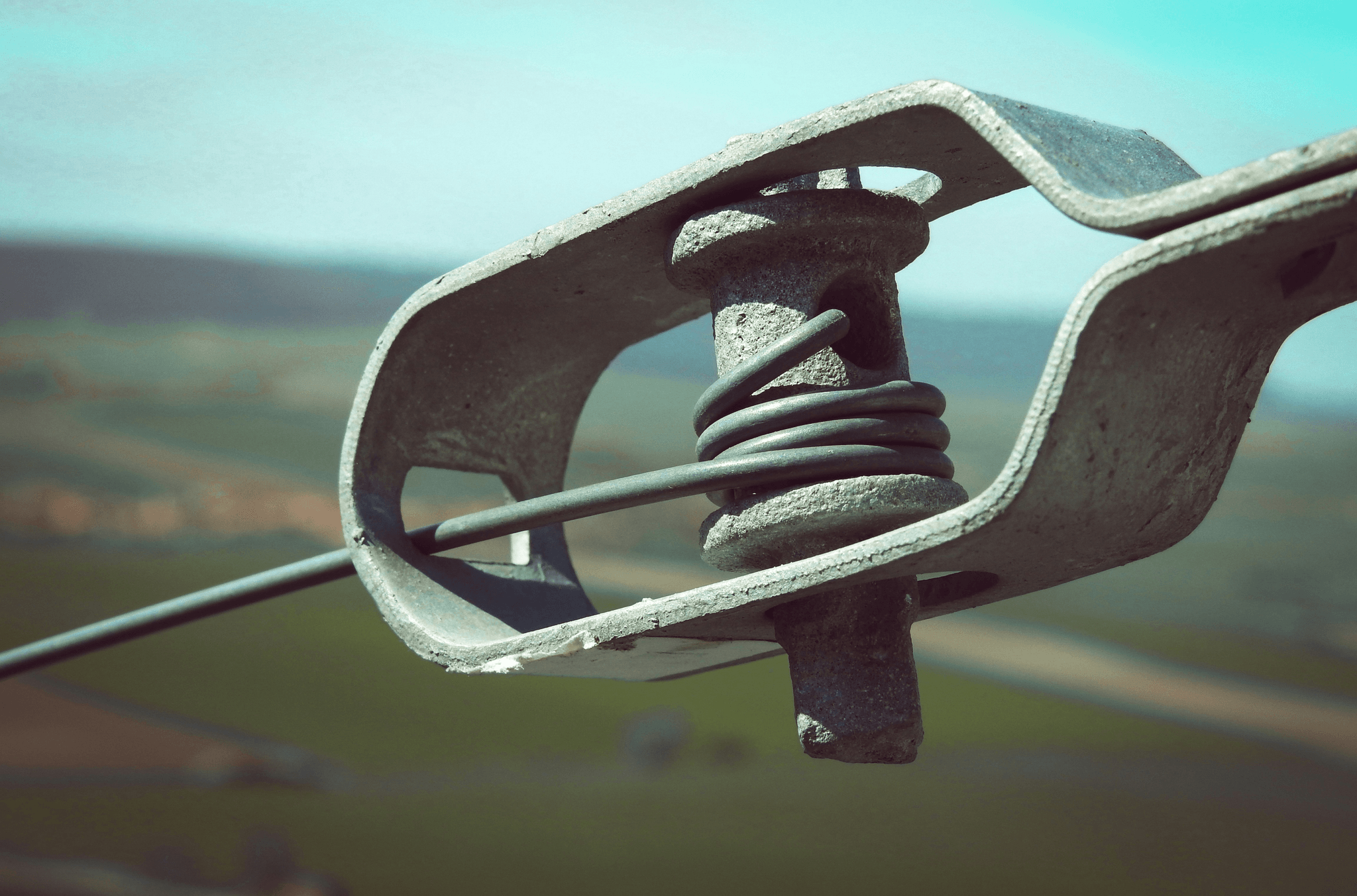

Distinct Features of Line Guards and Armor Rods

Line guards are protective devices designed to shield power lines and insulators from damage caused by external factors such as wildlife, weather, and debris. They are typically made of durable materials such as polymer, fiberglass, or rubber, offering flexibility and resistance to harsh environmental conditions. On the other hand, armor rods are specifically used to protect overhead power lines from abrasion caused by vibration or wind-induced motion.

Line guards are essential for protecting power lines and insulators from potential damage caused by various external factors. They are particularly useful in areas where wildlife, such as birds or squirrels, might come into contact with the power lines, as well as in regions prone to extreme weather conditions like heavy rain, snow, or high winds. The flexibility and durability of materials used in line guards make them ideal for withstanding harsh environmental elements, ensuring the longevity of the power lines and insulators they protect.

When to Use Line Guards vs. Armor Rods

Line guards are ideal for preventing flashovers and outages on distribution lines with insulator strings, while armor rods are best suited for providing mechanical protection to the conductor where it is attached to the insulator. When choosing between line guards and armor rods, it is important to consider the specific needs of your power line infrastructure in order to provide adequate protection against potential threats.

When choosing between line guards and armor rods, it is important to consider the specific needs of your power line infrastructure in order to provide adequate protection against potential threats. Line guards are designed to prevent flashovers and outages on distribution lines with insulator strings, making them a crucial component for maintaining uninterrupted power supply. On the other hand, armor rods offer mechanical protection to the conductor where it is attached to the insulator, safeguarding against wear and tear caused by environmental factors and physical stress. By understanding the distinct functions of these two protective measures, you can make informed decisions about which solution best suits your infrastructure's requirements.

Choosing the Right Protection for Your Insulators

When selecting protection for your insulators, it's crucial to assess the environmental conditions in which your power lines operate. Line guards offer comprehensive coverage for insulator strings on distribution lines, safeguarding against animal contact and environmental wear. On the other hand, armor rods provide targeted support for specific areas of the power line where mechanical stress is a concern.

By understanding the distinct features of line guards and armor rods, you can make informed decisions about how to best protect your power lines from potential threats such as wildlife interference or mechanical stress. Whether you choose line guards or armor rods, both options play a crucial role in maintaining the integrity of your electrical infrastructure.

Where Line Guards Are Positioned

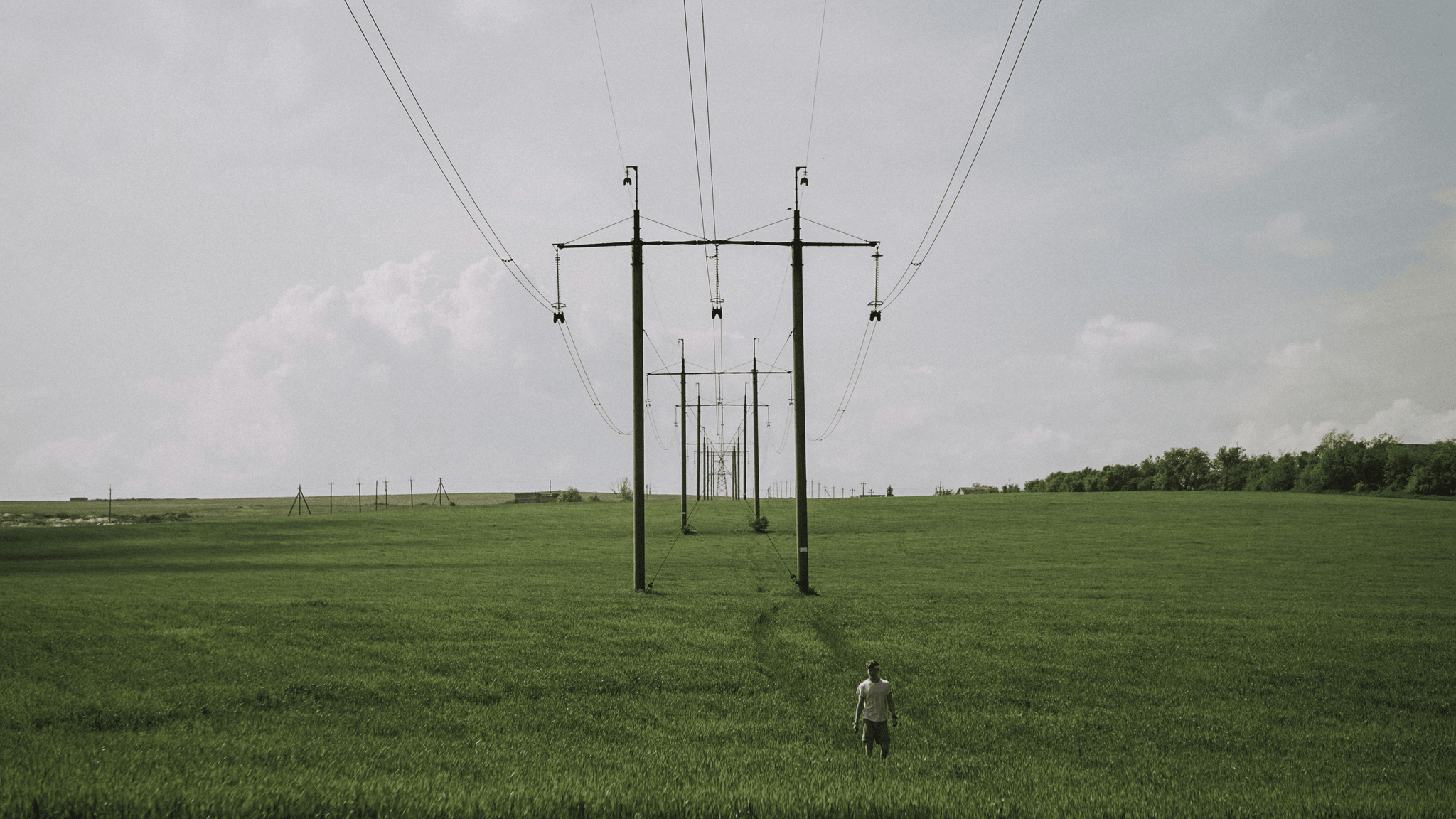

Line guards are strategically positioned along overhead power lines to provide protection against various environmental and mechanical factors. Proper placement of line guards is crucial in ensuring the safety and longevity of power lines, as they act as a barrier against wildlife interference, weather-related damage, and physical contact from nearby objects.

Importance of Proper Placement of Line Guards

The importance of proper placement of line guards cannot be overstated, as it directly impacts the effectiveness of the protection they provide. Placing line guards at vulnerable points along the power lines, such as sharp angles or areas prone to animal contact, is essential for maximizing their impact in preventing damage and outages.

Factors to Consider When Installing Line Guards

When installing line guards, several factors must be taken into consideration to ensure their optimal performance. Factors such as the type of power line, environmental conditions, and potential sources of interference should be carefully evaluated to determine the most suitable placement for line guards.

Best Practices for Aligning Line Guards

Aligning line guards with precision is crucial for their effectiveness in safeguarding power lines. Utilizing advanced tools and equipment from reputable manufacturers like Spark Fittings can ensure accurate alignment during installation, enhancing the overall protection provided by line guards.

To further enhance the precision of line guard alignment, it is essential to conduct regular inspections and maintenance. This proactive approach can help identify any misalignments or issues with the line guards, allowing for prompt adjustments to be made. By staying vigilant and addressing any alignment issues early on, you can ensure that the line guards continue to provide optimal protection for power lines.

Understanding the Role of Guard Wire in Transmission Lines

Guard wires play a crucial role in enhancing insulator protection by providing an additional layer of defense against environmental factors and potential damage from external forces. They act as a barrier, shielding the insulators from debris, wildlife, and weather-related wear and tear.

How Guard Wires Enhance Insulator Protection

Guard wires are designed to prevent flashovers and protect insulators from physical damage. By creating a protective perimeter around the transmission lines, guard wires effectively minimize the risk of power outages and equipment failure caused by adverse conditions or external interference.

Types of Guard Wires Available

There are various types of guard wires available, including galvanized steel, aluminum, and composite materials. Each type offers unique benefits in terms of strength, durability, and resistance to corrosion, allowing for customized solutions based on specific environmental and operational requirements.

Integrating Guard Wires with Line Guards

Integrating guard wires with line guards provides a comprehensive approach to safeguarding power lines. By combining these protective measures, operators can ensure maximum reliability and longevity for their electrical infrastructure while minimizing maintenance needs and downtime.

Overhead Power Line Guards: Essential for Safety

When it comes to protecting power lines, line guards play a crucial role in ensuring safety and preventing accidents. These guards are essential for maintaining the integrity of electrical lines and preserving the overall functionality of the transmission system.

Safety Regulations and Standards for Line Guards

In order to maintain high safety standards, there are specific regulations in place that govern the use of line guards in electrical transmission systems. These regulations ensure that line guards meet certain criteria for durability, reliability, and effectiveness in protecting power lines from potential damage.

Impact of Line Guards on Preventing Accidents

The implementation of line guards has a significant impact on preventing accidents related to power lines. By providing an extra layer of protection, line guards help minimize the risk of electrical faults, insulator damage, and potential hazards to personnel working near the transmission lines.

Innovations in Overhead Power Line Guard Technology

With advancements in technology, there have been innovative developments in overhead power line guard technology. New materials and designs have improved the efficiency and effectiveness of line guards, leading to enhanced protection for power lines and increased longevity of the equipment.

By staying updated on safety regulations, understanding the impact of line guards on accident prevention, and embracing technological innovations, it is possible to protect power lines effectively with high-quality line guards. Spark Fittings offers top-notch equipment for preformed armor rods and cable accessories to support this crucial aspect of electrical infrastructure maintenance.

Conclusion

When it comes to protecting power lines, choosing the right line guard is crucial. Look for durable materials such as polymer or fiberglass, and consider the specific needs of your transmission lines. To ensure longevity, regular inspection and maintenance of line guards are essential. By investing in quality line guards, you can effectively protect power lines from damage and prevent accidents.

Tips for Choosing the Right Line Guard

When selecting a line guard, consider factors such as the voltage of the power lines, environmental conditions, and the type of insulators being used. It's important to choose a line guard that is compatible with your specific requirements to ensure effective protection against electrical faults and lightning strikes. Always consult with experts in the field to make an informed decision.

Ensuring Longevity of Line Guard Protection

To maintain the effectiveness of line guard protection, conduct regular inspections to check for signs of wear and tear. Replace any damaged or worn-out line guards promptly to prevent potential hazards. Additionally, follow manufacturer guidelines for installation and maintenance to maximize the lifespan of your line guards.

Protecting Power Lines with Quality Line Guards

Investing in high-quality line guards is essential for safeguarding power lines from various external threats. By choosing reliable manufacturers like Spark Fittings, you can ensure that your line guards are built to withstand harsh environmental conditions and provide long-term protection for your transmission lines.