Introduction

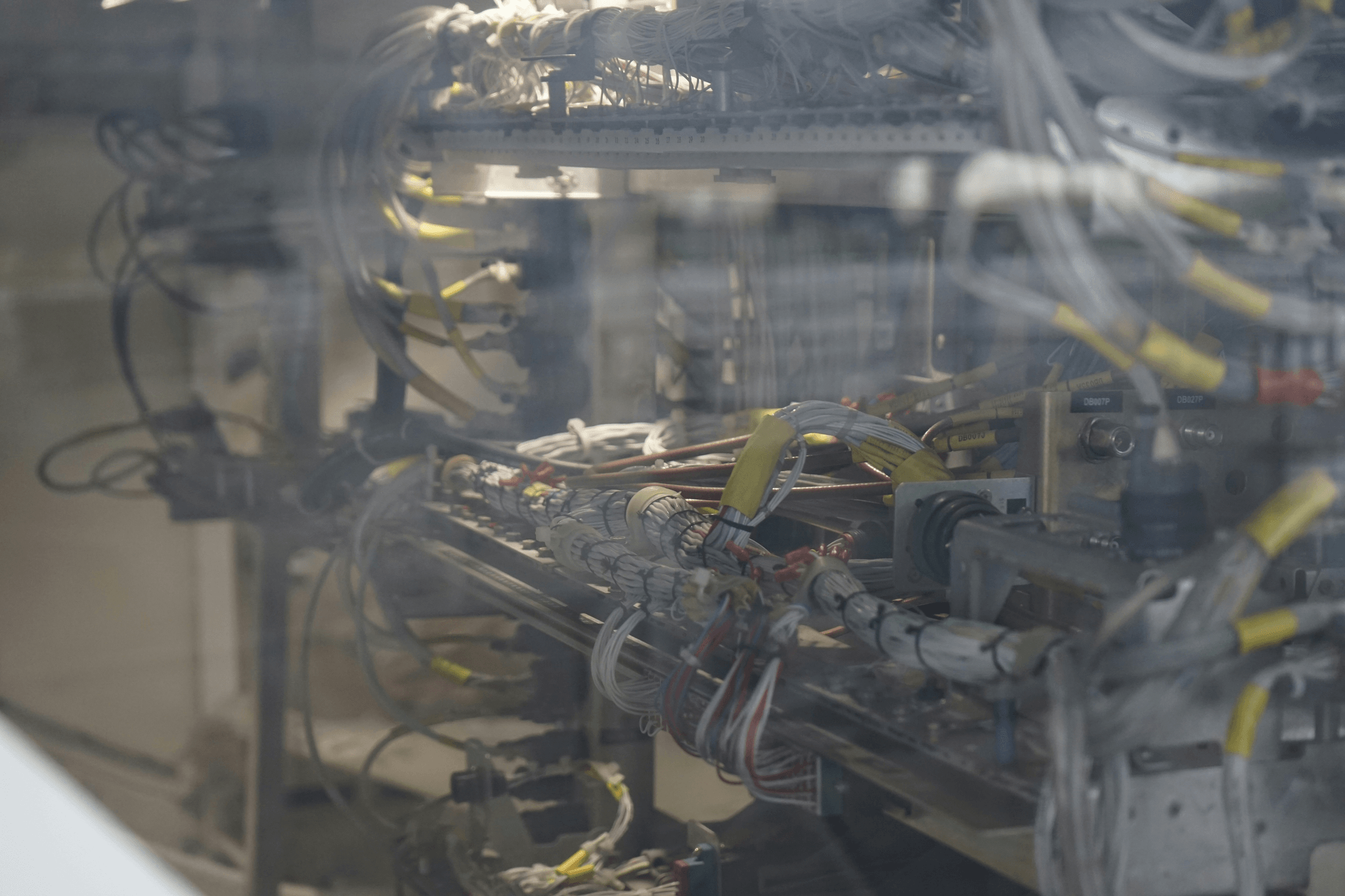

In today's fast-paced manufacturing industry, wire forming machines play a crucial role in shaping metal wires into various components and products. These innovative machines have revolutionized the production process, offering efficiency, precision, and versatility to businesses across different sectors.

The Importance of Wire Forming Machines

Wire forming machines are essential for creating intricate wire shapes and designs that are used in a wide range of industries, including automotive, aerospace, construction, and consumer goods. These machines enable manufacturers to produce custom wire forms with high accuracy and consistency, meeting the demands of modern production processes.

Top Features to Look for in Wire Forming Machinery

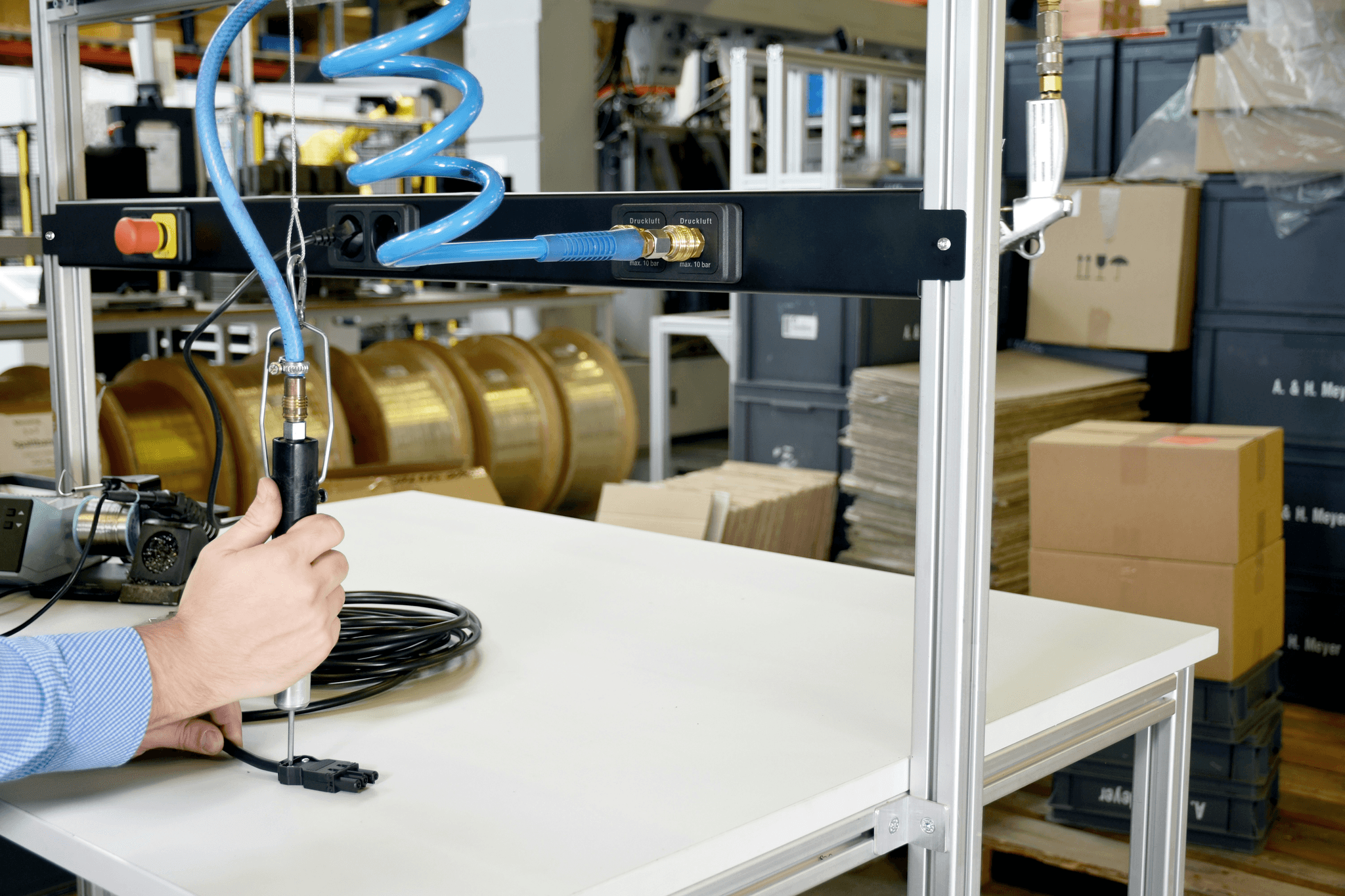

When searching for wire forming machinery, it's important to consider key features such as advanced automation capabilities, CNC controls for precise shaping, and the ability to work with various materials including stainless steel wire. The latest models also offer quick changeover times and flexibility to accommodate different wire diameters and shapes.

Benefits of Investing in High-Quality Wire Forming Machines

Investing in high-quality wire forming machines can significantly enhance a company's production capabilities by increasing output volume while maintaining exceptional quality standards. These machines also reduce labor costs and minimize material waste, making them a cost-effective solution for businesses looking to streamline their manufacturing processes.

Industry Leaders in Wire Forming Machine Manufacturing

When it comes to wire forming machine manufacturers, Moyer Wire Products Inc. is a standout choice. With a focus on innovative solutions for wire forming, Moyer offers a range of cutting-edge machinery designed to meet the diverse needs of various industries. Their commitment to quality and precision makes them a top contender in the market.

Moyer Wire Products Inc.: Innovative Solutions for Wire Forming

Moyer Wire Products Inc. leads the pack when it comes to providing innovative solutions for wire forming. Their state-of-the-art machinery incorporates advanced technology, ensuring efficient and precise production processes. Whether it's stainless steel wire forming or spring winding machines, Moyer's equipment is designed to deliver exceptional results while meeting the highest industry standards.

Moyer Wire Products Inc. has a team of highly skilled engineers and technicians who are dedicated to pushing the boundaries of wire forming technology. Their relentless pursuit of innovation has led to the development of cutting-edge solutions that have revolutionized the industry. From custom wire forms to complex wire bending, Moyer's expertise and creativity shine through in every project they undertake.

AIM Inc.: Cutting-Edge Technology for Wire Forming Machinery

AIM Inc. is another industry leader known for its cutting-edge technology in wire forming machinery. Their commitment to pushing the boundaries of innovation has led to the development of advanced equipment that caters to the evolving needs of modern manufacturing processes. From complex wire forms to intricate designs, AIM's machinery sets a new standard for excellence.

Furthermore, AIM Inc.'s dedication to research and development has resulted in the integration of state-of-the-art automation and control systems into their wire forming machinery. This not only ensures precision and efficiency but also enhances the overall reliability of their equipment. As a result, manufacturers can depend on AIM's machinery to consistently deliver high-quality wire forms while streamlining their production processes.

WAFIOS Machinery Corporation: Precision and Reliability in Wire Forming Machines

WAFIOS Machinery Corporation stands out for its precision and reliability in wire forming machines, making them a top choice for businesses seeking high-quality equipment. With a focus on durability and performance, WAFIOS' machinery is engineered to withstand rigorous production demands while maintaining exceptional accuracy and consistency.

WAFIOS Machinery Corporation's commitment to precision and reliability extends beyond just the quality of their machines. They also provide exceptional customer service and support, ensuring that businesses have the assistance they need to maximize the potential of their equipment. This dedication to customer satisfaction sets WAFIOS apart as a partner in success, not just a provider of machinery.

Cutting-Edge Technology in Wire Forming Machinery

Incorporating Stainless Steel Wire Forming in Production

In today's competitive market, wire forming machine manufacturers are increasingly incorporating stainless steel wire forming into their production processes. This trend is driven by the growing demand for high-quality, corrosion-resistant wire products across various industries. By utilizing stainless steel wire, manufacturers can ensure that their products are durable and long-lasting, making them an attractive choice for customers.

The Advantages of Spring Winding Machines

Spring winding machines have revolutionized the wire forming industry by streamlining the process of creating springs of different shapes and sizes. These machines offer precision and efficiency, allowing manufacturers to produce high volumes of springs with consistent quality. With the ability to adjust tension and diameter, spring winding machines provide unparalleled flexibility in meeting diverse customer needs.

Spring winding machines not only increase efficiency and precision in the production process but also contribute to cost savings for manufacturers. By automating the spring forming process, these machines reduce the need for manual labor, leading to lower labor costs and improved overall productivity. Additionally, the consistent quality of springs produced by these machines minimizes the risk of defects or errors, ultimately saving manufacturers time and money on rework or replacements.

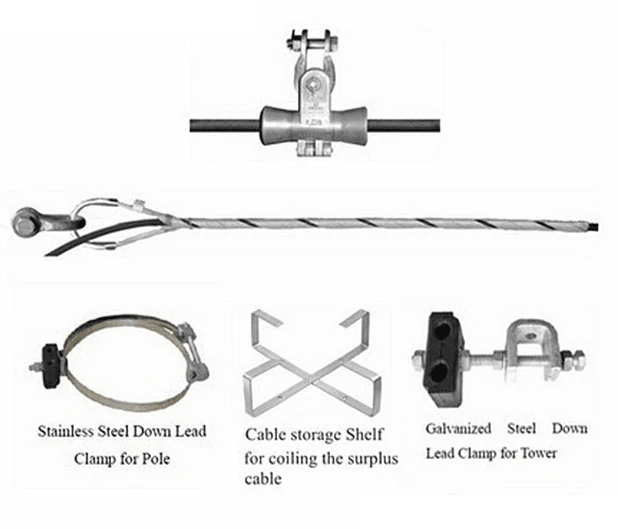

The Role of 16A Pre-Twisted Wire Automatic Forming Production Line

The 16A pre-twisted wire automatic forming production line represents a significant advancement in wire forming machinery. This innovative technology enables manufacturers to automate the production of complex wire forms with speed and accuracy. By pre-twisting the wires before forming them into specific shapes, this production line ensures superior strength and structural integrity in the final products.

With the 16A pre-twisted wire automatic forming production line, manufacturers can also benefit from reduced material waste and increased production efficiency. The precision and consistency of the pre-twisting process ensure that each wire form meets exact specifications, minimizing the need for rework or scrap. This results in cost savings and improved overall productivity for manufacturers, making the 16A production line a valuable asset for modern wire forming operations.

Finding the Right Wire Forming Machine for Your Business

When looking for the perfect wire forming machine, customization options from leading manufacturers are crucial. Top wire form manufacturers offer the ability to tailor machines to your specific production needs, ensuring optimal performance and efficiency. Whether it's custom tooling, size specifications, or additional features, having a machine that is tailored to your exact requirements can make all the difference in your production process.

Customization Options from Leading Manufacturers

Wire forming machine manufacturers understand that every business has unique needs when it comes to wire forming machinery. That's why they offer a wide range of customization options to ensure that their machines can meet the specific requirements of different industries. From custom tooling and bending capabilities to specialized finishing processes, leading manufacturers work closely with their clients to create a bespoke solution that fits their exact production needs.

Leading manufacturers also understand the importance of durability and longevity in wire forming equipment. They use high-quality materials and advanced manufacturing processes to ensure that their machines can withstand the rigors of daily production and continue to perform at a high level for years to come. By prioritizing durability, manufacturers help their clients minimize downtime and maintenance costs, ultimately improving their overall productivity.

The Importance of Durability and Longevity in Wire Forming Equipment

When investing in wire forming machinery, durability and longevity are key factors to consider. Top wire form manufacturers prioritize the use of high-quality materials and precision engineering in their machines to ensure long-term reliability and performance. By choosing a durable machine, businesses can minimize downtime, reduce maintenance costs, and increase overall productivity.

Choosing a durable wire forming machine also allows businesses to adapt to changing market demands and production requirements. With a versatile machine, manufacturers can easily switch between different wire forming processes and produce a wide range of products, from simple shapes to complex designs. This flexibility enables companies to take on diverse projects and meet the needs of various industries, ultimately expanding their customer base and increasing revenue.

The Versatility of Wire Forming Machines for Various Industries

One of the great advantages of modern wire forming machines is their versatility across different industries. Whether it's automotive manufacturing, aerospace engineering, or consumer goods production, wire forming machinery can be adapted to suit various applications. Leading manufacturers offer a wide range of machine configurations and tooling options to accommodate different industry requirements, making them an ideal choice for businesses with diverse production needs.

In addition to their adaptability, reputable wire form manufacturers also offer a high level of customization for their machines. This means that businesses can work closely with manufacturers to tailor the machinery to their specific production needs, whether it's creating unique wire forms or optimizing the manufacturing process. This level of customization can lead to increased efficiency and cost savings for businesses, as they are able to get exactly what they need from their wire forming machinery.

Advantages of Working with Reputable Wire Form Manufacturers

Guaranteeing Quality and Performance from Wire Forming Machines

When working with reputable wire form manufacturers, you can rest assured that the wire forming machines you invest in will deliver top-notch quality and exceptional performance. These manufacturers prioritize precision engineering and stringent quality control measures to ensure that their machinery meets the highest industry standards.

Reliable After-Sales Support and Maintenance Services

One of the key advantages of partnering with reputable wire form manufacturers is the reliable after-sales support and maintenance services they offer. From technical assistance to spare parts availability, these manufacturers are committed to providing comprehensive support to keep your wire forming machines running at peak efficiency for years to come.

The Impact of Industry Certifications and Accolades in Choosing a Manufacturer

Industry certifications and accolades serve as a testament to the credibility and expertise of wire form manufacturers. By choosing a manufacturer with recognized certifications and accolades, you can be confident in their commitment to excellence and innovation in producing high-quality wire forming machinery.

Conclusion

Investing in Quality Wire Forming Machinery for Long-Term Success

When it comes to the success of your business, investing in high-quality wire forming machinery is crucial. By choosing reputable wire form manufacturers, you can ensure that your production processes are efficient and reliable, leading to long-term success and profitability. With cutting-edge technology such as stainless steel wire forming and spring winding machines, you can stay ahead of the competition and meet the demands of various industries.

The Future of Wire Forming: Innovations and Trends to Watch

As technology continues to advance, the future of wire forming machinery looks promising. Innovations such as automation and customization options from leading wire forming machine manufacturers will revolutionize the industry, making production processes more efficient and cost-effective. Keeping an eye on these trends will help you stay ahead in the market and adapt to changing industry needs.

Choosing the Right Wire Forming Machine Manufacturer for Your Business

When selecting a wire forming machine manufacturer, it's essential to consider factors such as reputation, reliability, and after-sales support. Look for industry leaders who offer a wide range of customization options and prioritize durability and longevity in their equipment. Consider certifications and accolades as indicators of quality when choosing a manufacturer for your business.

In conclusion, by investing in quality wire forming machinery from reputable manufacturers like Moyer Wire Products Inc., AIM Inc., or WAFIOS Machinery Corporation, you can set your business up for long-term success. Stay informed about innovations and trends in the industry to remain competitive, and choose a manufacturer that aligns with your business needs for maximum efficiency.