Introduction

In recent years, the manufacturing landscape has undergone a significant transformation, largely driven by advancements in technology. One of the standout innovations in this arena is the rise of CNC wire bending machines, which have revolutionized how businesses approach wire fabrication. These machines bring unparalleled precision and efficiency to the table, making them indispensable tools for modern manufacturers.

The Rise of CNC Wire Bending Machines

The advent of CNC (Computer Numerical Control) technology has marked a turning point for wire bending processes across various industries. CNC wire bending machines offer automated solutions that enhance both speed and accuracy, allowing manufacturers to produce complex shapes with minimal human intervention. This shift not only streamlines production lines but also significantly reduces waste and resource consumption.

Advantages of Automated Wire Bending Techniques

Automated wire bending machines provide myriad advantages that traditional methods simply can't match. For starters, they boost production efficiency by operating at higher speeds while maintaining consistent quality throughout each batch. Additionally, these machines minimize labor costs and errors associated with manual operations, making them an attractive investment for businesses aiming to stay competitive.

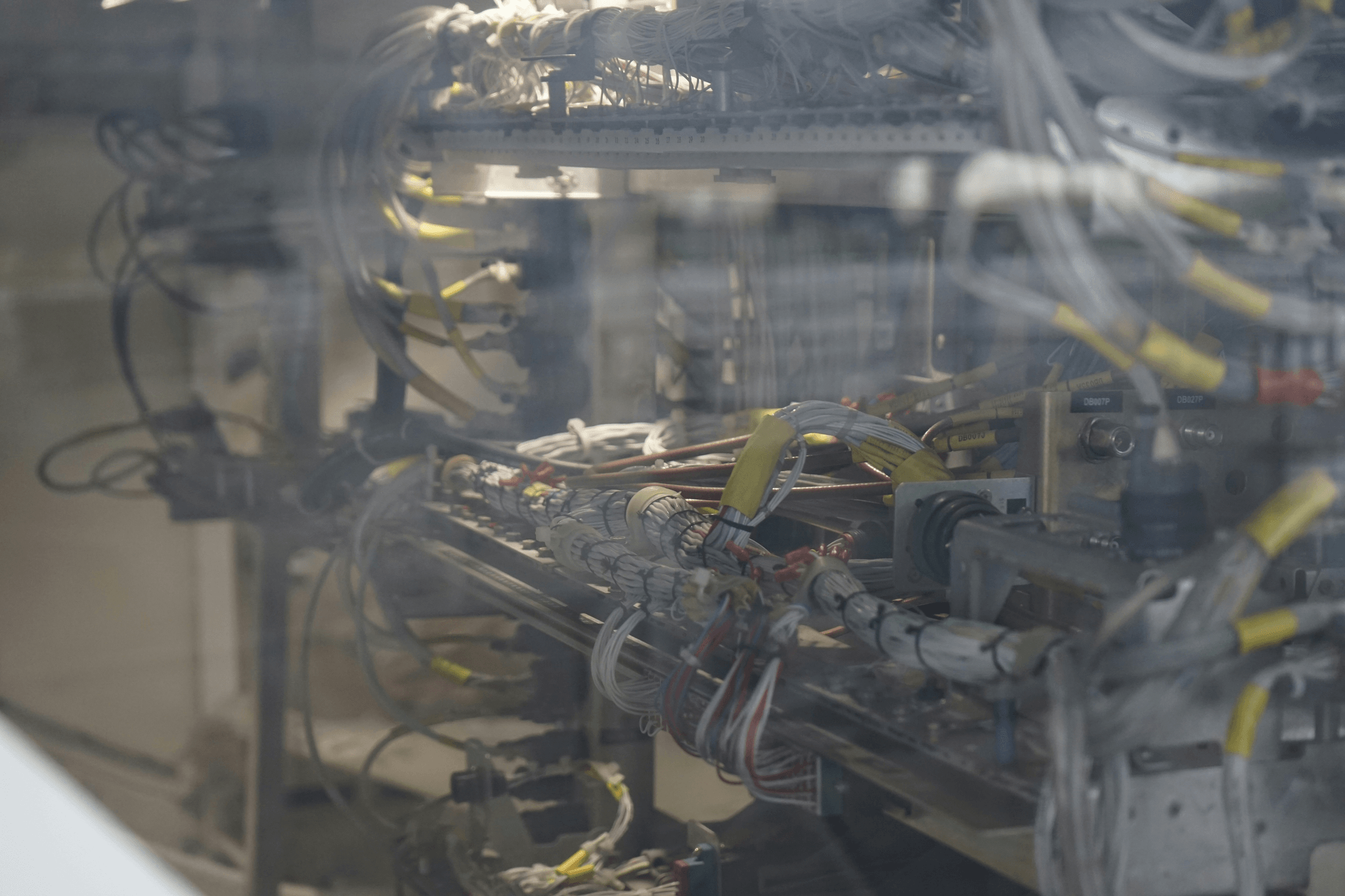

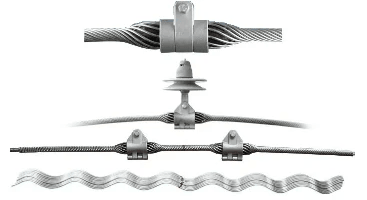

Overview of 16A Pre-Twisted Wire Automatic Forming Production Line

At the forefront of innovation is the 16A Pre-Twisted Wire Automatic Forming Production Line, which exemplifies the capabilities of modern automated systems. This cutting-edge line combines advanced machinery with intelligent design to produce pre-twisted wires efficiently and accurately. By leveraging such technology, companies can achieve remarkable production rates while ensuring high-quality output that meets stringent industry standards.

Key Components of CNC Wire Bending Machines

CNC wire bending machines are marvels of modern engineering, designed to automate the bending process with unparalleled efficiency. Understanding their key components is essential for appreciating how they operate and the advantages they bring to manufacturing. This section delves into the intricacies of the bending mechanism, precision requirements, and the vital role of control software in operations.

Understanding the Bending Mechanism

At the heart of every automated wire bending machine lies a sophisticated bending mechanism that transforms raw wire into precisely shaped components. This mechanism typically employs various tools such as rollers and dies that guide and shape the wire as it passes through them. The 16A Pre-Twisted Wire Automatic Forming Production Line showcases advanced mechanisms that enhance flexibility, allowing for multiple bends and shapes in a single setup.

The bending process starts with feeding straight wire into the machine, where it is then clamped securely before being bent according to programmed specifications. The combination of mechanical force and precise angles ensures that each piece meets stringent design criteria, which is crucial for industries requiring exact dimensions. Understanding this mechanism helps operators optimize performance and troubleshoot any issues that may arise during production.

Importance of Precision and Accuracy

In manufacturing, precision and accuracy are non-negotiable standards; this holds particularly true for CNC wire bending machines. These machines must consistently produce parts that adhere to tight tolerances to ensure compatibility with other components in an assembly line or final product. With automated wire bending machines like those found in the 16A Pre-Twisted Wire Automatic Forming Production Line, achieving such precision becomes not just possible but routine.

The importance of maintaining accuracy cannot be overstated—any deviation can lead to costly rework or even product failure down the line. Advanced sensors integrated within CNC machines monitor parameters continuously during operation, ensuring any discrepancies are corrected immediately. This level of vigilance significantly reduces waste while enhancing overall production quality.

Role of Control Software in Operations

Control software serves as the brain behind CNC wire bending machines, orchestrating their movements with remarkable finesse. It translates complex design specifications into actionable commands that dictate how each bend should occur throughout production cycles. For instance, when utilizing a 16A Pre-Twisted Wire Automatic Forming Production Line, operators rely on intuitive interfaces that simplify programming even for intricate designs.

Moreover, this software allows for real-time monitoring and adjustments during operation—an invaluable feature when dealing with high-speed production scenarios common in automated environments. By leveraging advanced algorithms and user-friendly dashboards, operators can swiftly adapt to changing requirements without significant downtime or loss in productivity. As a result, businesses can maximize their investment in CNC technology while ensuring consistent output quality across all manufactured parts.

Benefits of Using Automated Wire Bending Machines

Automated wire bending machines, particularly CNC wire bending machines, are revolutionizing the manufacturing landscape. By streamlining production processes, these machines significantly enhance operational efficiency and output quality. The 16A Pre-Twisted Wire Automatic Forming Production Line exemplifies how automation can transform traditional manufacturing methods into dynamic, efficient systems.

Increased Production Efficiency

One of the standout benefits of CNC wire bending machines is their remarkable ability to increase production efficiency. These automated wire bending machines can operate continuously without the fatigue and downtime associated with manual labor. Additionally, they can produce complex shapes and designs at a speed that would be nearly impossible for human operators to match, allowing businesses to meet high-demand cycles with ease.

Moreover, the integration of advanced software in these systems enables real-time adjustments and optimizations during production runs. This means that manufacturers can quickly adapt to changes in design specifications or production volume without sacrificing quality or speed. Consequently, the 16A Pre-Twisted Wire Automatic Forming Production Line showcases how such efficiencies translate into higher output rates and reduced lead times for fulfilling customer orders.

Enhanced Consistency in Output

Consistency is key in manufacturing, especially when it comes to producing components that must fit together perfectly. Automated wire bending machines ensure that every piece produced meets stringent quality standards through precise control mechanisms. Unlike human operators who may vary in performance due to fatigue or distraction, CNC wire bending machines deliver uniform results every time.

This consistency not only enhances product quality but also builds trust with clients who rely on predictable outcomes for their projects. With features like programmable settings and repeatable processes, these machines eliminate variability often encountered in manual operations. The 16A Pre-Twisted Wire Automatic Forming Production Line further exemplifies this benefit by maintaining high levels of precision across large production runs.

Reduction in Labor Costs and Errors

The adoption of CNC wire bending machines leads to significant reductions in labor costs while simultaneously minimizing human error rates. By automating repetitive tasks traditionally performed by skilled workers, companies can reallocate their workforce toward more strategic roles that require critical thinking and creativity rather than manual labor. This shift not only saves money but also enhances job satisfaction among employees.

Moreover, automated systems are designed with error-reducing technologies that help prevent mistakes during the manufacturing process—something that's much harder to achieve when relying solely on human operators. As a result, businesses experience fewer defects and waste materials due to inaccuracies in production runs. Overall, integrating automated wire bending solutions like the 16A Pre-Twisted Wire Automatic Forming Production Line represents a smart investment towards optimizing resources while maintaining top-notch quality standards.

Innovations in Wire Bending Technology

The world of wire bending is undergoing a remarkable transformation, driven by cutting-edge innovations that redefine how we approach manufacturing. CNC wire bending machines, for instance, have evolved to incorporate sophisticated technologies that enhance their capabilities and efficiency. As we delve into the advancements in bending techniques, the integration of artificial intelligence (AI) and machine learning, and real-world case studies, it becomes clear that automated wire bending machines are not just tools; they are pivotal players in modern production lines.

Advancements in Bending Techniques

Recent advancements in bending techniques have revolutionized the functionality of CNC wire bending machines. These innovations include multi-axis capabilities that allow for complex geometries to be produced with unprecedented precision. The introduction of adaptive bending processes ensures that these automated wire bending machines can adjust to variations in material properties on-the-fly, significantly improving output quality.

Moreover, the development of specialized tooling has enhanced the versatility of the 16A Pre-Twisted Wire Automatic Forming Production Line. This line can efficiently produce intricate designs while maintaining tight tolerances—something traditional methods often struggle with. As a result, manufacturers are now able to meet diverse customer demands without compromising on quality or speed.

Integration of AI and Machine Learning

The integration of AI and machine learning into CNC wire bending machines marks a significant leap forward for automated manufacturing processes. By leveraging data analytics, these systems can learn from previous production runs and optimize future operations accordingly. This means less downtime due to errors and more efficient use of materials—both crucial factors for any business aiming to stay competitive.

Furthermore, predictive maintenance powered by AI algorithms helps anticipate potential equipment failures before they occur. This proactive approach reduces unexpected breakdowns and ensures that the 16A Pre-Twisted Wire Automatic Forming Production Line operates smoothly at all times. Ultimately, this fusion of technology not only enhances productivity but also drives down operational costs.

Case Studies of Modern Applications

Several case studies highlight how innovations in wire bending technology have transformed industries ranging from automotive to electronics manufacturing. For instance, one major automotive supplier implemented advanced CNC wire bending machines to streamline their production process for complex wiring harnesses used in electric vehicles. By utilizing automated wire bending machines equipped with smart software solutions, they increased output by over 30% while reducing scrap material significantly.

Another compelling example comes from an electronics manufacturer that integrated AI-driven CNC wire bending systems into their assembly line for consumer gadgets. The precision offered by these advanced systems allowed them to cut down on assembly time while ensuring consistent quality across thousands of units produced daily—a feat previously unattainable with manual methods alone. These case studies not only showcase the effectiveness of modern applications but also emphasize the transformative potential embedded within CNC technologies like those found in the 16A Pre-Twisted Wire Automatic Forming Production Line.

The 16A Pre-Twisted Wire Automatic Forming Production Line

The 16A Pre-Twisted Wire Automatic Forming Production Line represents a significant leap in the realm of automated wire bending machines. This cutting-edge system is designed to streamline the production process, enhancing both efficiency and output quality. With its innovative features, it stands as a testament to how CNC wire bending machines are revolutionizing manufacturing.

Breakdown of the Conveyor System

At the heart of the 16A Pre-Twisted Wire Automatic Forming Production Line lies an advanced conveyor system that ensures seamless movement of materials throughout the production process. This system is engineered for precision, reducing delays and ensuring that each component reaches its destination without hiccups. By integrating high-speed conveyors with real-time monitoring, this setup minimizes downtime and maximizes throughput—key advantages for any operation relying on automated wire bending machines.

Features of the Forming Machine

The forming machine within this production line boasts several impressive features designed to enhance functionality and adaptability. Equipped with state-of-the-art CNC technology, it can execute complex bends with unparalleled accuracy, making it ideal for various applications—from automotive parts to intricate electronic components. Additionally, its user-friendly interface allows operators to easily program specifications, making adjustments quick and efficient—an essential characteristic for businesses looking to leverage automated wire bending machines effectively.

Impact on Production Rates and Quality

Implementing the 16A Pre-Twisted Wire Automatic Forming Production Line has profound implications for production rates and product quality in any manufacturing setting. By automating crucial processes that were once labor-intensive, companies can significantly increase their output while maintaining consistent quality across batches. The result? A marked reduction in errors and waste, leading not only to cost savings but also a stronger competitive edge in today’s market where precision is paramount.

Choosing the Right CNC Wire Bending Machine

Selecting the right CNC wire bending machine can be a daunting task, especially with the plethora of options available on the market today. Your choice will significantly impact your production efficiency, quality of output, and overall operational costs. Therefore, understanding your specific business needs and aligning them with the features offered by automated wire bending machines is crucial.

Factors to Consider for Your Business

When choosing a CNC wire bending machine, several factors should be top of mind. First and foremost is the type of materials you’ll be working with; different machines cater to various wire types and thicknesses. Additionally, consider the complexity of your designs—machines like the 16A Pre-Twisted Wire Automatic Forming Production Line excel in handling intricate shapes seamlessly.

Another critical factor is production volume. If you’re looking to ramp up output quickly, investing in an automated wire bending machine that offers high-speed capabilities will pay off in spades. Lastly, don’t overlook ease of use; user-friendly interfaces can drastically reduce training time for operators and minimize errors during operations.

Comparison of Leading Brands

Navigating through brands can feel like wandering through a maze without a map; however, some stand out in the realm of CNC wire bending machines. Companies such as Mazzella, KUKA, and Geka have built solid reputations for producing reliable automated wire bending machines equipped with advanced technology features. Each brand offers unique strengths—Mazzella is known for its robust designs while KUKA excels in automation integration.

When evaluating these brands, consider aspects such as machine versatility and maintenance requirements alongside price points. The 16A Pre-Twisted Wire Automatic Forming Production Line represents cutting-edge innovation from leading manufacturers that enhance efficiency without sacrificing quality or precision. Ultimately, reading customer reviews and seeking recommendations can provide valuable insights into which brand aligns best with your business goals.

Importance of After-Sales Support

After-sales support is often an overlooked aspect when purchasing CNC wire bending machines but can make all the difference down the line. A responsive support team ensures that any issues are swiftly addressed—minimizing downtime during critical production periods is essential for maintaining profitability in competitive markets. Look for manufacturers that offer comprehensive training programs alongside ongoing technical assistance to help you maximize your investment in automated wire bending technology.

Additionally, consider warranty terms; longer warranties often indicate manufacturer confidence in their products’ durability and reliability. Having access to spare parts quickly also matters; it helps keep your 16A Pre-Twisted Wire Automatic Forming Production Line running smoothly without unnecessary delays caused by waiting on replacements or repairs. In essence, strong after-sales support translates into peace of mind and long-term success for your business.

Conclusion

As we wrap up our exploration of CNC wire bending machines, it becomes clear that these advanced tools are not just a passing trend but a vital component in modern manufacturing. The investment in automated wire bending machines, such as the 16A Pre-Twisted Wire Automatic Forming Production Line, can yield significant returns through increased efficiency and reduced operational costs. Companies that embrace these technologies will not only enhance their production capabilities but also position themselves competitively in an evolving market.

Maximizing Your Investment in CNC Technology

To maximize your investment in CNC technology, it's crucial to understand the specific needs of your business and how automated wire bending machines can address them. Investing in high-quality CNC wire bending machines ensures precision and durability, which translates to long-term savings and reduced downtime. Moreover, integrating advanced features like AI-driven control software can further optimize operations, making your production line more agile and responsive to market demands.

The Future of Automated Wire Bending Machines

The future of automated wire bending machines looks promising with continuous advancements on the horizon. Innovations such as enhanced machine learning algorithms will enable these systems to adapt dynamically to varying production requirements while maintaining accuracy and speed. As manufacturers increasingly adopt solutions like the 16A Pre-Twisted Wire Automatic Forming Production Line, we can expect a shift towards even greater automation and smarter manufacturing processes that redefine industry standards.

Final Thoughts on Wire Bending Innovations

In conclusion, the evolution of CNC wire bending machines represents a significant leap forward for various industries reliant on precision metalwork. Embracing innovations in automated wire bending techniques is no longer optional; it’s essential for businesses aiming to thrive in today's competitive landscape. The journey towards optimizing production processes through technologies like the 16A Pre-Twisted Wire Automatic Forming Production Line is just beginning—get ready for what lies ahead!