Introduction

Understanding Tension Clamps

Tension clamps are specialized devices designed to hold cables or wires under tension, preventing sagging or movement that could lead to failure. These clamps come in different shapes and sizes, catering to various applications such as electrical installations, telecommunications, and even construction projects. By grasping the mechanics behind how these tools work, you'll be better prepared to identify the best solution for your project.

Importance of Choosing the Right Clamp

Selecting the appropriate clamp can significantly impact the performance and safety of your installation. For instance, if you're wondering what is a bolt clamp or how it compares to other types like spring tension clamps or constant tension clamps, understanding their unique features is crucial. The right choice not only ensures stability but also enhances longevity and reduces maintenance needs.

Common Types of Tension Clamps

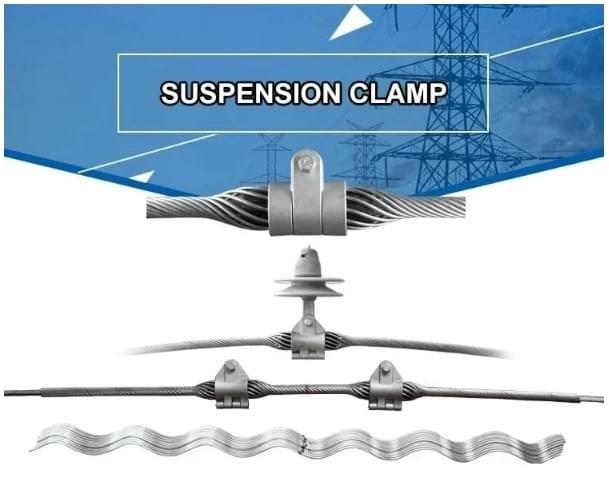

There are several common types of tension clamps available on the market today. Some popular options include bolt clamps, pipe clamps, bar clamps, and constant tension clamps—each serving distinct purposes based on their design and functionality. Additionally, products like tension and suspension cable clamps from companies such as Spark Fittings provide tailored solutions for specific electrical applications.

What is a Tension Clamp?

Tension clamps are specialized devices designed to hold and secure components under tension, ensuring they remain in place during operation. They play a crucial role in various applications, particularly in electrical installations and construction projects. Understanding what a tension clamp is and how it functions can greatly enhance your project's efficiency and safety.

Definition and Functionality

A tension clamp, by definition, is a device that applies pressure to an object, keeping it securely fastened while allowing for some movement or flexibility. This functionality is essential in applications where materials must withstand dynamic forces, such as wind or vibration. Unlike other fastening options like bolt clamps or pipe clamps, tension clamps provide adjustable pressure settings that can accommodate changes in load over time.

Common Applications

Tension clamps find their way into numerous industries due to their versatility. They are commonly used in electrical installations for securing cables and wires, ensuring they remain taut without risking damage from slackness. Additionally, you’ll often see them employed in construction for holding structural elements together under stress—making them indispensable tools on any job site.

Benefits of Using Tension Clamps

The benefits of using tension clamps are manifold; they offer enhanced stability while reducing the risk of component failure due to excessive movement. These clamps also allow for easy adjustments based on changing conditions—perfect for projects that may evolve over time. Moreover, with companies like Spark Fittings specializing in manufacturing high-quality tension clamps designed for robust performance, you can trust that your installation will stand the test of time.

What is a Bolt Clamp?

Bolt clamps are essential fastening devices designed to secure various components together, often used in construction and electrical applications. These clamps utilize a bolt mechanism to create a strong grip, ensuring stability and safety in different environments. Understanding the features and functionalities of bolt clamps is crucial for selecting the right type for your specific needs.

Features of Bolt Clamps

Bolt clamps typically feature a robust design that includes a threaded bolt, which allows for precise adjustments in tension. This adjustability makes them ideal for applications requiring varying levels of pressure or support, such as securing pipes or cables in place. Additionally, many bolt clamps are made from durable materials like stainless steel or galvanized metal, providing excellent resistance to corrosion and wear over time.

Comparison with Other Clamps

When exploring what is a bolt clamp?, it's essential to compare it with other types of clamps like tension clamps and pipe clamps. Unlike tension clamps that maintain constant pressure on cables or wires, bolt clamps provide a more rigid hold that can be adjusted as needed. Furthermore, while pipe clamps are specifically designed for circular objects like pipes, bolt clamps offer versatility across various shapes and sizes—making them suitable for diverse applications.

Ideal Use Cases

Bolt clamps shine in situations where secure fastening is paramount, such as in construction sites or heavy machinery installations. They are particularly effective when working with structural components that require high strength and stability under load conditions—think beams or large piping systems. Additionally, if you're wondering about the difference between a pipe clamp and a bar clamp, keep in mind that while pipe clamps excel at securing cylindrical items, bar clamps can be more effective when clamping flat surfaces together; however, bolt clamps combine the strengths of both types by offering adaptability across multiple scenarios.

Pipe Clamps vs. Bar Clamps

Key Differences Explained

Pipe clamps are specifically designed to hold cylindrical objects, such as pipes or tubes, securely in place. They typically feature a curved design that conforms to the shape of the pipe, providing even pressure distribution and preventing damage to the surface. On the other hand, bar clamps are more versatile; they utilize a long bar with adjustable arms that can grip flat or irregularly shaped objects effectively—making them ideal for woodworking projects or assembling furniture.

One significant difference between these two types of clamps lies in their tension mechanism. While pipe clamps often rely on a screw mechanism for tightening around the pipe, bar clamps allow for quick adjustments via sliding mechanisms along the bar itself. This distinction makes each type suitable for different tasks: if you're working with plumbing or electrical installations requiring tension clamp properties, go for pipe clamps; if you need something adaptable for various shapes and sizes, bar clamps are your best bet.

When to Use Each Type

Choosing between a pipe clamp and a bar clamp largely depends on your specific project requirements. If you're dealing with plumbing systems or any application where round materials need secure fastening without damaging their surfaces, then using a tension clamp designed as a pipe clamp is essential. Conversely, if you're assembling wood pieces or working on intricate designs where flexibility is key—like crafting furniture—a bar clamp will provide the necessary adjustability.

Additionally, consider factors such as material compatibility and load-bearing capacity when making your choice. For instance, heavy-duty applications may benefit from robust spring tension clamps that offer enhanced grip strength over traditional options like simple pipe or bar clamps. Understanding what is the difference between a pipe clamp and a bar clamp will empower you to select wisely based on your project needs.

Real-World Scenarios

Imagine you're installing new plumbing fixtures in your home; using pipe clamps ensures that pipes remain securely fastened while minimizing potential leaks due to shifting connections—a perfect example of when tension and suspension cable clamps come into play in electrical installations too! Alternatively, think about building custom cabinetry: here’s where bar clamps shine by allowing easy adjustments during assembly without compromising structural integrity.

In another scenario involving electrical work with overhead cables—this is where Spark Fittings comes into play with their high-quality products like preformed armor rods and specialized tension clamps tailored for ADSS (All-Dielectric Self-Supporting) cables! Their equipment ensures reliable performance while maintaining safety standards across various applications—whether you’re opting for spring tension clamps or exploring other variants like constant tension ones designed for specific environments.

How Does a Constant Tension Clamp Work?

Constant tension clamps are designed to maintain a consistent level of tension on cables or wires, ensuring stability and reliability in various applications. These clamps utilize a unique mechanism that allows them to adapt to changes in load or environmental conditions while keeping the tension steady. Understanding how a constant tension clamp works can help you appreciate its role in electrical installations and other applications where cable integrity is crucial.

Mechanics Behind Constant Tension

The mechanics of a constant tension clamp involve a combination of spring-loaded mechanisms and adjustable components that work together to maintain optimal tension levels. When load conditions change, such as during temperature fluctuations or physical movement, the spring mechanism automatically adjusts the clamp's grip on the cable or wire. This ensures that regardless of external factors, the tension remains consistent, preventing slippage or damage—an essential feature when considering what is a bolt clamp versus other types.

Advantages in Specific Applications

The advantages of using constant tension clamps are particularly evident in applications involving suspension cables and overhead power lines, where maintaining proper tension is critical for safety and performance. These clamps help prevent wear and tear on cables by reducing stress points that could lead to failure over time. Moreover, their ability to adapt makes them ideal for use in dynamic environments—something you might not get from traditional pipe clamps or bar clamps.

Maintenance Tips for Longevity

To ensure longevity and optimal performance from your constant tension clamp, regular maintenance is key. Inspecting the springs and adjusting mechanisms periodically can prevent issues before they arise; this simple step can save you from costly repairs down the line. Additionally, keeping the clamps clean and free from debris will enhance their functionality—allowing you to enjoy the full benefits of your investment in high-quality equipment like those offered by Spark Fittings.

Exploring Tension and Suspension Cable Clamps

Tension and suspension cable clamps play a pivotal role in electrical installations, ensuring that cables remain securely fastened while accommodating necessary movement. These clamps are essential for maintaining the integrity of electrical systems, particularly in environments where vibrations or thermal expansion can cause shifts. Understanding how these clamps function is crucial for anyone involved in electrical engineering or installation projects.

Importance in Electrical Installations

In the realm of electrical installations, tension clamps serve as a critical component for stabilizing cables and preventing sagging. Without proper tension management, cables can become loose, leading to potential failures or hazards. The use of tension and suspension cable clamps ensures that cables are held firmly in place, reducing the risk of wear and tear over time.

Moreover, these clamps are designed to handle varying loads and environmental conditions, making them suitable for both indoor and outdoor applications. For instance, during storms or high winds, properly secured cables minimize the chances of damage to infrastructure. Thus, selecting the right clamp is not just about functionality; it's about safety and reliability.

Types of Cable Clamps Available

There is a variety of cable clamps available on the market today, each designed for specific applications within electrical systems. Common types include spring tension clamps that automatically adjust to changes in cable tension, providing consistent support regardless of environmental conditions. Other options include fixed tension clamps that offer robust stability but require careful installation to ensure optimal performance.

Additionally, some manufacturers provide specialized designs tailored for unique requirements—such as those found in electrified railways or overhead power lines—where durability is paramount. Understanding what is a bolt clamp versus other types can also help determine which clamp best suits your project needs; bolt clamps typically offer strong fastening but may not allow for flexibility like spring tension models do.

Recommendations from Spark Fittings

When it comes to sourcing high-quality tension and suspension cable clamps, Spark Fittings stands out as a leading manufacturer specializing in equipment for preformed armor rods and cable accessories used in ADSS (All-Dielectric Self-Supporting) and OPGW (Optical Fiber Composite Overhead Ground Wire) applications. Their products are designed with precision engineering to ensure they meet rigorous industry standards while providing exceptional performance under various conditions.

Spark Fittings' range includes innovative designs such as adjustable spring tension clamps that cater specifically to dynamic environments where cable movement is expected. Their expertise ensures that customers receive reliable products capable of withstanding harsh weather elements without compromising safety or effectiveness. For anyone looking into what is a tension clamp or exploring options like constant tension models, Spark Fittings offers valuable insights alongside top-notch solutions tailored to meet diverse project requirements.

Conclusion

Choosing the right tension clamp is crucial for ensuring the integrity and safety of your projects. With various types available, understanding what is a tension clamp, its applications, and how it compares to other clamps can help you make informed decisions. Whether you're dealing with electrical installations or mechanical assemblies, selecting the appropriate clamp can significantly impact performance and durability.

Key Considerations for Choosing a Tension Clamp

When selecting a tension clamp, consider factors such as load capacity, material compatibility, and environmental conditions. Understanding what is a bolt clamp versus other types like spring tension clamps can also guide your choice based on specific project needs. Additionally, recognizing the difference between a pipe clamp and a bar clamp will help you determine which option best suits your application.

Popular Brands and Their Offerings

Several brands excel in providing high-quality tension clamps tailored for various industries. Spark Fittings stands out as a leading manufacturer specializing in equipment for preformed armor rods, tension clamps, and cable accessories designed for ADSS and OPGW applications. Their products are engineered to meet rigorous standards while ensuring reliable performance in demanding environments.

Final Thoughts on Your Project Needs

Ultimately, understanding how does a constant tension clamp work or the role of tension and suspension cable clamps can enhance your project's success rate. By considering all aspects—from functionality to brand reliability—you'll be better equipped to choose the right solution that meets your unique requirements. Remember that investing time in selecting the appropriate tools today will pay off with increased efficiency tomorrow.