Introduction

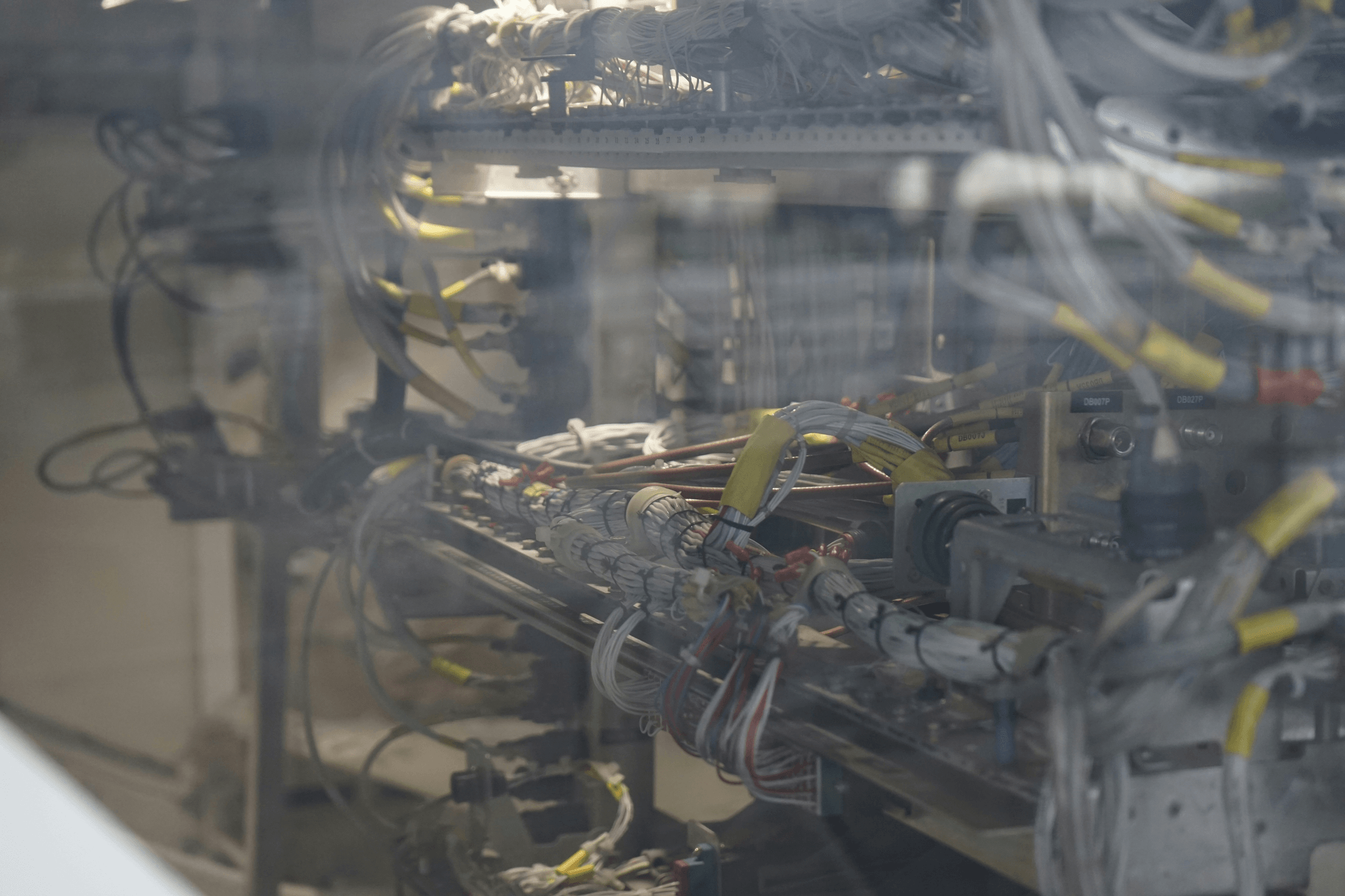

In the fast-paced world of industrial production, an efficient labeling process is crucial for streamlining operations and ensuring product traceability. One of the key solutions to this challenge is the automatic cable and wire labeling machine, a game-changer in the field of wire identification and organization. Spark Fittings’ Twisted Wire Folding Labeling Machine stands out as a top contender in this arena, offering innovative features that revolutionize the labeling process.

Introduction to Automatic Cable and Wire Labeling Machines

Automatic cable and wire labeling machines are designed to streamline the process of identifying and organizing wires in industrial settings. These machines automate the application of labels onto cables, wires, and other products, saving time and ensuring accuracy in labeling.

Importance of Efficient Labeling in Industrial Settings

Efficient labeling is essential for maintaining order and safety within industrial environments. Properly labeled cables and wires allow for quick identification, reducing the risk of errors or accidents. In addition, efficient labeling contributes to overall productivity by enabling smooth workflow processes.

Overview of Spark Fittings’ Twisted Wire Folding Labeling Machine

Spark Fittings’ Twisted Wire Folding Labeling Machine offers a comprehensive solution for automated cable labeling needs. With its innovative features such as twisted wire integration, folding mechanism, automated labeling functionality, high-speed operation, customizable options, easy integration with existing production lines, touchscreen controls, and durable construction; it sets itself apart as a top choice for industrial applications.

Twisted Wire Integration

Twisted Wire Integration Provided by Spark Fittings

Spark Fittings’ Twisted Wire Folding Labeling Machine offers a unique feature of securely twisting wire around products, ensuring a secure and durable labeling solution. This innovative integration provides a reliable method for labeling cables and wires in industrial settings, enhancing safety and efficiency throughout the production process.

The Twisted Wire Folding Labeling Machine from Spark Fittings not only ensures a secure and durable labeling solution, but it also offers a cost-effective method for labeling cables and wires in industrial settings. By securely twisting wire around products, this innovative integration minimizes the risk of labels becoming detached or damaged during handling and transportation. This ultimately leads to reduced rework and maintenance costs, contributing to overall cost savings for businesses.

Benefits of Securely Twisting Wire Around Products

The automatic wire labeler by Spark Fittings ensures that wires are tightly secured around products, preventing any potential hazards or accidents caused by loose or misplaced labels. This feature not only enhances the overall appearance of the labeled products but also contributes to the longevity and durability of the wire identification labels. Furthermore, the twisted wire integration provides a sleek and professional look, adding to the aesthetic appeal of the labeled products. In addition, the secure attachment of the labels ensures that they remain intact even in high-impact environments, making them suitable for a wide range of applications.

Ensuring Safety and Durability with Twisted Wire Integration

By securely twisting wire around products, Spark Fittings’ labeling machine guarantees safety and durability in industrial environments. The twisted wire integration provides a robust solution for cable labeling, offering peace of mind for manufacturers and workers alike.

In addition to ensuring safety and durability, Spark Fittings’ labeling machine also offers unparalleled efficiency in the cable labeling process. By securely twisting wire around products, the machine streamlines the labeling process, saving valuable time for manufacturers and workers. This increased efficiency translates to cost savings and improved productivity, making it a valuable asset in any industrial environment.

Folding Mechanism

Spark Fittings’ Twisted Wire Folding Labeling Machine is equipped with an advanced folding mechanism that automatically folds labels or tags, streamlining the labeling process. The machine’s folding mechanism ensures that labels are neatly and precisely folded, saving time and effort for industrial workers.

Overview of Folding Mechanism in Spark Fittings’ Labeling Machine

The folding mechanism in Spark Fittings’ labeling machine is designed to seamlessly integrate with the labeling process, ensuring that labels or tags are neatly folded around cables and wires. This innovative feature eliminates the need for manual folding, increasing efficiency and reducing labor costs.

The automatic folding of labels or tags in Spark Fittings’ labeling machine offers a consistent and professional finish to the labeling process. By eliminating the variations that can occur with manual folding, this feature ensures that every label is neatly and uniformly folded around cables and wires. This not only enhances the overall appearance of the labeled products but also contributes to a more polished and professional brand image.

Advantages of Automatic Folding of Labels or Tags

The automatic folding feature of Spark Fittings’ labeling machine not only saves time but also ensures that the labels are neatly and uniformly folded, enhancing the overall presentation of the products. This level of consistency contributes to a more efficient production process, as workers can rely on the machine to consistently deliver high-quality folded labels without the need for manual intervention. As a result, businesses can streamline their operations and allocate resources more effectively, ultimately increasing productivity and profitability.

Efficiency and Precision in Label Folding Process

With the automatic folding mechanism, Spark Fittings’ labeling machine delivers unparalleled efficiency and precision in the label folding process. This not only saves time but also ensures that each label is neatly folded without any creases or misalignments, contributing to a seamless wire identification process. In addition, the machine's ability to handle a high volume of labels without sacrificing quality makes it a valuable asset for businesses with large-scale labeling needs. Furthermore, the precision of the label folding process reduces the likelihood of errors, leading to increased overall productivity and customer satisfaction.

Automated Labeling

In the realm of industrial settings, efficiency and precision are paramount when it comes to labeling cables and wires. Spark Fittings’ Twisted Wire Folding Labeling Machine is equipped with an advanced Automated Labeling System for Wire Identification, ensuring seamless and accurate label application.

Spark Fittings’ Automated Labeling Functionality

The automatic wire labeler from Spark Fittings boasts a state-of-the-art automated labeling functionality, enabling the swift and precise application of labels onto cables and wires. This innovative feature significantly reduces manual labor, leading to increased productivity and streamlined production processes.

Furthermore, the automated labeling functionality of the wire labeler ensures precision and accuracy in the application of labels. This means that there are fewer errors and rework needed, saving time and resources for the production process. With consistent and reliable labeling, there is a higher level of quality control, resulting in satisfied customers and a stronger brand reputation.

Precision and Accuracy in Label Application

With the electrical wire labeling machine by Spark Fittings, precision is key. The automated labeling system ensures that labels are applied with utmost accuracy, eliminating the risk of errors commonly associated with manual labeling processes. This results in a consistent and professional finish on every labeled product.

Streamlining Production with Automated Labeling

By integrating an automatic cable labeling machine into the production line, companies can streamline their operations and achieve higher levels of efficiency. The automated labeling process minimizes downtime while maximizing output, ultimately leading to cost savings and improved overall productivity.

The high-speed operation of the automatic cable labeling machine ensures that products move quickly through the production line, reducing bottlenecks and delays. This rapid labeling process allows for a seamless workflow, enabling companies to meet tight deadlines and fulfill orders in a timely manner. As a result, businesses can enhance their reputation for reliability and prompt delivery, leading to increased customer satisfaction and loyalty.

High-Speed Operation

When it comes to high-speed operation, Spark Fittings’ Automatic Cable and Wire Labeling Machine takes the lead. With its advanced technology and efficient design, this labeling machine can handle large volumes of cables and wires quickly and effectively. Whether you’re dealing with a high-demand production line or a time-sensitive project, this machine will increase productivity with its high-speed labeling capabilities.

Speed and Efficiency of Spark Fittings’ Labeling Machine

Spark Fittings’ Automatic Cable and Wire Labeling Machine is engineered for maximum speed and efficiency. Its cutting-edge technology allows for rapid application of labels onto cables and wires, ensuring that your production line runs smoothly without any bottlenecks. With its high-speed operation, you can meet tight deadlines and keep up with demanding workloads effortlessly.

Handling Large Volumes Quickly and Effectively

The automatic wire labeler from Spark Fittings is designed to handle large volumes of cables and wires with ease. Its high-speed operation means that even the most extensive labeling tasks can be completed in a fraction of the time it would take with manual labeling methods. This not only saves valuable time but also ensures that your products are labeled accurately and consistently. In addition, the user-friendly interface of the wire labeler makes it easy for operators to input data and select the appropriate labels, further streamlining the labeling process. With its efficient design and intuitive controls, this labeler is a valuable asset for any business looking to increase productivity in their wire labeling operations.

Increasing Productivity with High-Speed Labeling

By investing in Spark Fittings’ Automatic Cable Labeling Machine, you’re making a smart move towards increasing overall productivity in your industrial setting. The high-speed operation of this machine allows for more efficient workflow, reducing downtime and maximizing output. With its ability to handle large volumes quickly, you can expect a significant boost in productivity that will positively impact your bottom line.

With customizable options available, Spark Fittings’ Automatic Cable Labeling Machine can be tailored to meet the specific needs of your industrial operation. Whether you require unique label designs, different label sizes, or specific printing capabilities, this machine can be adjusted to fit your requirements. This level of customization ensures that you are getting a labeling solution that is perfectly suited to your production processes, further enhancing efficiency and productivity.

Customizable Options

The Automatic Cable and Wire Labeling Machine from Spark Fittings offers adjustable settings for different label sizes and styles, allowing for flexibility in meeting various labeling needs. Whether it's small cable labels or larger wire tags, the machine can be customized to accommodate a range of requirements.

Adjustable Settings for Different Label Sizes and Styles

With the ability to adjust settings for label sizes and styles, the automatic wire labeler from Spark Fittings ensures that it can cater to diverse labeling needs in different industries. This flexibility allows for seamless integration into existing production lines, making it a versatile solution for various applications. Additionally, the adjustable settings make it easy to switch between different label sizes and styles without the need for manual adjustments, saving time and reducing downtime in production processes. This adaptability also means that the wire labeler can meet the evolving needs of a dynamic production environment, ensuring that labeling requirements are always met with precision and efficiency.

Flexibility and Adaptability in Labeling Machine

The electrical wire labeling machine by Spark Fittings is designed with flexibility and adaptability in mind, offering customizable options to suit specific requirements. Its user-friendly interface and touchscreen controls make it easy to operate and monitor, providing a convenient solution for efficient labeling processes.

Catering to Diverse Labeling Needs in Different Industries

From cable labeling machines to automatic wire labelers, Spark Fittings' labeling solutions are engineered to cater to diverse labeling needs across different industries. The customizable options ensure that the machine can be tailored to meet specific requirements, making it a top choice for efficient and precise wire identification.

In addition to offering customizable options, Spark Fittings' labeling solutions are also designed to be user-friendly, making them accessible for a wide range of industries and skill levels. With intuitive interfaces and easy-to-follow instructions, the machines can be operated with minimal training, saving time and resources for businesses. This user-centric approach sets Spark Fittings apart as a reliable partner for efficient wire identification solutions.

Conclusion

When it comes to choosing the right automatic cable and wire labeling machine, it's crucial to consider factors such as efficiency, precision, and durability. An automated labeling system for wire identification is essential in industrial settings to streamline processes and ensure accurate labeling. Spark Fittings’ twisted wire folding labeling machine stands out as a top option for its innovative features and reliable performance.

Choosing the Right Automatic Cable and Wire Labeling Machine

Selecting the right cable labeling machine is a decision that can significantly impact industrial operations. It's essential to look for features such as high-speed operation, customizable options, and easy integration with existing production lines. The automatic wire labeler from Spark Fittings ticks all these boxes, making it a standout choice in the market.

Optimizing Labeling Processes for Industrial Efficiency

Efficient labeling processes are crucial in industrial settings to maintain productivity and quality standards. An electrical wire labeling machine that offers automated functionality, precision application, and durable construction can optimize these processes effectively. Spark Fittings’ solution provides all these benefits, ensuring smooth operations.

Spark Fittings’ Twisted Wire Folding Labeling Machine as a Top Option

In conclusion, Spark Fittings’ automatic cable labeling machine with twisted wire integration, folding mechanism, high-speed operation, and customizable options emerges as a top option for industrial applications. Its user-friendly interface with touchscreen controls further enhances its appeal as a reliable solution for diverse labeling needs.