Introduction

Understanding the Importance of Aluminium Clamps

Aluminium clamps play a crucial role in ensuring stability and safety across numerous industries. Their lightweight yet durable composition makes aluminium an ideal choice for a variety of applications, from woodworking to electrical installations. Furthermore, knowing what is a metal clamp and how it functions opens up new possibilities for efficient project execution.

Exploring Different Types of Clamps

In the world of fastening solutions, one might wonder: What are the three types of clamps? Each type—screw clamps, spring clamps, and fastening clamps—serves distinct purposes that cater to different needs. Understanding these variations helps users select the best option for their specific projects, maximizing both efficiency and effectiveness.

Selecting the Right Clamp Material

Choosing the right material is critical when it comes to clamp selection; this leads us to ask: What is the best material for clamps? While various materials are available on the market, aluminium stands out due to its unique combination of durability and weight considerations. Additionally, knowing how aluminium compares with other materials can guide you toward making cost-effective decisions without compromising quality.

The Basics of Aluminium Clamps

Aluminium clamps play a crucial role in various applications, from construction to electrical distribution. Understanding the basics of these clamps can significantly enhance your selection and usage, ensuring you choose the right tool for your project. In this section, we will explore what a C-clamp is, provide an overview of metal clamps, and highlight the benefits of using aluminium clamps.

What is a C-Clamp?

A C-clamp, often referred to as an aluminum C-clamp when made from this lightweight material, is a versatile tool designed for holding objects tightly together. Its distinctive C shape allows it to apply pressure across two surfaces, making it ideal for woodworking and metalworking projects alike. With its adjustable screw mechanism, a C-clamp can secure materials without damaging them—an essential feature when working with delicate components.

Overview of Metal Clamps

Metal clamps are essential tools used across various industries for securing or fastening items together. These clamps come in different shapes and sizes, including the popular aluminium clamp known for its lightweight yet durable nature. Understanding what is a metal clamp involves recognizing that they can be made from materials like steel or plastic; however, aluminium clamps stand out due to their corrosion resistance and strength-to-weight ratio.

Benefits of Using Aluminium Clamps

Using aluminium clamps offers several advantages that make them a preferred choice among professionals and hobbyists alike. Firstly, they are incredibly lightweight compared to their steel counterparts while still providing substantial strength—perfect for those lengthy projects where every ounce counts! Secondly, aluminium's natural resistance to rust ensures longevity in outdoor conditions or humid environments; thus addressing the question: what is the best material for clamps? Lastly, these clamps are cost-effective options that deliver excellent performance without breaking the bank.

What Are the Three Types of Clamps?

Clamps are essential tools in various applications, and understanding their types can significantly enhance your efficiency. In this section, we will delve into the three primary types of clamps: screw clamps, spring clamps, and fastening clamps. Each type serves a unique purpose and is suited for different tasks, making it crucial to know what works best for your specific needs.

Comparing Screw, Spring, and Fastening Clamps

Screw clamps are renowned for their robust design and ability to hold materials securely in place. The classic aluminium C-clamp falls into this category, featuring a screw mechanism that allows for precise adjustments in pressure. On the other hand, spring clamps utilize a simple yet effective spring mechanism to open and close quickly; they are ideal for lighter tasks where speed is essential.

Fastening clamps combine features from both screw and spring designs but often include additional mechanisms like levers or quick-release options. This versatility makes them suitable for various applications where ease of use is paramount. When considering what is the best material for clamps, aluminium emerges as a popular choice due to its lightweight nature without compromising strength.

When to Use Each Type

Choosing the right clamp depends heavily on the task at hand. For heavy-duty work requiring maximum grip—like woodworking or metal fabrication—screw clamps are your best bet; they provide adjustable pressure that can be finely tuned to secure materials tightly together. Conversely, if you need something quick and easy for light projects like crafting or temporary holds, spring clamps shine due to their fast operation.

Fastening clamps come into play when you need flexibility combined with ease of use; they excel in scenarios where you frequently adjust or reposition items during assembly processes. Understanding what are the three types of clamps helps you select accordingly based on project demands while ensuring safety and effectiveness throughout your work.

Best Applications for Aluminium Clamps

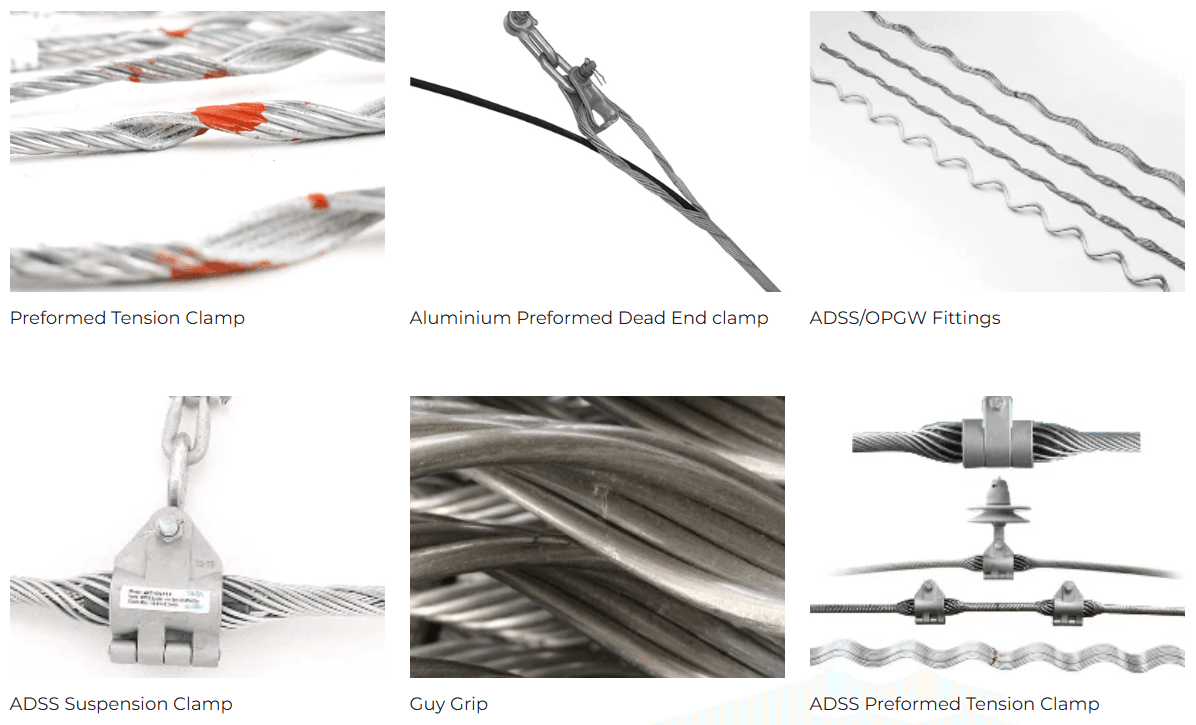

Aluminium clamps find their niche across numerous industries thanks to their unique properties and benefits. In construction or manufacturing settings, an aluminium clamp's lightweight yet durable structure allows workers to handle heavy materials without excessive strain—making them ideal for both temporary holds and long-term fixtures alike. Additionally, these versatile tools serve well in electrical applications; preformed tension clamps from companies like Spark Fittings ensure reliable connections in cable installations.

In more specialized scenarios such as packaging or shipping industries, using specific types of aluminium clamps—like bale or carton variants—can optimize operations significantly by providing tailored solutions based on material size and weight requirements. By recognizing these best applications for aluminium clamps within various fields, users can maximize productivity while ensuring quality outcomes.

Material Matters: What is the Best Material for Clamps?

When it comes to selecting the right material for clamps, aluminium stands out due to its unique properties that cater to various applications. Understanding what is the best material for clamps can significantly influence performance, longevity, and usability. While there are several materials available, aluminium clamps have gained popularity for their lightweight nature and excellent strength-to-weight ratio.

Advantages of Aluminium vs. Other Materials

Aluminium clamps offer several advantages over traditional metal clamps made from steel or other materials. Firstly, aluminium is naturally resistant to corrosion, making it ideal for outdoor and industrial applications where exposure to moisture is a concern. Additionally, compared to heavier metals like steel, an aluminum C-clamp provides similar strength while being much easier to handle and transport.

Another notable advantage of aluminium is its ability to be easily machined or formed into intricate designs without compromising structural integrity. This flexibility allows manufacturers like Spark Fittings to produce specialized products such as preformed tension clamps tailored for specific needs in electrical distribution systems. Overall, when asking what are the three types of clamps? It’s clear that those crafted from aluminium often lead the pack in versatility and efficiency.

Durability and Weight Considerations

Durability is a critical factor when evaluating clamp materials; fortunately, aluminium strikes an excellent balance between weight and strength. While some might argue that heavier materials like steel provide better durability, it's essential to consider how weight impacts usability in real-world scenarios. An aluminium clamp can withstand substantial forces while remaining lightweight enough for easy manipulation during installation or adjustment.

Moreover, the durability of an aluminium clamp extends beyond just physical strength; its resistance to rust means it maintains functionality over time with minimal maintenance required. For instance, when we explore what is a metal clamp? The answer often leads us back to metal types like steel that may require additional coatings or treatments to prevent corrosion—yet with aluminium's natural properties, you sidestep those concerns entirely.

Cost-Effectiveness of Aluminium Clamps

Cost-effectiveness plays a vital role in any purchasing decision regarding tools and equipment; hence why many professionals favor aluminium clamps over more expensive alternatives like stainless steel or heavy-duty plastic options. Not only does the initial purchase price tend to be lower for an aluminum C-clamp compared with other materials but considering their longevity due to corrosion resistance further enhances their value proposition.

Additionally, because they are lighter than their counterparts made from other metals or plastics, shipping costs also decrease—an important consideration for businesses looking at bulk purchases of equipment such as preformed tension clamps used in power distribution systems by companies like Spark Fittings. Ultimately investing in high-quality yet affordable solutions ensures you get maximum return on investment while meeting your project requirements effectively.

Specialty Clamps: Bale vs. Carton Clamps

What is the Difference Between a Bale Clamp and a Carton Clamp?

Bale clamps are designed primarily for lifting and transporting large bales of material, such as textiles or agricultural products, while carton clamps are tailored for handling boxes or cartons. The primary distinction lies in their design; bale clamps typically feature wider arms to accommodate bulkier items, whereas carton clamps have narrower grips suited for more compact shapes. Additionally, the operational mechanism may differ slightly; while both utilize hydraulic or mechanical systems, their configurations cater to specific load types—bales versus cartons.

Applications for Bale Clamps

Bale clamps excel in environments where heavy loads need to be moved efficiently without damaging the contents. Common applications include warehouses dealing with cotton bales or recycling facilities managing paper bales—both scenarios benefit from this robust aluminium clamp design that ensures secure gripping without crushing materials. In sectors like agriculture and textiles, using an aluminium C-clamp variant can further enhance efficiency by allowing operators to handle multiple bales simultaneously.

Best Uses for Carton Clamps

Carton clamps shine in settings where precision is key—think packaging lines or distribution centers where boxes must be moved swiftly without compromising structural integrity. These specialized aluminium clamps are perfect for stacking and transporting various products ranging from electronics to food items safely. When assessing your clamp needs, considering how often you handle different packaging types can guide you toward selecting either a bale clamp or a carton clamp based on your operational requirements.

Spark Fittings: Leading the Way in Clamps

Overview of Spark Fittings and Their Products

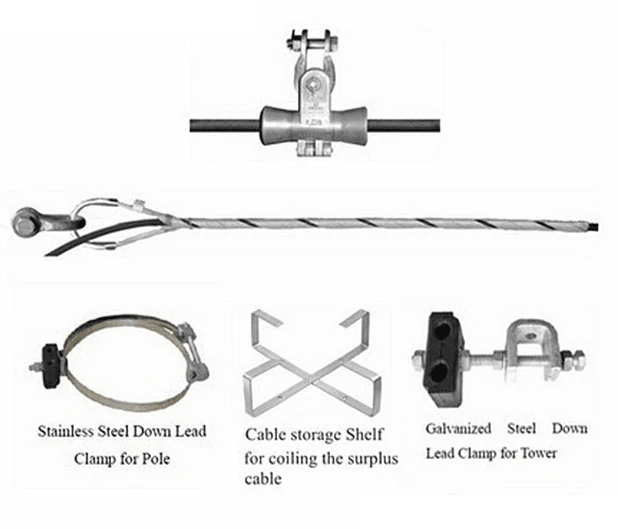

Spark Fittings is synonymous with excellence in clamp manufacturing. Their extensive lineup features an array of aluminium clamps designed to cater to different applications, including preformed tension clamps that play crucial roles in securing cables effectively. By focusing on high-quality materials and cutting-edge technology, they ensure that their products can withstand the rigors of electrical distribution while maintaining optimal performance.

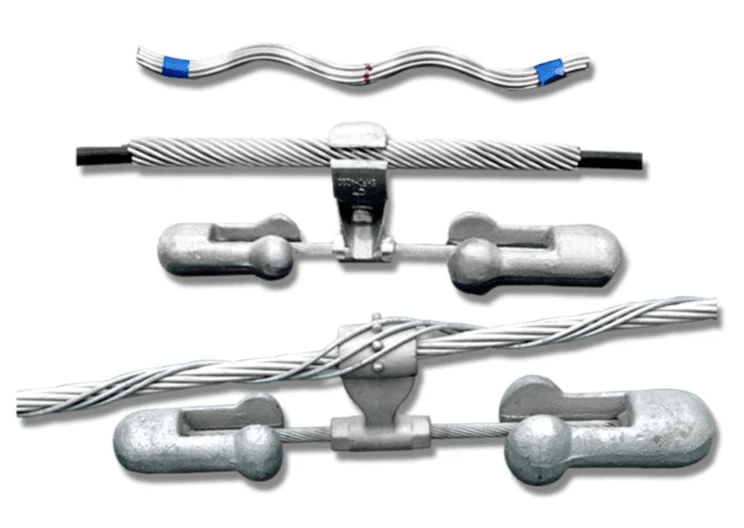

Role of Preformed Tension Clamps in Electrical Distribution

Preformed tension clamps are essential components in electrical distribution systems, ensuring secure connections between conductors and supporting structures. These aluminium clamps provide not only strength but also flexibility, making them ideal for various installation scenarios. Understanding what is a C-Clamp or how it differs from other types helps highlight the importance of choosing the right clamp; preformed tension clamps excel where traditional metal clamps may fall short.

High-Quality Standards in Clamp Manufacturing

Quality is paramount at Spark Fittings; they adhere to rigorous manufacturing standards that guarantee durability and reliability across all their products. Each aluminium clamp undergoes thorough testing to ensure it meets safety requirements while remaining cost-effective compared to alternatives made from other materials. This dedication to excellence means customers can trust that every clamp—from standard models to specialized options—will perform reliably under demanding conditions.

Conclusion

In conclusion, selecting the right aluminium clamp for your project is crucial to ensure efficiency and safety. With various options available, understanding what are the three types of clamps—screw, spring, and fastening—can simplify your decision-making process. Additionally, knowing what is the best material for clamps can significantly impact performance and longevity.

Key Takeaways for Choosing Aluminium Clamps

When choosing an aluminium clamp, it’s essential to consider its intended use and environmental factors. Aluminium clamps offer a unique combination of lightweight durability and resistance to corrosion, making them ideal for diverse applications. Remember that while you may find cheaper alternatives in metal clamps or other materials, investing in high-quality aluminium options often pays off in the long run.

Assessing Your Clamp Needs

Assessing your clamp needs begins with understanding the specific requirements of your project. Consider factors such as load capacity, environmental exposure, and whether you need a C-Clamp or another type for your application. For instance, if you're working with heavy loads or require precision holding power, an aluminum C-clamp may be more suitable than other types like spring clamps.

Final Thoughts on Quality and Application

In summary, quality matters when it comes to clamps—especially with products like preformed tension clamps from companies like Spark Fittings that specialize in high-performance equipment for electrical distribution. Understanding concepts such as what is the difference between a bale clamp and a carton clamp can also streamline your selection process based on application needs. Ultimately, choosing the right aluminium clamp ensures not just functionality but also safety across various projects.