Introduction

In the world of electrical infrastructure, vibration dampers play a crucial role in ensuring the longevity and performance of power lines. These devices are designed to mitigate unwanted mechanical vibrations that can lead to structural failures or operational inefficiencies. Understanding how vibration dampers function and their significance in transmission line performance is essential for engineers and technicians alike.

Understanding Vibration Dampers in Power Lines

A vibration damper is a device that absorbs and dissipates vibrational energy, preventing it from causing damage to structures like overhead power lines. By reducing oscillations induced by environmental factors such as wind or seismic activity, these dampers enhance the stability of transmission lines. In essence, they act as a protective barrier against the detrimental effects of mechanical vibrations.

Importance of Transmission Line Performance

The performance of transmission lines is paramount for reliable electricity distribution, affecting everything from grid stability to energy efficiency. When power lines experience excessive vibrations, it can lead to premature wear and tear on components, resulting in costly repairs or outages. Therefore, implementing effective vibration dampers becomes vital in maintaining optimal transmission line performance while safeguarding infrastructure investments.

Exploring Spark Fittings Contribution

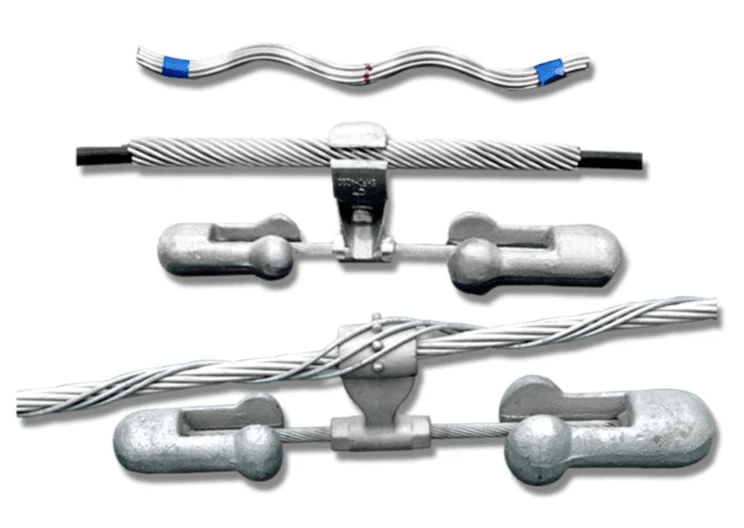

Spark Fittings is at the forefront of innovation with its specialized equipment designed for preformed armor rods, tension clamps, and cable accessories tailored for ADSS and OPGW applications. Their expertise not only helps produce high-quality preformed products but also significantly contributes to enhancing the effectiveness of vibration dampers in transmission systems. By integrating advanced manufacturing techniques with cutting-edge materials, Spark Fittings ensures that their solutions effectively address issues related to vibration damper detection and overall system reliability.

What is a Vibration Damper?

Vibration dampers are essential devices designed to reduce or eliminate unwanted vibrations in various systems, including power lines. By absorbing and dissipating energy from oscillations, these dampers play a crucial role in maintaining structural integrity and enhancing performance. Understanding the definition, functionality, and applications of vibration dampers is key to appreciating their importance in engineering.

Definition and Functionality

A vibration damper can be defined as a mechanical device that minimizes the amplitude of vibrations within a system. Its primary function is to absorb vibrational energy, thereby reducing the potential for damage caused by excessive oscillations. In essence, these dampers act like shock absorbers for structures, ensuring that vibrations do not propagate unchecked through transmission lines or other engineering applications.

Common Applications in Engineering

Vibration dampers find application across various fields of engineering beyond just power lines. They are commonly used in buildings to enhance seismic performance, in bridges to mitigate sway during high winds, and even in automotive applications as driveline dampers to reduce engine vibrations. The versatility of vibration dampers ensures that they are integral components in systems where stability and reliability are paramount.

Role in Enhancing Transmission Line Stability

In the context of transmission lines, vibration dampers play a pivotal role in enhancing stability by mitigating oscillations caused by wind or other environmental factors. These devices help prevent fatigue failure due to cyclic loading on conductors and support structures over time. By incorporating vibration damper technology into overhead power lines, engineers can significantly improve overall system reliability while also extending the lifespan of critical infrastructure.

What are the Three Main Types of Dampers?

Discussion on Tuned Mass Dampers

Tuned Mass Dampers (TMDs) are sophisticated devices designed to counteract specific frequencies of vibration. They consist of a mass attached to a spring and damper system that is tuned to resonate with the frequency of the unwanted vibrations, effectively reducing their amplitude. In transmission line applications, TMDs can significantly improve stability by minimizing oscillations caused by wind or other environmental factors.

The beauty of a TMD lies in its ability to absorb energy from vibrations without adding excessive weight or complexity to the structure. This makes them particularly valuable in overhead power lines where maintaining structural integrity is paramount. Spark Fittings recognizes the importance of TMDs and provides high-quality components that enhance their effectiveness in transmission line applications.

Overview of Friction Dampers

Friction dampers operate on a simple yet effective principle: they dissipate energy through friction between surfaces as they move relative to each other during vibrations. These devices can be installed at critical points along structures like power lines to reduce dynamic responses caused by external forces such as wind or seismic activity. By converting kinetic energy into heat through friction, these dampers help protect infrastructure from damage.

One major advantage of friction dampers is their adaptability; they can be tailored for various applications beyond just transmission lines—think bridges or high-rise buildings! Their simplicity also means lower maintenance requirements compared to more complex systems like TMDs or viscoelastic dampers. Spark Fittings offers robust solutions designed specifically for implementing friction damping technology effectively in overhead power line systems.

Insight into Viscoelastic Dampers

Viscoelastic dampers combine properties of both elastic and viscous materials, making them versatile tools for vibration mitigation across many applications—including transmission lines! These dampers work by absorbing and dissipating vibrational energy through internal molecular motion when subjected to stress or strain. The result? Reduced oscillation amplitudes and enhanced overall stability for structures exposed to dynamic loading conditions.

What sets viscoelastic dampers apart is their ability to perform well across a wide range of temperatures and loading frequencies while maintaining consistent damping characteristics over time. This makes them particularly appealing for long-term infrastructure projects like power lines where reliability is key! With Spark Fittings' expertise in manufacturing high-performance components, engineers can leverage viscoelastic technology for optimal results in vibration damper implementation.

What is a Vibration Damper Used For?

Vibration dampers play a crucial role in various engineering applications, especially in the context of transmission lines. Their primary purpose revolves around managing mechanical vibrations, safeguarding infrastructure, and enhancing overall system reliability. Understanding what a vibration damper is used for can help engineers make informed decisions about their implementation.

Mitigating Mechanical Vibrations

One of the key functions of a vibration damper is to mitigate mechanical vibrations that can occur due to wind, seismic activity, or operational loads. These vibrations can lead to fatigue and failure in structural components if left unchecked. By effectively absorbing and dissipating energy from these forces, dampers reduce stress on transmission lines and other structures.

In the realm of power lines, understanding what is a vibration damper used for becomes essential for maintaining operational integrity. The use of vibration dampers ensures that oscillations are minimized, leading to smoother performance and prolonged lifespan for cables and supporting structures alike. This proactive approach not only enhances safety but also reduces maintenance costs over time.

Protecting Infrastructure from Damage

Protecting infrastructure from damage is another vital application of vibration dampers in engineering systems. When excessive vibrations occur, they can cause wear and tear on critical components such as insulators and towers, potentially leading to catastrophic failures. Vibration dampers act as the first line of defense against these damaging effects by absorbing shock energy before it reaches sensitive parts.

The installation of a vibration damper in transmission line setups significantly decreases the likelihood of structural failures caused by environmental factors or operational stresses. This protective mechanism contributes to the longevity of power line infrastructures while ensuring reliable electricity distribution across vast networks. Ultimately, investing in effective damping solutions leads to enhanced safety standards for both workers and communities relying on electrical services.

Improving Overall System Reliability

Improving overall system reliability is perhaps one of the most compelling reasons why engineers prioritize using vibration dampers in their designs. By minimizing oscillations within transmission lines, these devices help maintain consistent electrical performance even under challenging conditions like high winds or seismic events. A reliable power supply is paramount; hence understanding what are the three main types of dampers enables engineers to select appropriate solutions tailored to specific needs.

Furthermore, with advancements in technology—such as those offered by Spark Fittings—engineers have access to innovative damping solutions that improve efficiency while ensuring compliance with industry standards. Regularly monitoring and maintaining these systems through Transmission Line Vibration Damper Detection techniques ensures that any potential issues are addressed promptly before they escalate into major problems. In conclusion, integrating vibration dampers into engineering projects not only protects infrastructure but also fosters trust among stakeholders relying on uninterrupted service delivery.

Vibration Damper in Transmission Line

Vibration dampers play a crucial role in ensuring the stability and reliability of overhead power lines. By mitigating vibrations caused by environmental factors such as wind and ice, these devices protect the integrity of transmission systems. This section delves into the key benefits of vibration dampers, showcases case studies demonstrating their effectiveness, and outlines best practices for implementation.

Key Benefits for Overhead Power Lines

The primary advantage of using a vibration damper in transmission lines is its ability to reduce mechanical vibrations that can lead to structural damage over time. By absorbing these vibrations, dampers enhance the longevity of power line components and minimize maintenance costs. Furthermore, they improve overall system reliability, ensuring that electricity delivery remains uninterrupted even under adverse conditions.

Another significant benefit is the reduction of oscillatory movements that can result from wind-induced forces or thermal expansion. This stabilization not only protects infrastructure but also enhances safety by minimizing risks associated with equipment failure. Additionally, implementing vibration dampers contributes to maintaining optimal performance levels across transmission lines, ultimately benefiting utility operators and consumers alike.

Moreover, vibration dampers are versatile tools applicable to various settings beyond just power lines; they are integral in other engineering fields as well. For instance, understanding what is damper in piping or exploring what is a driveline damper highlights their widespread utility across different applications. This versatility underscores the importance of integrating vibration damper technology into modern engineering practices.

Case Studies on Effectiveness

Several case studies illustrate the effectiveness of vibration dampers in enhancing transmission line performance. One notable example involves a major utility company that faced persistent issues with conductor oscillations due to high winds. After installing tuned mass dampers specifically designed for overhead power lines, they observed a remarkable reduction in both amplitude and frequency of vibrations, leading to less wear on hardware and improved service continuity.

In another case study focused on an electrified railway system using OPGW (Optical Ground Wire), Spark Fittings provided specialized damping solutions that significantly decreased vibrational energy transfer between components during operation. The results were clear: reduced maintenance downtime and enhanced operational efficiency were achieved through strategic application of vibration dampers tailored for specific environmental challenges.

These examples underscore not only the immediate benefits realized from implementing damping technologies but also highlight long-term savings associated with reduced infrastructure damage and maintenance needs over time. As engineers continue to explore what is a vibration damper used for across various sectors, these case studies serve as compelling evidence supporting their adoption.

Best Practices for Implementation

To maximize the benefits derived from vibration dampers in transmission lines, adhering to best practices during implementation is essential. First and foremost, conducting thorough assessments prior to installation ensures that engineers select appropriate types based on specific site conditions—whether it be tuned mass dampers or friction dampers tailored for unique challenges encountered along each line segment.

Regular inspection and maintenance should follow installation efforts; this includes utilizing advanced techniques for monitoring vibration damper performance over time—a critical aspect within Transmission Line Vibration Damper Detection strategies employed today. Implementing technology such as real-time monitoring systems can help identify potential issues before they escalate into costly repairs or failures down the road.

Finally, collaboration between manufacturers like Spark Fittings and utility companies fosters innovation while sharing knowledge about emerging trends within damping technologies—ensuring engineers remain informed about cutting-edge solutions available in today’s market landscape as they seek ways to optimize their systems further.

Transmission Line Vibration Damper Detection

Detecting the effectiveness of vibration dampers in transmission lines is crucial for maintaining the stability and reliability of power systems. Regular monitoring helps identify potential issues before they escalate, ensuring that the infrastructure remains intact and functional. This section will delve into the techniques used for monitoring vibration dampers, highlight the importance of regular inspection and maintenance, and explore how technology can enhance detection methods.

Techniques for Monitoring Vibration Dampers

When it comes to vibration damper detection, several techniques are employed to ensure optimal performance. One common method is using accelerometers to measure vibrations along transmission lines; these devices provide real-time data on how well a vibration damper is functioning. Another technique involves visual inspections where engineers assess physical wear or damage to the dampers themselves, ensuring they remain effective in mitigating vibrations.

Moreover, advanced methods such as modal analysis can be utilized to understand how different types of dampers respond under various load conditions. By employing these techniques regularly, engineers can answer questions like What are the three main types of dampers? while also ensuring that each type is performing its intended function effectively. Understanding these monitoring techniques allows for a proactive approach in maintaining vibration damper efficiency within transmission lines.

Importance of Regular Inspection and Maintenance

Regular inspection and maintenance of vibration dampers are paramount for long-term infrastructure integrity. Just like any mechanical component, a vibration damper can experience wear over time due to environmental factors or mechanical stress; thus, routine checks help catch issues early on before they lead to significant failures or costly repairs. If left unchecked, even minor degradation could compromise not only the damper itself but also overall system reliability.

Incorporating a structured maintenance schedule that includes both visual inspections and data analysis ensures that engineers can accurately determine What is a vibration damper used for?—primarily protecting infrastructure from damage caused by excessive vibrations. Furthermore, understanding what is damper in piping or what is a driveline damper can provide insights into how similar principles apply across different engineering fields, highlighting the universal importance of regular upkeep.

Utilizing Technology for Enhanced Detection

The integration of technology into vibration damper detection has revolutionized how engineers monitor performance in transmission lines. Utilizing IoT (Internet of Things) sensors allows for continuous data collection and remote monitoring capabilities; this means potential issues can be identified before they become critical problems without needing constant physical inspections on-site. Additionally, software tools equipped with machine learning algorithms analyze collected data trends over time to predict when maintenance might be required.

With advancements like drone inspections offering aerial views of transmission lines and their associated dampers, detecting anomalies has never been easier or more efficient than it is today. These technologies not only streamline operations but also enhance understanding regarding Vibration damper in transmission line applications—ultimately leading to improved safety standards across electrical infrastructures worldwide.

Conclusion

In the world of engineering, vibration dampers play a crucial role in ensuring the stability and reliability of various infrastructures, especially in transmission lines. As we look to the future, advancements in vibration damper technology will likely enhance their effectiveness and efficiency. Understanding what a vibration damper is used for can guide engineers toward innovative solutions that bolster infrastructure resilience.

Future Trends in Vibration Dampers

The future of vibration dampers is bright, with ongoing research focusing on developing smarter materials and designs that adapt to environmental changes. Emerging technologies such as active damping systems could revolutionize how we mitigate vibrations by allowing real-time adjustments based on detected movement. Moreover, integrating IoT devices for monitoring purposes will ensure that maintenance schedules are optimized, enhancing the longevity of these essential components.

Spark Fittings Role in Innovation

Spark Fittings stands at the forefront of innovation within this field by manufacturing high-quality equipment tailored for transmission line applications. Their products not only include advanced vibration dampers but also preformed armor rods and tension clamps designed to withstand harsh conditions while maintaining performance integrity. By investing in state-of-the-art machinery and processes, Spark Fittings ensures that engineers have access to reliable solutions that improve overall system reliability.

Key Takeaways for Transmission Line Engineers

For transmission line engineers, understanding the three main types of dampers—tuned mass dampers, friction dampers, and viscoelastic dampers—is essential for selecting the right solution for specific challenges. Knowing what a vibration damper is used for can significantly impact infrastructure longevity and safety; they mitigate mechanical vibrations effectively while protecting against potential damage from environmental factors. Regular inspection and maintenance through effective Transmission Line Vibration Damper Detection techniques will ensure these systems remain operationally sound.