Introduction

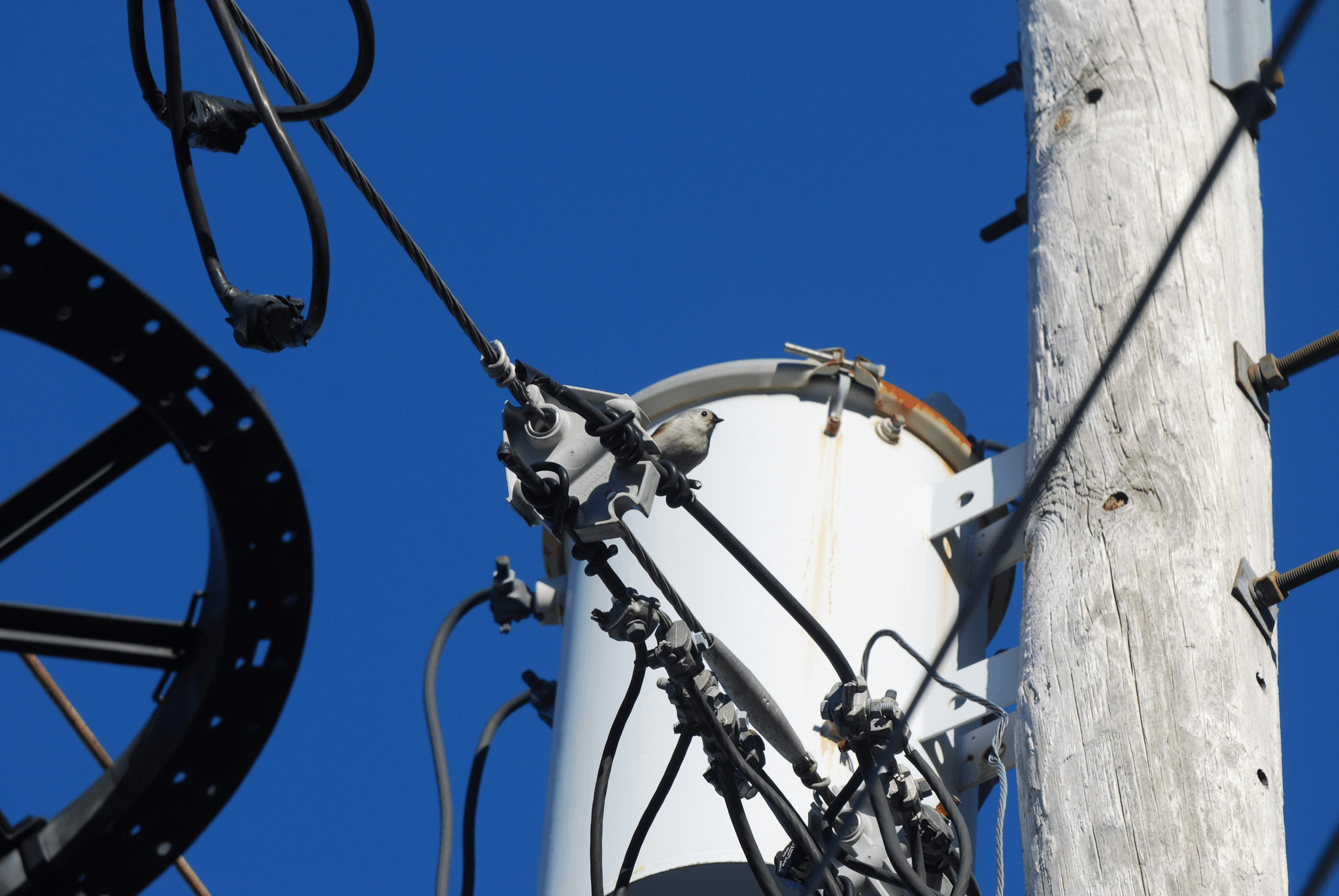

Understanding Electrical Guy Wire Basics

So, what is an electrical guy wire? In essence, it's a tensioned cable used to stabilize structures like utility poles by counteracting lateral forces. The term guy in guy wire has nothing to do with gender; it originates from the French word guie, meaning a guide or support—hence the confusion: Is it guy or guide wire? Regardless of the terminology, these wires play a pivotal role in maintaining structural integrity.

Importance of Proper Installation

The importance of proper installation cannot be overstated when discussing electrical guy wires. Incorrectly installed wires can lead to catastrophic failures that jeopardize both equipment and public safety. Moreover, understanding what is the difference between guy wire and stay wire helps ensure that each type serves its intended purpose effectively; after all, you wouldn't want your support system to be anything less than perfect.

Common Misconceptions About Guy Wires

Many misconceptions surround electrical guy wires that can lead to improper use or installation. One common myth is that all tensioned cables serve the same function—this couldn't be further from reality! Knowing why they are called guy wires helps clarify their specific role in supporting structures while debunking myths about their functionality will empower users with better knowledge for safe practices.

Defining Electrical Guy Wire

What is an electrical guy wire?

An electrical guy wire is a tensioned cable that helps stabilize vertical structures by anchoring them to the ground or another solid point. Typically made from high-strength steel or other durable materials, these wires are essential for maintaining the integrity of power lines and communication systems. Without proper installation of electrical guy wires, utility poles could lean or collapse under pressure, leading to outages and safety hazards.

Is it guy or guide wire?

The term guy wire is the correct terminology; it's not guide wire. The confusion often arises due to the similarity in pronunciation and spelling between guy and guide. However, while guide wires serve different purposes—often assisting with navigation or positioning—guy wires specifically refer to those that provide structural support.

Why do they call them guy wires?

The origin of the term “guy” in relation to these cables dates back centuries but is believed to have derived from the French word “guie,” meaning a stay or support. Essentially, they are called guy wires because they “guy” or secure structures against tipping over by providing lateral support. In addition to their functional role, this quirky name adds a bit of character to an otherwise technical aspect of engineering.

Installation Errors to Avoid

Incorrect tension settings

One of the most critical aspects of installing electrical guy wires is achieving the correct tension settings. Incorrect tension can lead to excessive strain on the wire, causing it to snap or become loose over time. It’s essential to understand that proper tension ensures stability and longevity; if you’re asking yourself, What is an electrical guy wire? remember that its effectiveness hinges on correct installation practices.

Improper anchoring techniques

Anchoring techniques are another vital area where mistakes often occur during installation. If the anchoring system isn’t robust enough or improperly installed, it can result in a catastrophic failure of the entire structure supported by the guy wire. Knowing Is it guy or guide wire? may not help much if your anchoring methods are flawed; always prioritize secure and reliable anchoring systems.

Ignoring environmental factors

Environmental factors should never be overlooked when installing electrical guy wires; they play a significant role in determining how well these wires perform over time. Weather conditions such as wind, rain, and temperature fluctuations can affect both tension and material integrity, leading to potential hazards down the line. Understanding What is the difference between guy wire and stay wire? can provide insights into how different applications might react under various environmental stresses.

Choosing the Right Materials

Selecting the right materials for electrical guy wires is crucial for ensuring their durability and effectiveness. The materials used can significantly impact the performance and longevity of these wires, especially when considering factors like environmental exposure and mechanical stress. Understanding what goes into these components will help you make informed choices, ultimately leading to safer installations.

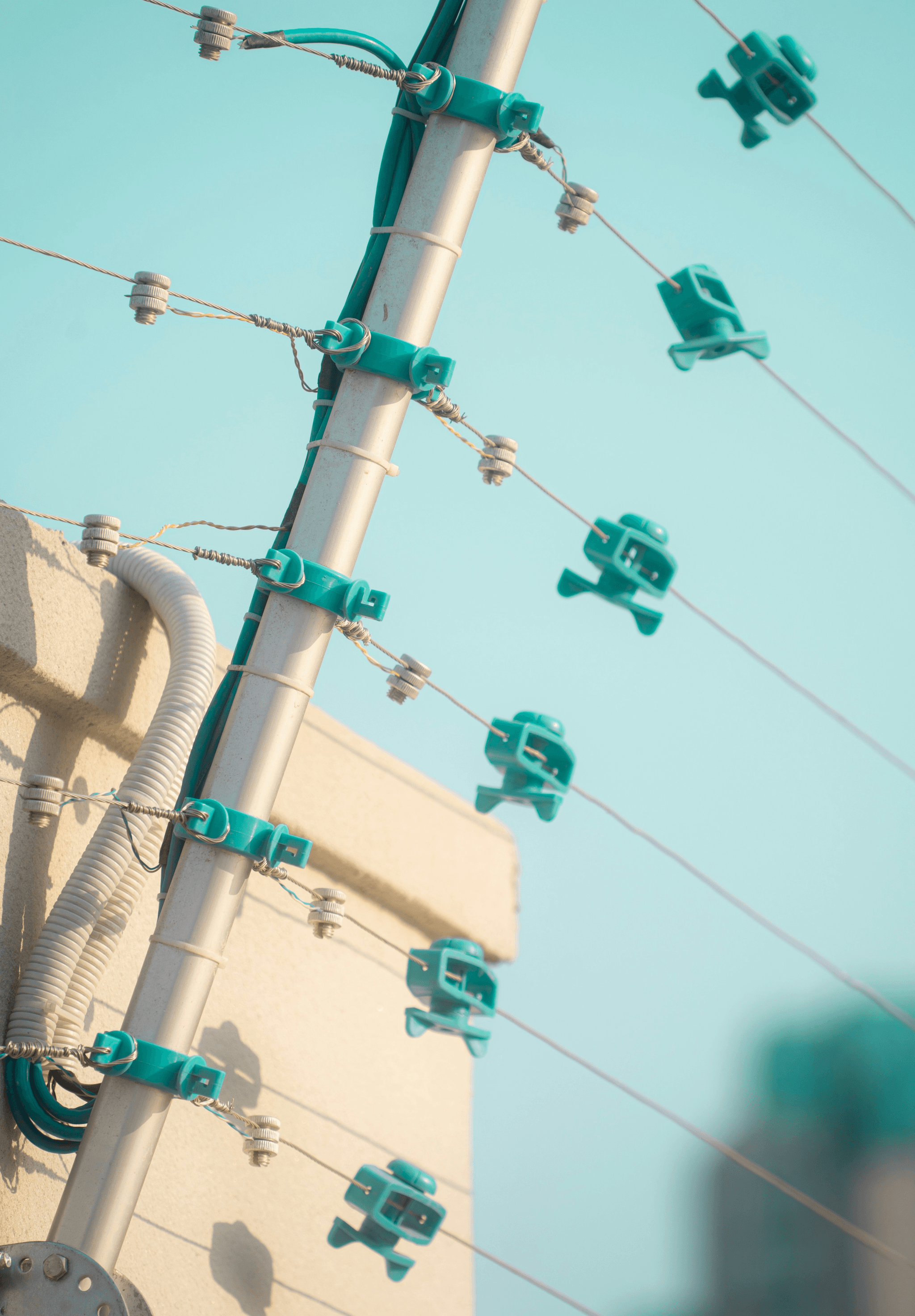

Understanding armor rod materials

Armor rods are vital components in the assembly of electrical guy wires, providing additional protection and stability to the conductor. Commonly made from aluminum wire, galvanized steel wire, or aluminum clad steel wire, each option offers unique benefits depending on the specific application requirements. When asking What is an electrical guy wire?, it’s essential to recognize that these rods play a significant role in maintaining tension and supporting overhead lines.

Choosing materials to avoid corrosion

Corrosion can be a silent killer for electrical guy wires if not properly addressed during installation. Selecting materials that are compatible with each other is key; for instance, using armor rod material similar to the conductor's surface material helps prevent galvanic corrosion between different elements. This attention to detail ensures that your electrical guy wire remains robust over time while minimizing maintenance headaches down the road.

Spark Fittings and customized armor rods

When it comes to specialized needs in your installations, Spark Fittings stands out as a go-to provider for customized armor rods tailored specifically for your project requirements. They offer a range of options based on conductor material, ensuring compatibility while also providing color-coded identification for easy installation reference. By utilizing Spark Fittings’ expertise in preformed tension clamps and accessories, you can enhance your understanding of what is the difference between guy wire and stay wire—ensuring you choose the right solutions every time.

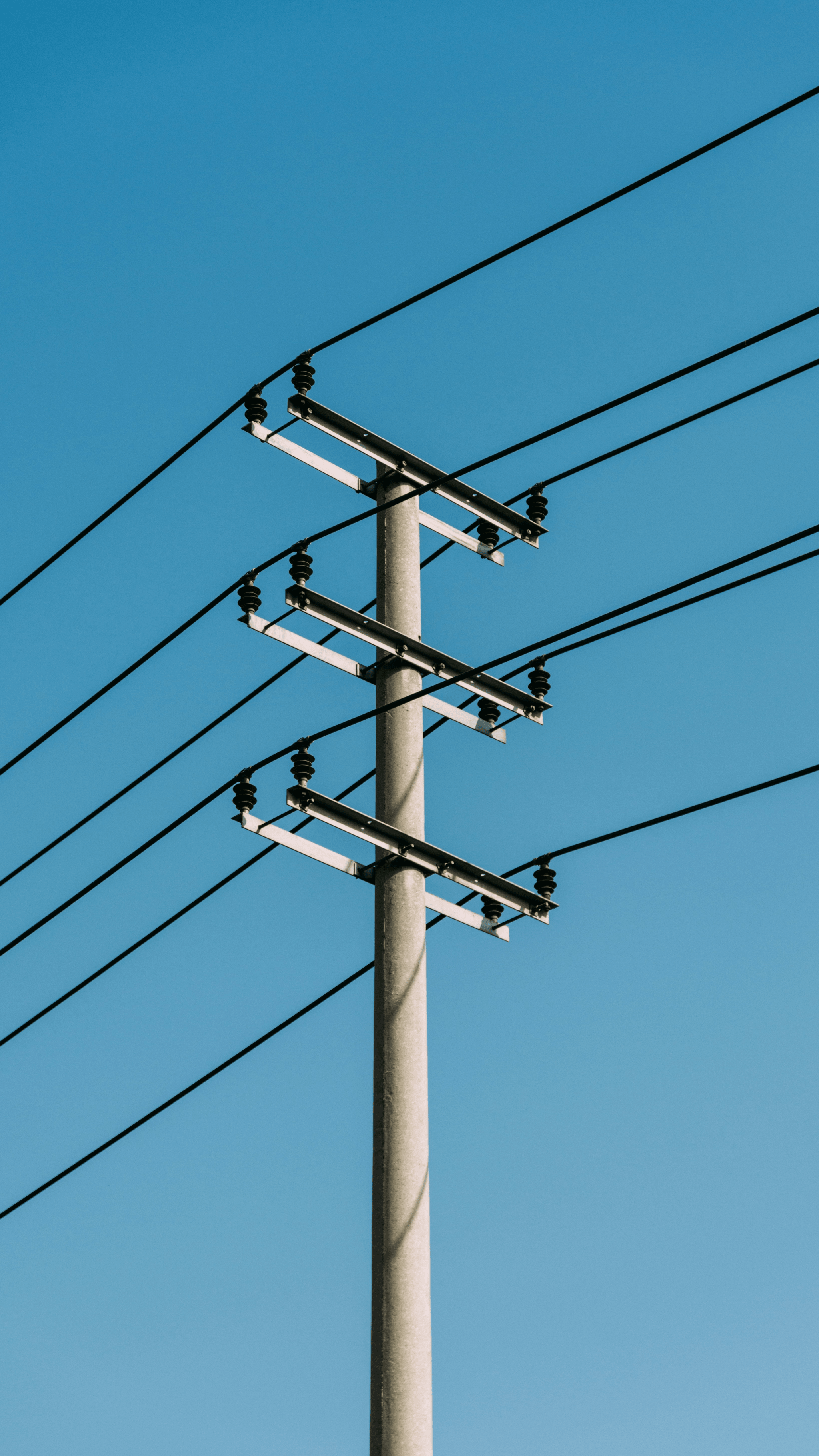

Differences Between Guy Wire and Stay Wire

When discussing the world of electrical supports, it's essential to differentiate between guy wire and stay wire. While both serve the purpose of stabilizing structures, their applications and characteristics vary significantly. Understanding what is an electrical guy wire compared to stay wire can help avoid confusion and ensure proper installation.

What is the difference between guy wire and stay wire?

The primary distinction lies in their design and function. An electrical guy wire is typically used to support vertical structures like utility poles or towers by anchoring them at an angle to the ground, providing stability against lateral forces. In contrast, stay wires are usually employed in tension applications where they provide support without significant angles, often seen in masts or other vertical installations.

Moreover, while both types of wires are crucial for structural integrity, their installation techniques differ due to their unique roles. For instance, when asking Is it guy or guide wire? one can clarify that guy refers specifically to those used for lateral support rather than guiding systems. This distinction is vital for engineers and technicians when planning installations.

Applications of each type

Electrical guy wires find their applications primarily in telecommunications and power distribution systems where tall structures need stabilization against wind or weight from equipment. They are commonly seen supporting transmission towers that require robust anchoring solutions due to environmental challenges.

On the other hand, stay wires are often utilized in radio masts or flagpoles where vertical stability is paramount but lateral movements are less of a concern. This difference leads to varied installation practices; hence understanding what is the difference between guy wire and stay wire ensures that each type is applied correctly based on specific needs.

Common mistakes in their usage

One common mistake involves misidentifying which type of support system should be used for a particular application; using an electrical guy wire where a stay wire would suffice can lead to unnecessary complications in tension management. Additionally, improper tension settings on either type can result in structural failure over time due to inadequate support.

Another frequent oversight occurs when technicians neglect environmental factors that impact these wires differently; for instance, forgetting about wind loads might lead someone to miscalculate how much tension an electrical guy wire should have versus a stay wire's requirements. Recognizing these differences not only enhances safety but also prolongs the lifespan of installations involving these critical components.

Maintenance Mistakes

Maintaining electrical guy wire systems is crucial for their longevity and reliability. Unfortunately, many overlook key maintenance aspects, leading to potentially hazardous situations. By understanding common maintenance mistakes, you can ensure that your electrical guy wire remains in optimal condition.

Neglecting regular inspections

Regular inspections of your electrical guy wire are essential to catch potential issues before they escalate. Without routine checks, you may miss signs of wear or damage that could compromise the integrity of the system. Remember, what is an electrical guy wire if not properly maintained? It’s like a car without regular oil changes—eventually, it will break down.

Overlooking wear and tear signs

Over time, all components experience some level of wear and tear; ignoring these signs can be detrimental to your structure's stability. Look for fraying wires or rust on fittings; these are clear indicators that something needs attention. Understanding what is the difference between guy wire and stay wire can also help you identify specific wear patterns associated with each type.

Failing to replace old fittings

Old fittings may seem harmless at first glance but can lead to catastrophic failures if not replaced regularly. Over time, materials degrade due to environmental factors like moisture and temperature fluctuations—especially in regions with extreme weather conditions. Spark Fittings offers customized armor rods designed for durability; investing in quality materials ensures that your electrical guy wire remains secure and functional.

Conclusion

In summary, understanding the nuances of electrical guy wire is essential for ensuring the stability and longevity of overhead structures. Proper installation and maintenance can prevent costly repairs and hazardous situations. By adhering to best practices, using quality materials, and ensuring regular inspections, you can significantly enhance safety and performance.

Best Practices for Electrical Guy Wire

When considering what is an electrical guy wire, it’s crucial to install it with the correct tension settings to maintain structural integrity. Additionally, proper anchoring techniques are vital; they ensure that the wires stay in place despite environmental pressures. Remember that ignoring environmental factors can lead to premature wear or failure—so always take weather conditions into account during installation.

Importance of Using Quality Materials

Using quality materials is paramount when dealing with electrical guy wire; this includes selecting armor rod materials wisely. The raw materials of the armor rod should ideally match the conductor's surface material to avoid corrosion between different elements—this is where Spark Fittings shines with their customized options. With a color code system in place for identifying conductor sizes easily, investing in high-quality components ensures reliability over time.

Ensuring Safety Through Proper Maintenance

Regular maintenance is key to ensuring safety when working with electrical guy wire; neglecting inspections can lead to catastrophic failures down the line. Overlooking signs of wear and tear could mean missing critical issues that require immediate attention—don’t let that happen! Finally, make it a habit to replace old fittings promptly; this simple act can save lives and preserve your infrastructure’s integrity.