Introduction

Understanding CNC Wire Bending Basics

So, what is CNC wire bending? It stands for Computer Numerical Control wire bending, a method that utilizes computer software to control the movement of machinery for shaping wire into desired forms. This process allows for intricate designs and consistent results that would be nearly impossible with manual methods.

Importance of Choosing the Right Machinery

Choosing the right machinery is essential in any manufacturing setting, but it takes on added significance in CNC applications. The right wire bending CNC machine can drastically impact production speed and quality, while also affecting overall operational costs. Therefore, understanding your specific needs and how different machines perform is key to making an informed decision.

Key Factors in Wire Bending Selection

When selecting a wire bending CNC machine, several factors come into play—such as material compatibility, machine size, and automation capabilities. Additionally, prospective buyers often ask questions like How much is the Pensa Labs wire bender? which highlights the importance of budget considerations alongside functionality. Ultimately, knowing what tool is used to bend wires can help clarify your options and guide you toward making a sound investment in your manufacturing future.

What is CNC Wire Bending?

CNC wire bending is a sophisticated process that utilizes computer numerical control (CNC) technology to bend wires into precise shapes and angles. This technology has revolutionized the way manufacturers approach wire bending, enabling them to create complex designs with high accuracy and consistency. So, what is CNC wire bending? It's essentially a blend of creativity and engineering, allowing for the production of intricate components that are essential in various industries.

Overview of CNC Technology

At its core, CNC technology involves the use of computers to control machine tools for manufacturing processes. In the case of a wire bending CNC machine, this means that intricate designs can be programmed into software, which then guides the machine to execute precise bends in the wire according to specified dimensions. This level of automation not only enhances productivity but also minimizes human error, ensuring that each piece produced meets stringent quality standards.

Advantages of CNC Wire Bending

The advantages of CNC wire bending are numerous and compelling for manufacturers looking to streamline their operations. One significant benefit is the ability to produce complex shapes quickly and accurately, which traditional manual methods struggle to achieve consistently. Moreover, using a CNC bending machine reduces labor costs while increasing efficiency—two vital factors for any business aiming to remain competitive in today's fast-paced market.

Applications in Electrical Conductors

CNC wire bending finds extensive applications in electrical conductors where precision is paramount. From creating connectors and terminals to forming intricate harnesses used in automotive or aerospace industries, this technology plays a crucial role in ensuring reliability and performance. By utilizing advanced machinery like the Pensa Labs wire bender, companies can enhance their production capabilities while meeting specific industry standards effortlessly.

Types of Wire Bending CNC Machines

When it comes to selecting the right wire bending CNC machine, the variety can be overwhelming. From compact models designed for small-scale operations to heavy-duty machines suited for high-volume production, understanding the differences is crucial. Each type of CNC bending machine offers unique features tailored to specific applications, making it essential to know what you need before diving into your purchase.

Comparing Different Models

Different models of wire bending CNC machines cater to various needs and budgets. For instance, entry-level machines may offer basic functionalities suitable for simple bends and smaller projects, while advanced models provide intricate programming capabilities and higher precision for complex designs. Understanding these distinctions can help businesses choose a machine that aligns perfectly with their operational requirements.

In comparing models, it's important to consider factors such as speed, accuracy, and ease of use. Some machines come equipped with user-friendly interfaces that simplify programming tasks, while others may require more technical expertise. Additionally, evaluating the maximum wire size each model can handle will ensure that your chosen wire bending CNC machine meets your production demands.

Notable Manufacturers and Their Offerings

The market is filled with reputable manufacturers offering a range of wire bending CNC machines tailored to different industries. Brands like Pensa Labs are known for their innovative solutions that combine functionality with affordability—perfect if you're asking yourself how much is the Pensa Labs wire bender? Other notable manufacturers include BLM Group and Boschert, both recognized for their robust machinery designed for high efficiency and precision.

Each manufacturer has its own set of features that differentiate their products from competitors. For example, some brands might focus on automation capabilities while others emphasize ease of maintenance or versatility in handling various materials. By exploring these offerings thoroughly, buyers can make informed decisions based on performance metrics that align with their specific manufacturing needs.

Understanding Features and Specifications

When evaluating a wire bending CNC machine, it's vital to understand its key features and specifications since they directly impact performance and productivity. Common features include programmable controls for precise bending angles, automatic feeding systems for increased efficiency, and robust safety mechanisms to protect operators during use. These attributes not only enhance production speed but also ensure consistent quality in electrical conductor manufacturing processes.

Moreover, specifications such as maximum bend radius and material compatibility should be closely examined when considering what tool is used to bend wires effectively within your operation's context. The right combination of features will ultimately determine how well a machine fits into your workflow—whether you need something compact or a powerhouse capable of handling large-scale projects efficiently.

Investing in a quality wire bending CNC machine requires careful consideration of all these factors; after all, this decision impacts not just productivity but also long-term operational success.

How Much is the Pensa Labs Wire Bender?

When considering the investment in a wire bending CNC machine, one might wonder, How much is the Pensa Labs wire bender? Pricing for these machines can vary significantly based on features, capabilities, and manufacturers. Understanding the budget implications is crucial for businesses looking to enhance their production processes with CNC technology.

Pricing Overview and Budget Considerations

The cost of a CNC wire bending machine like the Pensa Labs model typically ranges from several thousand to tens of thousands of dollars. Factors influencing this price include the complexity of the machine, its automation level, and additional features that enhance its functionality. Businesses should carefully evaluate their production needs and budget constraints when deciding on which model fits best.

Budget considerations also extend beyond just the initial purchase price; maintenance costs and potential upgrades should be factored in as well. Investing in a high-quality wire bending CNC machine may seem steep at first glance, but it often results in long-term savings through increased efficiency and reduced labor costs. Ultimately, understanding what is a CNC bending machine can help buyers make informed decisions about their investments.

Value for Money in Wire Bending CNC Machines

When evaluating value for money in wire bending CNC machines, it’s essential to consider not just upfront costs but also operational efficiency and longevity. The Pensa Labs wire bender offers advanced features that can streamline production processes, making it an attractive option for businesses aiming to boost productivity without sacrificing quality. This balance between cost and performance often leads companies to see a significant return on investment over time.

Moreover, investing in reliable machinery translates into fewer breakdowns and lower repair costs down the line—an important consideration when asking how much is the Pensa Labs wire bender? The robust construction of these machines ensures they stand up to rigorous use while maintaining precision in every bend made during operations. This durability means less downtime and more consistent output—a win-win scenario for any manufacturer.

Financing Options for Businesses

For many companies looking to invest in a wire bending CNC machine like the Pensa Labs model, financing options can ease budgetary constraints significantly. Various lenders offer tailored financing solutions specifically designed for manufacturing equipment purchases; these options allow businesses to spread out payments over time rather than making a hefty upfront investment all at once. By exploring leasing or loan opportunities, companies can acquire state-of-the-art technology without straining their cash flow.

Additionally, some manufacturers may provide financing directly or partner with financial institutions to offer competitive rates on loans or leases—making it easier than ever to get your hands on what tool is used to bend wires efficiently! It’s worth investigating these options thoroughly as they could lead you toward acquiring essential equipment that enhances your production capabilities while keeping finances manageable.

In conclusion, understanding how much is the Pensa Labs wire bender involves more than just looking at sticker prices; it's about weighing long-term value against initial investments along with available financing solutions that can fit various budgets perfectly.

What Tool is Used to Bend Wires?

When it comes to the world of wire bending, particularly with a wire bending CNC machine, understanding the tools involved is essential. These machines are equipped with specialized tools designed to bend wires precisely and efficiently. The right tool not only ensures accuracy but also contributes to the overall productivity of your wire bending operations.

Essential Tools in CNC Wire Bending

In the realm of CNC wire bending, several essential tools play a pivotal role in achieving high-quality results. The primary tool is the CNC bending machine itself, which utilizes advanced software and hardware to manipulate wire into desired shapes. Additionally, other tools such as rotary benders, end forming machines, and coiling devices complement the process by enhancing flexibility and offering diverse bending options.

Moreover, these tools are engineered for specific types of materials and diameters, ensuring that whatever your project entails—be it electrical connectors or intricate designs—there's a suitable tool available. When considering “What is CNC wire bending?” it's crucial to recognize that these specialized instruments are what enable precision while reducing manual labor significantly.

How These Tools Enhance Production Efficiency

The efficiency of production is significantly enhanced through the use of advanced tools in a wire bending CNC machine setup. Automated processes reduce human error and speed up production times; tasks that once took hours can now be completed within minutes thanks to precise programming capabilities. Furthermore, these machines allow for batch processing where multiple pieces can be bent simultaneously without sacrificing quality or accuracy.

As businesses seek answers like “How much is the Pensa Labs wire bender?” they should also weigh this investment against potential productivity gains from using modern CNC technology. The integration of sophisticated tools means less downtime for maintenance and more uptime for production—an ideal scenario for any manufacturing operation focused on growth.

Maintenance of Bending Tools

Just like any other machinery used in manufacturing processes, maintenance plays a critical role in keeping your CNC wire bending equipment running smoothly. Regular checks on components such as blades and motors ensure that everything operates at peak performance levels while extending the lifespan of your investment in a wire bending CNC machine. Neglecting maintenance can lead to costly repairs or replacements down the line.

Routine cleaning and lubrication are vital practices that help maintain optimal function in these intricate systems; after all, you wouldn’t want your machine stalling mid-production because it wasn’t cared for properly! Understanding what tool is used to bend wires also involves recognizing how essential it is to keep those tools well-maintained for consistent output quality over time.

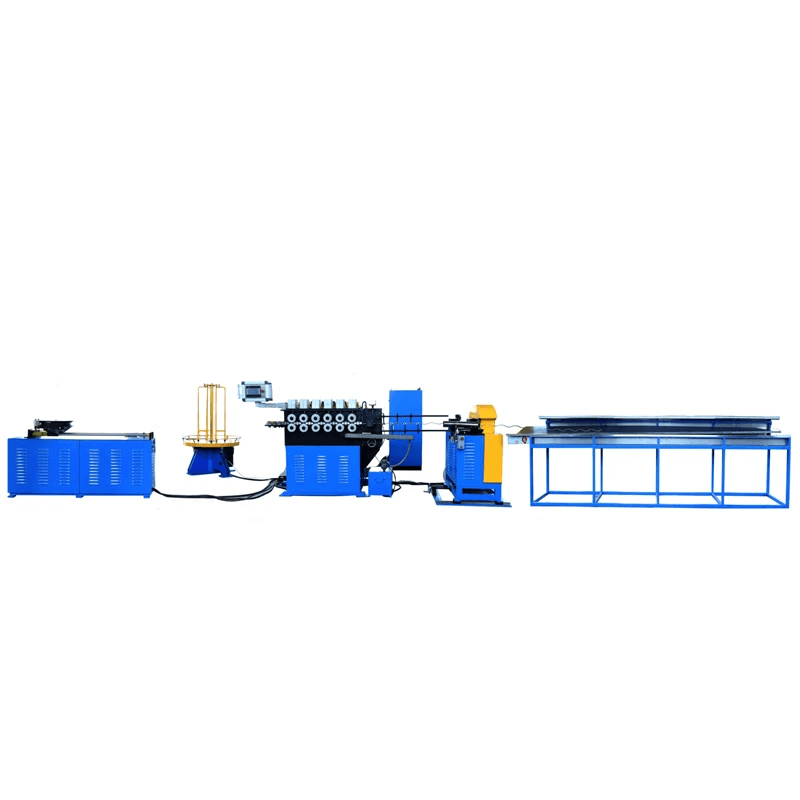

Spark Fittings 16A Pre-Twisted Wire Automatic Forming Production Line

In the world of electrical conductors, efficiency and precision are paramount. The Spark Fittings 16A Pre-Twisted Wire Automatic Forming Production Line stands out as a remarkable solution, integrating advanced technology with streamlined processes. This production line is designed to enhance the capabilities of a wire bending CNC machine, ensuring optimal performance in manufacturing.

Overview of the Production Line Components

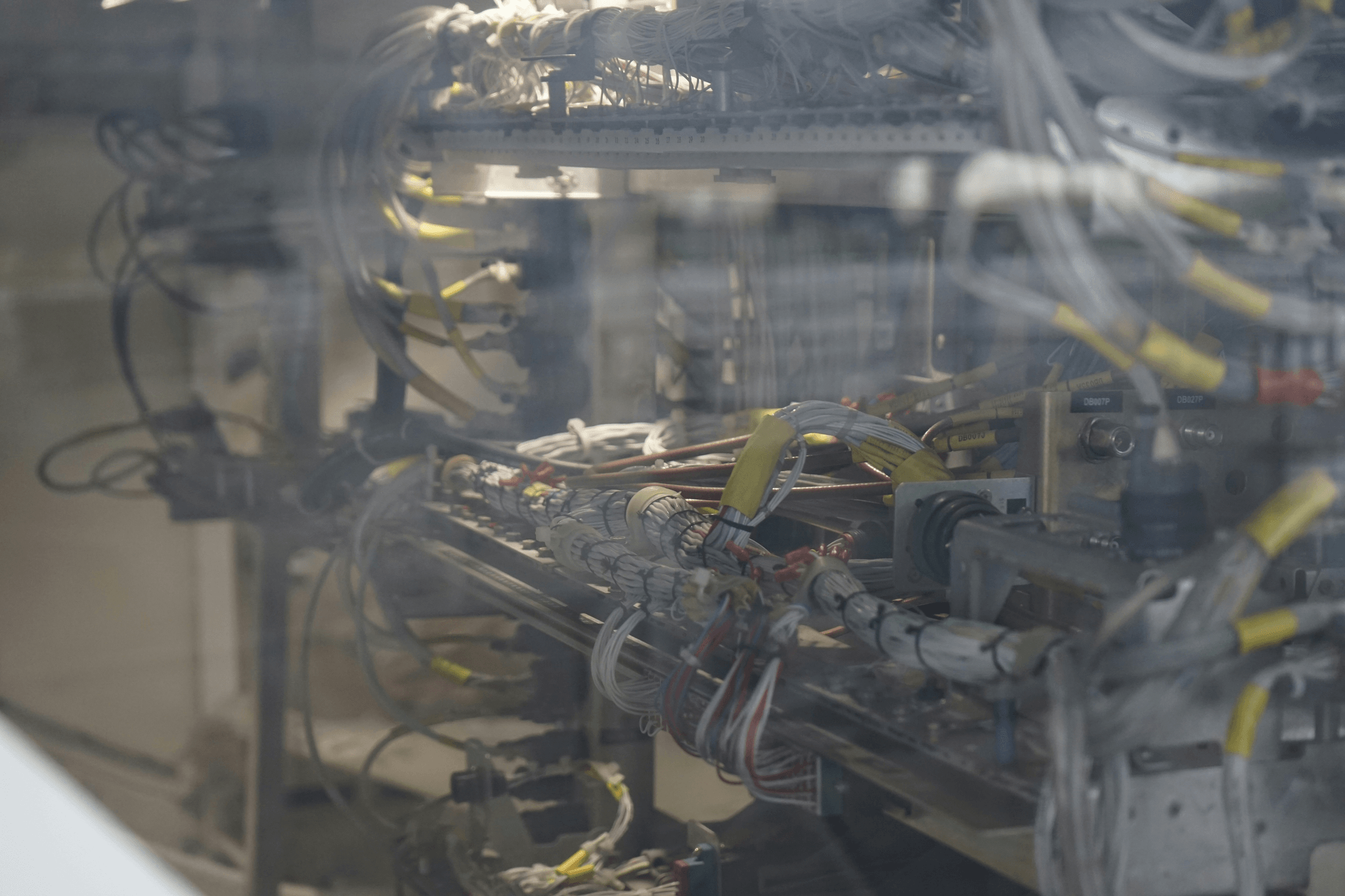

The Spark Fittings production line comprises several key components that work in harmony to produce high-quality pre-twisted wires. At its core is a sophisticated CNC bending machine that utilizes cutting-edge software and hardware for precise wire manipulation. Additionally, it includes an integrated conveyor system that facilitates seamless movement of materials, enhancing workflow efficiency and reducing downtime.

This robust system also features specialized tools used to bend wires, ensuring consistent quality across batches. Each component is engineered for durability and reliability, making it an ideal choice for businesses looking to scale their operations. By understanding what a CNC bending machine entails, manufacturers can appreciate how these components contribute to overall productivity.

Benefits of Integrated Conveyor and Forming Machine

One of the standout benefits of this production line is its integrated conveyor system paired with the forming machine. This combination allows for continuous operation without interruptions, significantly boosting output rates compared to traditional methods. When considering how much the Pensa Labs wire bender costs in comparison, it's clear that investing in such integrated systems can lead to substantial long-term savings.

Moreover, this setup minimizes manual handling and reduces labor costs while maintaining high standards of safety and quality control. The efficiency gained from using an automatic forming production line translates directly into quicker turnaround times for clients who demand rapid delivery without compromising on quality. As manufacturers explore their options in wire bending CNC machines, they will find that integration enhances both productivity and profitability.

Impact on Electrical Conductor Manufacturing

The introduction of the Spark Fittings 16A Pre-Twisted Wire Automatic Forming Production Line has had a transformative impact on electrical conductor manufacturing processes worldwide. By automating complex tasks traditionally done by hand or with less efficient machinery, companies can now produce more intricate designs with greater precision than ever before—essentially redefining what is CNC wire bending?

As demand for high-quality electrical conductors continues to grow across various industries, adopting such advanced technology becomes crucial for staying competitive. Businesses leveraging these automated solutions not only improve their output but also gain a reputation for reliability among clients seeking top-notch products at competitive prices. With all these advantages combined, it's clear that understanding what tool is used to bend wires can lead manufacturers toward smarter investments in their future.

Conclusion

CNC wire bending technology has revolutionized the manufacturing of electrical conductors, offering precision and efficiency that traditional methods simply can't match. Buyers looking for a wire bending CNC machine should consider not only the cost but also the long-term benefits it brings to their production lines. Understanding what is CNC wire bending and its applications will empower buyers to make informed decisions tailored to their specific needs.

Key Takeaways for Buyers

When considering a wire bending CNC machine, it's crucial to assess your production requirements and budget constraints. Notably, inquiries like How much is the Pensa Labs wire bender? often arise, highlighting the importance of evaluating pricing versus features. Ultimately, investing in a quality CNC bending machine can lead to significant returns through enhanced efficiency and reduced waste.

Future Trends in CNC Wire Bending

As technology continues to advance, future trends in CNC wire bending are likely to include greater automation and integration with other manufacturing processes. Innovations such as AI-driven programming and real-time monitoring systems will enhance what is a CNC bending machine’s capabilities even further. This evolution suggests that businesses willing to adapt will enjoy competitive advantages in speed, accuracy, and overall production quality.

Making an Informed Investment Decision

To make an informed investment decision regarding a wire bending CNC machine, potential buyers should conduct thorough research on available models and manufacturers. Questions like What tool is used to bend wires? can guide you toward understanding essential machinery components that contribute to optimal performance. By weighing all factors—including price points like “How much is the Pensa Labs wire bender?”—buyers can ensure they choose equipment that meets their operational demands without breaking the bank.