Introduction

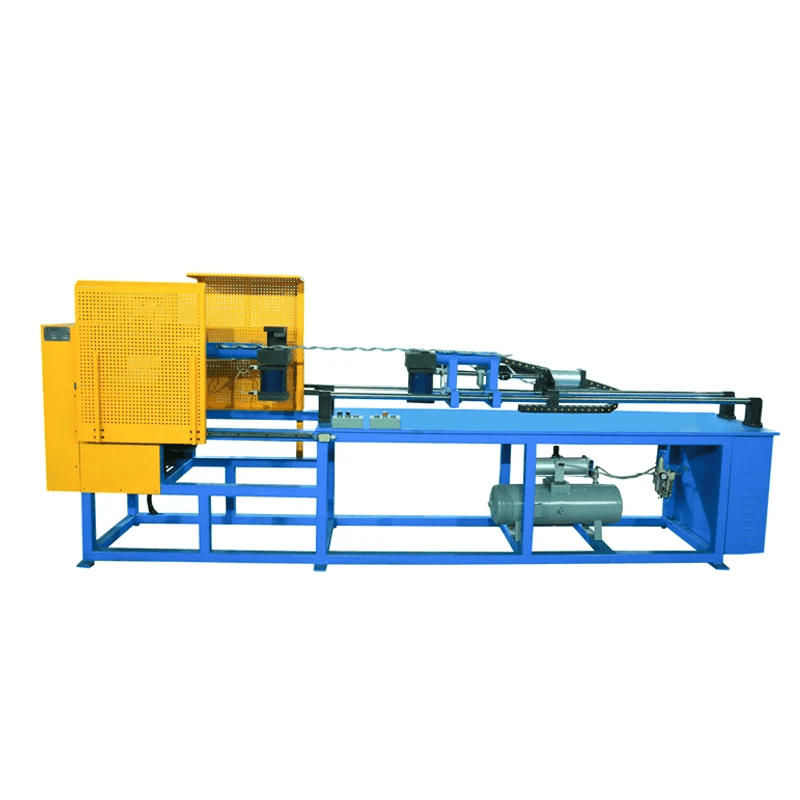

In the world of manufacturing and fabrication, the wire bender machine stands out as a vital tool for creating precision components used in various industries. These machines are designed to bend wires into specific shapes and configurations, ensuring that each piece meets stringent specifications. As technology advances, understanding the capabilities and features of wire bending machines becomes essential for businesses aiming to enhance their production processes.

Understanding Wire Bender Machines

Wire bender machines come in various forms, including CNC coiling and bending machines, which offer unparalleled precision and efficiency. These sophisticated devices utilize computer numerical control (CNC) technology to automate the bending process, allowing for complex shapes that would be nearly impossible to achieve manually. By mastering wire bending techniques, manufacturers can produce everything from simple brackets to intricate designs used in electrical utilities and telecommunications.

Why Quality Matters in Wire Bending

Quality is paramount when it comes to wire bending, as even minor imperfections can lead to significant issues down the line. High-quality wire bending machines ensure consistent results that meet industry standards while minimizing waste and rework costs. Investing in superior CNC Wire Bending Machines not only enhances productivity but also boosts a company's reputation for reliability among clients.

The Rise of Automated Solutions

The rise of automated wire bending machines marks a transformative shift in how industries approach manufacturing processes. Automation streamlines production by reducing manual labor and increasing accuracy while allowing operators to focus on higher-level tasks such as design optimization or quality control. As businesses strive for greater efficiency and lower operational costs, embracing these cutting-edge solutions is becoming increasingly essential.

Key Features of Wire Bender Machines

Wire bender machines are marvels of engineering, designed to meet the diverse needs of various industries. From creating intricate designs in architecture to producing robust components for automotive applications, these machines offer unparalleled versatility. With advancements in technology, wire bending machines now accommodate a wide range of wire types and sizes, making them indispensable tools across multiple sectors.

Versatility for Various Applications

One of the standout features of wire bender machines is their remarkable versatility. These machines are adept at handling different materials such as steel, aluminum, and copper wires, allowing manufacturers to tailor their products to specific requirements. Whether you’re looking to produce simple brackets or complex shapes for artistic installations, CNC coiling and bending machines can adapt easily to any project.

This adaptability extends beyond just material types; it also includes the ability to create various shapes and bends with precision. Automated wire bending machines can execute intricate designs that would be challenging or impossible with manual methods. As a result, businesses can expand their offerings and cater to a broader customer base without compromising quality.

Precision Engineering for Perfect Curves

Precision is paramount when it comes to wire bending; even the slightest miscalculation can lead to costly errors in production. CNC Wire Bending Machines are engineered with advanced technology that ensures every bend is executed flawlessly according to specifications. This level of accuracy not only enhances product quality but also streamlines manufacturing processes by reducing waste.

Moreover, the precision offered by these machines allows for repeatability in production runs, which is crucial for industries like automotive and aerospace where consistency is key. The ability to produce perfect curves consistently means that designers can push creative boundaries without worrying about structural integrity or fitment issues later on. Ultimately, investing in high-quality wire bender machines translates into better end products and increased customer satisfaction.

User-Friendly Interface and Controls

In today's fast-paced manufacturing environment, ease of use is essential when selecting equipment like automated wire bending machines. Modern models come equipped with intuitive user interfaces that simplify operation for both seasoned professionals and newcomers alike. These user-friendly controls allow operators to program complex bends quickly without needing extensive training or experience.

Additionally, many CNC coiling and bending machines feature touchscreen displays that provide real-time feedback on machine performance and progress during production runs. This interactivity not only enhances usability but also allows operators to make adjustments on-the-fly if necessary—saving time and ensuring optimal results every step of the way. With such advancements in technology wrapped up in an accessible package, it's no wonder that businesses are increasingly turning toward sophisticated wire bender machines for their manufacturing needs.

The Technology Behind Wire Bending

The technology behind wire bending has evolved significantly, leading to the creation of sophisticated wire bender machines that enhance efficiency and precision. At the heart of this evolution are CNC coiling and bending machines, which leverage computer numerical control to produce intricate bends with remarkable accuracy. These advancements not only streamline production but also ensure consistency across various applications, making them invaluable in industries ranging from automotive to telecommunications.

CNC Coiling and Bending Machines Explained

CNC coiling and bending machines are designed to automate the process of shaping wire into specific forms required for different applications. By utilizing computer programming, these machines can execute complex bending patterns that would be nearly impossible to achieve manually. This level of automation not only increases productivity but also reduces human error, ensuring that every wire bender machine produces high-quality results consistently.

In addition to their precision, CNC coiling and bending machines offer versatility in terms of material compatibility. They can handle a wide range of wire types and thicknesses, making them suitable for producing components in diverse industries. Whether it's crafting intricate designs for artistic projects or creating robust components for electrical utilities, these machines adapt seamlessly to various requirements.

Automated Wire Bending Machines and Their Benefits

Automated wire bending machines take efficiency a step further by integrating advanced robotics and automation systems into the production process. These machines can operate continuously with minimal supervision while maintaining high levels of output quality. The benefits extend beyond mere speed; automated systems significantly reduce labor costs and improve workplace safety by minimizing manual handling.

Moreover, automated wire bending machines come equipped with user-friendly interfaces that allow operators to program complex bends easily without extensive training. This accessibility means businesses can quickly adapt to changing demands or product specifications without significant downtime or retraining efforts. As companies strive for greater flexibility in their manufacturing processes, investing in automated solutions becomes increasingly attractive.

Innovations in CNC Wire Bending Machines

The landscape of CNC wire bending technology is constantly evolving with innovative features that enhance functionality and precision further. Recent developments include real-time monitoring systems that provide instant feedback on machine performance, allowing operators to make adjustments on-the-fly for optimal results. Such innovations ensure that every wire bender machine operates at peak efficiency while minimizing waste.

Additionally, advancements in software have made it easier than ever for users to design custom bends digitally before production begins—saving time and resources during the prototyping phase. As manufacturers push boundaries on what’s possible with CNC Wire Bending Machines, we see an increasing integration of artificial intelligence (AI) capabilities that optimize processes based on historical data trends.

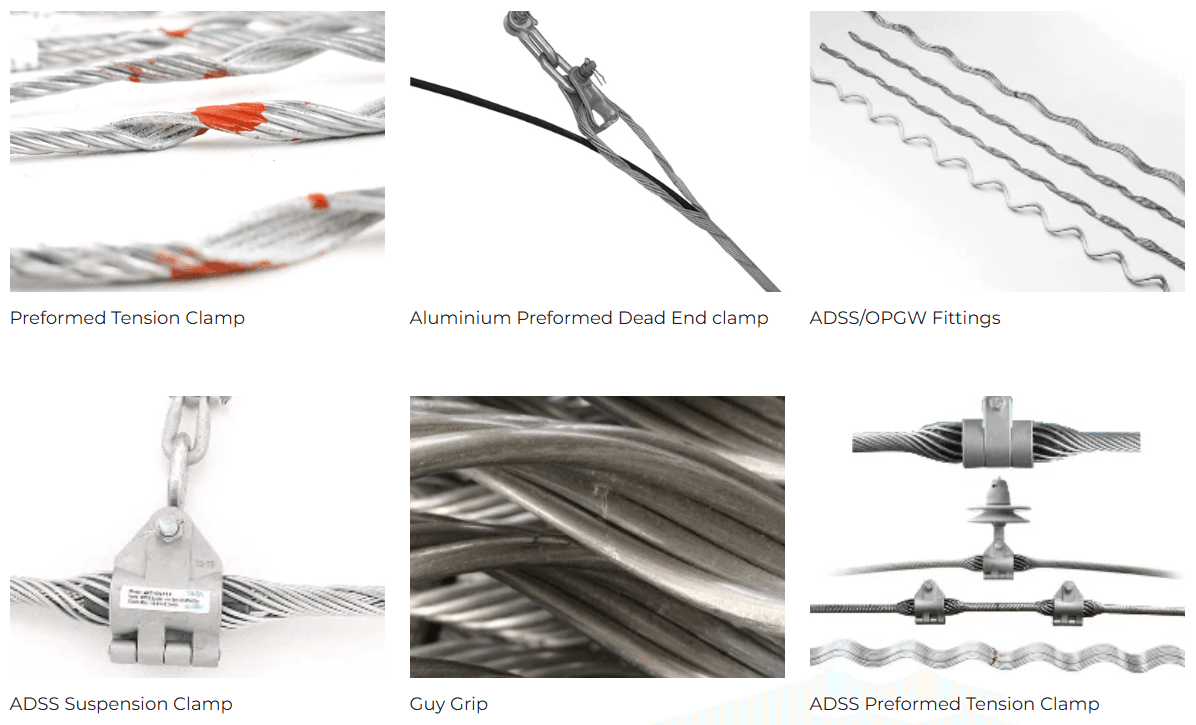

In this fast-paced industry landscape where quality is paramount, Spark Fittings stands out as a leading company specializing in manufacturing equipment tailored specifically for preformed armor rods, tension clamps, and cable accessories used across various sectors including electrified railways and electricity transmission systems.

Importance of Build Quality

Robust Construction for Longevity

The longevity of wire bending machines is largely determined by their construction quality. Machines designed with strong frames and durable components can endure the stresses associated with bending various types of wire without compromising their integrity. This robustness not only minimizes downtime but also enhances productivity, allowing businesses to meet demanding production schedules effectively.

The Role of Materials in Performance

The materials used in CNC coiling and bending machines play a crucial role in their overall performance. High-quality metals and alloys are essential for parts that experience significant wear and tear during operation, ensuring consistent results over time. Additionally, using superior materials helps prevent issues such as rust or corrosion, which can drastically affect the performance of automated wire bending machines.

Maintenance Considerations for Durability

Regular maintenance is key to ensuring the durability of CNC Wire Bending Machines and keeping them running smoothly over time. Simple tasks like lubrication, cleaning, and periodic inspections can prevent small issues from becoming major problems down the line. Businesses that prioritize maintenance will find their wire bender machine not only lasts longer but continues to deliver precise bends day after day.

Choosing the Right Wire Bender Machine

Selecting the ideal wire bender machine can significantly impact your production efficiency and product quality. With a plethora of options available, it's essential to understand your specific requirements and how different machines align with those needs. Whether you're leaning towards traditional models or exploring the latest automated wire bending machines, making an informed choice is key.

Evaluating Your Specific Needs

Before diving into the world of wire bending machines, take a moment to assess your operational requirements. Consider factors such as the types of materials you'll be working with, the complexity of bends required, and your production volume. If you frequently create intricate designs or need high precision, CNC coiling and bending machines might be more suitable than traditional models.

Additionally, think about future scalability; will your operations expand in the coming years? Investing in a versatile wire bender machine that can adapt to changing demands can save you time and money down the road. By understanding your specific needs upfront, you can avoid costly missteps in selecting a machine that may not meet your long-term goals.

Comparing Traditional vs. Automated Machines

When weighing traditional versus automated wire bending machines, each has its own set of advantages that cater to different business models. Traditional machines often require skilled operators but offer lower initial costs and straightforward maintenance procedures. However, if you're aiming for speed and consistency in production runs, automated wire bending machines come equipped with advanced technology that streamlines processes while minimizing human error.

CNC Wire Bending Machines stand out for their precision and flexibility; they allow for complex designs without compromising on speed or accuracy. In contrast, traditional options might struggle with intricate shapes but excel in simpler tasks where craftsmanship is paramount. Ultimately, the choice hinges on balancing initial investment against productivity gains—consider what aligns best with your operational strategy.

Expert Recommendations from Spark Fittings

At Spark Fittings, we understand that navigating through various wire bender machine options can be daunting without expert guidance. Our team specializes in providing tailored recommendations based on extensive industry experience and customer feedback—ensuring you find a machine that fits like a glove! We encourage customers to explore our range of CNC coiling and bending machines designed specifically for producing high-quality preformed products used in electrical transmission systems.

Moreover, our commitment extends beyond just selling equipment; we aim to be partners in innovation by offering ongoing support even after purchase. Whether you're interested in automated solutions or more traditional approaches to wire bending machinery, our expertise ensures you make an informed decision tailored to your unique needs within industries such as telecommunications or electrified railways.

Industry Applications of Wire Bending

Wire bending machines have found their niche in various industries, showcasing their versatility and essential role in modern manufacturing. From electrical utilities to automotive engineering, the applications of wire bending technology are vast and varied. In this section, we will explore three key sectors where wire bender machines have made a significant impact.

Electrical Utility and Telecommunications

In the electrical utility sector, wire bending machines are indispensable for creating components that ensure the reliable transmission of electricity. Automated wire bending machines streamline the production of intricate parts like brackets and supports that hold cables in place. By utilizing CNC coiling and bending machines, manufacturers can achieve precise shapes that meet stringent industry standards while enhancing overall safety.

Telecommunications also heavily relies on these machines for producing specialized wiring harnesses and connectors needed for networking equipment. The ability to customize designs with CNC wire bending machines allows companies to adapt quickly to technological advancements. This adaptability not only improves efficiency but also reduces lead times, enabling faster deployment of critical infrastructure.

Moreover, Spark Fittings stands out in this domain by providing high-quality equipment tailored for preformed armor rods and tension clamps used in electrical distribution systems. Their expertise ensures that every wire bender machine they manufacture meets rigorous performance requirements, thereby supporting seamless operations across various utility applications.

Automotive and Aerospace Industries

The automotive industry has embraced wire bending technology to produce essential components ranging from seat frames to suspension systems. Wire bender machines enable manufacturers to create complex shapes with precision, ensuring that each part fits perfectly within the vehicle assembly process. With the increasing demand for lightweight materials in automotive design, CNC coiling and bending machines play a pivotal role in optimizing strength-to-weight ratios.

In aerospace engineering, where safety is paramount, automated wire bending machines are utilized to fabricate critical components such as brackets and support structures for aircraft interiors. The precision offered by CNC wire bending machines ensures that every piece meets strict regulatory standards while contributing to overall performance efficiency. This attention to detail is crucial when considering factors like weight reduction and structural integrity.

Spark Fittings has also made strides within these industries by offering machinery designed specifically for high-performance applications like aerospace cable accessories. Their commitment to quality guarantees that customers receive robust products capable of withstanding the harsh conditions often encountered during flight or on the road.

Architectural and Artistic Wire Designs

Wire bender machines are not limited to industrial applications; they also find a home in architectural design and artistic creations. Designers leverage automated wire bending technology to craft unique sculptures or intricate railings that enhance aesthetic appeal while maintaining functionality. With CNC coiling and bending machines at their disposal, artists can push creative boundaries without sacrificing precision or quality.

In architecture, these versatile tools allow for innovative designs that incorporate both form and function seamlessly into buildings or public spaces. The ability to produce custom shapes quickly means architects can experiment with unconventional ideas without worrying about time constraints or fabrication limitations associated with traditional methods.

Spark Fittings recognizes this growing demand for artistic applications by providing specialized machinery tailored for creative projects as well as industrial needs. Their commitment ensures artists have access to top-notch equipment capable of transforming imaginative concepts into tangible masterpieces using advanced wire-bending techniques.

Conclusion

In conclusion, investing in quality wire bending machines is crucial for any business that relies on precision and efficiency. The right wire bender machine can significantly enhance productivity while ensuring that the end products meet stringent quality standards. As industries continue to evolve, the demand for high-quality wire bending solutions will only grow, making it essential to choose wisely.

Investing in Quality Wire Bending Machines

When considering a wire bender machine, it's vital to prioritize build quality and technological advancements. High-quality wire bending machines not only improve output but also reduce the likelihood of errors and rework. By selecting CNC coiling and bending machines with robust features, businesses can ensure they remain competitive in a rapidly changing market.

Quality matters because it directly impacts the longevity and reliability of your equipment. Automated wire bending machines offer enhanced precision and efficiency, which translates into better product consistency over time. By investing in top-tier CNC Wire Bending Machines, companies can safeguard their operations against future challenges.

The Future of CNC Wire Bending Technology

The landscape of CNC Wire Bending Machines is continuously evolving due to advancements in technology. Innovations such as smart automation and AI integration are paving the way for even more efficient production processes. As industries increasingly adopt these automated wire bending machines, we can expect significant improvements in speed, accuracy, and overall performance.

Moreover, the future will likely see an even greater emphasis on versatility within wire bending technologies. Businesses will benefit from machines capable of handling diverse materials and complex designs without sacrificing quality or precision. This adaptability will be key as markets demand more customized solutions tailored to specific applications.

Spark Fittings: Your Partner in Innovation

Spark Fittings stands at the forefront of this evolution by specializing in manufacturing equipment designed for high-performance applications such as preformed armor rods and tension clamps for ADSS and OPGW systems. Our commitment to innovation ensures that our customers receive cutting-edge solutions that enhance their operations across various sectors including electrical utilities and telecommunications. With Spark Fittings by your side, you gain not just a supplier but a partner dedicated to helping you navigate the complexities of modern manufacturing with ease.