Introduction

Understanding Powerline Equipment Importance

Powerline equipment plays a pivotal role in maintaining the integrity of electrical systems. Whether it's insulators that prevent leakage or tension clamps that secure cables, each component contributes to a robust network designed to withstand environmental challenges. Professionals recognize that investing in high-quality power line equipment not only enhances operational efficiency but also reduces long-term maintenance costs.

Key Features of Quality Power Line Hardware

Quality powerline hardware is characterized by durability, reliability, and compatibility with existing systems. Features such as corrosion resistance and high tensile strength are essential for ensuring that components can endure harsh weather conditions without compromising performance. Furthermore, advanced designs in Distribution Hardware offer improved functionality, making it easier for professionals to implement effective solutions.

Why Professionals Choose Specific Powerline Products

Professionals often gravitate towards specific powerline products based on their proven track record and reputation within the industry. Factors such as ease of installation, availability of replacement parts, and manufacturer support play significant roles in their decision-making process. Ultimately, choosing trusted brands ensures that professionals can deliver safe and efficient service while minimizing downtime associated with equipment failures.

Overview of Powerline Equipment

Understanding the various aspects of powerline equipment is essential for anyone involved in the electrical distribution industry. This section will delve into the types of powerline hardware available, their applications, and the benefits of using reliable distribution hardware. By grasping these concepts, professionals can make informed decisions that enhance efficiency and safety.

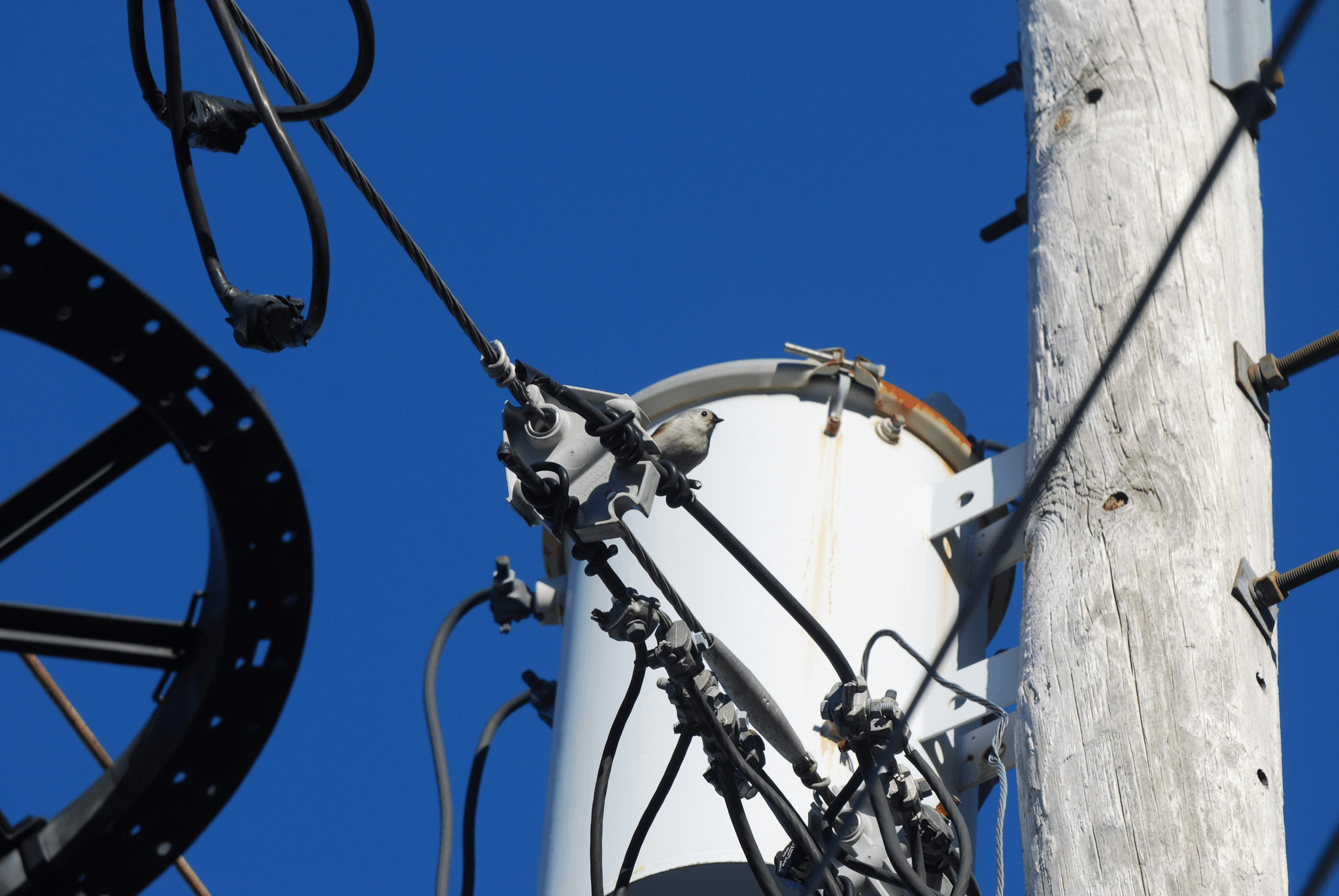

Types of Powerline Hardware

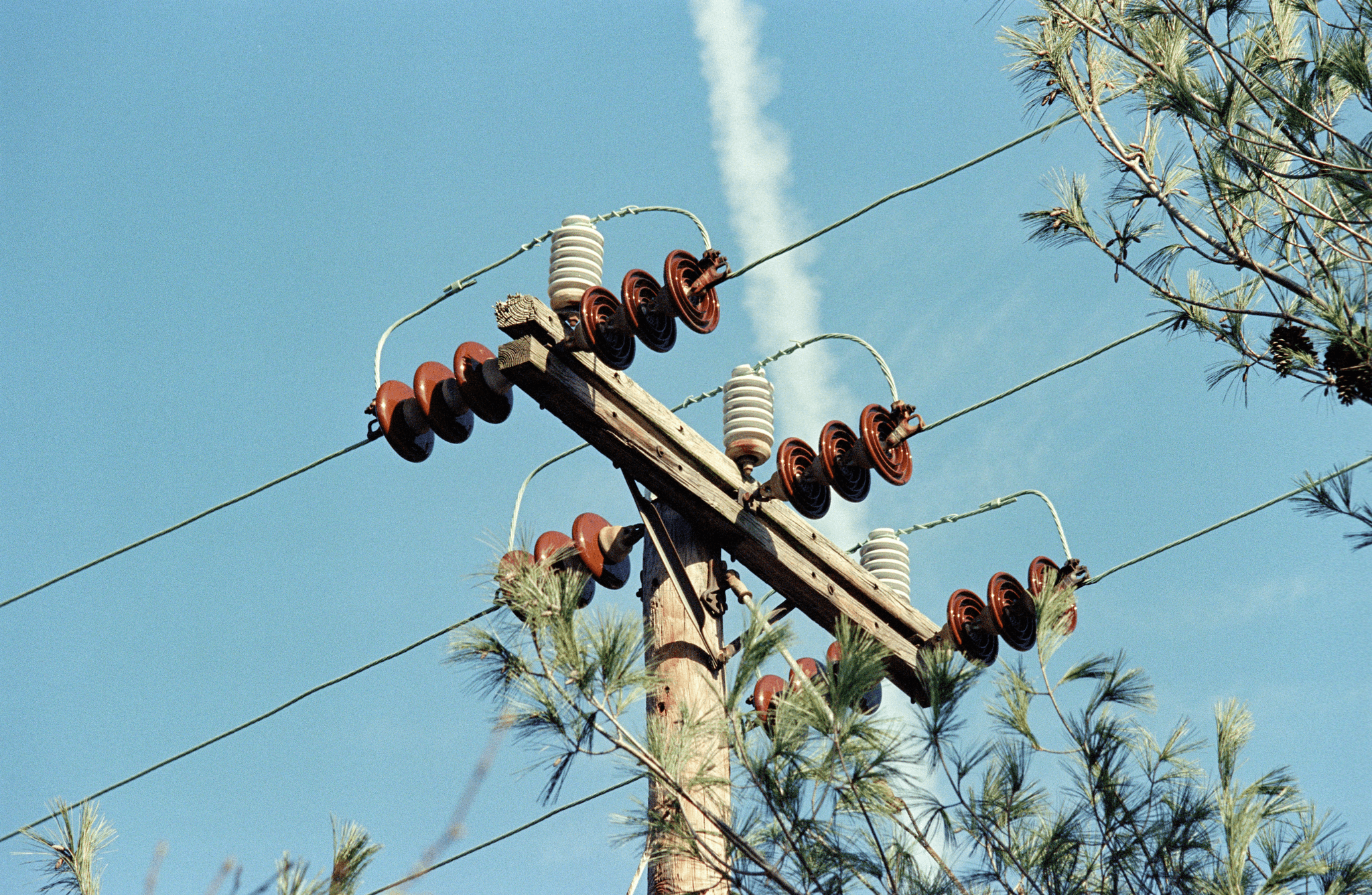

Powerline hardware encompasses a wide array of components designed to support the transmission and distribution of electrical energy. Key types include insulators, tension clamps, connectors, and pole hardware—all vital for maintaining system integrity. Each type serves a unique function; for instance, insulators prevent unwanted current flow while ensuring that power lines remain securely in place.

Applications of Power Line Equipment

Power line equipment finds its application in numerous settings—from rural areas needing reliable electricity to urban centers with complex distribution networks. These products are critical in overhead and underground installations as they facilitate safe energy transmission across vast distances. Additionally, powerline products are employed in renewable energy systems, enhancing their role in sustainable development.

Benefits of Using Reliable Distribution Hardware

Investing in quality distribution hardware yields significant advantages for both safety and performance. Reliable powerline equipment minimizes downtime by reducing failures caused by inferior materials or design flaws—saving time and money in maintenance costs. Furthermore, top-notch insulators and other components enhance system efficiency, ensuring that electricity reaches consumers without unnecessary losses.

Essential Powerline Products for Professionals

Analyzing Spark Fittings Offerings

Spark fittings are crucial components in powerline equipment that ensure secure connections between conductors and other elements of the distribution system. These fittings come in various designs, each tailored to specific applications and environmental conditions. By analyzing the offerings from different manufacturers, professionals can select spark fittings that not only meet safety standards but also enhance overall system efficiency.

The right spark fittings help minimize energy loss and reduce maintenance costs over time, making them a wise investment in quality powerline products. Additionally, features such as corrosion resistance and ease of installation further elevate their appeal among those working with power line equipment. Ultimately, choosing high-quality spark fittings contributes significantly to the longevity and reliability of your entire distribution hardware setup.

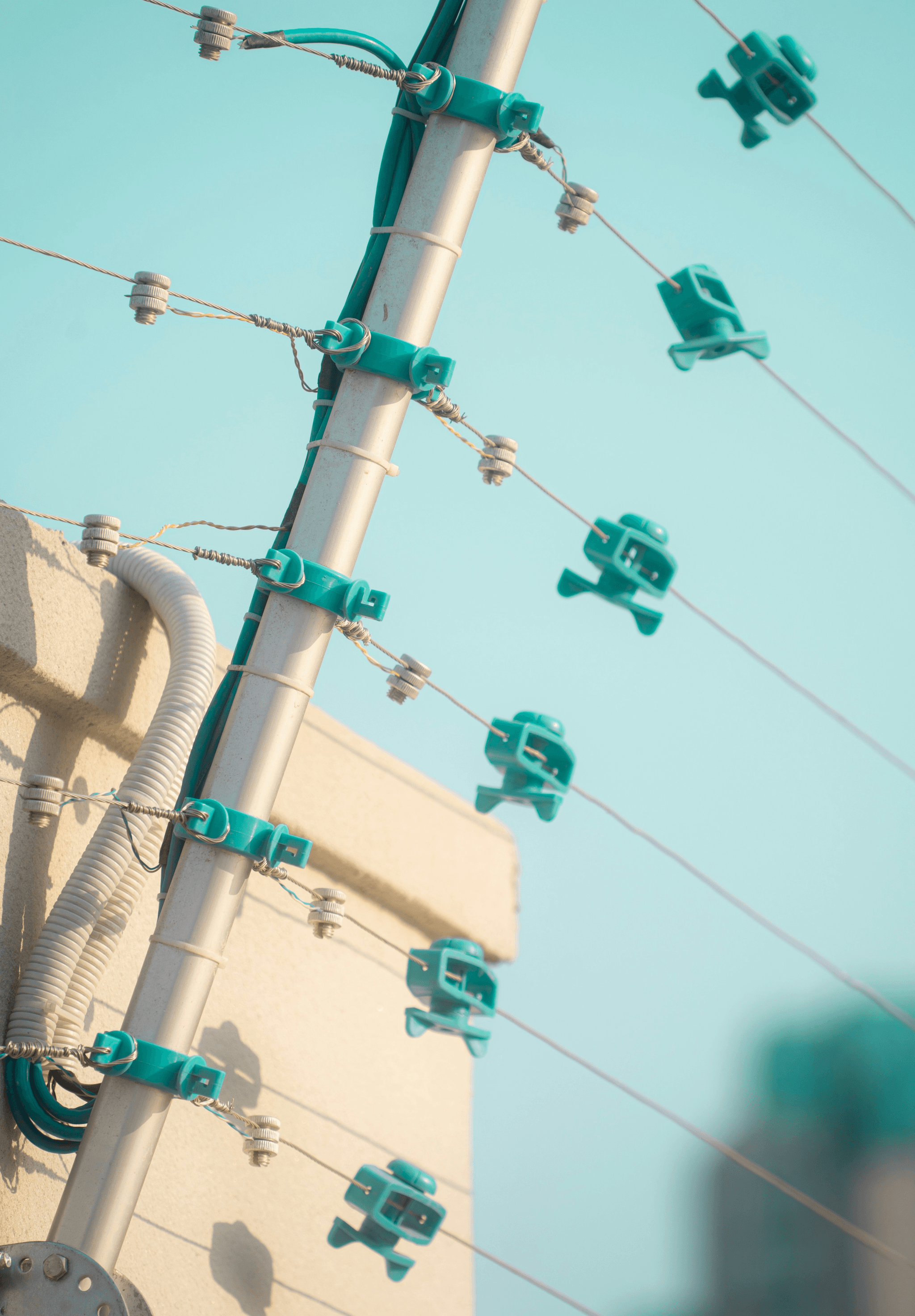

Advantages of Quality Insulators

Quality insulators play an indispensable role in ensuring the safety and effectiveness of powerline hardware systems. They provide electrical insulation while supporting conductors under various weather conditions, which is critical for maintaining uninterrupted service. High-quality insulators are designed to withstand mechanical stress and environmental factors like temperature fluctuations or UV exposure.

Investing in superior insulators not only protects your infrastructure but also enhances overall system performance by reducing energy losses due to leakage currents. Furthermore, reliable insulators contribute to lower maintenance costs over time since they are less likely to fail or require frequent replacements—an important consideration for any professional managing extensive power line equipment networks. In short, selecting quality insulators is a no-brainer for those who prioritize durability and efficiency.

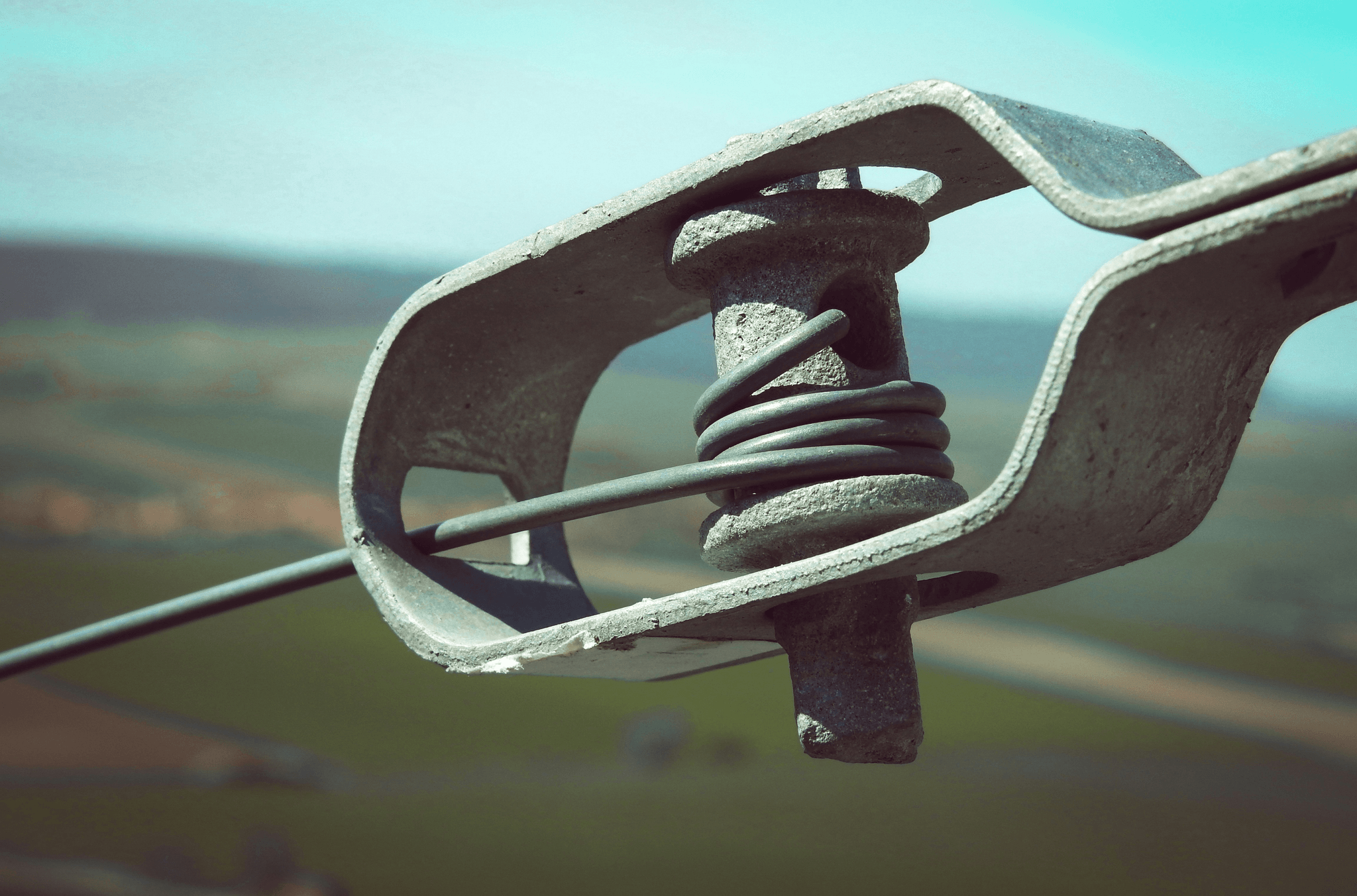

Choosing the Right Tension Clamps

Tension clamps are another essential component within the realm of powerline products that demand careful selection based on application needs and environmental conditions. These clamps secure overhead conductors while allowing for thermal expansion and contraction without compromising stability—a vital feature given how temperature changes can affect line tension significantly.

When choosing tension clamps, professionals should consider materials that resist corrosion and wear while ensuring compatibility with existing power line hardware systems—after all, mismatched components can lead to costly failures down the road! Moreover, opting for adjustable tension clamps can provide additional flexibility during installation or maintenance operations by accommodating varying cable sizes or tensions effortlessly.

How to Select the Best Powerline Equipment

Choosing the right powerline equipment can feel like navigating a maze, but with the right guidance, it becomes a straightforward process. The selection of power line hardware is crucial for ensuring safety, efficiency, and longevity in your electrical systems. Here’s how to make informed decisions about your powerline products.

Key Factors for Evaluating Equipment

When evaluating powerline equipment, several key factors should take center stage. First and foremost is durability; quality power line hardware must withstand harsh environmental conditions while maintaining functionality over time. Additionally, consider the specifications that align with your project needs—load capacity, voltage ratings, and compliance with industry standards are essential elements that can't be overlooked.

Another critical factor is user-friendliness; even the best distribution hardware won’t serve its purpose if it’s complicated to install or operate. Look for products that come with clear guidelines and support from manufacturers to ease this process. Lastly, cost-effectiveness matters—investing in reliable powerline products may have a higher upfront cost but can save money over time through reduced maintenance and replacement needs.

Comparing Popular Powerline Hardware Brands

Navigating through various brands of powerline hardware can be overwhelming due to the sheer number of options available on the market today. Some brands have established themselves as leaders by consistently delivering high-quality products tailored for specific applications within the industry. Familiar names like TE Connectivity and Hubbell are often trusted for their innovation and reliability in producing insulators and other essential components.

When comparing brands, pay attention to customer reviews and testimonials; real-world experiences provide valuable insights into product performance that specifications alone cannot convey. Additionally, consider warranty offerings as they reflect a brand's confidence in its own powerline equipment quality—longer warranties often indicate better durability and reliability standards among products like tension clamps or insulators.

Importance of Compatibility in Powerline Products

Compatibility among various components of your power line equipment is paramount for seamless operation. Using mismatched or incompatible hardware can lead to inefficiencies or even catastrophic failures down the line—literally! Ensure that all pieces of equipment work together harmoniously by reviewing manufacturer guidelines regarding compatibility between different types of distribution hardware.

Furthermore, when upgrading or replacing existing installations with new powerline products, always double-check compatibility with older systems to avoid costly errors during installation or operation phases. This diligence not only ensures safety but also maximizes performance across all aspects of your electrical infrastructure—a win-win situation!

Best Practices for Power Line Installation

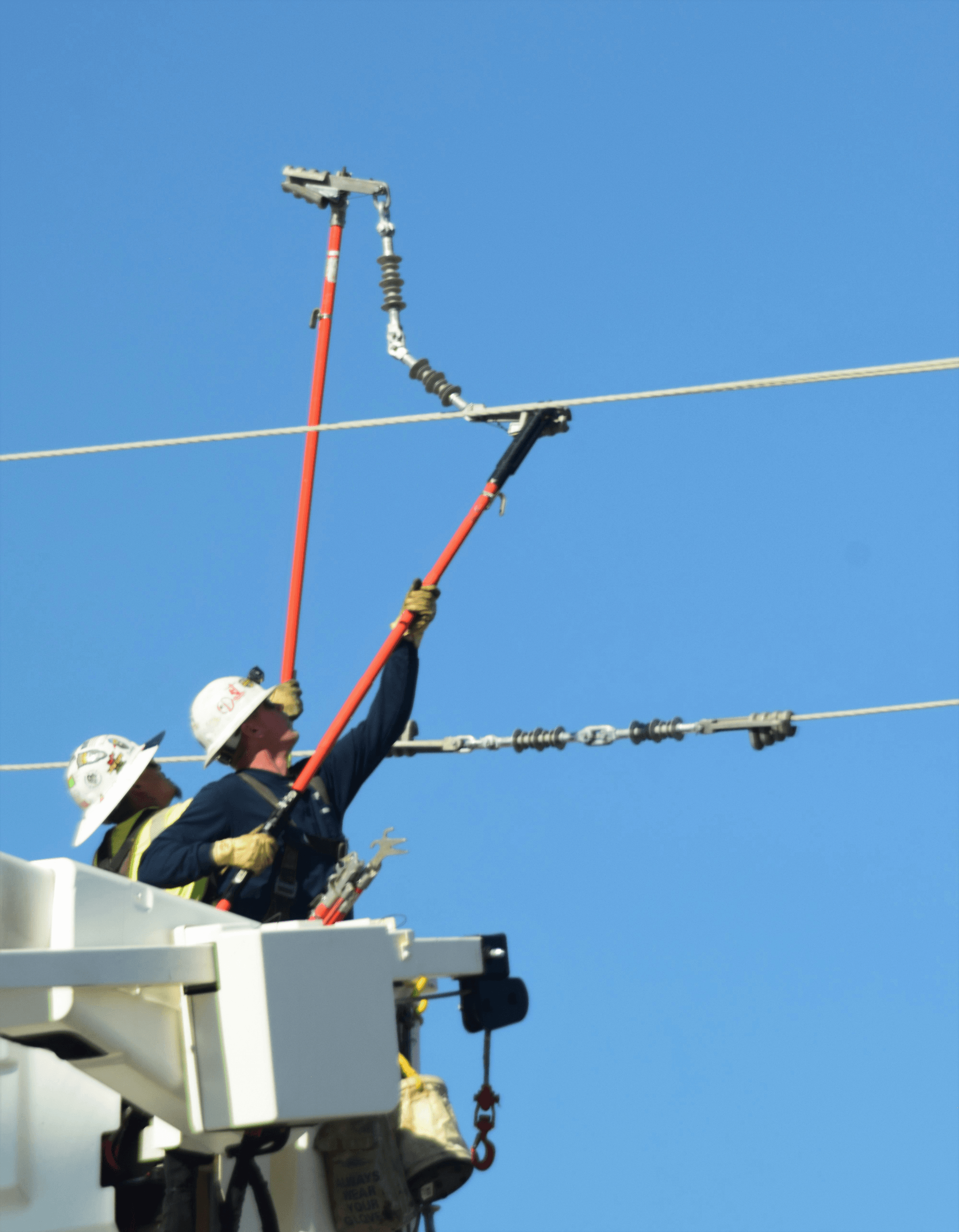

Safety Measures During Installation

Safety should always be the top priority when working with powerline hardware. Before beginning any installation, it’s essential to conduct a thorough risk assessment, identifying potential hazards such as live wires or adverse weather conditions. Wearing appropriate personal protective equipment (PPE) like helmets, gloves, and insulated tools is critical to safeguarding against electrical shocks and injuries while handling insulators and other components.

Additionally, ensuring that all team members are trained in emergency response procedures can make a significant difference in case of an accident. Utilizing proper grounding techniques when working with powerline products helps prevent electrical faults that could lead to serious injuries or damage. Remember, a well-planned safety strategy not only protects workers but also ensures that your installation meets industry standards.

Tools Needed for Effective Installation

Equipping yourself with the right tools is essential for effective installation of power line equipment. Some must-have tools include cable cutters, crimping tools, tensioning devices, and specialized wrenches designed for handling various types of distribution hardware. Investing in high-quality tools ensures durability and reliability during installations while reducing maintenance costs over time.

Moreover, having access to measuring devices like torque wrenches can help ensure that fittings are installed correctly according to specifications—this is particularly important when working with tension clamps or insulators. Don’t forget about safety gear such as harnesses and ladders; they’re just as crucial as your installation tools when it comes to completing jobs efficiently and safely at height.

Maintenance Tips for Longevity

Maintaining your powerline products is key to ensuring their longevity and optimal performance over time. Regular inspections should be conducted on all components—including insulators—to identify signs of wear or damage before they lead to failures in the system. Keeping detailed records of maintenance activities can help track issues over time and inform future improvements in your approach.

Additionally, cleaning distribution hardware periodically prevents dirt buildup that could compromise functionality; this is especially true for insulators where contaminants may cause tracking or flashover problems. Lastly, staying updated on manufacturer recommendations regarding maintenance schedules will help you keep all powerline equipment functioning smoothly well into the future.

Future Trends in Powerline Equipment

The landscape of powerline equipment is evolving rapidly, driven by advancements in technology and a growing emphasis on sustainability. As the demand for reliable energy distribution increases, innovations in powerline hardware are becoming essential for meeting modern energy needs. This section explores the latest trends that are shaping the future of power line hardware.

Innovations in Powerline Technology

The future of powerline equipment is marked by exciting innovations that enhance efficiency and reliability. Smart grid technology is at the forefront, allowing for real-time monitoring and management of power line equipment, which minimizes outages and optimizes performance. Additionally, advancements in materials science are leading to stronger and lighter insulators, making them more durable against environmental stresses while improving overall safety.

Another significant innovation involves the integration of IoT (Internet of Things) devices into power line hardware systems. These devices can provide valuable data analytics on equipment performance, helping professionals make informed decisions about maintenance and upgrades. Ultimately, these technological advancements are not just about enhancing functionality; they also aim to create a more resilient infrastructure that can withstand the challenges posed by climate change.

The Role of Sustainability in Power Line Hardware

Sustainability has become a crucial consideration in the development of powerline products and distribution hardware. Manufacturers are increasingly focusing on eco-friendly materials that reduce environmental impact without compromising quality or durability. For instance, recycled composites are being used to create insulators that not only meet performance standards but also contribute to a circular economy.

Furthermore, sustainable practices extend beyond materials; they encompass entire manufacturing processes as well. Companies are adopting energy-efficient production methods and reducing waste to align with global sustainability goals. As consumers become more environmentally conscious, the demand for sustainable power line equipment will likely drive innovation further within this sector.

Predictions for Powerline Products Advancements

Looking ahead, we anticipate several exciting advancements in powerline products that will redefine industry standards. One major prediction is the rise of autonomous systems capable of self-diagnosing issues within power line hardware before they escalate into larger problems—this could revolutionize maintenance protocols across various applications.

Moreover, increased collaboration between tech companies and traditional manufacturers may lead to hybrid solutions combining software intelligence with robust physical components like tension clamps and insulators. Such collaborations promise enhanced compatibility among different types of power line equipment while ensuring optimal performance across diverse environments.

In conclusion, staying abreast of these trends will be vital for professionals aiming to optimize their operations with cutting-edge solutions tailored for tomorrow's energy demands.

Conclusion

In wrapping up our exploration of powerline equipment, it's clear that understanding the essentials is vital for both safety and efficiency. Quality powerline hardware plays a crucial role in ensuring reliable electricity distribution, while the right selection of power line products can significantly impact performance. By focusing on key components like insulators and distribution hardware, professionals can make informed choices that enhance their work.

Recap of Powerline Equipment Essentials

Throughout this guide, we've emphasized the importance of selecting quality powerline equipment tailored to specific needs. From various types of power line hardware to essential components such as insulators and tension clamps, each piece serves a unique purpose in maintaining electrical infrastructure. Remember, investing in reliable powerline products not only ensures safety but also contributes to long-term operational efficiency.

Final Thoughts on Choosing Powerline Hardware

When it comes to choosing powerline hardware, professionals should prioritize quality over cost-cutting measures. Durable and efficient power line equipment can save time and money in the long run by reducing maintenance needs and enhancing system reliability. Ultimately, making informed decisions based on thorough evaluations will lead to better outcomes for any project involving distribution hardware.

Staying Updated with Powerline Products Trends

The world of powerline equipment is continuously evolving with new technologies and practices emerging regularly. Keeping abreast of these trends will empower professionals to leverage advancements that enhance performance and sustainability in their projects. Whether it's innovations in materials or shifts towards greener solutions, staying informed about the latest developments in power line products is essential for future success.