Introduction

In today's fast-paced world, effective cable management is more important than ever. Cable clips play a crucial role in keeping our environments tidy and organized, whether in homes or industrial settings. Among the various options available, aluminum cable clamps stand out for their durability and versatility.

Understanding the Importance of Cable Clips

Cable clips are essential tools that help prevent tangling and damage to wires and cables. By using quality clips, you can ensure that your cables are securely fastened, reducing the risk of accidents or disruptions in both residential and commercial spaces. Understanding how to calculate aluminum cable size is vital for selecting the right type of clip for your specific needs.

Overview of Aluminum Cable Clamps

Aluminum cable clamps offer a robust solution for holding cables firmly in place while being lightweight and resistant to corrosion. These clamps come in various sizes and designs, making them suitable for different applications—from home theaters to industrial machinery. With their competitive aluminum cable clamps price, they provide an economical choice without compromising on quality.

Common Uses for Cable Clamps

Cable clamps are used extensively across multiple industries, serving purposes from securing electrical wiring in homes to organizing extensive cabling systems in factories. They are particularly favored for their adaptability; aluminum cable clamps can be employed on metal surfaces without fear of rusting or deterioration over time. Whether you're wondering what can I use instead of cable clips or looking into specialty applications, understanding these common uses will guide you toward making informed decisions.

What are the Different Types of Cable Clips?

Plastic vs Aluminum Cable Clips

Plastic cable clips are lightweight and often more affordable than their aluminum counterparts. They work well in low-stress environments and are perfect for indoor use, where moisture isn't a concern. However, aluminum cable clamps offer superior durability and resistance to environmental factors like heat and corrosion, making them ideal for outdoor or industrial applications.

Choosing between plastic and aluminum cable clips often boils down to your project requirements. If you're looking for longevity and strength, aluminum is the way to go; if cost is a primary concern, plastic might suffice. It's essential to evaluate your specific needs before deciding which type will secure your cables effectively.

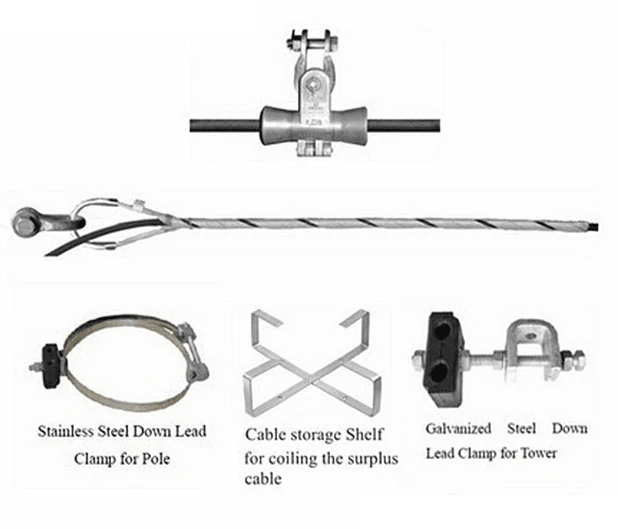

Specialty Clips for Various Applications

Specialty clips cater to unique situations where standard clips may not suffice. For instance, there are clips designed specifically for high-voltage cables or those that require additional insulation properties. These specialty aluminum cable clamps can be invaluable in ensuring safety and efficiency in various settings.

From automotive applications to telecommunications installations, there's likely a specialty clip tailored just for that purpose. This versatility helps streamline installation processes while providing reliable support for different types of cables. When selecting specialty clips, it's crucial to consider what makes them suitable for your particular application.

Key Features to Look For

When choosing the right cable clip—whether it's an aluminum or plastic option—certain features should be on your radar. First off, look at the material's strength; aluminum cable clamps typically offer better load-bearing capabilities than plastic ones. Additionally, consider factors like ease of installation, resistance to environmental conditions, and compatibility with different cable sizes.

Another important aspect is adjustability; some clips allow you to modify their grip as needed without compromising security. Also worth noting is whether they come with mounting hardware included—this can save time during installation! Ultimately, knowing what key features align with your project will help ensure you select the most effective solution.

How to Calculate Aluminum Cable Size?

Calculating the size of aluminum cables is essential for ensuring safety and efficiency in electrical installations. Proper sizing helps prevent overheating, reduces energy loss, and ensures that aluminum cable clamps can securely hold the cables in place. Understanding how to calculate aluminum cable size will empower you to make informed choices for your projects.

Factors Affecting Cable Sizing

Several factors influence how to calculate aluminum cable size effectively. First, the current-carrying capacity of the cable is crucial; it determines how much electrical load a cable can handle without overheating. Additionally, ambient temperature, installation conditions, and the length of the cable run all play significant roles in determining which aluminum cable clamps are suitable for your needs.

Another factor is the type of insulation used on the cables, as different materials have varying thermal properties. The number of conductors bundled together also affects sizing since multiple cables generate more heat than a single one. Lastly, local regulations may dictate specific requirements for cable sizes and types, so always check compliance standards when selecting aluminum cable clamps.

Step-by-Step Calculation Guide

To calculate aluminum cable size accurately, follow this step-by-step guide:

1. **Determine Load Requirements**: Start by calculating the total amperage needed for your application based on connected devices or equipment.

2. **Select Proper Voltage Drop**: Decide on an acceptable voltage drop percentage (typically 3-5% for most installations) to maintain efficiency.

3. **Use Cable Sizing Charts**: Refer to standard sizing charts that list amperage ratings based on conductor size and insulation type.

4. **Account for Environmental Factors**: Adjust your calculations according to temperature ratings and installation conditions (e.g., underground vs overhead).

5. **Final Check with Aluminum Cable Clamps Sizes**: Once you've calculated your required wire gauge, ensure it fits within standard sizes available in aluminum cable clamps.

By following these steps systematically, you'll have a better understanding of what is a suitable size for your project.

Practical Examples to Illustrate

Let’s look at practical examples that illustrate how to calculate aluminum cable sizes effectively:

For instance, if you need to power a device requiring 30 amps at 240 volts over a distance of 100 feet with an acceptable voltage drop of 3%, you'd first determine that you need at least #10 AWG wire based on general sizing charts for copper equivalents adjusted for aluminum's lower conductivity.

In another example involving industrial applications where multiple cables are bundled together using aluminum cable clamps for metal structures, consider that you might need larger gauges due to increased heat generation from multiple conductors closely packed together—often requiring #6 AWG or larger depending on environmental factors.

These examples show how crucial it is not only to know how to calculate aluminum cable size but also which types of clamps will accommodate them securely while meeting safety standards.

What is a Cable Clamp Used For?

Cable clamps are essential tools that help maintain organization and safety in both residential and industrial environments. They secure cables, preventing tangling or damage, which can lead to hazards or inefficient setups. Understanding the various applications of cable clamps can assist you in choosing the right type for your specific needs.

Securing Cables in Residential Settings

In homes, aluminum cable clamps play a vital role in managing electrical wires and cables efficiently. They help keep cords tidy along walls, under desks, or in entertainment systems, reducing clutter and minimizing tripping hazards. When installing lighting fixtures or home theater systems, knowing how to calculate aluminum cable size ensures that you use the correct clamp size for optimal safety and performance.

Industrial Applications of Cable Clamps

In industrial settings, aluminum cable clamps are indispensable for organizing power cables and ensuring operational efficiency. They are used extensively on construction sites, manufacturing plants, and warehouses to secure heavy-duty cables that power machinery or connect equipment. The durability of aluminum makes these clamps ideal for rugged environments where they may encounter moisture or extreme temperatures.

Benefits of Using Aluminum Cable Clamps

Aluminum cable clamps offer numerous advantages over other materials when it comes to securing cables effectively. Their lightweight nature makes them easy to install without compromising strength and stability—perfect for both residential and industrial applications. Additionally, their resistance to corrosion ensures longevity, making them a cost-effective choice when considering aluminum cable clamps prices over time.

Exploring Aluminum Cable Clamps Sizes

Standard Sizes and Their Uses

Aluminum cable clamps come in a variety of standard sizes to accommodate different cable diameters and applications. Common sizes range from small clamps designed for lightweight cables to larger ones suited for heavy-duty industrial use. Knowing the aluminum cable clamps sizes is crucial because using the wrong size can lead to ineffective support or even cable damage.

For instance, smaller aluminum cable clamps are typically used in residential settings where lower voltage cables are common, while larger ones are often found in industrial environments handling thicker cables. Additionally, some standard sizes cater specifically to metal surfaces, ensuring a secure grip without compromising structural integrity. When considering what is a cable clamp used for? The answer often lies in its size and application context.

Choosing the Right Size for Your Project

Choosing the right aluminum cable clamp size can feel daunting at first, but it doesn’t have to be! Start by measuring your cables accurately; this will give you a solid foundation for selecting an appropriate clamp size. Remember that if you're wondering how to calculate aluminum cable size? You’ll need these measurements as part of your overall assessment.

Once you have your measurements, consider the environment where you'll be installing these clamps—are they going on wood or metal? This information will help narrow down your options further since some aluminum cable clamps are specifically designed for metal surfaces and may offer added benefits like corrosion resistance. Ultimately, selecting the right clamp will ensure optimal performance and longevity of both your cables and their supports.

Custom Sizing Options from Spark Fittings

If standard sizes just don’t cut it for your unique project requirements, fear not! Spark Fittings offers custom sizing options that allow you to get exactly what you need without settling for less effective alternatives. Custom aluminum cable clamps can be tailored not only in dimensions but also in features such as additional padding or specialized coatings suitable for various environments.

These tailored solutions provide an excellent opportunity when you're considering what can I use instead of cable clips? Custom clamps can fulfill specific needs that generic clips simply cannot meet—like accommodating unconventional shapes or securing multiple cables together seamlessly. Plus, with competitive pricing on custom orders compared to off-the-shelf solutions, investing in quality never felt so good!

What Can I Use Instead of Cable Clips?

Alternative Solutions for Cable Management

If aluminum cable clamps aren’t your cup of tea, there are plenty of alternatives out there to consider. For instance, adhesive cable organizers provide a clean look and can be easily attached to walls or surfaces without drilling holes. Velcro straps are another flexible option that allows for easy adjustments and removals, making them ideal for temporary setups or frequently changed configurations.

Additionally, zip ties offer a quick and affordable way to bundle cables together neatly. They’re especially useful in situations where you need a tight hold but don’t mind sacrificing some flexibility in terms of reusability. Each alternative has its own unique benefits, so it's worth exploring what fits your project best.

Pros and Cons of Various Alternatives

While exploring alternatives like adhesive organizers or zip ties can be tempting, it's essential to weigh the pros and cons carefully. For example, adhesive solutions might look sleek but could damage walls upon removal or may not adhere well in humid environments—definitely something to consider if you're working in an area prone to moisture! On the other hand, while zip ties are inexpensive and effective at bundling cables tightly together, they lack the versatility that aluminum cable clamps provide when it comes to repositioning or adjusting cables later on.

Moreover, while some solutions may save you money upfront—like using duct tape—they might not offer the same durability as aluminum cable clamps over time. It's all about finding that sweet spot between cost-effectiveness and long-term reliability based on how you plan to use your cables.

When to Stick with Cable Clips

Despite the myriad alternatives available for managing cables effectively, there are times when sticking with traditional aluminum cable clamps is simply the best choice. If you’re dealing with heavy-duty applications—such as industrial settings where safety is paramount—aluminum cable clamps shine due to their robust construction and ability to handle larger loads securely without risk of failure.

Conclusion

In wrapping up our exploration of cable clips and clamps, it's clear that selecting the right type is crucial for effective cable management. From understanding the various types of cable clips to knowing how to calculate aluminum cable size, each step in this process enhances safety and organization. Whether you're securing cables in a residential setting or tackling an industrial project, the right tools make all the difference.

Final Thoughts on Cable Clip Selection

When considering what are the different types of cable clips available, it’s essential to assess your specific needs and the environment in which they will be used. Aluminum cable clamps stand out for their durability and resistance to corrosion, making them a wise choice for both indoor and outdoor applications. Ultimately, your selection should reflect a balance between functionality and aesthetic appeal.

Importance of Quality in Cable Management

Quality matters when it comes to managing cables effectively; inferior products can lead to frayed wires or even electrical hazards. Investing in high-quality aluminum cable clamps not only ensures longevity but also provides peace of mind knowing your cables are secure. Remember that cheap alternatives may seem appealing at first glance, but they often fail when you need them most—so choose wisely!

Choosing Spark Fittings for Your Needs

When looking at aluminum cable clamps sizes and prices, Spark Fittings offers a range that caters to various requirements without breaking the bank. Their commitment to quality means you can trust their products whether you're working on small-scale projects or large industrial setups. So next time you ponder what can I use instead of cable clips, remember that Spark Fittings has got you covered with reliable options designed specifically for your needs.