Introduction

In the world of manufacturing and surface preparation, the Automatic Glue Sand Blasting Machine stands out as a game-changer. These machines revolutionize the way preformed armor rods are treated, ensuring superior adhesion and enhanced durability. Understanding how these machines operate and their importance in various industries is crucial for anyone looking to improve product quality and efficiency.

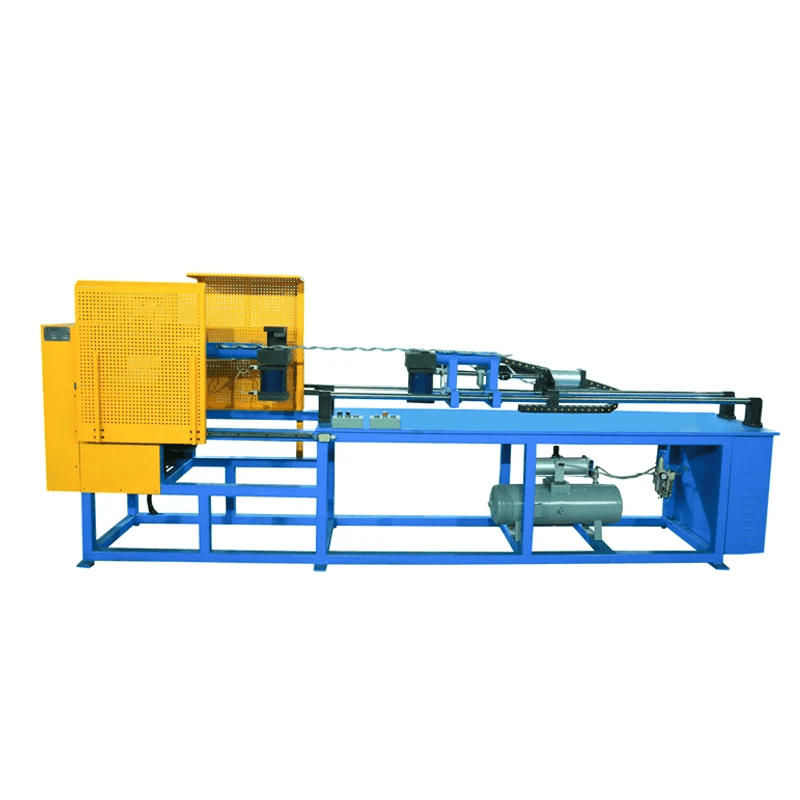

Understanding Automatic Glue Sand Blasting Machines

Automatic Glue Sand Blasting Machines are sophisticated devices that combine glue application with sand blasting techniques to prepare surfaces effectively. By automating this process, manufacturers can achieve consistent results while minimizing labor costs and time constraints. The synergy of glue and sand blasting for preformed armor rods not only enhances surface texture but also ensures that the adhesive bonds securely, leading to longer-lasting products.

Importance of Preformed Armor Rods

Preformed armor rods play a vital role in various applications, particularly in protecting cables from environmental stressors. These rods provide critical support and reinforcement, ensuring that cables maintain their integrity over time. The effectiveness of these components heavily relies on proper surface treatment, which is where the Automatic Glue Sand Blasting Machine comes into play.

Role of Spark Fittings in the Industry

Spark fittings have become synonymous with reliability and innovation in manufacturing processes involving glue and sand blasting for preformed armor rods. Their advanced technology not only enhances production capabilities but also offers customization options tailored to specific industry needs. As industries continue to evolve, spark fittings will remain at the forefront, driving efficiency and quality assurance across various sectors.

Overview of Automatic Glue Sand Blasting Machines

Automatic Glue Sand Blasting Machines are revolutionizing the way surface preparation is done across various industries. These machines uniquely combine the power of sand blasting with adhesive application, making them essential for tasks like glue and sand blasting for preformed armor rods. Their innovative design allows for efficient, consistent results that traditional methods simply can't match.

What Makes These Machines Unique

What sets Automatic Glue Sand Blasting Machines apart is their ability to seamlessly integrate both glue application and sand blasting in one streamlined process. This dual functionality not only saves time but also ensures that the surface is optimally prepared for adhesion, enhancing overall product quality. Moreover, these machines are equipped with advanced technology that allows for precise control over variables such as pressure and material flow, leading to superior finishes.

Applications in Various Industries

The applications of Automatic Glue Sand Blasting Machines span a wide range of industries including automotive, aerospace, and construction. In automotive manufacturing, they are used to prepare components for bonding and coating processes, while in aerospace, they ensure that critical parts meet stringent safety standards through effective surface treatment. Additionally, the glue and sand blasting for preformed armor rods proves invaluable in the construction sector where durability and reliability are paramount.

Benefits of Using These Machines

Utilizing Automatic Glue Sand Blasting Machines offers numerous benefits that can significantly enhance production efficiency. First off, these machines reduce labor costs by automating complex tasks that would otherwise require manual intervention. Furthermore, they provide consistent results with minimal variation between batches—an essential factor when quality assurance is non-negotiable in manufacturing processes.

Glue and Sand Blasting for Preformed Armor Rods

In the manufacturing of preformed armor rods, glue and sand blasting is a critical process that ensures optimal adhesion and surface integrity. The Automatic Glue Sand Blasting Machine plays a vital role in this operation, utilizing a combination of adhesive application and abrasive blasting techniques to prepare surfaces effectively. This method not only streamlines production but also enhances the overall quality of the final product.

The Process Explained

The glue and sand blasting process begins with the Automatic Glue Sand Blasting Machine applying an even layer of adhesive to the surface of preformed armor rods. Following this, fine sand particles are blasted onto the glued area, creating an ideal texture for bonding. This two-step approach allows for superior adhesion by ensuring that the surface is both clean and textured, which is crucial for high-performance applications.

The precision of these machines eliminates inconsistencies often found in manual processes, making them indispensable in modern manufacturing environments. By automating this procedure, manufacturers can achieve faster turnaround times while maintaining high standards of quality control. Ultimately, this leads to greater productivity without compromising on performance.

Importance of Surface Preparation

The Automatic Glue Sand Blasting Machine excels at preparing surfaces by removing contaminants such as dust, oil, or old adhesives that could interfere with bonding effectiveness. This meticulous cleaning process sets the stage for a robust bond that can withstand environmental stresses over time.

Moreover, proper surface preparation significantly reduces the likelihood of defects such as delamination or peeling later on in the product lifecycle. By investing in glue and sand blasting for preformed armor rods through automated systems, manufacturers can ensure their products meet stringent industry standards while enhancing customer satisfaction. In essence, good surface prep is akin to laying a solid foundation before building a house—it's essential for long-lasting results.

How It Enhances Product Quality

Utilizing an Automatic Glue Sand Blasting Machine not only improves adhesion but also enhances overall product quality through consistent application techniques. With precise control over both glue application and sand blasting pressure, manufacturers can produce uniform results across all batches of preformed armor rods. This consistency translates into fewer reworks and higher yields—a win-win situation!

Additionally, when products are well-prepared using these advanced machines, they exhibit better durability under demanding conditions such as extreme weather or mechanical stressors. Enhanced product quality ultimately leads to increased trust from customers who rely on these components in critical applications like electrical infrastructure or telecommunications systems. In short, investing in glue and sand blasting processes means investing in reliability—something every manufacturer strives for.

Features of Spark Fittings Equipment

When it comes to the world of manufacturing, Spark Fittings stands out with its impressive lineup of equipment tailored for precision and efficiency. Among these, the Automatic Glue Sand Blasting Machine shines brightly, showcasing innovative features designed to enhance performance. This section delves into the cutting-edge technology, customization options, and reliability that define Spark Fittings’ offerings.

Innovative Technology in Manufacturing

The heart of Spark Fittings' equipment lies in its innovative technology, particularly evident in the Automatic Glue Sand Blasting Machine. This machine integrates advanced automation systems that streamline the glue and sand blasting for preformed armor rods, ensuring consistency and precision in every operation. With real-time monitoring capabilities and user-friendly interfaces, operators can easily adjust settings to meet specific production requirements without breaking a sweat.

In addition to automation, this equipment employs state-of-the-art materials that enhance durability and reduce wear over time. The use of high-quality components means less downtime for maintenance and repairs—an essential factor in maintaining productivity levels across industries. As a result, companies investing in Spark Fittings’ technology can expect not only superior performance but also a significant boost in their operational efficiency.

Customization Options Available

One size does not fit all when it comes to manufacturing needs; that's why Spark Fittings offers extensive customization options for their Automatic Glue Sand Blasting Machines. Clients can tailor various aspects such as machine size, blasting pressure, and even nozzle configurations to suit their unique production processes involving glue and sand blasting for preformed armor rods. This level of personalization ensures that each machine operates at peak efficiency while addressing specific challenges faced by different industries.

Moreover, customization extends beyond technical specifications; aesthetic choices are also available so businesses can match their machines with their branding or workspace design. By allowing clients to personalize their equipment fully, Spark Fittings empowers manufacturers to create an environment where functionality meets style seamlessly. Ultimately, this flexibility enhances user experience while optimizing production outcomes.

Reliability and Efficiency

Reliability is paramount when selecting machinery for demanding production environments—this is where Spark Fittings excels with its Automatic Glue Sand Blasting Machines. Designed with robust engineering principles in mind, these machines promise consistent performance even under heavy workloads associated with glue and sand blasting for preformed armor rods. Customers can trust that they will achieve high-quality results without interruptions or unexpected breakdowns.

Efficiency goes hand-in-hand with reliability; every feature within the machine is engineered to minimize waste while maximizing output rates. From optimized air consumption during sand blasting operations to energy-efficient motors driving the system forward, users benefit from lower operational costs over time without sacrificing quality or speed. In an industry where margins matter significantly, investing in reliable equipment like those from Spark Fittings proves invaluable.

Comparing Traditional Methods with Automatic Systems

When it comes to production processes, the debate between traditional methods and modern automatic systems is as old as time. In the realm of glue and sand blasting for preformed armor rods, the advantages of using an Automatic Glue Sand Blasting Machine are hard to ignore. This section will delve into the remarkable benefits that these machines bring to the table, particularly in terms of time efficiency, production consistency, and long-term cost savings.

Time and Labor Efficiency

One of the standout features of an Automatic Glue Sand Blasting Machine is its ability to significantly reduce both time and labor costs. Unlike traditional methods that require extensive manual input and supervision, these machines can operate autonomously, allowing operators to focus on other critical tasks. This efficiency translates into faster turnaround times for glue and sand blasting for preformed armor rods, enabling businesses to meet tight deadlines without compromising quality.

Additionally, automation minimizes human error—an ever-present risk in manual operations—which can lead to costly rework or wasted materials. With an Automatic Glue Sand Blasting Machine handling the heavy lifting, companies can achieve higher output levels while requiring fewer personnel on-site. Ultimately, this leads not only to a more streamlined operation but also fosters a safer working environment by reducing physical strain on workers.

Consistency in Production Quality

Quality control is paramount in any manufacturing process; inconsistency can spell disaster for product integrity and customer satisfaction. The precision engineering behind an Automatic Glue Sand Blasting Machine ensures uniform application every single time—a feat that’s challenging to replicate with traditional methods. When engaging in glue and sand blasting for preformed armor rods, this consistency becomes crucial as it directly impacts performance metrics like durability and reliability.

Moreover, automated systems are equipped with advanced monitoring technologies that allow real-time adjustments based on feedback from the process itself. This means any deviations can be corrected instantly without halting production or requiring additional labor interventions. As a result, businesses enjoy not only enhanced product quality but also elevated reputations among clients who value reliability.

Cost-Effectiveness Over Time

While investing in an Automatic Glue Sand Blasting Machine may seem daunting initially due to upfront costs, the long-term savings are undeniable when compared to traditional methods. These machines often lead to reduced material waste through precise application techniques used during glue and sand blasting for preformed armor rods—saving money on raw materials over time. Furthermore, lower labor costs associated with automation contribute significantly toward improving profit margins.

Maintenance expenses also tend to be lower than those associated with older equipment since modern machines are designed with longevity in mind—requiring less frequent repairs or replacements due to their robust construction materials and technology-driven designs. By analyzing total cost ownership over a machine's lifespan rather than just initial purchase prices alone reveals how beneficial transitioning from traditional methods can be for manufacturers looking at their bottom line seriously.

Maintenance and Best Practices

Maintaining your Automatic Glue Sand Blasting Machine is essential for ensuring optimal performance and longevity. Just like any high-tech equipment, these machines require regular check-ups to keep them running smoothly. Following a structured maintenance routine can prevent costly downtime and enhance the efficiency of glue and sand blasting for preformed armor rods.

Routine Maintenance Tips

To keep your Automatic Glue Sand Blasting Machine in top shape, start with daily inspections. Check for any signs of wear, loose parts, or unusual noises that could indicate a problem brewing beneath the surface. Additionally, ensure that the glue and sand used in the blasting process are stored correctly to maintain their quality; moisture can ruin them faster than you think!

Weekly maintenance should include cleaning filters and checking hoses for blockages or leaks. Keeping these components clean helps maintain consistent pressure during operations, which is crucial for effective glue and sand blasting for preformed armor rods. Lastly, don’t forget to lubricate moving parts as specified in the manufacturer’s guidelines; this simple step can significantly extend machine life.

Troubleshooting Common Issues

Even with diligent maintenance, issues may arise with your Automatic Glue Sand Blasting Machine from time to time. One common problem is inconsistent blasting pressure; this could be due to clogged nozzles or air supply issues. A quick fix often involves cleaning or replacing nozzles and ensuring that air lines are clear of obstructions.

Another frequent hiccup involves adhesive application; if you notice uneven glue distribution during the process, it might be worth checking the glue pump settings or inspecting hose connections for leaks. Addressing these issues promptly not only saves time but also enhances the quality of glue and sand blasting for preformed armor rods—after all, nobody wants subpar results!

Lastly, if you encounter electrical problems like tripped breakers or non-responsive controls, consult your user manual before calling in a technician. Often times these issues can be resolved with a simple reset or by replacing a blown fuse.

Maximizing Machine Lifespan

To truly maximize the lifespan of your Automatic Glue Sand Blasting Machine, consider implementing a proactive approach to its care rather than just reactive fixes after problems occur. Establishing a detailed schedule for both routine checks and more extensive annual servicing will help you catch potential issues before they escalate into major repairs.

Additionally, invest in operator training to ensure that everyone using the machine understands its functions thoroughly—this reduces human error significantly! When operators know how to handle glue and sand blasting for preformed armor rods effectively, they’re less likely to misuse equipment or overlook vital maintenance tasks.

Finally, always use quality materials compatible with your machine specifications; cheap alternatives can lead not only to inferior results but also wear down components quicker than expected. By following these best practices diligently, you'll enjoy years of reliable service from your Automatic Glue Sand Blasting Machine while producing top-tier products!

Conclusion

In wrapping up our exploration of Automatic Glue Sand Blasting Machines, it's clear that these innovations are not just a trend but a significant leap forward in manufacturing processes. As industries continue to evolve, the demand for efficient and high-quality production methods will only grow. The future of these machines looks bright, with advancements in technology promising even greater capabilities and applications.

Future of Automatic Glue Sand Blasting Machines

The future of Automatic Glue Sand Blasting Machines is poised for exciting developments as manufacturers seek to integrate more advanced technologies such as AI and automation. These enhancements will likely lead to improved precision and efficiency, making glue and sand blasting for preformed armor rods even more effective. With ongoing research and innovation, we can expect these machines to become integral components in various industrial settings.

Enhancing Productivity with Spark Fittings

Spark Fittings play a crucial role in enhancing productivity within the realm of automatic systems by providing reliable connections that withstand demanding conditions. This reliability ensures that the glue and sand blasting process remains uninterrupted, thereby maximizing output while maintaining quality standards. As industries increasingly adopt these advanced fittings, they will undoubtedly experience significant boosts in operational efficiency.

Final Thoughts on Quality Assurance

In conclusion, quality assurance remains paramount when utilizing Automatic Glue Sand Blasting Machines in any production line. By ensuring proper surface preparation through glue and sand blasting for preformed armor rods, manufacturers can achieve superior product durability and performance. Embracing these technologies not only enhances product quality but also sets the stage for continued innovation in manufacturing practices.