Introduction

When it comes to the efficient transmission of electricity, the choice of insulators plays a crucial role. Good insulators of electricity are essential for maintaining the integrity of power lines and ensuring safety. Understanding what makes the best insulator of electricity is key to optimizing electrical systems for maximum performance and reliability.

Understanding the Role of Composite Insulators

Composite insulators are among the top choices for electrical insulation due to their exceptional properties. They are designed to provide high dielectric strength and low conductivity, making them reliable in preventing electrical leakage and breakdown.

Benefits of Using Composite Insulators

The benefits of using composite insulators extend beyond their insulation properties. Their lightweight design, resistance to harsh weather conditions, and longevity make them a preferred choice for various electrical applications.

Why Spark Fittings's Composite Insulators Stand Out

Spark Fittings is renowned for its commitment to producing high-quality equipment for the transmission and distribution of electricity, including composite insulators. Their products stand out due to their advanced manufacturing process, compliance with industry standards, and unwavering dedication to customer satisfaction.

What Makes Composite Insulators Exceptional

Composite insulators are known for their exceptional properties that make them good insulators of electricity. At Spark Fittings, our composite insulators are designed with a lightweight construction, making them easy to handle and install without compromising on strength and reliability. This lightweight design allows for easier transportation and reduces the strain on support structures, making it a preferred choice for various electrical applications.

Lightweight Design

Our composite insulators are engineered to be lightweight yet durable, providing an ideal balance between strength and weight. This makes them the best insulator of electricity for applications where weight is a concern, such as in overhead power lines and electrified railways. The lightweight design also contributes to easier handling during installation and maintenance, saving time and labor costs in the long run.

Resistance to Harsh Weather Conditions

One of the key features that sets Spark Fittings's composite insulators apart is their exceptional resistance to harsh weather conditions. Whether it's extreme temperatures, high winds, or heavy rainfall, our composite insulators are designed to withstand the elements without compromising their electrical insulation properties. This makes them a reliable choice for outdoor applications where exposure to weather is inevitable.

Longevity and Durability

When it comes to finding good electrical insulators with longevity and durability, Spark Fittings's composite insulators excel in providing long-term performance under demanding conditions. The materials used in their construction are carefully selected to resist degradation from UV exposure, chemical pollutants, and other environmental factors that can affect the lifespan of traditional insulators. As a result, our composite insulators offer extended service life and reduced maintenance requirements.

The Electrical Insulation Properties of Composite Insulators

Composite insulators are known for being good insulators of electricity, making them a reliable choice for various electrical applications. Their high dielectric strength allows them to withstand high voltage levels without conducting electricity, ensuring the safety and efficiency of power transmission systems.

High Dielectric Strength

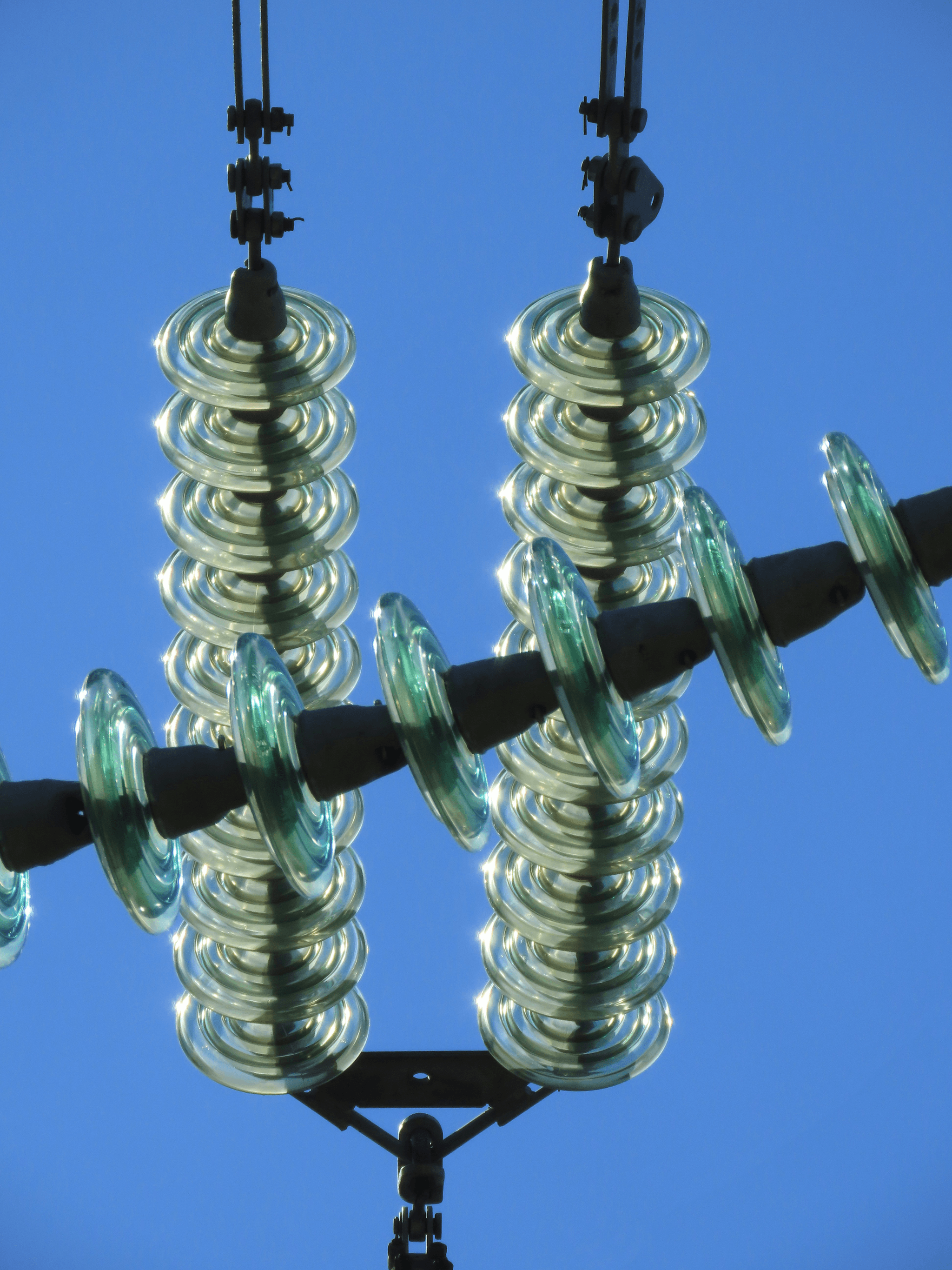

Composite insulators exhibit exceptional dielectric strength, which is essential for maintaining electrical insulation in high-voltage environments. This property makes them the best insulator of electricity in comparison to traditional materials like porcelain or glass. With their ability to resist electrical breakdown, composite insulators ensure the reliable and uninterrupted flow of electricity.

Composite insulators also offer a lightweight and durable alternative to traditional materials, making them easier to transport, install, and maintain. This not only reduces the overall cost of electrical infrastructure but also minimizes the risk of accidents during handling and installation. Additionally, their resistance to corrosion and weathering ensures a longer lifespan, providing a more sustainable solution for high-voltage insulation needs.

Low Conductivity

One of the key advantages of composite insulators is their low conductivity, which prevents the flow of electric current through the material. This characteristic makes them one of the top 5 electrical insulators available in the market, as they effectively minimize energy loss and enhance the overall performance of electrical systems.

In addition to their low conductivity, composite insulators also boast excellent resistance to tracking and erosion. This means that they are highly durable and can withstand harsh environmental conditions, such as extreme temperatures, moisture, and pollution. As a result, composite insulators have a longer lifespan compared to traditional insulating materials, making them a cost-effective choice for electrical systems. Their ability to resist tracking and erosion also contributes to the overall safety and reliability of electrical infrastructure.

Resistance to Tracking and Erosion

In addition to their high dielectric strength and low conductivity, composite insulators demonstrate remarkable resistance to tracking and erosion. This means that even when exposed to harsh environmental conditions or contaminants, such as salt spray or industrial pollution, these insulators maintain their integrity and continue to function effectively.

Furthermore, the resistance to tracking and erosion in composite insulators also contributes to their longevity and low maintenance requirements. Unlike traditional insulators, which may degrade over time and require frequent cleaning or replacement, composite insulators can withstand the test of time without losing their effectiveness. This makes them a cost-effective and reliable choice for various electrical applications.

Applications and Advantages of Composite Insulators

Composite insulators are known for being good insulators of electricity, making them ideal for various applications in the electrical industry. They offer exceptional electrical insulation properties, making them the best insulator of electricity for power transmission and distribution systems. Here are five electrical insulators that are commonly used: glass, porcelain, plastic, rubber, and air. Some examples of good insulators include wood, glass, plastic, rubber, and air. Spark Fittings's composite insulators are among the top choices for those looking for four good electrical insulators that provide reliability and longevity.

Power Transmission Lines

When it comes to power transmission lines, composite insulators offer significant advantages over traditional materials like porcelain or glass. Their lightweight design reduces strain on supporting structures and makes installation easier. Additionally, their resistance to harsh weather conditions ensures consistent performance even in extreme environments. Spark Fittings's composite insulators are a top choice for power transmission lines due to their exceptional durability and ability to withstand high voltage levels.

Furthermore, composite insulators offer a longer service life compared to traditional materials, reducing the need for frequent maintenance and replacement. This not only saves time and money but also minimizes disruptions to power transmission operations. In addition, their non-porous surface prevents the accumulation of dirt and pollutants, ensuring optimal performance over time. Spark Fittings's composite insulators are designed to provide reliable and long-lasting support for power transmission lines, making them a cost-effective choice for utility companies.

Substations and Switchyards

In substations and switchyards, the need for good conductors of electricity is crucial to ensure safe and reliable operations. Composite insulators excel in this aspect by providing high dielectric strength and low conductivity, reducing the risk of electrical failures or outages. With resistance to tracking and erosion, they offer long-term performance with minimal maintenance requirements. Spark Fittings's composite insulators are a preferred choice for substations and switchyards due to their superior insulation properties.

In addition to their superior insulation properties, Spark Fittings's composite insulators also offer exceptional resistance to environmental factors such as UV radiation and pollution. This ensures that they maintain their high performance and reliability even in harsh outdoor conditions, making them an ideal choice for substations and switchyards located in challenging environments. By choosing composite insulators, operators can have peace of mind knowing that their electrical infrastructure is well-protected against the elements.

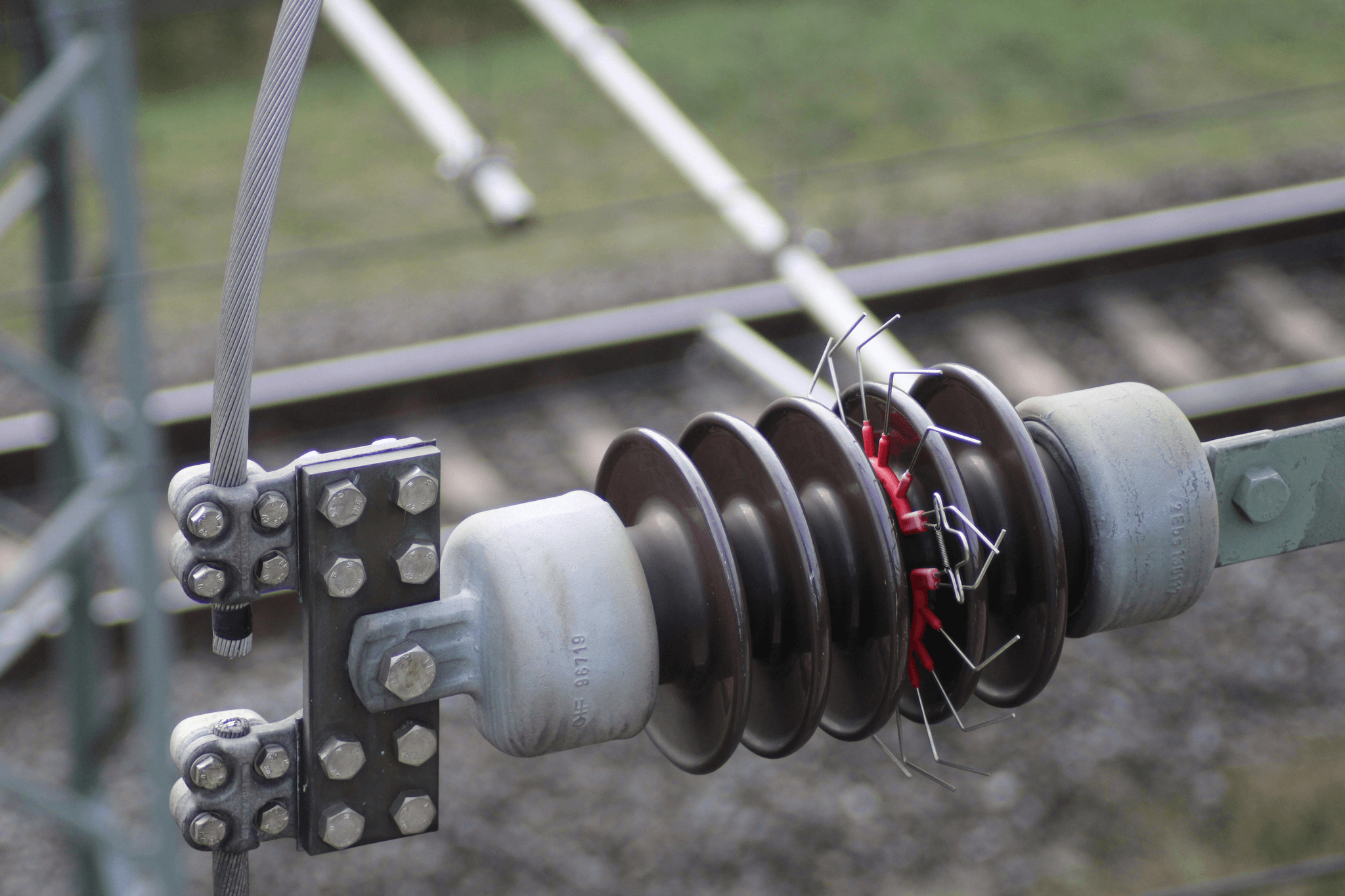

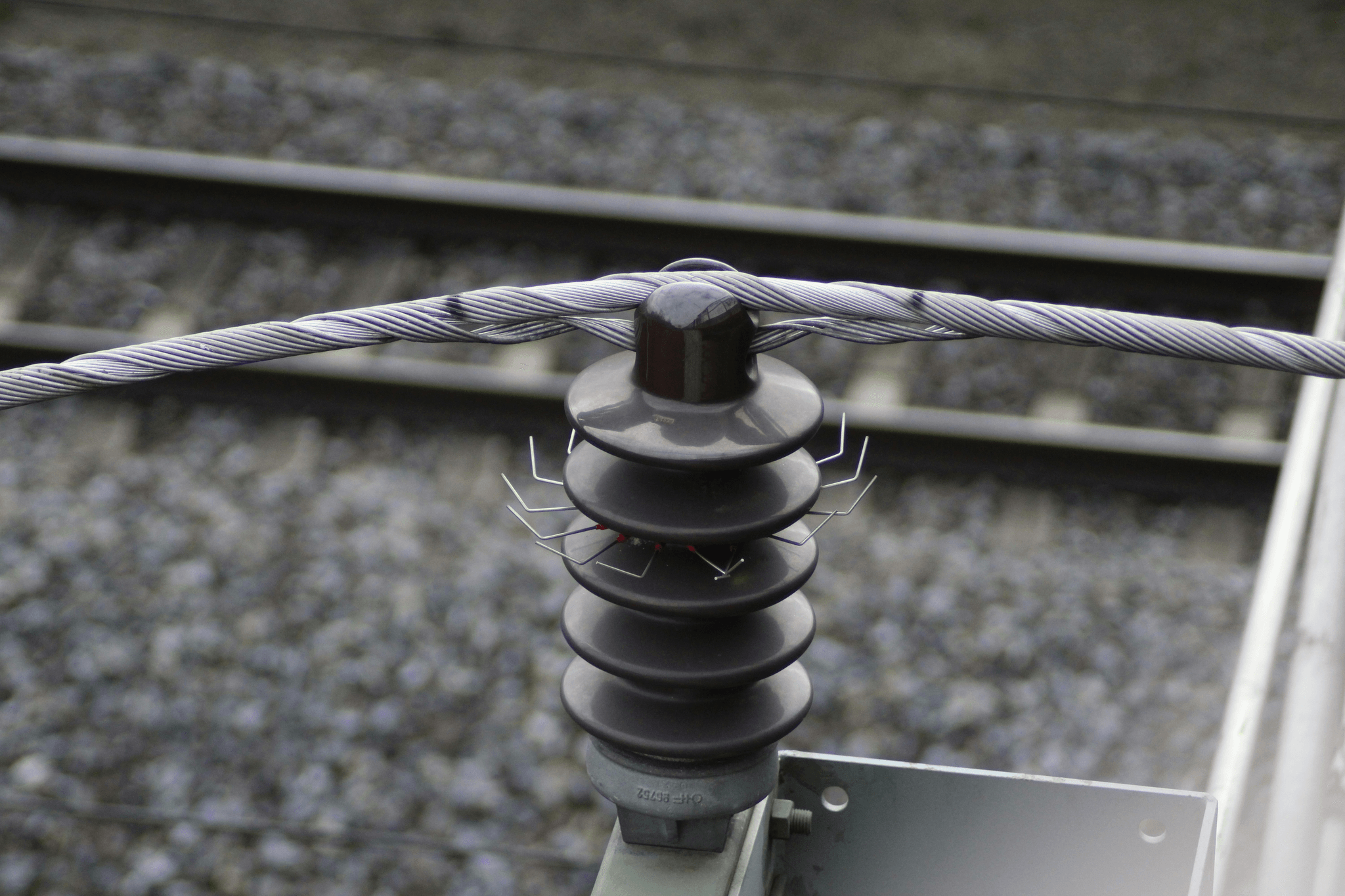

Electrified Railways

For electrified railways, good conductors of electricity play a vital role in ensuring efficient power distribution along the tracks. Composite insulators offer excellent insulation properties that contribute to the reliable operation of railway systems while minimizing the risk of electrical hazards. Their longevity and durability make them a cost-effective solution for electrified railways with minimal maintenance needs. Spark Fittings's composite insulators are widely used in electrified railways due to their proven track record in delivering superior electrical insulation.

In addition to their excellent insulation properties, composite insulators also offer a lightweight and compact design, making them easy to install and maintain along electrified railway tracks. This not only reduces the overall installation time but also minimizes the need for frequent maintenance, resulting in cost savings for railway operators. The streamlined design of composite insulators also helps to improve the overall aesthetics of electrified railways, creating a modern and efficient transportation infrastructure.

Comparing Composite Insulators to Traditional Insulators

Performance in Contaminated Environments

When it comes to performance in contaminated environments, composite insulators outshine traditional insulators. The unique design and materials used in composite insulators make them highly resistant to pollution and contaminants, ensuring consistent and reliable electrical insulation even in harsh conditions. This is a significant advantage over traditional insulators, which are more prone to performance degradation in contaminated environments.

Maintenance and Cost Efficiency

In terms of maintenance and cost efficiency, composite insulators offer substantial benefits compared to traditional insulators. Their durability and longevity reduce the need for frequent maintenance and replacement, resulting in significant cost savings over time. Additionally, the lightweight design of composite insulators makes installation and handling more efficient, further contributing to cost-effectiveness.

Environmental Impact

When considering the environmental impact, composite insulators emerge as the more sustainable choice. Their resistance to tracking and erosion minimizes the risk of environmental contamination from insulator degradation, making them environmentally friendly options for electrical insulation. In contrast, traditional insulators may pose environmental risks due to their susceptibility to pollution-related performance issues.

Spark Fittings is at the forefront of producing high-quality composite insulators that excel in performance, cost efficiency, and environmental sustainability. By leveraging advanced manufacturing processes and adhering to industry standards, Spark Fittings ensures that their composite insulators meet the highest quality and reliability standards for various applications.

Ensuring Quality and Reliability with Spark Fittings's Composite Insulators

Advanced Manufacturing Process

At Spark Fittings, our composite insulators are crafted using an advanced manufacturing process that ensures precision and quality. We utilize cutting-edge technology and stringent quality control measures to produce insulators that are reliable and long-lasting, making them good insulators of electricity.

Compliance with Industry Standards

Our composite insulators adhere to the highest industry standards for electrical insulation. We prioritize safety and performance, ensuring that our products meet or exceed all necessary regulations and requirements. This commitment to excellence makes our insulators the best insulator of electricity for various applications.

Customer Satisfaction and Trust

We take pride in the satisfaction and trust of our customers who rely on our composite insulators for their electrical insulation needs. With a focus on exceptional customer service, we work closely with clients to understand their specific requirements and deliver tailored solutions that meet their expectations. Our dedication to customer satisfaction sets us apart as a trusted provider of good insulators of electricity.

Remember that Spark Fittings is a leading company specializing in manufacturing equipment for preformed armor rods, tension clamps, and cable accessories for ADSS and OPGW. Our machines help customers produce high-quality preformed products for the transmission and distribution of electricity, as well as electrified railways.

Conclusion

When it comes to finding good insulators of electricity, composite insulators are the best choice for their exceptional performance and longevity. With resistance to harsh weather conditions, high dielectric strength, and low conductivity, they outshine traditional insulators in every aspect. Spark Fittings's commitment to superior electrical insulation ensures that the future of electricity transmission is in good hands.

Investing in the Long-Term Benefits of Composite Insulators

Investing in composite insulators means investing in the long-term benefits of reliable electrical insulation. Their durability and resistance make them a cost-effective choice for power transmission and electrified railways. With Spark Fittings's advanced manufacturing process, you can trust that you're making a wise investment in the future.

Spark Fittings's Commitment to Superior Electrical Insulation

Spark Fittings is dedicated to providing high-quality equipment for the transmission and distribution of electricity, ensuring that customers have access to superior electrical insulation solutions. Their expertise in manufacturing preformed armor rods, tension clamps, and cable accessories sets them apart as a leader in the industry.

Embracing the Future of Electricity Transmission with Composite Insulators

Embracing the future of electricity transmission means embracing composite insulators as the go-to choice for efficient and reliable electrical insulation. With their resistance to tracking and erosion, they offer a sustainable solution for power transmission lines, substations, switchyards, and electrified railways.