Introduction

Understanding Lashing Rods

So, what is a lashing rod? Essentially, it's a tool designed to secure cables together or to a supporting structure using lashing techniques. By grasping how these rods work and their significance in maintaining cable integrity, you can better appreciate their role in electrical and telecommunications applications.

Importance of Choosing the Right Equipment

Choosing the right equipment is paramount when it comes to effective lashing. With various options available, such as aluminum-clad steel and galvanized steel, making informed decisions will ensure optimal performance for your specific application. Remember that selecting quality lashing rods not only enhances functionality but also contributes to overall safety and durability.

Overview of Key Considerations

In your quest for reliable lashing solutions, several key considerations come into play. You'll want to evaluate material types—like aluminum-clad steel versus other options—and understand their unique advantages for different scenarios. Additionally, familiarizing yourself with trusted manufacturers like Spark Fittings can lead you toward high-quality lashing equipment tailored to your needs.

What is a Lashing Rod?

Lashing rods are essential components in the world of cable management, specifically designed to secure and stabilize cables in various applications. Understanding what a lashing rod is can significantly enhance your approach to effective lashing, ensuring that your installations are both durable and efficient. Let’s dive deeper into the definition, functions, and applications of these crucial tools.

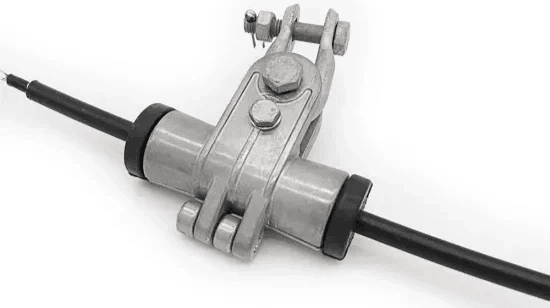

Definition and Explanation

So, what is a lashing rod? A lashing rod is a specialized tool used to bind multiple cables together securely, preventing them from sagging or moving out of position. Typically made from materials like aluminum-clad steel or galvanized steel, these rods provide the necessary strength and flexibility needed for effective cable management.

Key Functions in Lashing

What is the function of a lashing? The primary function of lashing rods involves maintaining tension on the cables they secure, which helps prevent wear and tear over time. By keeping cables organized and tightly bound, these rods also minimize the risk of damage caused by environmental factors such as wind or ice accumulation.

Various Applications in the Field

Lashing rods find their place across various industries where cable management is critical. From telecommunications to electrical distribution systems, these tools ensure that cables remain aligned and functional under different conditions. Additionally, preformed lashing rods are often used for specific applications where custom solutions are required for optimal performance.

Selecting the Right Material

Choosing the right material for lashing rods is crucial to ensure optimal performance and longevity in various applications. The material not only affects the durability of the lashing equipment but also its effectiveness in managing cables. By understanding the differences between aluminum-clad steel, aluminum wire, and galvanized steel, you can make an informed decision that suits your specific needs.

Aluminum-clad Steel vs. Other Options

Aluminum-clad steel is a popular choice among professionals for lashing rods due to its unique combination of strength and lightweight properties. Unlike pure aluminum or traditional steel, aluminum-clad steel provides excellent corrosion resistance while maintaining structural integrity, making it ideal for outdoor applications. When comparing aluminum-clad steel to other options, it's evident that this hybrid material offers a balanced solution for those asking, What is a lashing rod?—a tool designed to secure cables effectively.

Advantages of Aluminum Wire

Aluminum wire has gained traction as a viable alternative for lashing rods due to its lightweight nature and cost-effectiveness. One of the primary advantages of using aluminum wire is its resistance to corrosion; it does not rust like traditional steel materials do. Additionally, when considering what is the function of a lashing rod in cable management systems, aluminum wire excels by providing flexibility and ease of installation without compromising durability.

Consideration of Galvanized Steel

While galvanized steel may not be as popular as aluminum options, it still holds value in certain applications where strength is paramount. Galvanized steel offers impressive resistance against wear and tear but lacks some corrosion-resistant properties found in aluminum-clad materials or pure aluminum wire. Therefore, when evaluating what is lashing equipment best suited for your project needs, consider how galvanized steel might fit into your overall strategy while keeping durability in mind.

Evaluating the Function of Lashing

What is the Function of Lashing?

So, what is a lashing rod? In essence, it's a specialized tool designed to bind cables together tightly, preventing them from sagging or becoming misaligned. The function of a lashing involves securing these cables to structures like poles or towers, using materials such as aluminum-clad steel or galvanized steel for optimal durability and strength.

Through effective lashing techniques, you can ensure that your cables remain organized and functional over time. This not only enhances safety but also reduces the likelihood of costly repairs due to cable damage or mismanagement. In short, understanding what is lashing a cable helps you appreciate how pivotal these rods are in maintaining an efficient cable system.

Importance in Cable Management

The importance of lashing in cable management cannot be overstated; it serves as the backbone for organizing complex networks of wires and cables. Without proper lashing rods in place, cables can become tangled or suffer from undue stress that leads to failures down the line. This structured approach not only aids technicians during installation but also simplifies future maintenance tasks.

In addition to organization, effective lashing contributes significantly to safety by minimizing hazards associated with loose or falling cables. By using high-quality lashing equipment like those offered by Spark Fittings, you are investing in reliable solutions that bolster your overall cable management strategy. Remember: good management today prevents chaos tomorrow!

Enhancing Longevity and Durability

When evaluating how well your system performs over time, consider how enhancing longevity and durability through proper use of lashing rods can make all the difference. Quality materials—like aluminum-clad steel—are essential since they resist corrosion and environmental wear better than their counterparts. Choosing appropriate armor rod materials based on conductor surface material ensures compatibility and prevents corrosion between different elements.

Moreover, reliable equipment from trusted manufacturers like Spark Fittings not only meets industry standards but also offers customization options tailored to specific needs—ensuring your installation will stand up against time’s test! So when pondering what is lashing equipment truly about, remember: it’s more than just tools; it’s about creating lasting solutions for your cabling challenges.

Recognizing Quality Lashing Equipment

What is Lashing Equipment?

Lashing equipment refers to the specific tools and materials used to secure cables together, ensuring stability and protection against environmental factors. This includes items like lashing rods, which play a vital role in maintaining the integrity of cable installations. In essence, lashing equipment is essential for effective cable management, preventing wear and tear while enhancing overall system performance.

Features of Reliable Gear

When selecting reliable gear for lashing rods, several key features should be considered to ensure optimal performance. First and foremost, durability is paramount; quality materials such as aluminum-clad steel can withstand harsh weather conditions without compromising strength. Additionally, ease of installation is crucial—look for designs that facilitate quick setup without sacrificing security or effectiveness.

Another important feature to consider is compatibility with various cable types; high-quality lashing equipment should accommodate different conductor sizes seamlessly. Moreover, attention to detail like color coding on armor rods can significantly simplify installation processes by helping identify conductor sizes quickly. Ultimately, investing in reliable gear ensures that your lashing efforts are both efficient and long-lasting.

Trusted Manufacturers like Spark Fittings

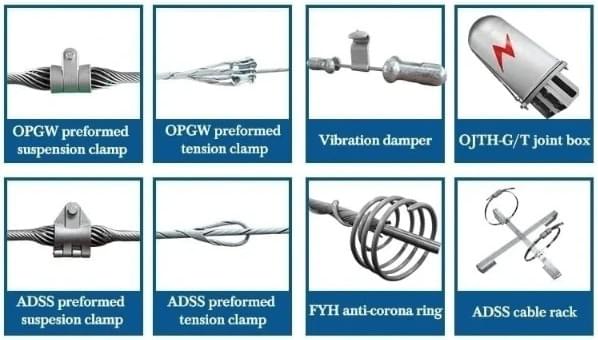

When it comes to sourcing quality lashing rods and related equipment, Spark Fittings stands out as a trusted manufacturer in the industry. Known for their expertise in producing preformed armor rods using high-quality raw materials such as aluminum wire and galvanized steel wire, Spark Fittings offers customized solutions tailored to meet specific project needs. Their commitment to excellence ensures that the armor rod material closely matches the conductor's surface material—an essential factor in avoiding corrosion between different elements.

In addition to their comprehensive range of products—including preformed tension clamps and OPGW cable accessories—Spark Fittings provides color-coded options that simplify installation while enhancing efficiency on-site. Their reputation as one of the few professional companies engaged in manufacturing production lines for these specialized tools speaks volumes about their dedication to quality assurance within the field of cable management solutions.

Understanding Lashing Techniques

Lashing techniques are crucial for ensuring the stability and longevity of cable installations. Proper lashing not only secures cables but also enhances their performance by minimizing wear and tear. Understanding how to effectively lash a cable can make all the difference in maintaining a reliable infrastructure.

What is Lashing a Cable?

Lashing a cable involves wrapping it with lashing rods or other materials to secure it in place, preventing movement that could lead to damage. This technique is particularly important in environments where cables are exposed to external forces such as wind, vibration, or physical contact. By using lashing rods, you create a stable support system that ensures the integrity of your cable setup.

Best Practices for Effective Lashing

To achieve effective lashing, start by selecting the right type of lashing equipment suited for your specific application—consider options like PREFORMED lashing rods for optimal performance. Ensure that the tension applied during lashing is consistent; too tight may cause damage while too loose can result in inadequate support. Additionally, always follow manufacturer guidelines and recommendations from trusted brands like Spark Fittings to ensure safety and reliability.

Tips for Troubleshooting Common Issues

When dealing with common issues related to lashing techniques, first assess whether your choice of material—such as aluminum-clad steel or galvanized steel—is appropriate for your specific application. If you encounter problems with slippage or instability, check if the tension on your lashing rods needs adjustment or if additional supports are required. Finally, always inspect your setup regularly; proactive maintenance can prevent minor issues from escalating into major problems.

Conclusion

In conclusion, selecting the right lashing rods is crucial for effective cable management and ensuring the longevity of your installations. Understanding what a lashing rod is and its function can guide you in making informed choices that enhance both safety and performance. With various materials available, including aluminum-clad steel, it’s essential to consider the specific needs of your project.

Key Takeaways for Choosing Lashing Rods

When choosing lashing rods, it's important to assess their intended use and the environment they will be exposed to. Knowing what a lashing rod is helps in understanding its role in securing cables effectively while minimizing wear and tear over time. Always prioritize quality; reliable lashing equipment from trusted manufacturers like Spark Fittings can make all the difference in performance.

Importance of Material Selection

Material selection plays a pivotal role when it comes to lashing rods, as it directly affects durability and compatibility with conductors. For instance, aluminum-clad steel offers excellent corrosion resistance, making it an ideal choice for outdoor applications where exposure to elements is inevitable. By selecting materials that align with your conductor's surface material, you can avoid potential corrosion issues that arise from using mismatched elements.

Final Thoughts on Quality Lashing Equipment

Quality lashing equipment is not just about meeting industry standards; it's about ensuring safety and reliability in every installation. Understanding what is lashing equipment encompasses—from preformed armor rods to tension clamps—can help you leverage these tools effectively for optimal results. Companies like Spark Fittings offer customized solutions tailored to meet specific project requirements, ensuring you have the best equipment at hand.