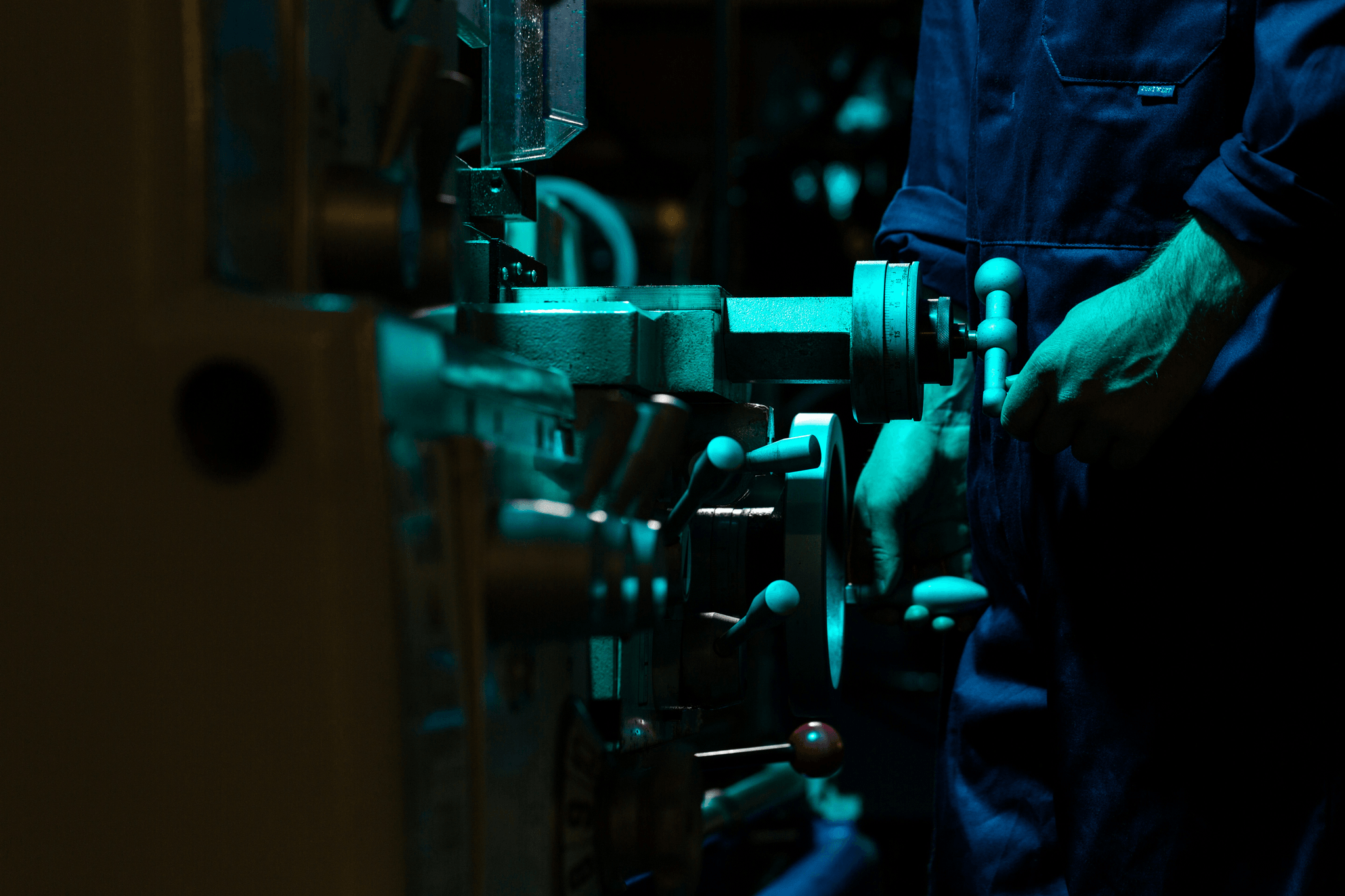

Introduction

In the world of manufacturing, precision is key, and that's where the CNC wire bending machine comes into play. These machines are revolutionizing how we shape metal, offering unparalleled accuracy and efficiency compared to traditional methods. But what exactly is CNC wire bending? This introduction will delve into the basics of CNC technology, highlight key features of high-performance wire bending machines, and explore some popular brands in the industry.

Understanding CNC Wire Bending Basics

CNC wire bending refers to the computer-controlled process of shaping metal wires into specific forms with high precision. Unlike manual bending techniques, which can be time-consuming and prone to human error, CNC coiling and bending machines streamline production by automating complex bends with ease. Understanding these basics lays the groundwork for appreciating how these machines can enhance your manufacturing processes.

Key Features of High Performance Wire Bending Machines

High-performance wire bending machines are equipped with advanced features that significantly boost productivity and quality. These include programmable controls for intricate designs, real-time feedback systems for monitoring performance, and robust build quality that ensures longevity even under heavy use. When investing in a CNC wire bending machine, these key features can make all the difference in achieving optimal results.

Popular Brands in Wire Bending Technology

Several brands have established themselves as leaders in the field of wire bending technology, each offering unique advantages tailored to different industrial needs. Companies like Di Wire Pro are renowned for their innovative solutions that cater to various applications while maintaining competitive pricing—so how much is Di Wire Pro worth? Exploring these brands will provide insights into which models might best suit your specific requirements while navigating the question: what is a CNC bending machine?

What is CNC Wire Bending?

CNC wire bending is a sophisticated process that involves the use of computer numerical control technology to manipulate wire into specific shapes and forms. This technology allows for high precision and consistency, making it an essential tool in various manufacturing processes. With CNC coiling and bending machines, manufacturers can produce complex designs that would be challenging to achieve with traditional methods.

Definition and Key Concepts

At its core, CNC wire bending refers to the automated process of shaping wire using a computer-controlled machine. The term CNC stands for Computer Numerical Control, which means that the machine operates based on programmed instructions fed into its system. These instructions dictate how the wire should be bent, coiled, or shaped, providing unmatched accuracy and repeatability compared to manual techniques.

Understanding what is a CNC bending machine is crucial for grasping this technology's impact on manufacturing efficiency. Unlike traditional NC (Numerical Control) machines that require manual input for each operation, CNC machines can execute complex tasks autonomously once programmed. This automation not only speeds up production but also reduces human error significantly.

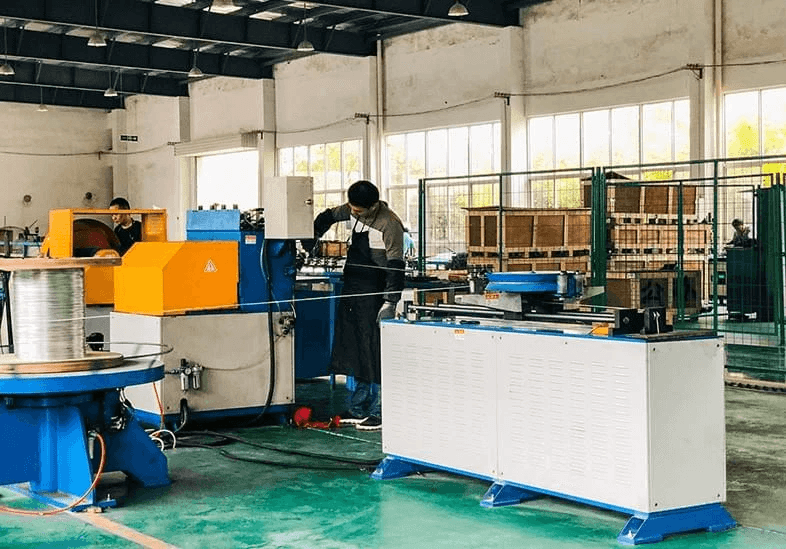

Applications in Various Industries

CNC wire bending finds applications across a multitude of industries ranging from automotive to aerospace and beyond. In the automotive sector, these machines are used to create intricate components like brackets, frames, and exhaust systems with remarkable precision. Similarly, in the aerospace industry, high-performance wire bending machines are vital for producing lightweight yet durable parts essential for aircraft performance.

Beyond these sectors, industries such as electronics rely on CNC technology for creating wiring harnesses and connectors that require exact specifications. The versatility of what is CNC wire bending extends even into furniture design where custom metal frames can be produced efficiently. As you can see, this technology has revolutionized how products are designed and manufactured across various fields.

Advantages Over Traditional Methods

The advantages of using a wire bending machine CNC over traditional methods are numerous and compelling. First off, precision is at the forefront; CNC machines can bend wires to tolerances as tight as ±0.1 mm—something nearly impossible with manual processes. Additionally, the speed at which these machines operate allows manufacturers to increase their output without sacrificing quality.

Another significant benefit lies in reduced labor costs; once set up properly, a single operator can oversee multiple machines working simultaneously instead of needing teams of workers manually shaping wires all day long. Furthermore, high-performance wire bending machines offer flexibility through programmable settings that allow quick changes between different designs or specifications without requiring extensive downtime or retooling efforts.

In summary, understanding what is CNC wire bending reveals its transformative role in modern manufacturing practices by enhancing efficiency while maintaining exceptional quality standards—a win-win scenario!

What is a CNC Bending Machine?

CNC bending machines are essential tools in modern manufacturing, transforming raw materials into intricately shaped components with precision and speed. These machines utilize computer numerical control (CNC) technology to automate the bending process, ensuring consistent quality and reducing human error. With the rise of High Performance Wire Bending Machines, industries can now achieve complex designs that were once labor-intensive and time-consuming.

Overview of CNC Technology

At its core, CNC technology refers to the automation of machine tools through computer programming. This technology allows for precise control over machinery like wire bending machine CNC units, enabling them to execute complex tasks with minimal operator intervention. The result? Enhanced accuracy, repeatability, and efficiency that traditional methods simply can't match.

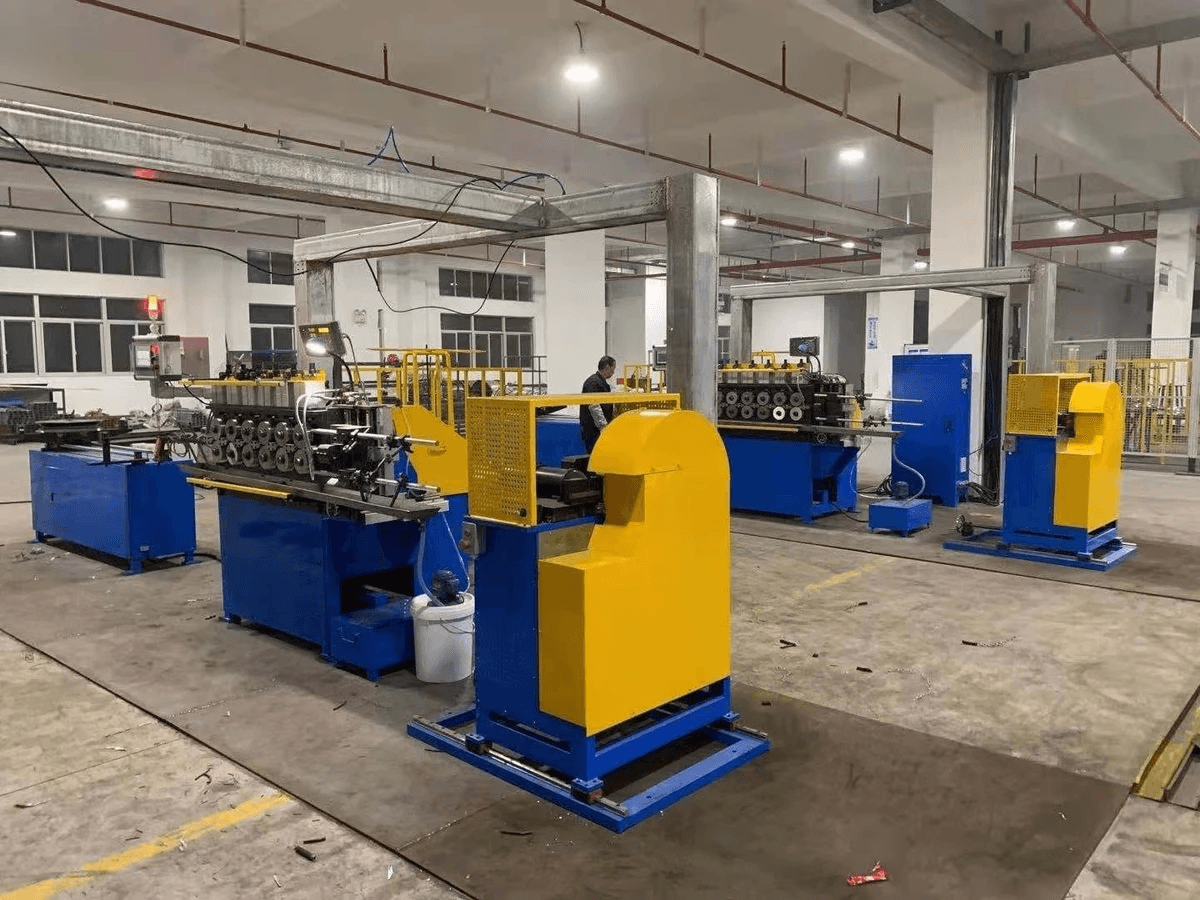

Types of CNC Bending Machines

There are various types of CNC bending machines tailored for different applications in wire bending processes. Some popular options include electric, hydraulic, and hybrid models—each offering unique benefits depending on the job requirements. For instance, CNC coiling and bending machines excel at creating coils or loops in wire materials while maintaining tight tolerances necessary for high-quality outputs.

How They Improve Efficiency

CNC bending machines significantly enhance production efficiency by automating repetitive tasks that would otherwise require manual labor. With features like programmable settings and real-time monitoring, these machines can produce parts faster while maintaining high standards of quality control—something that manual methods struggle to achieve consistently. Furthermore, as industries increasingly adopt automation in their operations, understanding what is a CNC bending machine becomes crucial for businesses aiming to stay competitive.

Comparing NC and CNC Bending Machines

When it comes to wire bending machines, understanding the distinctions between NC (Numerical Control) and CNC (Computer Numerical Control) is crucial for making informed decisions. Both types of machines are designed to automate the bending process, but they do so with varying degrees of sophistication and efficiency. In this section, we’ll delve into their definitions, performance differences, and tips for selecting the right machine for your needs.

Definitions of NC and CNC

NC bending machines utilize a straightforward control system that relies on punched tape or similar media to dictate movement. This method allows for basic automation but lacks the flexibility and programmability seen in more advanced systems. On the other hand, CNC bending machines leverage computer technology to provide precise control over complex shapes and designs, enabling users to execute intricate tasks with ease.

Understanding what is CNC wire bending is essential here; it involves using computer software to create detailed instructions that guide the machine's actions. This technology not only enhances precision but also allows for quick adjustments in design without needing extensive reconfiguration—something that’s often cumbersome with traditional NC systems. Therefore, if you’re looking at high performance wire bending machines, opting for a CNC model could significantly streamline your workflow.

Performance Differences Between NC and CNC

Performance-wise, there are notable differences between NC and CNC bending machines that can impact overall productivity. While NC machines may require manual input for each task—leading to longer setup times and potential human error—CNC machines can run multiple programs simultaneously with high accuracy. This capability translates into faster production rates, reduced waste material, and ultimately lower costs per unit produced.

Additionally, when evaluating what is a CNC bending machine in comparison to its NC counterpart, consider how each handles complex shapes or multiple bends in one operation. The advanced algorithms used by CNC systems allow them to perform intricate tasks seamlessly without sacrificing quality or speed. If you're weighing options like how much is Di Wire Pro versus an older NC model, remember that investing in a high-performance wire bending machine can pay off through improved efficiency over time.

Choosing the Right Machine for Your Needs

Selecting between an NC or a CNC wire bending machine hinges on your specific requirements—both current needs and future ambitions should be considered carefully. For businesses focused on high-volume production with intricate designs, investing in a high performance wire bending machine like those offered by leading brands may be advantageous despite higher upfront costs. Conversely, if your operations involve simpler tasks or lower volumes of work where budget constraints are tighter, an NC machine might suffice initially.

Ultimately, understanding what is the difference between an NC and CNC bending machine boils down to evaluating factors such as complexity of projects undertaken and available budgetary resources. Be sure to assess how much you anticipate growing your operations; sometimes spending more upfront can lead to significant long-term savings through enhanced productivity capabilities offered by modern technology like CNC coiling and bending machines.

Evaluating High Performance Wire Bending Machines

When it comes to investing in a wire bending machine CNC, understanding the performance metrics is crucial. High Performance Wire Bending Machines are designed to enhance precision and efficiency, making them indispensable in various manufacturing processes. Evaluating these machines involves understanding their specifications, exploring leading brands and models, and analyzing the balance between cost and performance.

Key Specifications to Consider

When assessing a wire bending machine CNC, several specifications should be at the forefront of your decision-making process. Look for features such as maximum bend radius, material compatibility, and bending speed; these factors directly affect the machine's versatility and output quality. Additionally, consider the software capabilities that come with CNC coiling and bending machines—advanced programming can significantly streamline operations.

Another important specification is the machine's tolerance levels; high-performance models often boast tighter tolerances that ensure better accuracy in production runs. Pay attention to automation features as well; machines equipped with automatic feeding systems can greatly reduce manual labor while enhancing throughput. Finally, don't overlook after-sales support—having access to reliable customer service can make or break your experience with any CNC bending machine.

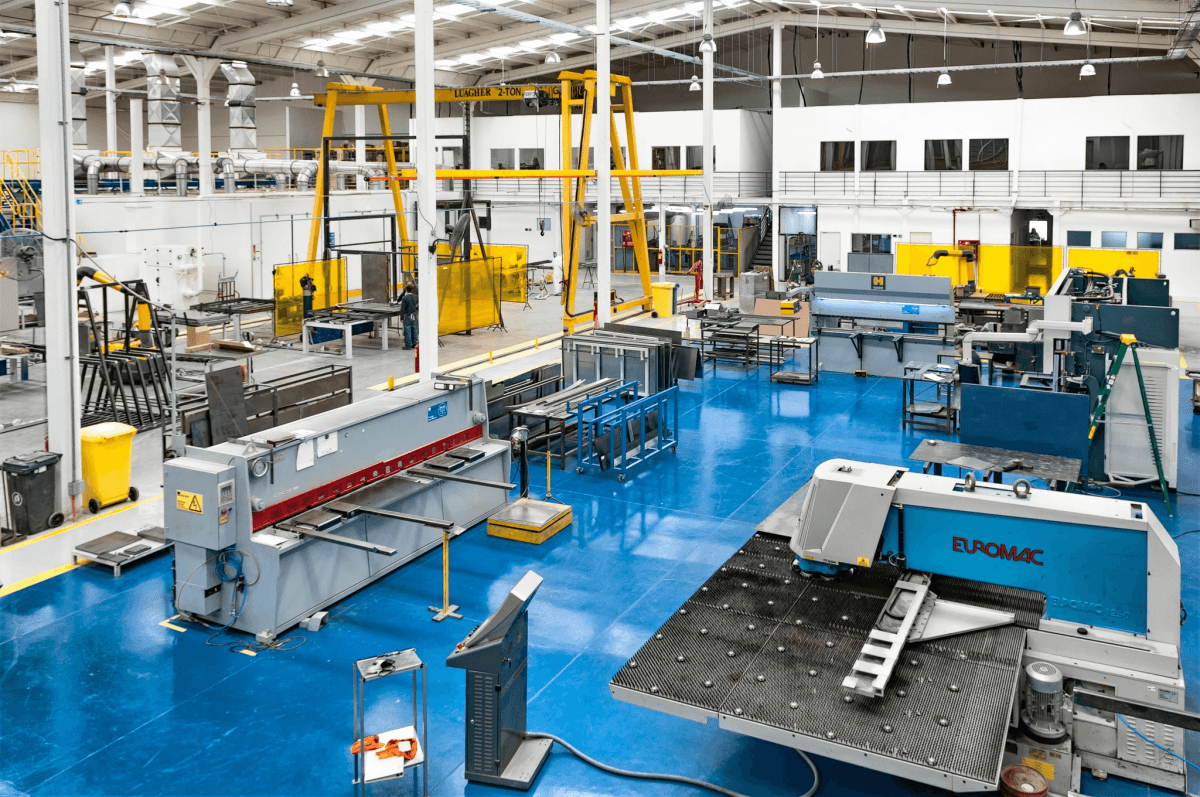

Top Brands and Models to Explore

The market for High Performance Wire Bending Machines is diverse, with several brands standing out for their innovation and reliability. Some of the top manufacturers include Boschert, Wafios, and KUKA Robotics; each offers unique features tailored to specific industry needs. For instance, Boschert’s line is known for its robust construction and user-friendly interface—perfect for those asking what is a CNC bending machine?

If you’re looking for cutting-edge technology in wire bending machines CNC, consider models like Wafios’ GS 8 or KUKA’s KR series which integrate advanced automation capabilities into their designs. These machines not only improve efficiency but also offer exceptional flexibility in terms of design alterations on-the-fly—a game changer when dealing with custom orders! Researching these brands will provide insight into which model best fits your operational requirements.

Cost vs. Performance Analysis

Investing in a wire bending machine CNC requires careful consideration of cost versus performance metrics; after all, you want your money well spent! When evaluating options like Di Wire Pro or other high-performance models on the market today, it’s essential to weigh initial costs against long-term benefits such as durability and maintenance expenses over time. Remember that while some machines may have a higher upfront price tag due to advanced features or brand reputation, they could save you significant amounts on labor costs down the road.

Additionally, look at how each model performs under various conditions—some may excel at high-volume production but falter when handling intricate designs or different materials. Understanding what is the difference between NC and CNC bending machines can also play a role here; while NC might be cheaper initially due to less complex technology, they often lack the efficiency gains provided by their CNC counterparts in many applications. Ultimately, striking this balance will help ensure you choose a wire bending machine that meets both your budgetary constraints and production goals.

Pricing Insights for Wire Bending Machines

When it comes to investing in a wire bending machine CNC, understanding the pricing landscape is crucial. The costs can vary significantly based on features, brand reputation, and specifications. As you delve into the world of High Performance Wire Bending Machines, you'll find that price is often an indicator of quality and capability.

How Much is Di Wire Pro?

The price of Di Wire Pro, a prominent name in CNC coiling and bending machines, typically ranges from $20,000 to $50,000 depending on the model and configuration. This cost reflects its advanced features that cater to both small-scale operations and large manufacturing setups. When considering how much is Di Wire Pro, it's essential to weigh the investment against your production needs and expected return on investment.

Factors Influencing Pricing

Several factors influence the pricing of wire bending machines CNC. First off, technological advancements play a significant role; machines equipped with state-of-the-art software or automation features tend to be pricier but offer enhanced efficiency and precision. Additionally, brand reputation can impact costs; established brands with proven performance may charge more due to their reliability in various applications of what is CNC wire bending? Lastly, customization options can also drive up prices—machines tailored for specific tasks often come at a premium.

Budgeting for Your Investment

Budgeting for your investment in a CNC bending machine requires careful planning and consideration of multiple aspects. Start by assessing your production volume and specific needs; this will help determine whether you need a high-end model or something more basic that still meets your requirements. Also factor in potential maintenance costs and training expenses—after all, investing in High Performance Wire Bending Machines isn’t just about the initial purchase price but also about ensuring long-term efficiency.

Conclusion

In the ever-evolving landscape of manufacturing, understanding the nuances of wire bending technology is crucial for making informed decisions. As we’ve explored, selecting the right machine can drastically impact production efficiency and quality. Whether you’re considering a high performance wire bending machine or delving into CNC coiling and bending machines, take your time to evaluate your specific needs before making a purchase.

Tips for Choosing the Right Machine

When it comes to choosing a wire bending machine CNC, start by identifying your production volume and complexity of designs. High performance wire bending machines should offer versatility in handling various materials and shapes while maintaining precision. Don't forget to compare features like automation capabilities, ease of use, and after-sales support; these factors can significantly influence your overall satisfaction with the machine.

Importance of Automation in Wire Bending

Automation is revolutionizing what is CNC wire bending? By integrating advanced technologies into CNC bending processes, manufacturers are seeing reduced labor costs and increased output quality. A well-automated CNC bending machine not only enhances productivity but also minimizes human error, ensuring that every bend meets exact specifications.

Future Trends in CNC Wire Bending Technology

Looking ahead, innovations in CNC coiling and bending machines are set to reshape the industry landscape further. We can expect advancements such as artificial intelligence integration for predictive maintenance and enhanced design software that streamlines operations even more efficiently than before. Moreover, as manufacturers seek cost-effective solutions like Di Wire Pro—how much is Di Wire Pro?—the demand for high performance wire bending machines will continue to rise alongside technological advancements.