Introduction

In the world of manufacturing, spring winding machines play a pivotal role in producing essential components used across various industries. Understanding how these machines operate and their significance can greatly enhance efficiency and product quality. As we delve into the realm of CNC spring coiling, it's crucial to grasp what a spring machine is and how it revolutionizes the process of creating compression springs.

Understanding Spring Winding Machines

A spring winding machine is designed specifically for crafting springs with precision and speed. These machines can produce various types of springs, including compression springs, which are vital for numerous applications from automotive to aerospace. By automating the winding process, manufacturers can achieve consistent quality while reducing production time significantly.

Importance of CNC Spring Coiling

CNC spring coiling machines elevate the efficiency of spring manufacturing by utilizing computer numerical control technology to ensure precise dimensions and repeatability. This automation minimizes human error and allows for complex designs that would be challenging to achieve manually. The importance of CNC technology cannot be overstated; it enables manufacturers to meet high demand while maintaining quality standards in their products.

Overview of Spring Winding Process

The process of spring winding involves several key steps that transform raw materials into finished products ready for use in various applications. Initially, wire is fed into the machine, where it is shaped into coils through a series of controlled movements and adjustments. Understanding how a spring coiler works will provide insights into each phase—from material selection to final inspection—ensuring that every coil meets rigorous industry standards.

What is a Spring Machine?

When diving into the world of spring manufacturing, one often encounters the term spring machine. But what is a spring machine? Essentially, it refers to specialized equipment designed for producing springs, including various types such as compression springs and torsion springs. These machines are pivotal in industries ranging from automotive to aerospace, where precision and efficiency are paramount.

Defining the Spring Winding Machine

A spring winding machine is a specific type of spring machine that focuses on creating coiled springs through automated processes. This machinery typically employs CNC (Computer Numerical Control) technology to ensure high precision and repeatability in the production of springs. Understanding what a CNC spring coiling machine entails is essential, as it allows manufacturers to produce complex designs with minimal manual intervention.

Types of Spring Machines

There are several types of spring machines available in the market today, each tailored for different applications and requirements. Among these, compression spring machines stand out due to their ability to create tightly wound coils that can withstand significant loads. Other notable types include torsion spring machines and extension spring machines, each serving unique purposes in various industries.

Applications of Spring Machines

Spring machines find applications across a multitude of sectors due to their versatility and reliability. From automotive suspension systems that rely on compression springs for shock absorption to industrial machinery that uses extension springs for tensioning mechanisms, these devices are everywhere! In addition, they play crucial roles in electronics and medical devices, making them indispensable tools in modern manufacturing processes.

Exploring Compression Spring Machines

Compression spring machines are essential tools in the manufacturing sector, specifically designed to produce compression springs with precision and efficiency. These machines play a pivotal role in various industries, from automotive to aerospace, where reliable spring performance is crucial. Understanding the features and benefits of Compression Spring Machines can significantly impact your production capabilities.

Features of Compression Spring Machines

Compression Spring Machines are equipped with advanced technology that allows for precise control over the spring winding process. Many models include CNC capabilities, which enable operators to program complex designs and automate the winding process seamlessly. Additionally, these machines often feature adjustable tension settings and speed controls, ensuring that each coil meets strict quality standards while minimizing material waste.

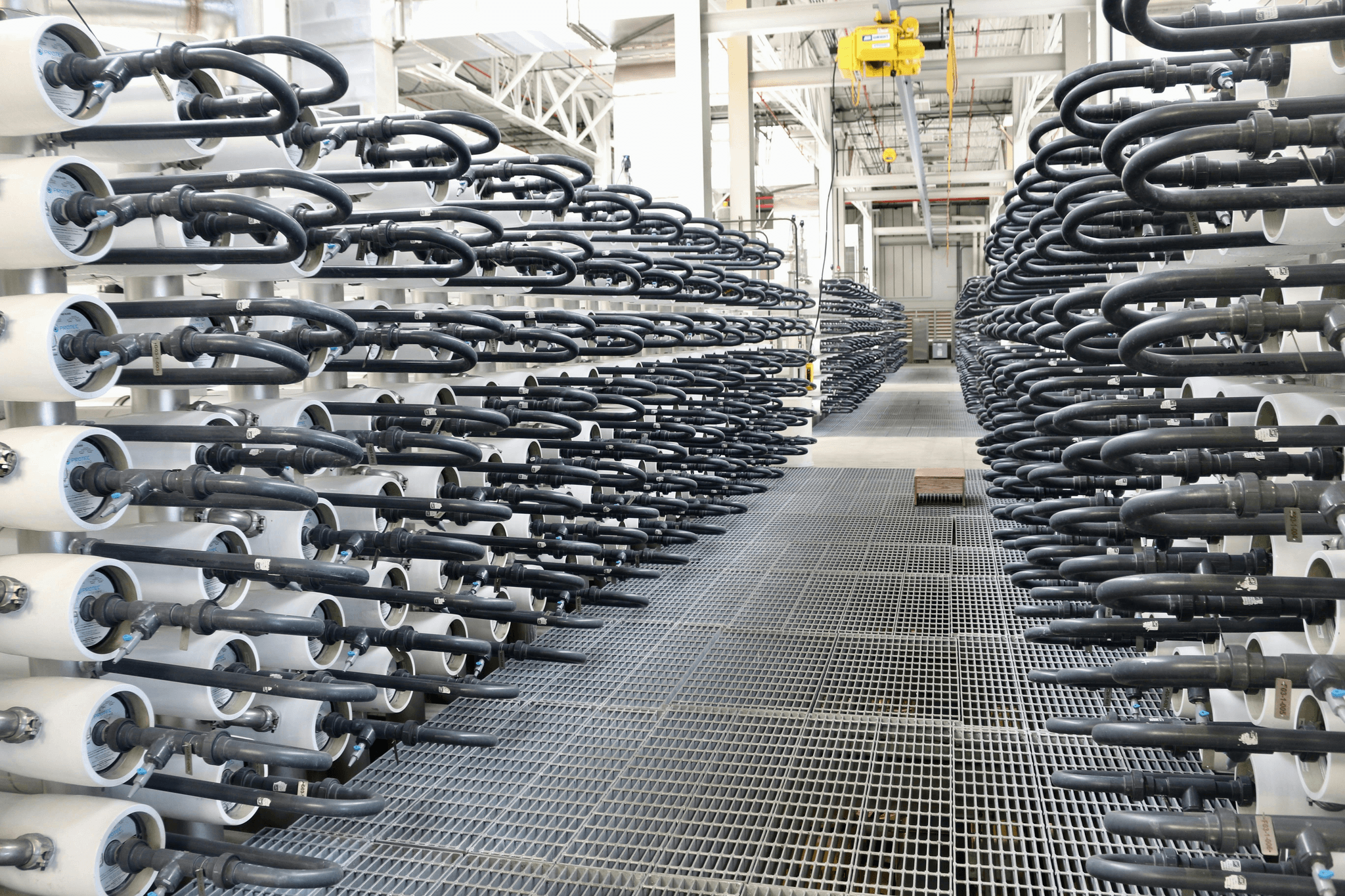

What is a spring machine? At its core, it refers to any device that shapes wire into coils or springs; however, a compression spring machine specifically focuses on creating tightly wound springs that can compress under load. These machines typically consist of a wire feeder, coiling mechanism, and cutting tools—all working harmoniously to produce high-quality compression springs efficiently.

Benefits of Using Compression Spring Machines

The advantages of using Compression Spring Machines are numerous and impactful for manufacturers looking to enhance their production processes. First and foremost, these machines increase efficiency by automating much of the winding process; this not only speeds up production but also reduces labor costs associated with manual winding techniques.

Furthermore, utilizing advanced CNC technology allows for consistent quality across all produced springs—what is the process of spring winding? It involves feeding wire through a series of rollers while it’s coiled around a mandrel; CNC systems ensure this happens flawlessly every time. This consistency leads to fewer defects in final products and greater customer satisfaction.

Leading Manufacturers in the Market

When exploring options for Compression Spring Machines, it's essential to consider leading manufacturers known for their quality and innovation in this space. Companies like Spark Electronic Technology Wuxi Co., Ltd., stand out due to their commitment to producing high-performance machinery tailored for specific applications such as preformed armor rods and tension clamps alongside compression spring equipment.

Spark Electronic's range includes state-of-the-art equipment like automatic glue sand blasting machines and hydraulic bending machines—key components that complement any modern spring manufacturing setup. With such advancements from reputable manufacturers, businesses can confidently invest in machinery that enhances productivity while maintaining high standards in quality control.

How Does a Spring Coiler Work?

Mechanism of a Spring Coiler

The mechanism of a spring coiler revolves around its ability to manipulate wire into specific shapes, forming coils that meet desired specifications. At its core, the machine often utilizes CNC (Computer Numerical Control) technology, allowing for precise control over dimensions and winding patterns. This means that when you ask, What is the process of spring winding? you're really referring to an automated ballet where wires dance around mandrels under exacting conditions.

Key Components of a Spring Coiler

A typical spring coiler consists of several key components that work harmoniously together to produce high-quality springs efficiently. These include the wire feed system, which supplies material; the forming unit, which shapes the wire; and the control panel for programming and monitoring operations. In asking What is a CNC spring coiling machine?, you are essentially inquiring about this sophisticated assembly that combines technology with mechanical engineering to produce Compression Spring Machines capable of meeting diverse industry needs.

Advantages of Automated Coiling

Automated coiling offers numerous advantages that make it an attractive option for manufacturers looking to streamline their processes. For starters, it significantly reduces labor costs while increasing production speed—two factors crucial in today's competitive market landscape. Moreover, machines like those from Spark Electronic Technology Wuxi Co., Ltd., come equipped with advanced features that enhance reliability and precision in every coil produced by their Compression Spring Machines.

The Spring Winding Process Explained

Step-by-Step Guide to Spring Winding

To grasp what is the process of spring winding, it's essential to start with the setup of a CNC spring coiling machine. First, operators load wire into the machine and configure settings based on desired specifications such as diameter and coil pitch. Next, the machine begins its work by feeding wire through rollers and bending it around a mandrel, which shapes it into coils with remarkable accuracy.

Once coiling is complete, springs are cut to length using automated tools integrated into Compression Spring Machines. This automation not only speeds up production but also ensures consistent quality across batches. Finally, finished springs undergo heat treatment if required, enhancing their strength and durability before they move on to quality inspection.

Quality Control in Spring Manufacturing

Quality control is paramount in ensuring that every spring produced meets stringent industry standards and client specifications. During manufacturing, operators utilize various techniques to monitor dimensions and tolerances throughout the winding process—this is where understanding what is a spring machine becomes critical for maintaining accuracy. Regular checks for defects or inconsistencies help prevent costly errors down the line.

Incorporating advanced technologies like digital gauges can further enhance quality assurance efforts within Compression Spring Machines. These devices provide real-time feedback on measurements during production runs, allowing for immediate adjustments if necessary. By prioritizing quality control at each stage of production, manufacturers can guarantee that their springs perform reliably in applications ranging from automotive components to industrial machinery.

Innovations in Spring Winding Technology

The landscape of spring manufacturing has evolved significantly due to technological advancements over recent years. Innovations such as smart CNC systems have transformed traditional methods by introducing features like predictive maintenance and real-time monitoring capabilities—making processes more efficient than ever before! Understanding how does a spring coiler work now includes recognizing its ability to adapt quickly based on operational data.

Moreover, companies like Spark Electronic Technology Wuxi Co., Ltd., are leading the charge with state-of-the-art equipment designed specifically for high-volume production needs while maintaining exceptional precision levels across all types of springs. Their key equipment offerings include automatic glue sand blasting machines and tensile testing machines which enhance both performance and reliability during manufacturing processes.

As we look ahead at future trends within this sector—such as increased automation and integration with IoT technologies—it’s clear that staying updated on innovations will be essential for any manufacturer aiming to excel in producing top-notch springs efficiently.

Spark Electronic and Spring Machines

In the world of spring manufacturing, Spark Electronic Technology Wuxi Co., Ltd. stands out as a beacon of innovation and quality. Specializing in equipment for producing preformed armor rods, tension clamps, and cable accessories, they play an essential role in enhancing the efficiency of spring winding machines, including CNC spring coiling machines. Their commitment to excellence ensures that customers can produce high-quality components crucial for various applications like electrified railways and electrical transmission.

Overview of Spark Electronic Technology

Spark Electronic Technology Wuxi Co., Ltd. has carved a niche in the manufacturing landscape by focusing on advanced machinery tailored for specific industrial needs. Their expertise extends to creating top-tier equipment that supports what is a spring machine?—a vital component in producing reliable springs for numerous applications. By integrating cutting-edge technology into their designs, they ensure that their products not only meet but exceed industry standards.

Key Equipment for Spring Production

When it comes to key equipment for spring production, Spark Electronic offers an impressive lineup that boosts productivity and quality control throughout the manufacturing process. From preformed armor rods forming machines to hydraulic bending machines, each piece of equipment plays a significant role in enhancing what is the process of spring winding? These tools are designed to work seamlessly with compression spring machines, ensuring optimal performance while reducing downtime.

Enhancements to Spring Manufacturing Processes

The enhancements brought about by Spark Electronic's technology redefine traditional methods used in spring production processes. With automated solutions like glue sand blasting machines and tensile testing machines, manufacturers can now achieve higher precision and consistency than ever before when utilizing a CNC spring coiling machine or any other type of spring winding machine. This leap forward not only streamlines operations but also significantly improves product quality across various industries.

Conclusion

In the world of manufacturing, understanding the nuances of spring winding machines is crucial for optimizing production processes. As we look ahead, the evolution of technology promises exciting advancements in CNC spring coiling and compression spring machines, paving the way for more efficient and precise operations. The future of spring manufacturing is not just about keeping up with trends; it’s about anticipating needs and adapting to new challenges.

Future Trends in Spring Winding Machines

The future trends in spring winding machines are heavily influenced by automation and smart technology integration. Innovations such as IoT connectivity are set to enhance how we monitor and control what is a spring machine, allowing real-time data analysis for better decision-making. Additionally, advancements in CNC spring coiling machines will likely lead to increased customization options, enabling manufacturers to produce a wider variety of springs with minimal downtime.

Choosing the Right Machine for Your Needs

When it comes to choosing the right machine for your needs, understanding what is a CNC spring coiling machine becomes essential. Factors like production volume, type of springs required, and budget constraints play critical roles in this decision-making process. By evaluating these aspects alongside your specific requirements for compression spring machines, you can select the most suitable equipment that will streamline your operations and enhance productivity.

Final Thoughts on Spring Manufacturing

In conclusion, mastering the process of spring winding involves not only knowing how does a spring coiler work but also staying informed about industry trends and technological innovations. As companies like Spark Electronic Technology Wuxi Co., Ltd. continue to lead with their advanced machinery tailored for various applications, it's clear that quality equipment will define success in this sector. Ultimately, investing wisely in modern spring winding machines will ensure that manufacturers remain competitive while meeting ever-evolving market demands.